A solar energy system's performance hinges on the synergy between its components. While solar panels capture the energy and batteries store it, the hybrid inverter directs it. This central role means the inverter's configuration has a profound impact on the health and lifespan of your LiFePO4 batteries. Fine-tuning specific parameters is a critical step in maximizing your energy investment by actively reducing battery aging.

Understanding the Key Stress Factors for LiFePO4 Batteries

LiFePO4 (Lithium Iron Phosphate) batteries are known for their safety and longevity, but their lifespan is not infinite. Three primary operational factors influence how quickly they age: State of Charge, charge/discharge rates, and temperature.

State of Charge (SoC) Management

Operating a LiFePO4 battery at the extremes of its state of charge—fully charged or fully depleted—accelerates degradation. Consistently charging to 100% or discharging to 0% puts stress on the battery's internal chemistry. The optimal approach is to operate within a more conservative window, such as 20% to 80% SoC, which significantly extends cycle life. This practice avoids the high-stress conditions that cause irreversible damage.

Charge and Discharge Rates (C-Rate)

The C-rate measures how quickly a battery is charged or discharged relative to its capacity. A 1C rate on a 100Ah battery means charging or discharging at 100 amps. While LiFePO4 batteries can handle high C-rates, doing so frequently generates excess heat and mechanical stress on the electrodes. Lowering the C-rate reduces these stresses, promoting a longer, healthier battery life. A moderate charge rate, such as 0.5C, is often recommended for daily use to balance charging speed with longevity.

Operating Temperature

Temperature is a critical factor in battery health. LiFePO4 batteries perform best within a moderate temperature range, typically between 15°C and 35°C (59°F and 95°F). High temperatures accelerate internal chemical reactions, leading to faster degradation, while very low temperatures can increase internal resistance and risk lithium plating during charging.

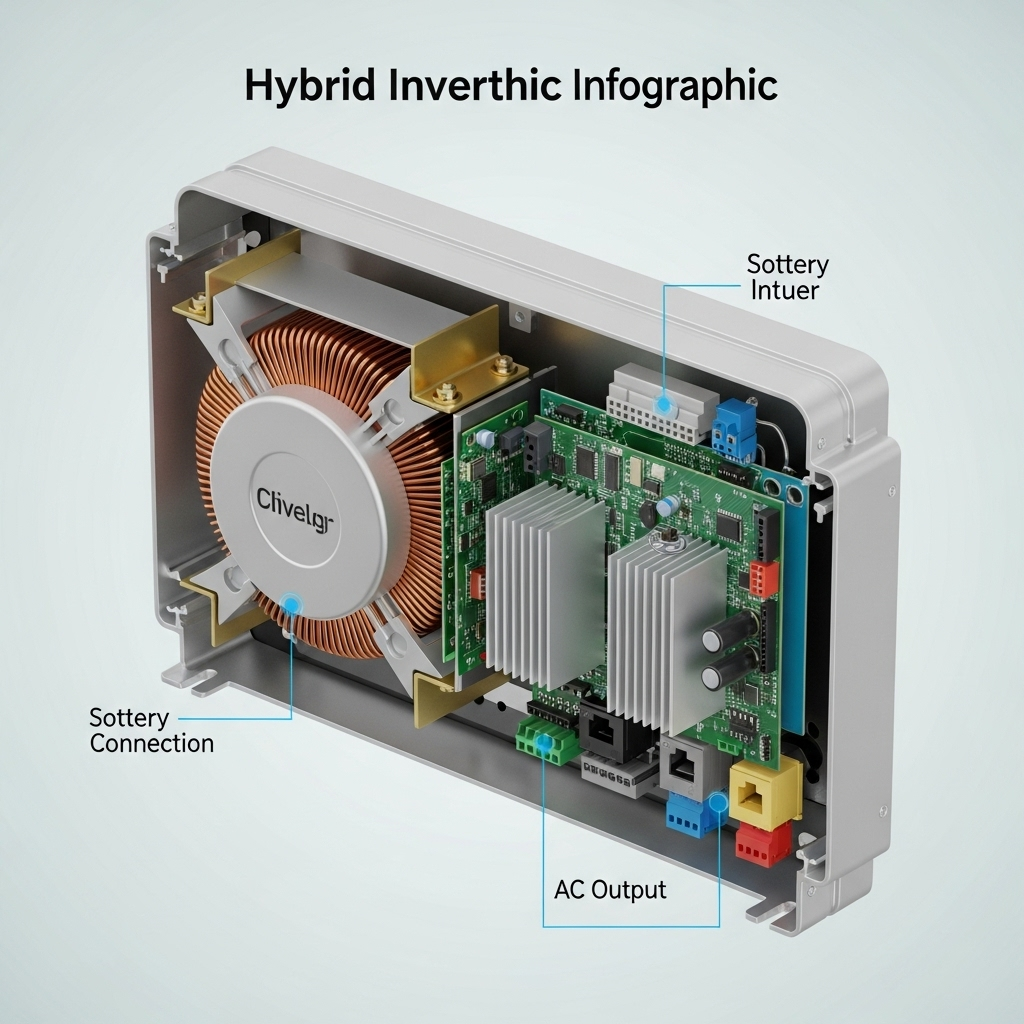

The Hybrid Inverter's Role in Battery Health Management

The hybrid inverter is the command center of your energy system. It dictates how and when the battery charges and discharges, making it the most powerful tool for implementing a battery longevity strategy.

