Your energy storage battery is the heart of your solar system, and its longevity is key to your energy independence. While basic care is beneficial, advanced tuning techniques can significantly extend its service life. One powerful strategy involves intelligently pairing charge and discharge rates (C-rates) with specific State of Charge (SOC) windows. This approach minimizes stress on the battery cells, directly reducing wear and maximizing your investment.

Understanding the Core Concepts: C-Rate and SOC

To implement this strategy, you first need a solid grasp of two fundamental battery parameters: C-rate and State of Charge (SOC). They are the primary levers you can adjust to influence battery health.

What is C-Rate?

The C-rate defines the speed at which a battery is charged or discharged relative to its maximum capacity. Think of it like the flow rate of water into or out of a bucket. A 100Ah battery charging at 100A is charging at a 1C rate. The same battery charging at 50A is charging at a 0.5C rate. Similarly, discharging it at 200A would be a 2C rate.

Higher C-rates deliver more power quickly but also generate more internal heat and place greater physical stress on the battery's internal components. For LiFePO4 batteries, operating at consistently high C-rates can accelerate capacity fade.

The Importance of State of Charge (SOC)

State of Charge is straightforward: it is the current charge level of your battery, expressed as a percentage. A 100% SOC means it is fully charged, and 0% means it is fully discharged. However, operating a battery at these extremes is a primary cause of degradation. The electrodes are under the most strain when nearly full or nearly empty. This is why establishing a daily 'SOC window'—a defined range like 20% to 80%—is a common practice for preserving battery health.

The Synergy: How C-Rates and SOC Windows Interact

The real magic happens when you coordinate C-rates with the battery's current SOC. It’s not just about avoiding high C-rates or extreme SOCs individually; it's about avoiding their combination.

