In an energy storage system, the battery and inverter work in tandem. They are not just electrically connected; they are also thermally linked. Heat generated by one component directly impacts the performance and health of the other. When this thermal relationship is ignored, the system suffers from derating—a protective measure where power output is intentionally reduced to prevent overheating. A smart battery-inverter design that embraces thermal coupling treats the two components as a single thermal unit. This integrated approach is fundamental to maximizing energy yield, ensuring system longevity, and achieving true energy independence.

The Interdependent Thermal Relationship

Understanding the thermal dynamics between a battery and an inverter is the first step toward creating a resilient system. Their proximity within an enclosure makes their thermal states deeply interconnected, creating a feedback loop that can either enhance or degrade performance.

How Inverter Heat Affects Battery Health

Inverters, particularly during high-load operations like converting DC to AC power, generate a substantial amount of heat. If this heat is not effectively managed, it raises the ambient temperature within the system enclosure. For the battery pack, especially lithium-ion chemistries like LiFePO4, elevated temperatures accelerate cell degradation. This reduces the battery's capacity and shortens its operational lifespan, compromising the long-term value of your energy storage investment.

How Battery Temperature Impacts Inverter Efficiency

The thermal influence flows in both directions. A battery warming up during a heavy charge or discharge cycle contributes to the overall heat load in the cabinet. This rise in ambient temperature reduces the effectiveness of the inverter's own cooling system. The inverter's heat sink, designed to dissipate heat into the surrounding air, becomes less efficient. As a result, the inverter's internal components reach their thermal limits faster, triggering derating even under normal load conditions.

The Vicious Cycle of Derating

When one component starts to derate, it can create a domino effect. For instance, if an inverter derates due to heat, it might operate less efficiently, potentially drawing power erratically and placing unusual stress on the battery. Conversely, a hot battery might not be able to deliver the current the inverter demands, forcing the inverter to operate outside its optimal parameters. This cycle of escalating thermal stress leads to chronic underperformance and premature component failure.

Core Principles of Integrated Thermal Management

Effective thermal coupling relies on a holistic design philosophy. Instead of treating the battery and inverter as separate entities with their own cooling solutions, an integrated approach optimizes heat dissipation for the entire system.

Unified Heat Dissipation Paths

A core strategy in battery-inverter design is creating a unified path for heat to escape. This can involve using a common chassis that acts as a large heat sink for both components. By mounting the inverter's power electronics and the battery's thermal plates to the same conductive structure, heat is drawn away more efficiently. This prevents localized hot spots and distributes the thermal load across a larger surface area, improving overall cooling performance.

Strategic Component Placement and Airflow

The physical layout inside an energy storage system is critical. Proper thermal management involves placing the inverter and battery modules to facilitate unobstructed airflow, whether through natural convection or forced air from fans. For example, positioning the inverter's heat sink fins vertically encourages natural heat rise. Placing sensitive battery modules in the path of the coolest incoming air helps maintain their optimal temperature. This meticulous planning ensures that no component is starved of cooling or exposed to another's exhaust heat.

Material Selection for Thermal Conductivity

The materials used to connect and house the components play a significant role. Thermal Interface Materials (TIMs), such as conductive pads or pastes, are used to fill microscopic air gaps between the inverter's processors and their heat sinks, ensuring efficient heat transfer. In some advanced designs, heat pipes are used to rapidly move thermal energy from the heat-generating components to a remote radiator, offering a powerful method for derating avoidance.

Advanced Thermal Coupling Techniques in ESS Design

As energy storage systems become more compact and powerful, advanced thermal management techniques are necessary to maintain peak performance. These methods offer superior control over the system's thermal environment.

