Off-grid solar depends on lithium batteries. That freedom comes with a duty to control heat, charge, wiring, and emergency response. Energy agencies point to rapid growth in solar and storage, which raises the bar for safety. The IEA Net Zero by 2050 highlights the need to expand energy storage and improve safety as systems scale. The U.S. DOE Solar Energy program also stresses robust engineering and risk controls as solar reaches more homes and microgrids. I have audited off‑grid systems in hot cabins, cold barns, and remote clinics. The rules below come from that field work plus current best practice.

Why fire-safe lithium handling matters off-grid

Remote sites often run hotter, face dust, and can lack on-site responders. Good design and disciplined operation reduce the chance of a thermal event. They also improve uptime. The EIA reports that electricity still carries a heavy emissions footprint, which is why more owners shift to solar-plus-storage. As adoption expands, safe lithium storage off-grid protects people, property, and the investment.

Policy bodies keep linking storage expansion with the need for flexible, resilient power. The IEA Status of Power System Transformation notes system integration and local grids require dependable control and protection. The IRENA platform also tracks storage as a key enabler of clean energy. That trend reaches cabins, farms, and island microgrids just as much as towns and cities.

Chemistry basics that shape risk

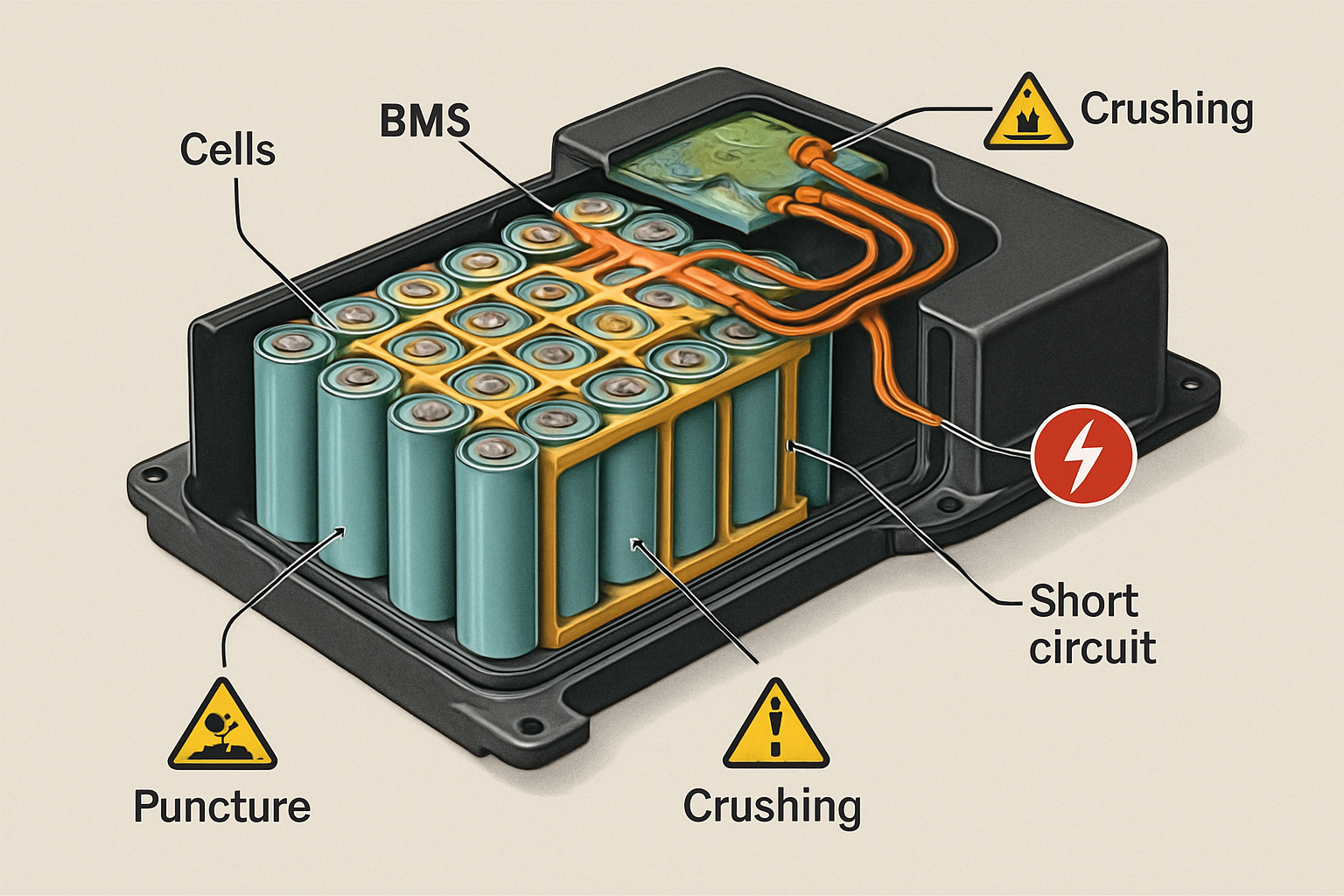

Most off-grid storage today uses LiFePO4 (LFP) or nickel-rich chemistries like NMC. LFP offers a higher thermal runaway onset temperature than many nickel-based cells. NMC provides higher energy density but needs more attention to thermal margins. Your battery management system (BMS), pack design, and system layout must reflect those differences.

| Parameter | LiFePO4 (LFP) | NMC (typical) |

|---|---|---|

| Typical charge temp range | 0 to 45°C | 0 to 45°C |

| Typical discharge temp range | -20 to 60°C | -20 to 60°C |

| Storage temp (ideal) | 10 to 30°C | 10 to 25°C |

| Recommended storage SoC | 30%–50% | 30%–50% |

| Thermal runaway onset (lab typical) | ≈ 270–300°C | ≈ 180–220°C |

Values above are typical manufacturer ranges. Always follow your pack and inverter manual. The NREL Utility-Scale PV guidance shows how disciplined engineering, cable layout, and O&M raise safety and reliability. The same mindset applies to small sites.

9 rules for Fire-Safe Lithium Handling

1) Choose the right place and keep separation

- Install batteries in a dedicated, clean, dry room or outdoor-rated metal enclosure. Keep away from bedrooms and open flames.

