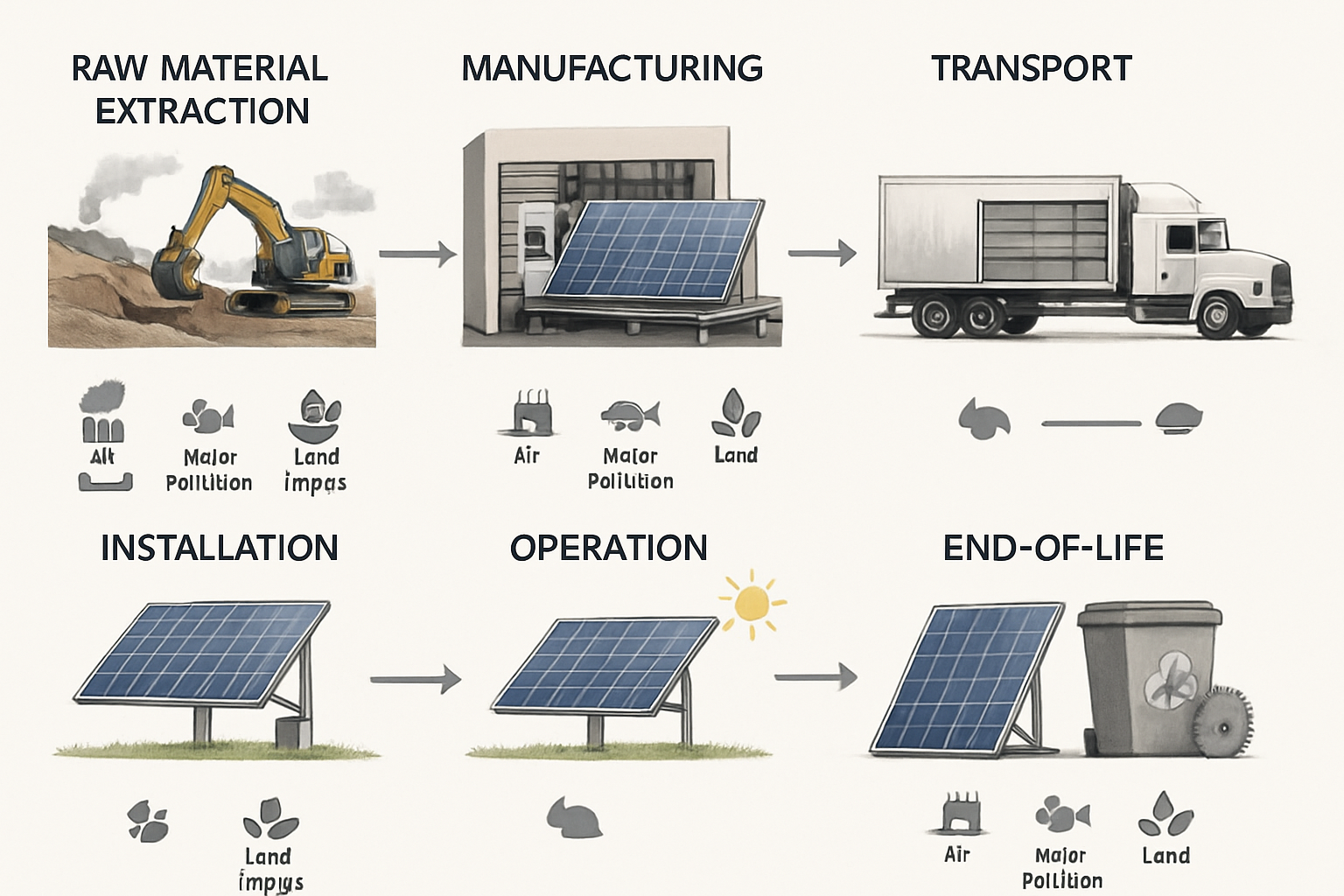

Solar panels are a cornerstone of modern renewable energy, transforming sunlight into electricity for homes and businesses. Understanding the complete life cycle of these photovoltaic (PV) modules, from their creation to their eventual end-of-life management, is crucial for appreciating their long-term benefits and ensuring a sustainable energy future. This guide provides a detailed look into each stage, offering insights into how solar panels are made, how they perform over decades, and what happens when they complete their service.

