Solar energy is a cornerstone of clean energy transitions. As solar panel installations rapidly increase, a new consideration emerges: managing end-of-life solar modules. These panels, after their typical 25-30 year lifespan, represent a growing waste stream. However, they are not merely waste; they are a rich source of valuable materials waiting for recovery. Understanding the composition of old solar panels helps us unlock their hidden economic and environmental potential.

The Anatomy of a Solar Panel: A Material Perspective

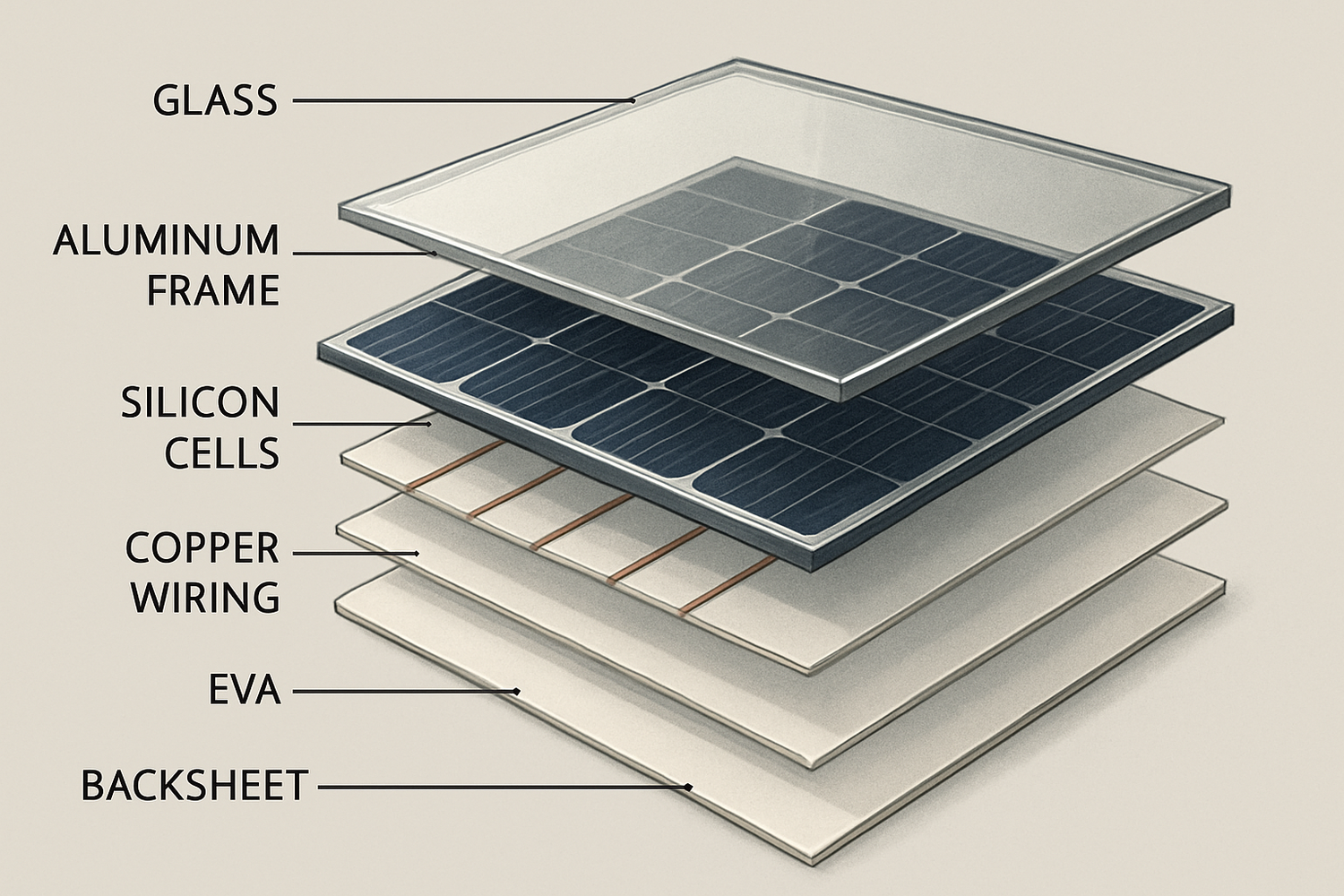

A typical crystalline silicon solar panel is a sophisticated assembly of various materials, each playing a crucial role in converting sunlight into electricity. Knowing these components helps us appreciate the complexity and the embedded value within each module.

