The cost of solar energy has seen a remarkable decline over the past few decades, making it an increasingly accessible technology for homeowners and businesses. While falling panel prices often get the credit, the complete story involves a powerful economic principle: the learning curve. This concept explains not just the drop in hardware costs but also the evolution of the entire solar installation process. Understanding this trend, especially its effect on Balance of System (BOS) costs, is key to making a savvy solar investment.

Understanding the Solar Learning Curve

The learning curve is a principle that describes how the cost of a technology decreases as experience in producing it grows. It's a virtuous cycle: as more units are produced, manufacturers and installers "learn" to be more efficient, which lowers costs. Lower costs then spur more demand, leading to even more production and further learning.

What is a Learning Curve?

The learning curve, or Wright's Law, states that for every cumulative doubling of production, the unit cost falls by a consistent percentage, known as the learning rate. For solar, this has been dramatic. Studies have shown a learning rate for solar PV at 24% or even higher, meaning for each time the world's installed solar capacity has doubled, the levelized cost of energy (LCOE) has dropped by 24%. This consistent, predictable cost reduction is driven by technological breakthroughs, manufacturing efficiencies, and process improvements.

The Dramatic Impact on Panel Prices

Solar panels are the most prominent example of the learning curve in action. Over the last four decades, the price of solar modules has fallen by over 99%. This precipitous drop is a direct result of scaled-up manufacturing, innovations in silicon wafer and cell production, and fierce market competition. This has fundamentally altered the financial breakdown of a solar project, shifting the focus away from the panels themselves and onto the other components and processes involved.

Beyond Panels: The Ripple Effect on BOS

The learning curve's influence extends well beyond the solar module. It affects every piece of hardware, from inverters to racking, and every step of the installation process. As installers complete more projects, they develop faster techniques, streamline their supply chains, and become more adept at system design and navigating local regulations. This "learning-by-doing" is a powerful force driving down the non-panel costs of a solar system.

Deconstructing Balance of System (BOS) Costs

Balance of System (BOS) encompasses every component and cost in a solar installation *except* for the solar modules. It's a broad category that has become increasingly important in the overall cost equation. As module prices have tumbled, BOS costs now represent the largest portion of a total solar system's price.

What's Included in BOS?

BOS costs are typically split into two main categories: hardware and soft costs. Understanding this division is crucial for evaluating a solar quote.

- BOS Hardware: This includes all the physical equipment needed to make the panels work. Key components are the inverter (which converts DC electricity from the panels to AC for your home), mounting and racking systems, wiring, conduits, and safety equipment like circuit breakers.

- Soft Costs: These are non-hardware expenses that are often less visible but make up a significant portion of the total price. Soft costs include installation labor, system design and engineering, permitting fees paid to local authorities, interconnection costs to connect to the utility grid, as well as sales, marketing, and installer overhead.

The Paradox: Why the BOS Share is Growing

Herein lies a key trend: the *share* of BOS costs in a project is increasing, even as the absolute dollar amount of these costs is falling. The reason is that panel prices have fallen much faster than BOS costs. A decade ago, hardware might have accounted for two-thirds of the total price. Today, soft costs alone can make up 65% or more of a residential system's total cost. This shift means that the next frontier for major cost reductions in solar lies squarely in optimizing the Balance of System.

How Learning Curves Are Driving Down BOS Costs

Just as manufacturing scale drove down module prices, experience and innovation are now reducing BOS costs. This happens through improvements in both hardware and processes.

Innovations in BOS Hardware

BOS hardware is continuously improving. Inverters are becoming more efficient, more reliable, and easier to install. Racking and mounting systems have evolved with innovations like rail-less designs and integrated grounding, which reduce both material use and the time installers spend on the roof. These technological advancements are a direct result of a maturing industry investing in research and development to solve practical installation challenges.

Streamlining Soft Costs Through Experience

Reducing soft costs is where an installer's experience really shines. This is a major area of focus for cost reduction across the industry.

- Labor Efficiency: Experienced installation crews work faster and more effectively. They refine their processes to complete jobs in less time, sometimes even a single day, which directly lowers the labor cost component.