As a company with extensive experience in the solar and energy storage industry, we focus on providing reliable and scalable energy solutions. We aim to help you achieve energy independence, and a deep understanding of solar panel longevity supports this goal. This article will cover the technical details, practical applications, and the evolving landscape of solar panel sustainability. You will gain insight into the entire process, helping you make informed decisions about your solar investments. For a step-by-step overview of the process, consider reading How to Map a Solar Panel's Full Life Cycle, Step by Step.

1. The Birth of a Solar Panel: Manufacturing and Installation

The journey of a solar panel begins long before it reaches your rooftop or solar farm. It involves a complex sequence of material sourcing, manufacturing, and careful installation to ensure optimal performance.

1.1. From Raw Materials to PV Module

The primary material in solar cells is silicon, derived from quartz. The manufacturing process starts with silicon purification, where quartz is heated in a furnace to produce metallurgical-grade silicon. This silicon then undergoes further chemical processing to yield highly pure electronic-grade silicon. The purified silicon melts in a crucible at high temperatures, then cools and solidifies into cylindrical or rectangular ingots. A seed crystal guides the formation of a single crystal structure, a process known as the Czochralski method, essential for efficient electricity generation. These ingots are then sawed into thin disks called wafers, which are polished to create a smooth surface.

Next, the wafers undergo doping, where impurities like boron or phosphorus are added to create a positive (p-type) and negative (n-type) electrical orientation, forming a p-n junction that converts sunlight into electricity. An anti-reflective coating, typically silicon nitride, is applied to the wafers to reduce sunlight reflection and increase absorption. Metal conductors are then screen-printed onto the wafer, forming the grid pattern seen on solar cells. Solar cells are interconnected using thin metal ribbons to form a string, which are then assembled into a module by sandwiching them between a glass layer and a back support sheet. The junction box and nameplate are attached, and the panel undergoes lamination to protect the cells from external elements. Quality checks are stringent throughout this process to ensure efficiency and durability.

While the production phase is energy-intensive, studies show that solar panels generate significantly more clean energy over their lifetime than the energy used to manufacture them, often offsetting their manufacturing emissions within 1-4 years.

1.2. Strategic Installation and System Integration

Proper installation is crucial for a solar panel's longevity and performance. It involves more than just mounting panels; it includes thoughtful system design and integration with other components. A solar power system typically includes solar panels, an inverter, a charge controller, and a battery pack. The inverter is a critical component, converting the direct current (DC) electricity generated by solar panels into alternating current (AC) for household or commercial use.

ANERN specializes in advanced solar solutions, including high-efficiency solar panels and innovative inverters. Our Solar Inverter technology, particularly hybrid inverters, offers maximum operational flexibility, seamlessly combining grid-tied and off-grid capabilities. These inverters ensure power continuity by automatically switching to battery power during grid outages, functioning as an uninterruptible power supply (UPS). They also feature Maximum Power Point Tracking (MPPT) charge controllers to maximize energy harvest, even in challenging conditions. Proper sizing of the inverter is key, requiring a continuous power rating at least 25% higher than the total simultaneous load to ensure stable operation.

For those seeking energy independence, ANERN's Home Energy Storage Systems integrate lithium batteries, hybrid inverters, and solar panels into an all-in-one modular design. These systems provide stable power, reduce electricity bills, and lessen reliance on the grid. Our Off-Grid Solar Solutions are particularly valuable for remote areas or locations with unreliable grid access, offering self-sufficient energy generation and storage.

2. The Active Service Life: Performance, Degradation, and Maintenance

Once installed, solar panels begin their decades-long work of generating clean electricity. However, their performance is not static; it evolves over time due to various factors.

2.1. Performance Over Time: Expected Lifespan and Degradation

Solar panels have a remarkable lifespan, typically lasting 25-30 years, with many continuing to function beyond this period at reduced efficiency. This longevity makes solar panels a sustainable energy technology. Over this operational period, panels gradually lose efficiency, a process known as degradation.

The average degradation rate for modern panels is around 0.5% to 0.8% per year, often less than the 1% rate used in warranties. Some studies have found even lower rates, with monocrystalline panels made after 2000 degrading at just 0.4% annually. However, some studies indicate higher degradation rates, particularly in certain climates or for specific module types, ranging from 1.2% to 1.8% in some grid-scale PV modules. Initial degradation, known as Light-Induced Degradation (LID), can cause a 1-3% efficiency reduction shortly after installation due to initial sun exposure, but the rate slows significantly afterward.