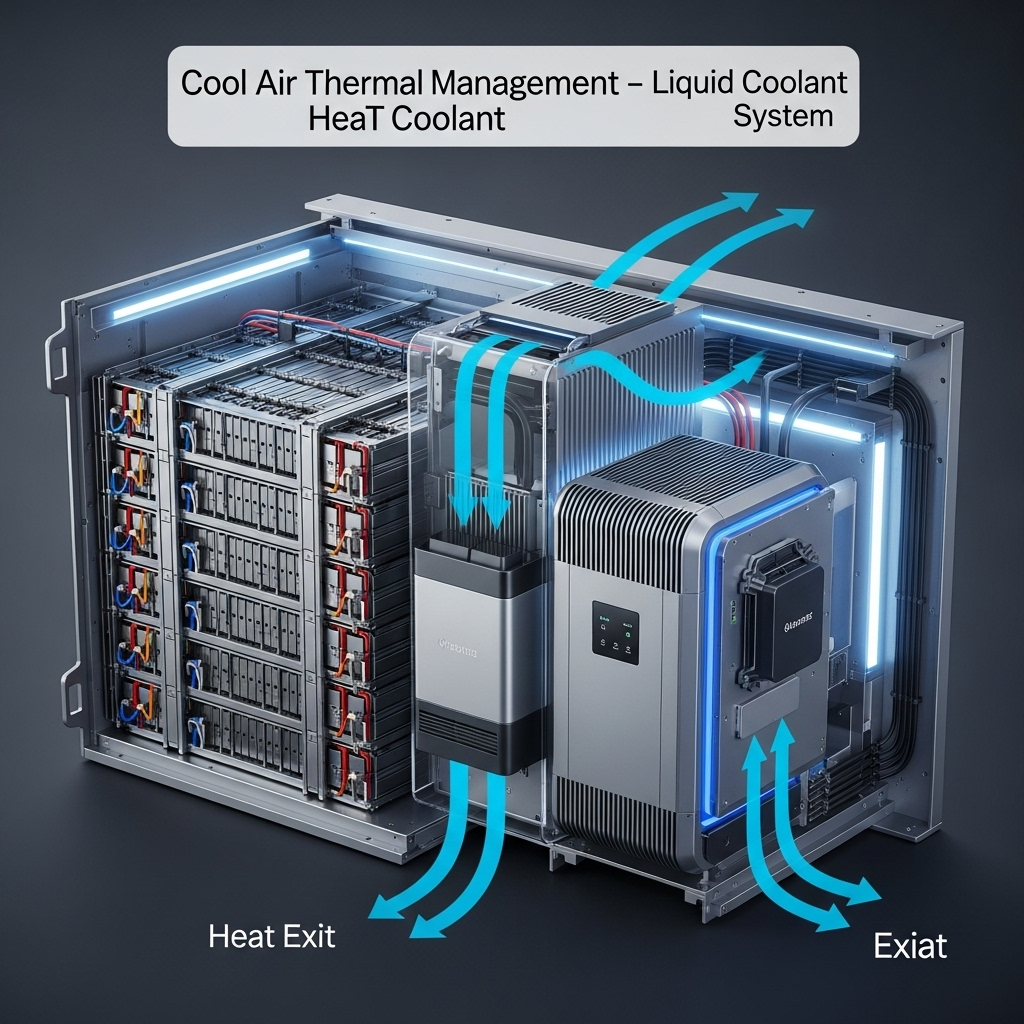

Liquid Cooling Systems

For high-power applications, liquid cooling offers a significant advantage over air cooling. A single, shared liquid cooling loop can be engineered to pass through a cold plate attached to the inverter and then circulate through channels within the battery pack. This closed-loop system is exceptionally effective at capturing and removing heat, keeping both components well within their ideal operating temperature ranges, even under extreme loads and high ambient temperatures.

Phase Change Materials (PCMs) for Buffering Heat

Phase Change Materials are substances that absorb or release large amounts of thermal energy when they change state (e.g., from solid to liquid). Integrating PCMs into an ESS design provides a thermal buffer. During peak operation, the PCM absorbs excess heat from the battery and inverter, preventing their temperatures from spiking. According to a report on thermal energy storage by the International Renewable Energy Agency (IRENA), research into novel composite PCMs is a key innovation for improving thermal management. This passive technique helps stabilize the system's internal temperature and delay the onset of derating.