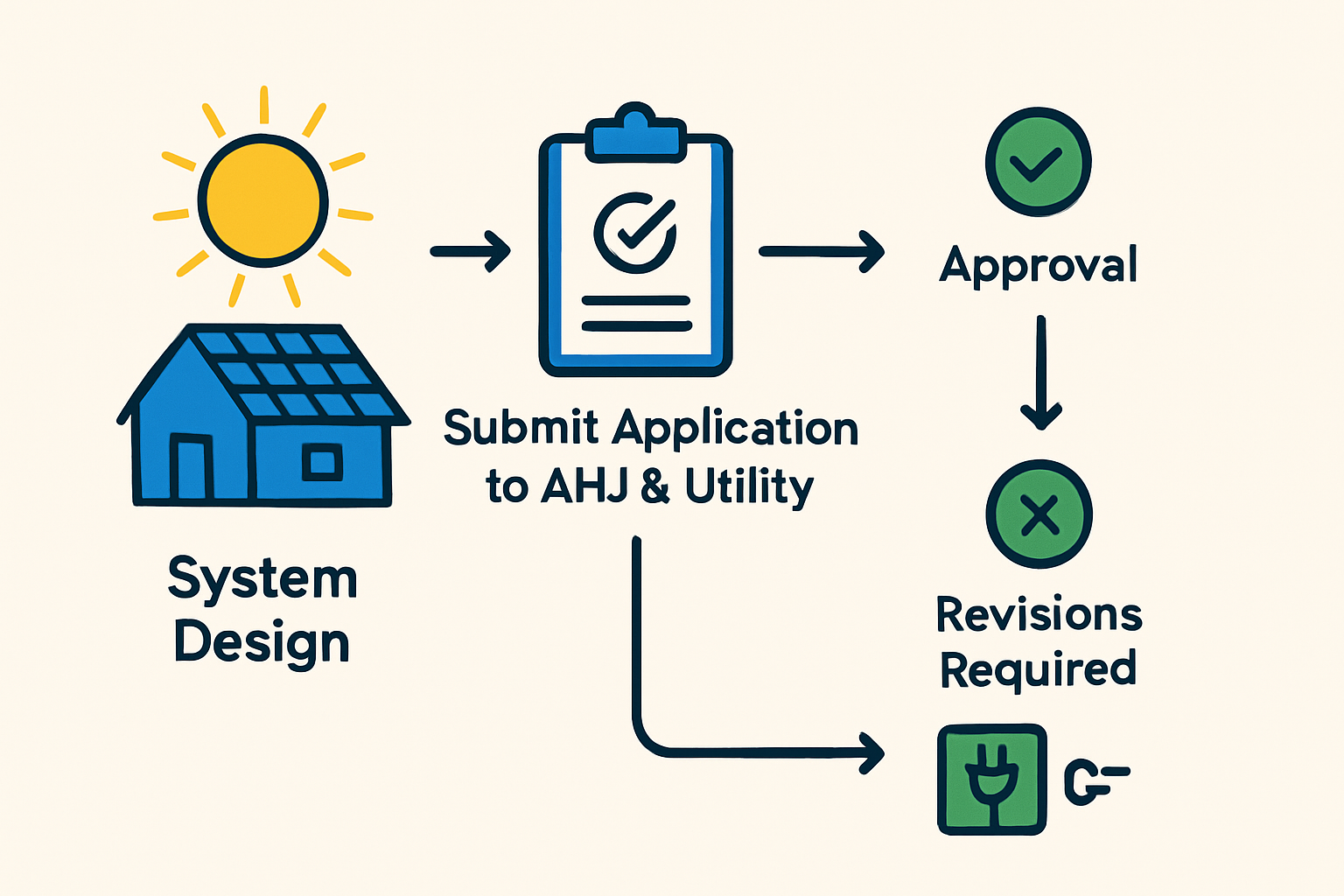

- Permitting and Interconnection: Navigating the administrative side of solar can be complex, with different rules in every municipality. According to the World Energy Investment 2023 report, permitting can be a key concern for investors. Experienced installers learn how to manage these processes efficiently, avoiding costly delays and rework. The development of standardized permitting processes helps streamline these approvals and reduce costs.

- Design and Procurement: Top installers use advanced software to optimize system design. They also develop efficient supply chains and procurement strategies, ensuring they have the right components at the right price without delays.

What This Trend Means for Your Solar Investment

This shift in cost structure from panels to BOS has direct implications for anyone considering a solar energy system. It changes how you should evaluate quotes and what you should look for in an installer.

Evaluating a Solar Quote with BOS in Mind

When you receive a solar quote, look beyond the total price or the cost-per-watt of the panels. A truly competitive quote reflects efficiency in all areas. An installer who has mastered the soft-cost side of the equation can offer a better overall value. Inquire about the specific inverter and racking equipment they use and ask about their experience with your local permitting office.

The Importance of Installer Efficiency

An installer's efficiency is a direct result of their position on the learning curve. A highly experienced installer minimizes wasted time and materials, which translates into lower soft costs. This efficiency is a sign of a well-run, professional operation that can deliver a high-quality installation at a fair price. Choosing an installer based on their proven ability to manage the entire process smoothly is just as important as the equipment they propose.

A Forward Look

The story of solar cost reduction is evolving. While panel innovation continues, the primary focus has shifted to the Balance of System. The learning curve is now working powerfully to drive down costs in installation labor, permitting, and BOS hardware. As a consumer, understanding that a significant portion of your investment is in these soft costs empowers you to ask better questions and choose an installation partner who provides true, comprehensive value. This knowledge ensures you are not just buying solar panels, but investing in an efficient, well-executed energy solution for your home.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.