Factors influencing degradation include exposure to UV radiation, temperature fluctuations, humidity, and physical damage like hail or microcracks. Potential-Induced Degradation (PID) can also occur due to high voltages, causing voltage leaks and reducing performance. High-quality panels are designed to withstand these conditions and maintain a significant portion of their initial power output even after 25 to 30 years. For example, a quality panel might only degrade by 9% over its lifespan, while a cheaper panel could lose 20% or more efficiency.

Here is a general overview of expected degradation:

| Timeframe | Typical Degradation Rate | Expected Power Output (relative to initial) |

|---|---|---|

| First Year (LID) | 1-3% (initial drop) | 97-99% |

| Years 1-10 | 0.4-0.8% per year | 90-97% |

| Years 10-25/30 | 0.4-0.8% per year | 80-90% |

| Beyond 25/30 years | Continues to degrade, but still produces power | Below 80% (but still functional) |

2.2. Maximizing Efficiency and Extending Lifespan

You can take proactive steps to ensure your solar panels deliver optimal performance throughout their operational life. Regular monitoring and maintenance are key. This includes routine cleaning to remove dust, dirt, or snow (known as soiling), which can reduce sunlight exposure and power output. Inspections help identify physical damage or issues like backsheet cracking, which can compromise electrical insulation and safety. Monitoring your system's energy output can identify potential issues early; a significant, unexplained drop in power generation may signal a problem requiring professional attention.

Advanced energy storage systems play a significant role in maximizing efficiency and extending the effective life of your solar system. ANERN's Lithium Batteries, specifically our Lithium Iron Phosphate (LiFePO4) batteries, are designed for high performance, safety, and reliability. These batteries feature an Intelligent Battery Management System (BMS) that provides multi-layered protection against overcharging, over-discharging, over-current, and short circuits. The BMS also ensures optimal cell balancing and thermal management, which are critical for maximizing the battery's operational lifespan to over 6000 deep cycles, translating to an operational lifespan exceeding 15 years in typical applications.

By integrating ANERN's LiFePO4 batteries with your solar installation, you can store excess energy generated during peak sunlight hours and use it when panels are not producing, such as at night or on cloudy days. This reduces reliance on the grid and ensures a stable power supply, even during outages. Our residential energy storage systems offer a high depth of discharge, allowing more usable energy to be extracted from the same nominal capacity, providing longer backup times and greater energy throughput. For more information on extending panel life, you might find Off-Grid to ESS: Extend Panel Life with Smart Storage helpful.

3. End-of-Life: Challenges and Opportunities

As solar panels complete their decades of service, managing them responsibly becomes a critical aspect of ensuring the sustainability of solar energy. This phase presents both environmental challenges and economic opportunities.

3.1. Managing Decommissioned Panels

The rapid growth of solar panel installations means a significant volume of panels will reach their end-of-life in the coming years. Projections indicate that the United States alone could have up to one million tons of solar panel waste by 2030, increasing to an estimated ten million tons by 2050. Globally, the cumulative value of recoverable raw materials from end-of-life panels could reach about $450 million by 2030, equivalent to the cost of raw materials for approximately 60 million new panels.

Traditional disposal methods, such as landfilling, pose challenges. Solar panels are complex products made from multiple layers of materials, making recycling more difficult than traditional products. While solar panels generate emission-free electricity during use, their components contain materials that require careful handling at disposal. Many panels include valuable recoverable materials like aluminum, copper, silicon, and small amounts of silver. Some panels may also contain potentially harmful metals such as lead or cadmium in quantities that could classify them as hazardous waste if not properly managed. Improper disposal can lead to the leaching of toxic substances into the environment, posing health risks. For a deeper look into this topic, consider Myth vs Reality: Are Solar Panels Hazardous Waste?

Logistical challenges also arise due to the varied lifespans of panels and the lack of a unified collection system, especially in regions without comprehensive legislation. Transportation costs also contribute to the overall environmental footprint of end-of-life management.