- Maintain clearances around packs for heat dissipation and access. Do not stack cells without manufacturer approval.

- Separate DC from AC wiring paths. Use grommets and glands at all penetrations to avoid chafing.

- Mount signage: DC disconnect, emergency shutdown, and hazard labels visible at the entry.

In my site reviews, many near-misses started with cramped layouts and mixed AC/DC wiring. A tidy, labeled layout prevents small faults from escalating.

2) Control temperature like uptime depends on it

- Target 15–30°C battery ambient. Shade outdoor enclosures. Add passive ventilation first, then active fans if needed.

- Place a temperature probe at the pack and on the hottest cell group if the BMS supports it. Set alarms at 40–45°C.

- In cold climates, block charging below 0°C unless your pack has built-in heating.

The IEA stresses scaling storage with robust operation. Temperature control is the first lever. It also extends cycle life.

3) Stick to a SoC discipline

- Store at 30–50% state of charge for weeks or during seasonal shutdowns. This reduces stress and fire risk.

- For daily cycling, use a moderate window, for example 15–90% SoC, unless your application needs deeper cycles.

- Enable periodic BMS balancing to keep cell drift under control.

Owners who adopt a SoC protocol see fewer nuisance alarms and lower heat generation during charge.

4) Set the charging profile for the chemistry

- Use CC/CV settings approved for your pack. For LFP, per‑cell full charge voltage often falls near 3.45 V; disable lead-acid equalization.

- Respect charge current limits at high SoC and high temperature. Configure the solar charge controller to taper early if the pack warms.

- Use a pre-charge resistor or soft-start feature to avoid inrush sparks that can pit contacts.

These small steps prevent overvoltage and heat buildup, common triggers in field incidents I’ve addressed.

5) Fuse every source and segment the DC

- Install a fuse or DC breaker on each battery string and at each energy source (PV, generator-charger).

- Place the main DC disconnect where you can reach it fast. Add a shunt trip linked to smoke/heat alarms for remote shutdown.

- Use an insulation monitoring device on floating DC systems. It can catch ground faults early.

Segmented DC limits fault energy. It also makes maintenance safer.

6) Detect early and move fumes outside

- Mount a smoke detector and a CO sensor in the battery space. Off-gas sensors are a plus.

- Duct ventilation to the outdoors. Avoid recirculating air into living areas. Use corrosion‑resistant fans.

- Keep PPE handy: safety glasses, gloves, and a respirator suitable for acidic fumes.

Good ventilation and early detection create time to respond. That time is priceless in remote cabins.