Key Components and Their Functions

- Glass: This forms the protective front layer, shielding the delicate photovoltaic (PV) cells from environmental damage while allowing maximum sunlight transmission. Tempered glass is commonly used for its strength and durability.

- Silicon Cells: These are the heart of the panel, made from highly purified silicon. They are responsible for the photovoltaic effect, converting solar energy into direct current (DC) electricity.

- Encapsulant (EVA): Ethylene Vinyl Acetate (EVA) is a transparent polymer layer that encapsulates the silicon cells, protecting them from moisture, dirt, and physical shock, and bonding them to the glass and backsheet.

- Backsheet: Typically made of a durable polymer like Polyvinyl Fluoride (PVF) or Polyethylene Terephthalate (PET), the backsheet provides electrical insulation and protection from moisture and UV radiation.

- Aluminum Frame: This sturdy frame provides structural integrity to the panel, protects the edges of the laminated layers, and facilitates mounting.

- Junction Box and Wiring: The junction box on the back of the panel houses bypass diodes and provides a safe enclosure for electrical connections, often utilizing copper wiring for efficient current flow.

Material Composition Breakdown

The precise composition can vary slightly between manufacturers and panel types, but crystalline silicon panels, which dominate the market, share a similar material breakdown. By weight, glass is the most abundant material, followed by polymers, aluminum, and silicon.

| Material | Approximate Percentage by Weight |

|---|---|

| Glass | 70-76% |

| Polymers (EVA, Backsheet) | 10-11% |

| Aluminum (Frame) | 8-13% |

| Silicon (Cells) | 3-5% |

| Copper (Wiring) | 1% |

| Silver & Other Metals | <0.1% |

While some materials like silver constitute a small fraction of the panel's weight, their high economic value makes them significant in the overall recycling value proposition.