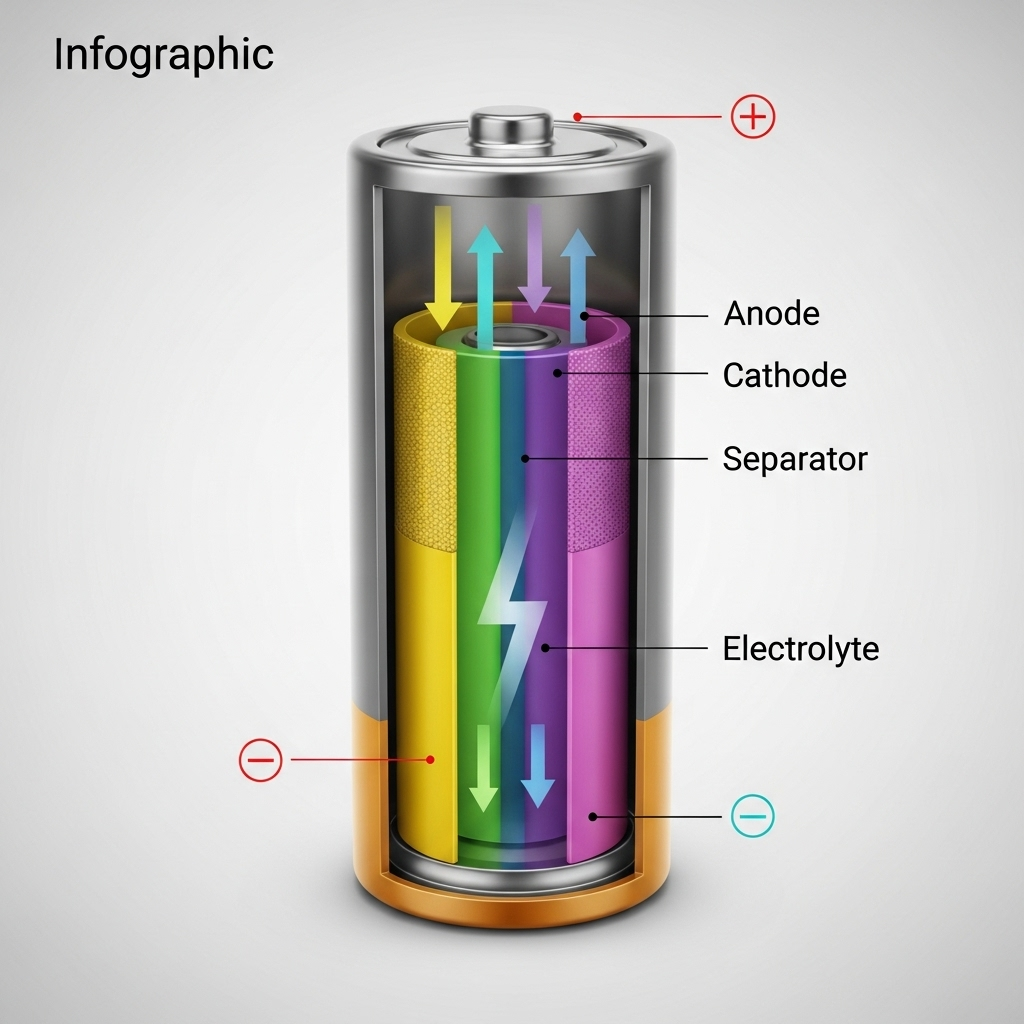

The High-Stress Zones

The most damaging activity for a lithium-ion battery is charging at a high C-rate when the SOC is already high (e.g., above 90%) or discharging at a high C-rate when the SOC is very low (e.g., below 10%). Charging aggressively near full capacity can lead to lithium plating on the anode, permanently reducing capacity. Discharging heavily when nearly empty can cause irreversible structural damage to the cathode.

Creating a Smart Charging and Discharging Profile

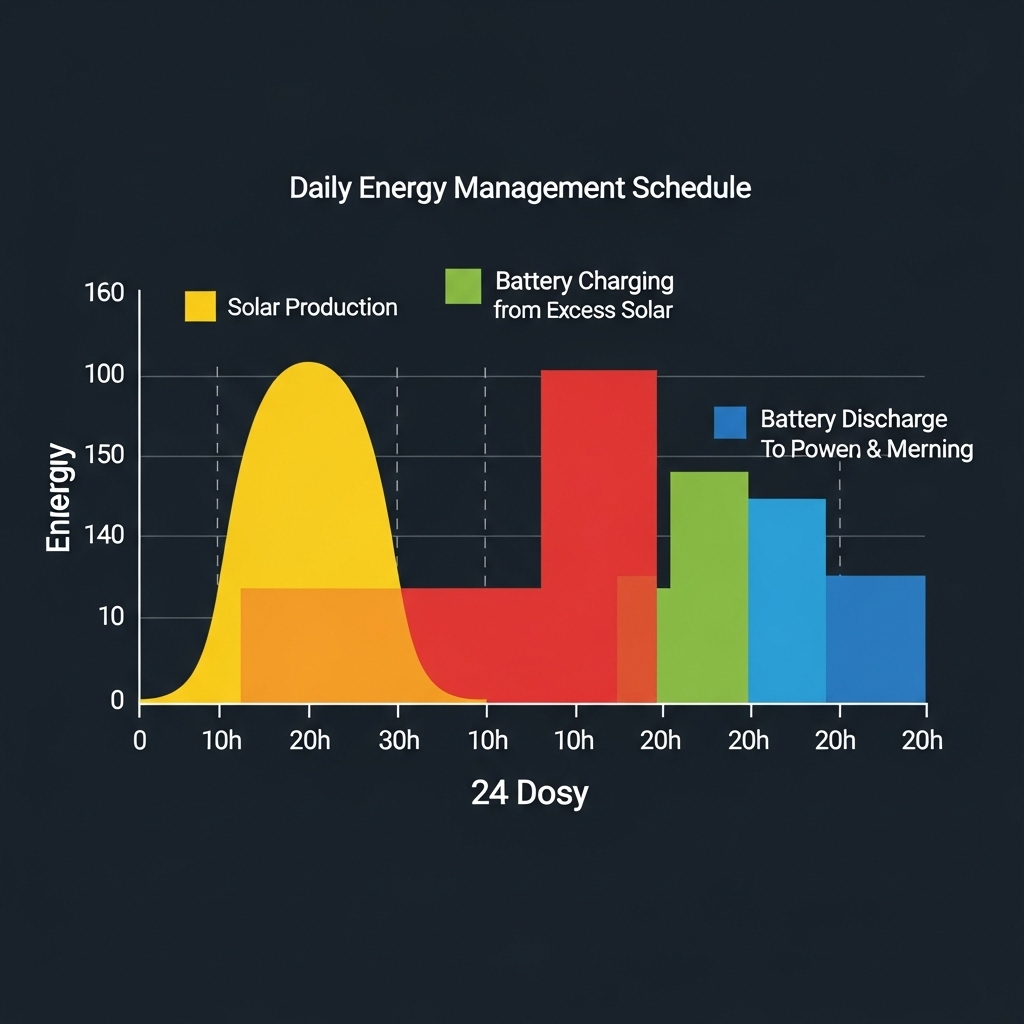

A smart profile uses variable C-rates. The strategy is to use lower, gentler C-rates at the edges of your SOC window and reserve higher C-rates for the stable middle range. For example, a system could be configured to:

- Charge at a moderate 0.5C when the SOC is between 20% and 80%.