3.2. The Promise of Recycling and Reuse

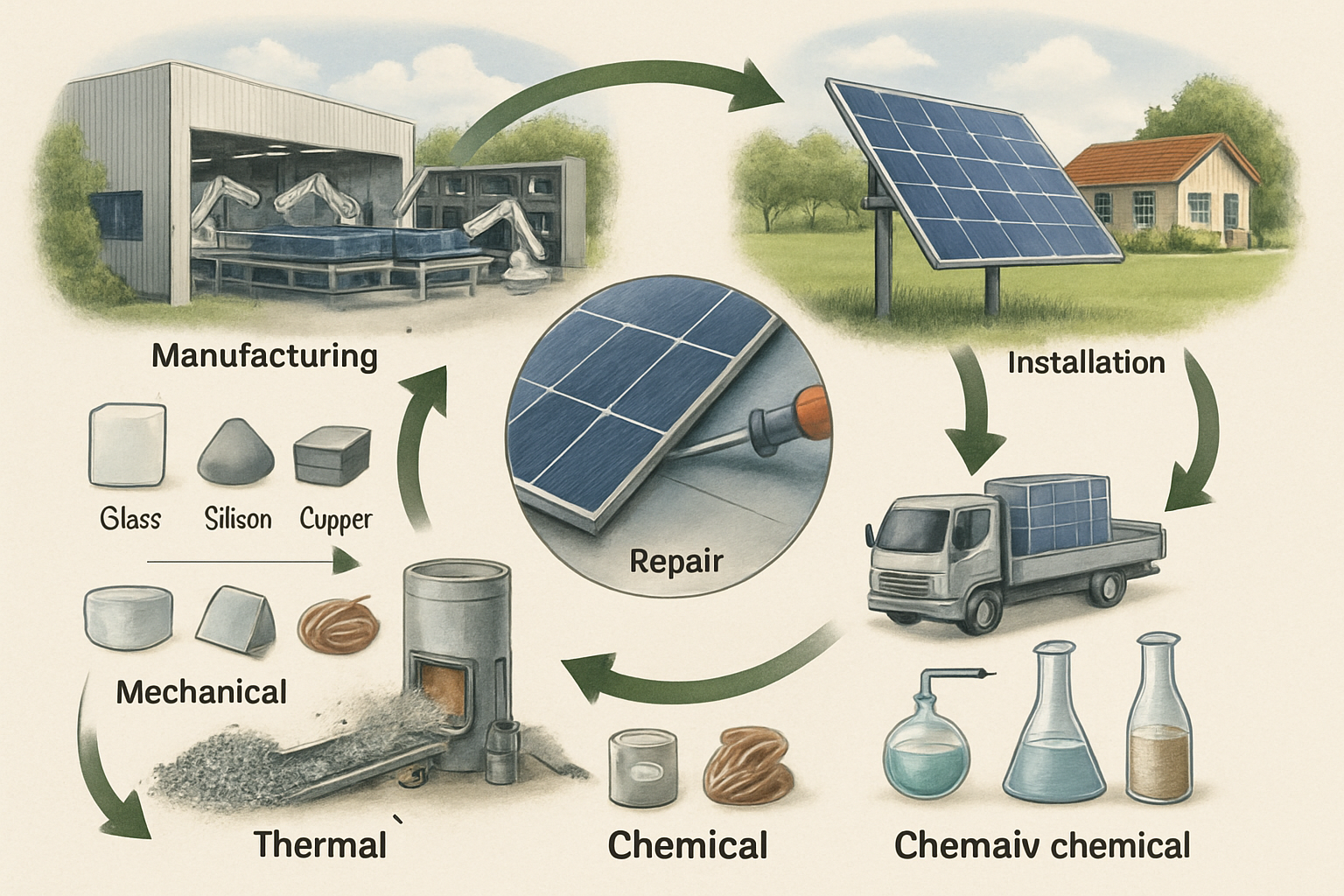

Despite the challenges, end-of-life solar panels offer significant opportunities for material recovery and reuse, contributing to a circular economy. Recycling processes aim to recover as much material as possible. Current methods often involve disassembling panels, separating aluminum frames and junction boxes, then shredding or crushing the remaining components. The glass, which makes up about 75% of a panel's weight, can be crushed and melted for reuse. Aluminum frames and copper wires are also easily recyclable.

The silicon cells undergo specialized recycling processes to extract silicon and other precious metals like silver and copper. Some methods involve heating shredded panel materials to over 500°C to separate silicon cells from melted polymers and glass. Recovered silicon can then be purified and reused in new solar panels or other applications. Advanced techniques, such as chemical baths, plasma treatment, or pyrolysis, are being explored to break down components more effectively and achieve higher purity recovery of materials. Some recycling technologies boast up to 96% recycling efficiency. For detailed insights into recycling, refer to The Ultimate Guide to PV Module Recycling and Reuse and Materials Breakdown: Where the Value Hides in Old Modules.