Unlocking Value: Recoverable Materials

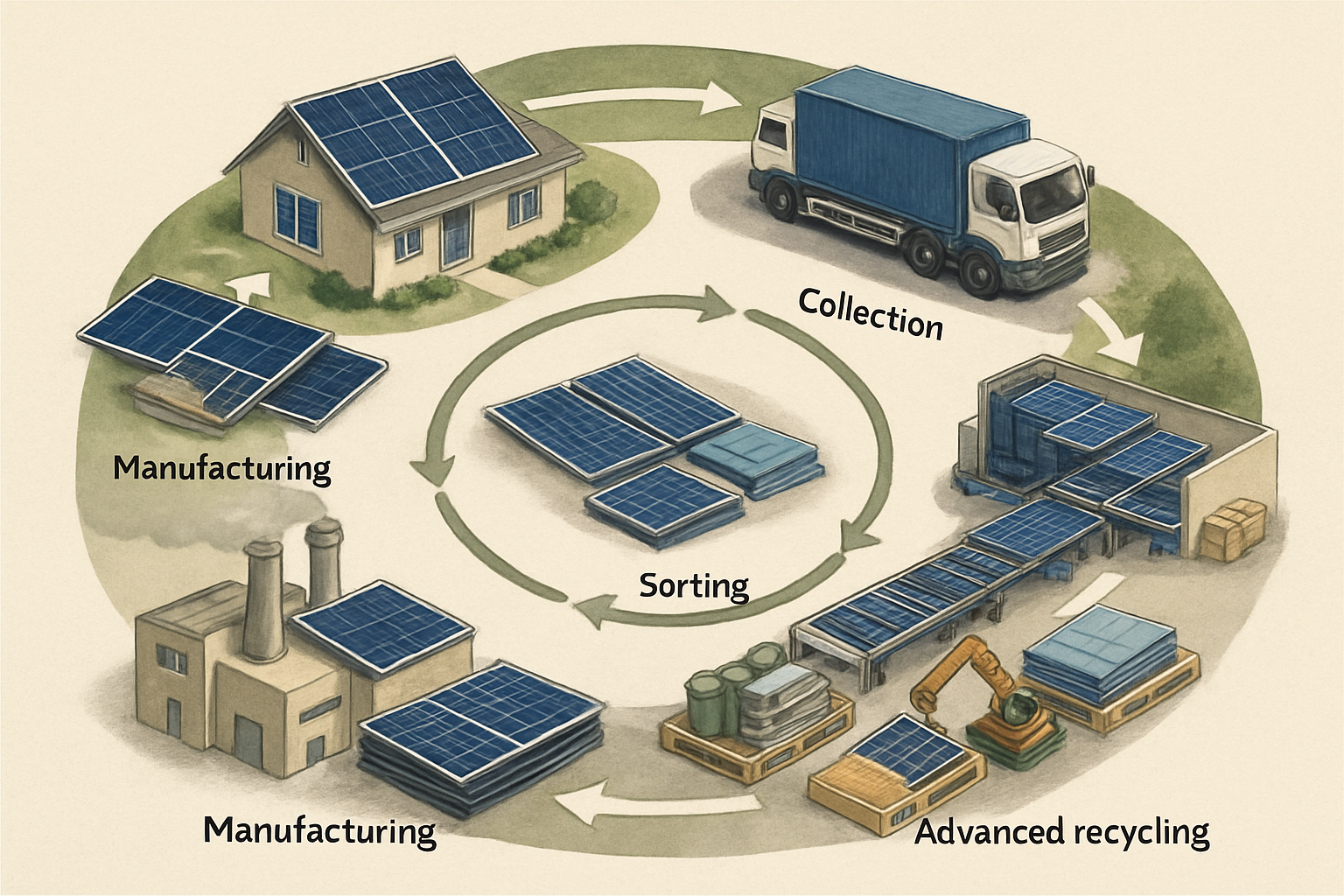

The end of a solar panel's service life does not mean the end of its usefulness. Instead, it marks an opportunity to recover valuable materials, transforming potential waste into new resources. This value recovery is a critical aspect of a sustainable solar industry.

High-Value Metals: Silver, Copper, and Aluminum

- Silver: Despite its small quantity (less than 0.1% by weight), silver is a high-value component due to its excellent conductivity and market price. It is crucial for electrical contacts in solar cells. Recycling technologies can achieve recovery rates of up to 80% for silver.

- Copper: Found in wiring and interconnections, copper is another valuable metal with high conductivity. Recycling rates for copper from solar panels can exceed 95%.

- Aluminum: The aluminum frame, making up 8-13% of a panel's mass, is highly recyclable. Recycling aluminum uses 95% less energy than producing it from raw bauxite, offering significant environmental and economic benefits.

Silicon and Glass Recovery

- Silicon: The silicon from PV cells, though representing 3-5% of the panel's weight, is a high-purity material. Advanced recycling methods can recover up to 96% of silicon, which can be repurposed for new solar cells or other semiconductor applications.

- Glass: Constituting the largest portion by weight (70-76%), tempered glass is efficiently recyclable. It can be recycled into new glass products or construction materials with approximately 90% recovery efficiency.

Emerging Opportunities: Polymers and Trace Elements

The polymer layers, such as EVA and the backsheet, pose challenges due to their adhesive properties and complex compositions. However, ongoing research aims to develop more effective methods for separating and recovering these materials. Beyond the main components, some panels may contain trace amounts of other valuable or potentially hazardous elements like lead or cadmium, which require careful management and specialized recycling processes to prevent environmental contamination.

The Economic Imperative of Recycling

Recycling end-of-life solar panels offers compelling economic advantages beyond simply reducing waste. It drives resource efficiency, creates new industries, and enhances energy security.