7) Build reliable terminations and busbars

- Use correctly sized lugs and a calibrated crimper. Avoid stacking too many lugs on a single stud.

- Torque to spec. Re-torque after 24–48 hours of first heat cycles. Log values in a maintenance sheet.

- Use tin-plated busbars. Apply anti-oxidation compound where recommended. Keep cable bends gentle.

Loose connections cause arcing and heat. Many “mystery” shutdowns vanish after a proper re-termination.

8) Store, ship, and quarantine safely

- For storage, keep packs dry, cool, and at 30–50% SoC. Check every 60–90 days.

- For transport, follow UN3480/UN3481 lithium-ion packaging and labeling. Use a certified carrier and declare contents.

- Quarantine any damaged or wet pack in a metal container with a nonflammable medium (e.g., sand). Monitor for at least 24–48 hours.

Log serial numbers and condition photos. Good records speed support and insurance claims.

9) Plan the emergency and drill it

- Post a simple flow: isolate DC, isolate AC, ventilate, call responders. Share it with everyone who uses the site.

- Keep the right extinguishers: ABC dry chemical for incipient fires; water fog for cooling and preventing spread. Class D is for metallic lithium, not lithium‑ion.

- Coordinate with your insurer and local responders. A 10‑minute walk-through can prevent risky tactics later.

The DOE Solar Energy materials promote risk-informed deployment. A practiced shutdown routine is part of that.

Quick off-grid checklist

- Temperature: 15–30°C target, alarms at 40–45°C, no charging below 0°C without heat.

- SoC: 30–50% for storage; moderate daily cycling window.

- Charging: correct CC/CV, no equalize, pre-charge enabled.

- Protection: fuses per string, main DC disconnect, insulation monitoring.

- Layout: metal enclosure, clear labels, AC/DC separation, clean cable routes.

- Detection: smoke + CO, outdoor ventilation, suitable PPE.

- Records: torque log, serials, photos, maintenance dates.

Field example

In a desert cabin install, the battery shed hit 36–38°C on hot afternoons. We added a reflective roof, a passive intake low on the wall, and a thermostatic exhaust fan. Average peak battery temperature dropped to 28–30°C. High‑temp alarms fell by more than 90% over the next summer. Charge limits were also tuned down at high SoC on hot days. The owner gained longer runtime and peace of mind.

Why this aligns with energy policy

As more sites add solar plus storage, safe practice avoids setbacks that can slow adoption. The IEA Net Zero roadmap calls for scaled flexible resources with strong safety practice. The IEA Power System Transformation work underscores local grid reliability, which includes quality controls in off-grid and microgrid projects. The IRENA platform reflects growing clean energy uptake, and the EIA data show why replacing combustion with solar plus storage matters. Good safety practice keeps that transition on track.

Frequently asked technical points

Do I need Class D extinguishers?

No, not for lithium-ion packs used in solar storage. Class D is for fires involving metallic lithium. Use ABC dry chemical for small electrical fires and water for cooling nearby materials, unless your local authority instructs otherwise.

Should I vent hydrogen?

Lithium-ion does not emit hydrogen under normal use. You still need ventilation to expel heat and any harmful off-gases during a fault.

How often should I re-torque?

Check terminations after the first week, then every 6–12 months. Follow your manufacturer’s schedule.

Final notes

These Fire-Safe Lithium Handling rules improve Off-Grid Solar Fire Safety without adding complexity. They cut heat, prevent arcs, and give you a clear response path. Combine them with certified equipment and a clean build. Small mistakes compound; small improvements do too.

Safety notice (not legal advice): This content supports safe practice but does not replace codes, standards, permits, or manufacturer instructions. Engage qualified professionals for design and inspection.

References

- International Energy Agency. Net Zero by 2050. Storage expansion and operational robustness are highlighted for clean power.

- International Energy Agency. Status of Power System Transformation 2018 – Technical Annexes. Notes on system integration and local grids inform microgrid best practices.

- U.S. Department of Energy. Solar Energy. Program materials emphasize reliable deployment and safety.

- U.S. Energy Information Administration. EIA. U.S. energy data, including emissions context and electricity trends.

- International Renewable Energy Agency. IRENA. Global clean energy trends and the role of storage in decarbonization.

- National Renewable Energy Laboratory. Utility-Scale PV Power Plants. Engineering practices for layout, cabling, and O&M that translate to safer systems.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.