Operations & Maintenance (O&M) and degradation are two critical factors that silently chip away at the long-term value of a solar PV system. For installers, mastering the art of minimizing these costs is not just about building a better system; it's about building a more profitable and reputable business. High O&M expenses lead to slimmer margins, while accelerated degradation means lower energy production and dissatisfied customers. This playbook provides actionable strategies to tackle these challenges head-on, ensuring every system you install performs optimally for decades.

Foundational Strategies: Smart Design and Component Selection

The first line of defense against future costs is established long before anyone steps onto a roof. It begins with intelligent system design and a commitment to using high-quality components.

Designing for Durability and Low Maintenance

A well-designed system anticipates and mitigates common failure points. Proper ventilation for inverters and energy storage systems is crucial to prevent overheating, a common cause of premature failure. Strategic panel orientation can reduce the accumulation of dust and debris, minimizing the need for frequent cleanings. Furthermore, as noted in the Next Generation Wind and Solar Power (Full Report), optimizing the DC-to-AC load ratio can enhance system performance and value, contributing to a more robust design from the outset.

Choosing High-Quality Components

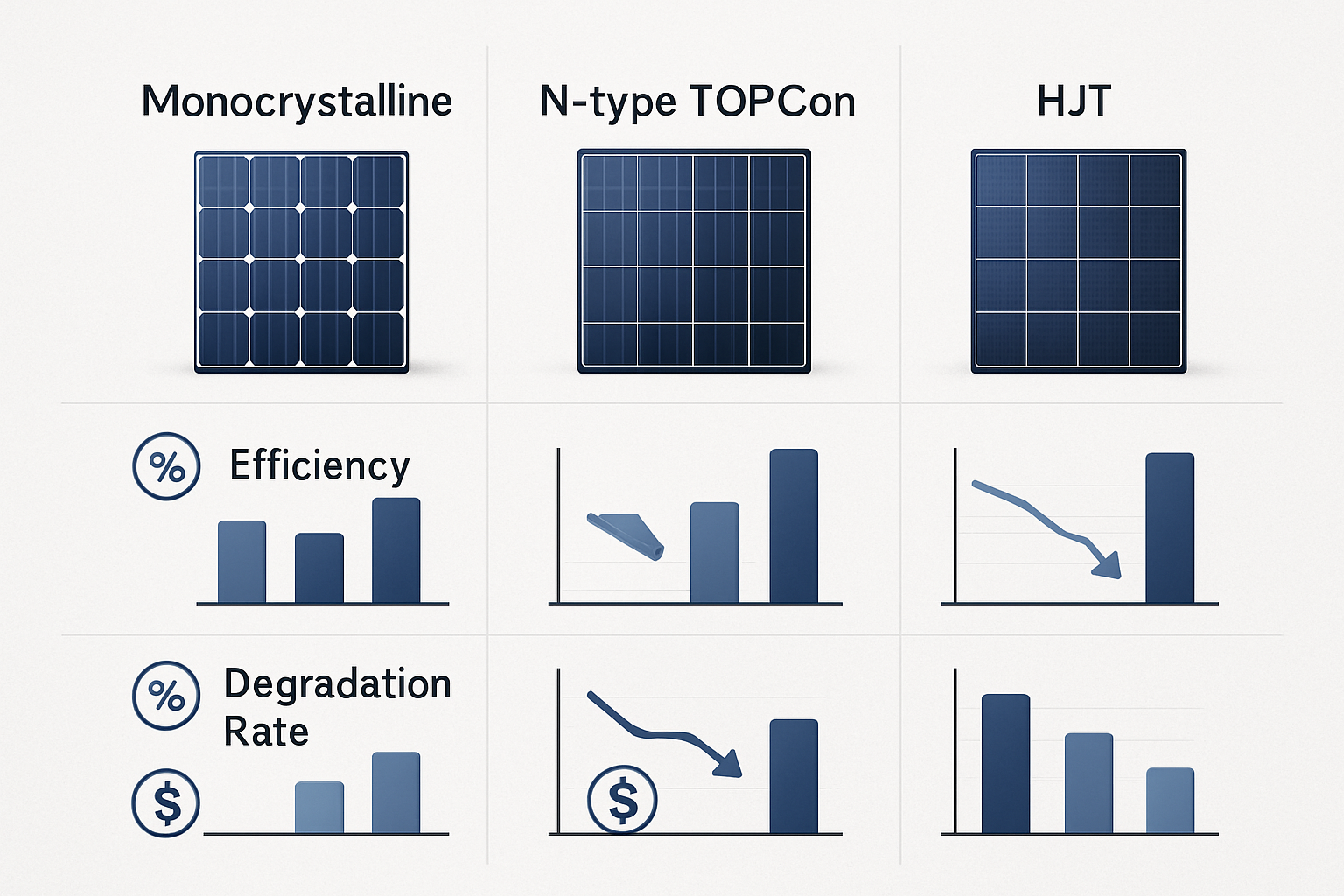

The quality of the materials used in a solar installation directly impacts its longevity and performance. High-quality panels manufactured with stringent controls are less susceptible to environmental stressors like UV exposure and temperature fluctuations. This translates to a lower rate of degradation. Similarly, reliable inverters reduce the frequency of service calls, which are a significant O&M expense. Investing in corrosion-resistant racking and mounting hardware engineered for local climate conditions—be it high winds or heavy snow—prevents structural failures that can lead to costly, complex repairs.

