Energy yield is the annual output a PV system delivers per rated DC capacity. It reflects real operating conditions, not only nameplate efficiency. Bifacial modules and solar trackers raise the light your array sees across the day, so they lift energy yield without a big cost premium. This piece shows the design moves that turn that promise into bankable gains, with numbers, controls, and O&M tips you can put to work.

Why bifacial + trackers lift yield

Bifacial modules capture light on both faces. Trackers point modules toward the sun across the day. Combined, they raise incident light and improve operating efficiency, which boosts annual energy yield.

- Single-axis trackers add roughly 12–25% annual output over fixed-tilt in sunny regions, based on the IEA Next-Generation Wind and Solar Power report.

- Dual-axis adds another 10–15% on top of single-axis, but added capex and O&M often erode the business case, as noted by the IEA full report.

- Bifacial gain depends on rear-side irradiance. Ground reflectivity (albedo), row spacing, height, and tracker geometry all matter. The knowledge base notes that systems are not always designed to maximize bifacial output; aligning layout with bifacial physics is key.

Most utility-scale plants in the U.S. now use single-axis trackers. That shift, coupled with bifacial adoption, continues to push fleet energy yield higher, in line with trends tracked by the U.S. EIA and sector analyses.

Design variables that control bifacial gain

Albedo engineering

Rear-side irradiance scales with albedo. Native soil may sit near 0.15–0.25. Light gravel, pale geotextiles, or seasonal snow can raise this to 0.3–0.6 or more.

- Target stable albedo ≥0.3 for a solid gain. White gravel or light aggregate often adds 3–7% rear energy vs. bare soil, depending on height and spacing.

- Manage vegetation. Keep grass short to avoid albedo drop and rear shading.

- Use on-site albedo meters during design to calibrate models; this de-risks P50/P90 estimates.

Row spacing and height

Rear-side light arrives from the ground and surroundings. Taller rows and wider spacing reduce self-shading and raise the view to bright ground.

- Module lower-edge height: raising from ~0.8 m to ~1.5 m can add a few percent rear gain on trackers, site-dependent.

- Ground coverage ratio (GCR): lower GCR (wider spacing) increases rear irradiance and reduces inter-row shade. Balance this against land cost and wiring runs.

- Terrain: undulations create shade mismatches; smarter, row-by-row backtracking helps.

Tracker architecture and backtracking

Self-shading from torque tubes, dampers, and rails reduces rear yield. Designs marketed as “bifacial-friendly” typically minimize rear obstructions.

- 1P vs 2P: single-portrait (1P) often outperforms 2P for bifacial due to less rear shadowing and simpler backtracking. Verify with your tracker OEM’s rear-irradiance maps.

- Backtracking: standard backtracking prevents front-side shade near solar noon in winter. Enhanced algorithms account for slope and row-to-row differences and can protect rear-side gain too.

- Clamps and junction boxes: keep shadows thin and symmetric; avoid wide rails or deep skirts that block the rear.

Indicative gains you can plan around

The table gives typical, model-based ranges. Use it to frame early-stage site screening, then refine with site data.

| Configuration | Assumptions | Annual yield gain vs. fixed-tilt monofacial |

|---|---|---|

| Fixed-tilt, monofacial | Baseline | 0% |

| Single-axis tracker, monofacial | High-irradiance site | +12% to +25% (IEA) |

| Single-axis tracker, bifacial | Albedo ~0.25–0.35; 1P; good backtracking | +20% to +35% total vs. fixed (tracker gain plus ~6% to ~12% rear) |

| Single-axis tracker, bifacial with high albedo | Albedo ~0.5–0.6; raised height | +30% to +45% total vs. fixed (rear adds ~15% to ~20%) |

| Dual-axis, monofacial | Flat terrain | +22% to +40% total vs. fixed (IEA) |

Ranges vary with climate, soiling, snow, and availability. The IEA provides tracker uplift context; bifacial uplift depends on site and design choices summarized above.

Controls and electrical design that protect yield

Inverter loading and clipping

Trackers stretch production into mornings and evenings, while bifacial raises daytime energy. Size the DC:AC ratio to capture this shape without heavy clipping.

- Typical ratios for tracker+bifacial sit around 1.3–1.5. Validate with hourly simulations.

- Check thermal limits. Higher current from bifacial modules can push string and inverter ratings.