Beyond recycling, the reuse of functional panels for a "second life" is gaining traction, especially for panels that still perform well but are no longer at peak efficiency for their original application. This approach aligns with circular economy principles, which prioritize material reduction, reuse, and repair before recycling. By recovering and reusing materials, the demand for virgin resources and energy-intensive production procedures for new panels decreases. This also helps reduce the carbon footprint associated with manufacturing and disposal.

4. A Sustainable Future: Innovation and Policy

The solar industry is continuously evolving, driven by innovation in technology and the development of supportive policies to ensure a truly sustainable future for solar energy.

4.1. Advancements in Design and Material Recovery

Ongoing research and development focus on improving solar panel design for easier disassembly and enhanced recyclability. This includes exploring new module designs with biodegradable or easily separable components. The goal is to make the separation and recovery of valuable materials more efficient and cost-effective. For example, advancements in recycling technology are improving recovery rates, with some processes recovering up to 90% of glass and 95% of semiconductor materials. Efforts also aim to recover more polymers and other materials currently lost in processing.

The integration of energy storage systems, like those offered by ANERN, also contributes to a sustainable future. By optimizing energy use and extending the operational life of solar installations, our advanced lithium iron phosphate (LiFePO4) batteries and hybrid inverters reduce the overall environmental impact of a solar system. Our focus on high-performance, long-lasting products supports the goal of maximizing the value extracted from solar technology before it reaches end-of-life. ANERN's commitment to quality and durability ensures that our products contribute to a more resilient and sustainable energy ecosystem.

4.2. Policy and Economic Drivers for a Circular Economy

Government policies and regulations are vital for building a more secure and sustainable solar PV supply chain. Globally, policies have historically focused on increasing demand and lowering costs. However, there is a growing recognition of the need for resilient and sustainable supply chains, including robust end-of-life management. Countries are assessing their domestic solar PV supply chain vulnerabilities and developing strategies to address them.

The concept of a circular economy for solar PV is gaining traction. This approach reimagines the traditional "take-make-dispose" model into a regenerative cycle where materials are reused, remanufactured, and recycled. Policies like the European Union's Waste Electrical and Electronic Equipment (WEEE) Directive mandate manufacturers and importers to take responsibility for the collection and recycling of end-of-life PV panels. This directive sets minimum recovery targets of 85% by weight and recycling targets of 80% for PV modules, ensuring valuable materials are recaptured. Some states in the US also have policies for decommissioning plans and funds, with a few requiring recycling or reuse of components. Niagara County, New York, for instance, has a local law for solar panel recycling.

Economic incentives are also crucial. Currently, PV recycling processes often struggle to generate enough revenue from recovered materials to cover recycling costs. However, effective recycling programs can reduce landfill waste by up to 40% and create new economic opportunities. Studies suggest that recycling solar panels can improve the levelized cost of electricity. Extended Producer Responsibility (EPR) regulations are expected to shift the economic burden of recycling from consumers to manufacturers, potentially improving the economics of recycling. By fostering a circular economy, the solar industry can minimize waste, reduce reliance on newly mined raw materials, create jobs in recycling and remanufacturing, and lower the carbon footprint of solar energy. For insights into the economic aspects, see PV Life Cycle vs Cost: LCOE, Embodied Carbon, ROI Tradeoffs.

Final Thoughts

The life cycle of a solar panel is a testament to human ingenuity and our pursuit of sustainable energy. From the intricate manufacturing processes that transform raw silicon into high-efficiency modules to their decades of clean energy production, solar panels represent a powerful solution for our energy needs. While degradation is a natural part of their operational life, diligent maintenance and the integration of advanced energy storage systems, like ANERN's LiFePO4 batteries and hybrid inverters, can significantly extend their effective service and enhance overall system performance.

As the solar industry continues its rapid expansion, the focus on responsible end-of-life management, including robust recycling and reuse initiatives, becomes increasingly important. Embracing a circular economy model for solar panels is not just an environmental imperative; it is an economic opportunity that will drive innovation, create jobs, and further solidify solar energy's role in a truly sustainable future. We remain committed to providing reliable, scalable, and environmentally conscious energy solutions, empowering you to achieve energy independence and contribute to a healthier planet.

Non-Legal Advice Disclaimer: The information provided in this article is for general informational purposes only and does not constitute legal, financial, or investment advice. You should consult with qualified professionals for advice tailored to your specific situation.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.