The Installation Phase: Where Quality Prevents Future Costs

Even the best components will underperform if not installed correctly. The installation phase is a critical control point for preventing a host of future O&M issues and minimizing PV degradation.

Meticulous Workmanship and Best Practices

Attention to detail during installation is paramount. Using a calibrated torque wrench on all electrical and mechanical connections prevents issues like loose wires, which can cause arc faults, and over-tightened clamps, which can create microcracks in modules. Proper wire management—securing cables away from sharp edges and ensuring they are not pinched—is essential to prevent insulation damage and ground faults over the system's lifetime. According to the U.S. Department of Energy, innovations in Plug and Play PV systems aim to simplify these processes, but the core principles of quality workmanship remain unchanged.

Commissioning for Peak Performance

A thorough commissioning process does more than just verify that the system works; it establishes a vital performance baseline. Conducting tests like IV curve tracing and insulation resistance measurements at the time of installation provides a detailed snapshot of the system's initial health. This data is invaluable for accurately tracking performance and degradation over time, making it easier to diagnose future problems. A robust commissioning process ensures the system starts its operational life at its maximum potential.

Proactive Operations & Maintenance (O&M) Playbook

Shifting from a reactive to a proactive O&M strategy is key to reducing long-term costs. This involves using modern tools to monitor system health and implementing a structured maintenance plan.

Leveraging Remote Monitoring and Analytics

Modern monitoring platforms are powerful tools for reducing O&M costs. They allow installers to track system performance in real-time and receive alerts for any deviations. This data-driven approach helps diagnose many issues remotely, such as inverter faults or string outages, reducing the need for expensive and time-consuming site visits, often called "truck rolls." By addressing problems before they escalate, you can maintain higher system uptime and improve customer satisfaction.

Developing a Tiered Maintenance Schedule

Not all maintenance tasks need to be performed with the same frequency. A tiered schedule optimizes resources by aligning tasks with their actual necessity. Regular maintenance is key to maximizing the life of a solar panel system.

| Tier | Frequency | Key Activities | Objective |

|---|---|---|---|

| Tier 1: Proactive Monitoring | Daily / Weekly | Remote performance analysis, alert review | Early fault detection, minimize downtime |

| Tier 2: Preventative Maintenance | Annually | Visual inspection of components, cleaning in high-soiling areas, basic vegetation management | Prevent physical damage, address soiling losses |

| Tier 3: Corrective Maintenance | As Needed | Component replacement (e.g., inverters), electrical testing, re-torquing connections | Resolve diagnosed faults, ensure long-term safety and performance |

Understanding and Mitigating Degradation

Solar panel degradation is the gradual decrease in power output over time. While some degradation is natural, certain types can be accelerated by poor quality or environmental factors. Common mechanisms include Light-Induced Degradation (LID), which occurs in the first few hours of sun exposure, and Potential-Induced Degradation (PID), which can be caused by voltage differences. Choosing high-quality, PID-resistant modules and ensuring proper system grounding during installation are effective strategies to minimize these effects and slow the overall degradation rate.

The Financial Impact: Connecting O&M to the Bottom Line

Every decision made in design, installation, and maintenance has a direct financial consequence. Reducing O&M and degradation costs is fundamental to improving a project's economic viability.

Lowering these operational expenses directly contributes to a lower Levelized Cost of Energy (LCOE), which is a critical measure of a power source's lifetime cost-effectiveness. As reported by the International Energy Agency, the LCOE for solar PV has seen dramatic reductions, making it highly competitive. A study from Lawrence Berkeley National Laboratory found that improvements in project life and operational expenses accounted for a significant portion of the LCOE decline over a decade. For your customers, a system that degrades less produces more energy over its lifespan, accelerating their return on investment. For your business, this translates to a stronger reputation, fewer warranty claims, and a healthier bottom line.

Building for the Long Term

Reducing PV O&M and degradation costs is not about cutting corners. It is about making strategic investments in quality, from initial design to long-term maintenance. By adopting a playbook focused on durable components, meticulous installation, and proactive, data-driven O&M, installers can deliver systems that stand the test of time. This commitment to long-term value not only protects your profitability but also builds a trusted brand in an increasingly competitive market, ensuring both your systems and your business continue to thrive.

Frequently Asked Questions

What is a typical annual degradation rate for solar panels?

After the first year, a typical solar panel degradation rate is between 0.5% and 1.0% annually. However, high-quality modern panels often degrade at a slower pace, with some studies showing rates as low as 0.4% per year. The rate is influenced by panel quality, technology type, and climate conditions.

How much do PV O&M costs typically add to a system's price?

O&M costs have decreased significantly over time. For recent utility-scale projects, levelized lifetime operational expenses can range from $13 to $25/kWdc-yr. For residential systems, costs are often managed through proactive monitoring, with corrective maintenance performed as needed rather than on a fixed schedule.

Can remote monitoring completely replace physical site visits?

Remote monitoring cannot completely replace physical visits, but it makes them far more efficient. It helps diagnose problems ahead of time, ensuring a technician arrives with the right tools and parts. It also eliminates the need for routine check-ups, reserving site visits for necessary preventative or corrective maintenance tasks.

What are the most common points of failure in a PV system?

The most common failure points in a PV system are often related to the inverter, which is a complex electronic device responsible for converting DC to AC power. Other common issues include faulty wiring or loose connections, communication system failures, and physical damage to the modules themselves.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.