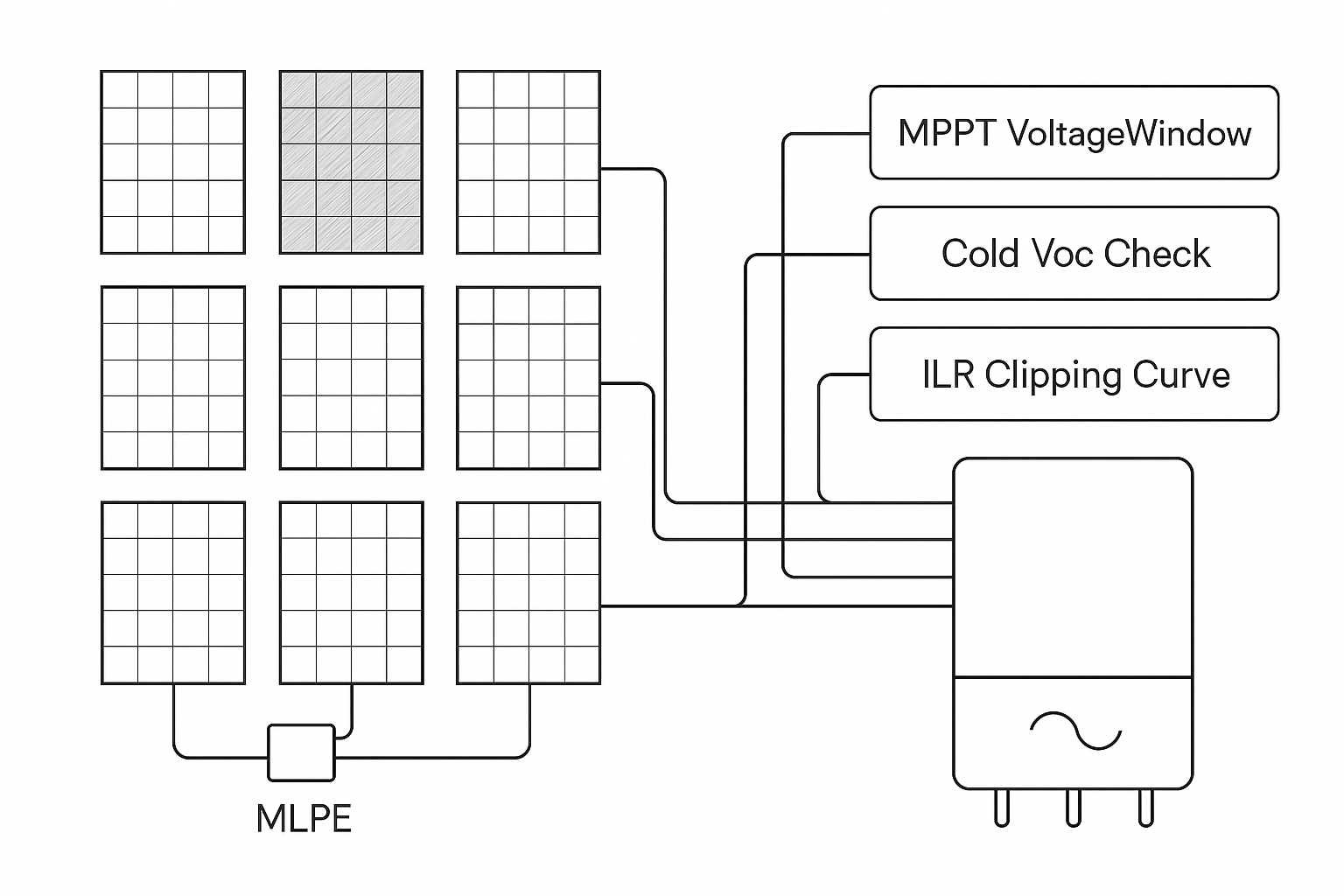

Mismatch and MPPT strategy

Mismatched rows reduce yield. Keep strings uniform in orientation, length, and shading profile. Use more MPPT channels to isolate terrain-driven differences. Module binning and tight IV control help. The knowledge base notes that module-level power electronics reduce mismatch in small systems; in utility plants, string-level strategies and better layout often suffice.

Availability and protection settings

Availability loss occurs during faults, repairs, or false trips. Better reliability and tuned protection settings keep energy flowing.

- Reduce ground-fault and arc-fault false trips with tested wiring practices and verified inverter firmware. This directly cuts availability loss, as highlighted in the knowledge base.