The Inverter as the System's Brain

A hybrid inverter intelligently manages energy flow from solar panels, the battery, and the grid to power your home. By programming its settings, you directly control the key stress factors affecting your battery. This control allows you to enforce the best practices for battery care automatically, ensuring the system operates efficiently and protects your hardware.

Key Tunable Parameters

Most quality hybrid inverters allow for user-defined battery settings. The most impactful parameters for LiFePO4 batteries include:

- Bulk/Absorption Charge Voltage: This is the maximum voltage the battery reaches during the main charging phase.

- Float Charge Voltage: A lower voltage meant to keep a battery topped off. This is often unnecessary for LiFePO4 and can be disabled or set to a neutral voltage.

- Low Voltage Cut-off (LVC): The voltage at which the inverter stops drawing power from the battery to prevent over-discharge.

- Maximum Charge/Discharge Current: This setting directly controls the C-rate, limiting how quickly the battery can be charged or discharged.

Case Study: A Practical Approach to Tuning

Let's consider a common residential setup: a 5kW hybrid inverter paired with a 10kWh (48V, 200Ah) LiFePO4 battery. Default inverter settings are often generic, not optimized for LiFePO4 chemistry.

Initial Setup and Baseline Performance

Out of the box, an inverter might have settings designed for lead-acid batteries or aggressive Li-ion profiles. These defaults could target a high charge voltage and a low cut-off, potentially reducing the battery's expected 5,000-cycle life by a significant margin.

Implementing Optimized Settings

By adjusting the inverter's parameters, we can create a much healthier operating environment for the battery. The goal is to avoid voltage extremes and limit high currents.

| Parameter | Default Setting | Optimized LiFePO4 Setting |

|---|---|---|

| Bulk/Absorption Voltage | 58.4V | 55.2V (3.45V per cell) |

| Float Voltage | 54.0V | 53.6V (or disabled) |

| Low Voltage Cut-off | 44.0V | 48.0V (3.0V per cell) |

| Max Charge Current | 100A (0.5C) | 60A (0.3C) |

| Max Discharge Current | 100A (0.5C) | 100A (0.5C) |

Analyzing the Results

The optimized settings yield substantial benefits. Lowering the bulk charge voltage from 58.4V to 55.2V prevents the battery from reaching a high-stress 100% SoC. Setting a higher low-voltage cutoff at 48.0V ensures a buffer remains, preventing deep discharges. Reducing the max charge current to 60A lowers thermal stress during solar charging. This careful tuning can extend the battery's projected lifespan from under 4,000 cycles to well over 6,000 cycles, effectively increasing the total energy throughput and value of the battery. For a deeper understanding of how these metrics affect overall system efficiency, the Ultimate Reference for Solar Storage Performance provides detailed data on performance benchmarks.

Advanced Strategies and System-Level Considerations

Beyond basic voltage and current settings, modern hybrid inverters offer advanced features that can further enhance battery life and system value.

Time-of-Use (TOU) Optimization

In areas with TOU electricity rates, you can program the inverter to charge the battery from the grid during cheap off-peak hours and discharge to power the home during expensive peak hours. This strategy can be combined with battery-preserving SoC limits. According to the Electricity Storage Valuation Framework by IRENA, the full benefit of a battery is realized when its operation is optimized for specific market conditions, such as energy arbitrage.

The Importance of a Quality BMS

While the inverter sets the high-level strategy, the internal Battery Management System (BMS) provides the essential cell-level protection. It monitors individual cell voltages and temperatures, preventing any single cell from going outside its safe operating limits. As noted in analysis by the International Energy Agency (IEA), innovation in battery systems, including sophisticated management, is crucial for the clean energy transition.

A Smarter Investment for Your Energy Future

Your LiFePO4 battery is a significant investment. By taking the time to properly tune your hybrid inverter, you move from a passive user to an active system manager. This proactive approach doesn't just add years to your battery's life; it ensures your entire solar and storage system operates with greater reliability and delivers a better return. You protect your hardware, enhance your energy independence, and secure a more sustainable energy future.

Disclaimer: The settings provided are for illustrative purposes. Always consult your battery and inverter manufacturer's specifications before making adjustments. This content does not constitute professional engineering or financial advice.

Frequently Asked Questions

Will these settings reduce my battery's usable capacity?

Yes, slightly on a daily basis. By operating within a narrower SoC window (e.g., 20-90%), you are not using the full nameplate capacity in each cycle. However, this trade-off dramatically increases the total energy the battery can deliver over its entire lifetime, resulting in a lower overall cost of energy.

How often should I check my inverter settings?

After the initial optimization, it is good practice to review them annually. You should also revisit the settings if you significantly change your energy usage patterns, such as adding an electric vehicle or other large appliances, to ensure they remain optimal.

Can I apply these principles to other battery chemistries?

The general principles of managing SoC, C-rate, and temperature apply to most lithium-ion batteries. However, the specific voltage and current setpoints are unique to LiFePO4 chemistry. Using these values for other battery types, like NMC or LTO, would be incorrect and could cause damage. Always use settings specified for your particular battery chemistry.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.