Smart Control and Monitoring

A modern ESS should feature a centralized control system that monitors the temperatures of both the battery and inverter in real-time. This controller can dynamically adjust fan speeds, coolant flow rates, or even system loads to maintain thermal balance. This concept of active power controllability is crucial for grid stability and system health, a point emphasized in IRENA's Grid Codes for Renewable Powered Systems report. By proactively managing the thermal state, the system can avoid derating altogether, ensuring consistent and reliable power delivery.

Quantifying the Benefits: Performance and Longevity

The advantages of a well-executed thermal coupling strategy are not just theoretical. They translate into tangible gains in performance, reliability, and financial return.

Measurable Gains in Energy Yield

Every hour an inverter spends in a derated state is an hour of lost energy production. By preventing derating, an integrated thermal design ensures the system consistently delivers its maximum possible power output. This directly increases the total energy yield over the system's lifetime. Maximizing output is a central theme in evaluating solar storage performance, where consistent power delivery is a key metric of a system's value. A system that avoids derating is a system that delivers on its promised performance.

Extending Component Lifespan

Heat is the primary enemy of electronic components and battery cells. Operating at lower, more stable temperatures significantly reduces wear and tear. This extends the lifespan of both the inverter and the battery, delaying costly replacements and improving the overall return on investment.

| Component | Temperature Increase | Estimated Lifespan Reduction |

|---|---|---|

| Power Inverter | +10°C above optimal | ~50% |

| LiFePO4 Battery | +10°C above optimal | ~30-40% |

Improved System Reliability and Safety

A system that runs cool is a system that runs reliably. Thermal stress is a leading cause of component failure. By effectively managing heat through thermal coupling, the risk of unexpected shutdowns is greatly reduced. For batteries, maintaining an optimal temperature is also a critical safety feature, as it helps prevent conditions that could lead to thermal runaway. A reliable system provides peace of mind and ensures power is available when you need it most.

A Unified Design for Peak Performance

Moving beyond isolated cooling solutions is no longer an option; it's a necessity for modern energy storage. Thermal coupling in battery-inverter design is a foundational principle for any high-performance system. By treating the battery and inverter as a single, interconnected thermal unit, engineers can create systems that are more efficient, reliable, and durable. This integrated approach stops derating before it starts, safeguarding your investment and ensuring your system delivers its full potential for years to come.

Frequently Asked Questions

What is thermal coupling in an energy storage system?

Thermal coupling is a design approach where the thermal management of the battery and the inverter are integrated. Instead of cooling each component separately, the design considers their combined heat load and creates a unified system to dissipate that heat, recognizing that the temperature of one directly affects the other.

Why does an inverter derate?

An inverter derates, or reduces its power output, as a self-protection mechanism to prevent its internal components from overheating. This happens when the heat generated during power conversion exceeds the capacity of its cooling system, often due to high ambient temperatures, poor ventilation, or sustained high loads.

How does temperature affect LiFePO4 battery performance?

Temperature significantly impacts LiFePO4 batteries. High temperatures (above 45°C) accelerate degradation, reducing lifespan and capacity. Very low temperatures (below 0°C) can reduce the battery's ability to deliver power and can cause damage if charged under freezing conditions. The ideal operating range is typically between 15°C and 25°C.

Can I place my battery and inverter in the same cabinet?

Yes, you can, provided the cabinet is specifically designed for integrated energy storage with proper thermal management. A well-designed system will manage airflow or use other cooling methods to ensure the heat from the inverter does not negatively impact the battery, and vice-versa. Simply placing them in a standard box without considering thermal coupling is not recommended.

What is the optimal operating temperature for a battery-inverter system?

The optimal operating temperature for most battery-inverter systems is generally between 15°C and 25°C (59°F to 77°F). In this range, the LiFePO4 battery maintains its health and longevity, and the inverter's power electronics operate with high efficiency and minimal thermal stress, reducing the risk of derating.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.