- Automatically taper the charge rate to 0.2C or lower as the SOC climbs from 80% to 95%.

- Limit the discharge rate when the SOC drops below 20% to prevent excessive voltage sag and cell strain.

This method allows you to quickly charge the bulk of the battery's capacity during peak solar production without stressing the cells at the top end. Modern, configurable Battery Management Systems (BMS) and hybrid inverters are often capable of implementing such sophisticated charging profiles.

Implementing Advanced Tuning for Longevity

Putting this theory into practice requires a system that offers some level of user configuration and a data-informed approach to setting your parameters.

Configuring Your System Parameters

Review the documentation for your inverter and battery system. Look for settings such as 'Max Charge Current', 'Max Discharge Current', and SOC limits for charging and discharging. Not all systems offer granular C-rate control tied to SOC, but most high-quality systems allow you to set the upper and lower SOC boundaries for daily operation. Setting these boundaries is the most critical first step.

A Data-Driven Approach to Setting Windows

The ideal daily SOC window balances usability with longevity. For LiFePO4 batteries, a daily operational window between 15% and 85% is an excellent starting point. This 70% Depth of Discharge (DoD) avoids the highest-stress zones. The impact of DoD on cycle life is significant. As detailed in this comprehensive reference on solar storage performance, limiting the DoD can dramatically increase the total number of cycles a battery can provide. For instance, moving from 100% DoD to 80% DoD can nearly double the expected cycle life.

The table below provides an illustration of this relationship for a typical LiFePO4 battery.

| Daily SOC Window | Usable Capacity (DoD) | Estimated Cycle Life | Relative Lifetime Throughput |

|---|---|---|---|

| 100% - 0% | 100% | ~3,000 cycles | 1.0x |

| 90% - 10% | 80% | ~6,000 cycles | 1.6x |

| 80% - 20% | 60% | ~10,000 cycles | 2.0x |

Note: These are illustrative figures. Actual performance varies by manufacturer, temperature, and specific C-rates used. The 'Relative Lifetime Throughput' is calculated as (Usable Capacity * Cycle Life), showing how a narrower window can deliver more total energy over the battery's lifespan.

The Broader Impact on System Flexibility

This type of intelligent battery management does more than just protect your hardware. It contributes to the overall stability and efficiency of the energy grid. This concept, known as 'sector coupling,' involves creating intelligent links between the power sector and other energy-consuming sectors. A fleet of well-managed residential batteries can act as a distributed resource, enhancing power system flexibility.

According to the International Energy Agency's report on Status of Power System Transformation 2019, this flexibility is vital for integrating variable renewable sources like solar. Furthermore, advanced flexibility measures can have a massive impact. Analysis in the China Power System Transformation report suggests these strategies can substantially reduce the need for fossil-fuel-based power generation. This aligns with findings from IRENA's Electricity Storage Valuation Framework, which confirms that storage adds significant value by improving system balancing and capacity, especially at high penetrations of renewables.

Final Thoughts on Smart Energy Management

Pairing C-rates with SOC windows is an advanced but highly effective method for cutting battery wear. By programming your system to operate gently at the edges of its state of charge and more robustly in the middle, you actively reduce the primary drivers of degradation. This proactive management results in a longer service life, improved reliability, and a greater lifetime return on your energy storage investment. It transforms your battery from a simple storage tank into an intelligently managed asset for your energy future.

Frequently Asked Questions

Is it bad to charge my LiFePO4 battery to 100%?

While not immediately harmful, consistently charging to 100% and leaving it at that state, especially in high temperatures, accelerates degradation. For daily cycling, it is better practice to stop the charge at 90-95% to promote a longer lifespan.

My system does not let me control C-rates. What can I do?

If you cannot directly control the C-rate based on SOC, you can still gain most of the benefit by managing the SOC window. Setting a daily operating range, for example, between 20% and 80%, is one of the most effective actions you can take. Most quality inverters and battery systems allow for this adjustment.

Does this apply to all battery chemistries?

The general principles of avoiding extreme states of charge and high C-rates apply to most lithium-ion chemistries. However, the specific SOC windows and C-rate tolerances vary. LiFePO4 chemistry is known for its robustness, but this tuning method is particularly effective for maximizing its already long lifespan. Always consult your battery manufacturer's specifications.

Is using a smaller SOC window wasteful?

It is a strategic trade-off. You access less of the battery's total capacity on any given day, but you dramatically increase the total number of cycles the battery can perform. This means the total energy delivered over its lifetime is much greater, leading to a lower cost per kWh in the long term.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.