- SCADA alarms should distinguish rear-soiling events from front-soiling. Rear dirt often goes unseen without rear sensors.

Field data, policy context, and cost signals

Public agencies capture the big picture: trackers lift energy yield, and bifacial adoption is rising, especially in utility plants.

- The IEA shows 12–25% annual uplift from single-axis tracking in sunny areas and notes the extra 10–15% from dual-axis with economic caveats.

- IRENA tracks falling PV costs and maturing system designs. Higher yield from trackers and bifacial tech supports lower LCOE.

- EIA data reflect the growing share of utility-scale PV and the role of tracking plants in daytime supply.

- Manufacturing scale and thin-film deposition advances have pushed module output up and costs down, as noted in an Energy.gov SunShot success story about a very large module factory and next-gen cell tooling.

- The U.S. DOE Solar Energy topic hub offers design and testing resources that support project bankability.

Worked example: translating physics into MWh

Assume a 100 MWdc plant in a high-irradiance region. Baseline: fixed-tilt, monofacial. Use relative math to keep it site-agnostic.

- Single-axis tracker uplift: +18% (midpoint of IEA range).

- Bifacial uplift on tracker at albedo ~0.3: +10%.

- Design penalties: −2% due to tighter spacing; −1% from residual clipping after inverter sizing.

Net factor = 1.18 × 1.10 × 0.97 ≈ 1.26. That is ~26% more annual energy vs. the baseline. If the baseline specific yield is 1,700 kWh/kWp, the upgrade produces ~2,142 kWh/kWp. Use your site’s measured albedo, soiling, and met data to refine these figures.

Practical checklist for higher bifacial-tracker performance

- Measure ground albedo across seasons; design for ≥0.3 if feasible.

- Adopt 1P tracker architecture where rear obstruction is minimal.

- Raise module height if capex allows; check wind and pile costs.

- Tune backtracking for slope; prefer row-wise control on undulating sites.

- Right-size DC:AC to limit clipping in high-albedo months.

- Limit rear shading from rails, clamps, and junction boxes; request bifacial ray-trace from suppliers.

- Plan rear-side cleaning access and safety.

- Instrument a pilot row with rear irradiance sensors to validate models.

PV + storage: capture value, not just kWh

Trackers smooth the output curve. Bifacial adds more energy in the same footprint. Add storage to shift surplus to high-price hours and stabilize feeder impacts. For C&I microgrids, farms, and off-grid sites, pairing lithium batteries with a hybrid inverter makes use of early-afternoon surplus and trims demand charges. This combination supports energy independence goals while improving project economics.

What to watch in procurement and QA

- Glass-glass weight/load: confirm tracker allowable module weight and wind-induced torsion for your site’s gust profile.

- Warranties: align module, tracker, and foundation warranties for wind/snow loads and long-term backsheet/glass durability.

- IEC/UL compliance: require bifacial-specific tests and tracker torsional gallop assessments.

- Performance modeling: use irradiance models that include rear view factor and self-shading. Calibrate with field data.

Policy and markets evolve. Trackers, bifacial modules, and smarter layouts are proven tools to raise yield. Agencies like the IEA, IRENA, and DOE provide reliable benchmarks and design guidance to keep risk in check.

Disclaimer: This content provides general technical and financial information and is not investment, engineering, or legal advice.

FAQs

How much bifacial gain can a single-axis tracker deliver?

On typical soil (albedo ~0.2–0.3), expect roughly 6–12% extra over a monofacial tracker, with site variation. With light-colored ground or seasonal snow, 15–20% is realistic. Validate with site albedo measurements and a pilot row.

Is dual-axis tracking worth the extra complexity?

Dual-axis can add 10–15% beyond single-axis, per the IEA. Capex, O&M, and downtime risks often offset gains. In many regions, single-axis plus bifacial and better controls wins on LCOE.

What GCR and height should I target?

Lower GCR and higher rows raise rear irradiance but cost more land and steel. A practical starting point is GCR ~0.35–0.45 with module lower-edge around 1.0–1.5 m, then optimize with site wind, soil, and albedo data.

1P or 2P trackers for bifacial modules?

1P usually has less rear obstruction and simpler backtracking. 2P can suit tight sites. Ask for rear-irradiance maps from tracker vendors and model both with your module.

Do bifacial modules help on pitched residential roofs?

No material gain on typical sloped residential roofs because the rear gets little reflected light, as noted in the knowledge base. Flat commercial roofs can see modest gains, especially with bright membranes.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.