Cost of Landfilling Versus Value of Recycling

Disposing of solar panels in landfills incurs costs and loses the embedded value of their materials. In contrast, recycling transforms these panels into a valuable resource. The International Renewable Energy Agency (IRENA) and the International Energy Agency Photovoltaic Power Systems Programme (IEA-PVPS) project that the technical potential of materials recovered from end-of-life solar PV panels could cumulatively exceed $15 billion by 2050. This value could produce billions of new panels or be sold into global commodity markets.

Recycling also helps reduce waste management costs. Current recycling costs range from $20 to $24 per 300-watt DC panel, which is less than 5% of a typical system installation cost.

Reducing Reliance on Virgin Materials and Enhancing Supply Chain Security

Recycling significantly reduces the demand for newly mined raw materials. This not only conserves natural resources but also lessens the environmental impact associated with mining and processing virgin materials. By providing a secondary source of raw materials, recycling enhances the security and resilience of the solar PV supply chain, reducing reliance on imports and mitigating the risks of price volatility.

Environmental and Social Benefits

Beyond economics, solar panel recycling offers substantial environmental and social benefits. It prevents hazardous materials like lead and cadmium from leaching into soil and water if panels are improperly disposed of. Each recycled panel can prevent approximately 97 pounds of CO2 emissions. Recycling silicon alone uses 90% less energy than creating it from raw materials. This contributes to a lower carbon footprint for the solar industry. Additionally, the recycling sector creates new green jobs in collection, transportation, dismantling, and material processing, supporting local economic growth.

Advanced Recycling Technologies

Recovering valuable materials from complex solar panel structures requires specialized and evolving technologies. The industry employs a combination of mechanical, thermal, and chemical processes, with continuous innovation driving higher recovery rates and greater efficiency.

Mechanical, Thermal, and Chemical Processes

- Mechanical Recycling: This typically involves initial dismantling, shredding, and crushing to separate larger components like aluminum frames and junction boxes. Further mechanical processes, such as electrostatic separation, help in separating fine particles of different materials, improving purity.

- Thermal Recycling: This method uses heat to break down organic materials like EVA. Techniques such as pyrolysis, which heats panels in an oxygen-free environment, can effectively recover silicon and metals by decomposing polymers. However, thermal methods can be energy-intensive.

- Chemical Recycling: This involves using solvents or chemical etching to dissolve and separate materials. Chemical treatments can achieve high recovery rates for silicon and precious metals by selectively corroding unwanted materials or dissolving the encapsulant.

Challenges and Innovations in Material Separation

The layered construction of solar panels, particularly the strong adhesion of the EVA encapsulant, makes separation challenging. Innovations are addressing these hurdles:

- Automated Delamination Systems: These systems use thermal and mechanical processes to efficiently separate panel components, achieving high recovery rates for materials like silicon, silver, and glass.

- Thermochemical Recycling: Combining thermal and chemical processes, methods like hydrothermal processing use high-temperature water under pressure to dissolve and separate materials, aiming for high-purity recovery with minimal environmental impact.

- Precision Dismantling: Automated systems are being developed for precise dismantling, reducing contamination and improving material recovery.

Through these advanced techniques, recovery rates for materials like silicon can reach up to 95%, according to the Fraunhofer Institute for Solar Energy Systems.

Beyond the End: A Sustainable Future

The journey of a solar panel extends beyond its operational lifespan. By recognizing the intrinsic value within end-of-life solar modules, we can transform a potential waste challenge into a significant economic and environmental opportunity. Maximizing material recovery through advanced recycling processes is not just an option; it is a fundamental pillar for building a truly circular economy in the solar industry. This commitment ensures a reliable, sustainable energy future for everyone.

Frequently Asked Questions

What are the most valuable materials in an old solar panel?

The most valuable materials in an old solar panel, despite often being present in small quantities, include silver, copper, and high-purity silicon. Aluminum from the frame also holds significant economic value due to its high recyclability and volume.

How much material can be recovered from a typical solar panel?

Modern recycling technologies can recover a substantial amount of material from end-of-life solar panels. For instance, up to 95% of glass, 95% of aluminum and copper, and 80-96% of silicon and silver can be recovered.

What are the main benefits of recycling solar panels?

Recycling solar panels offers multiple benefits: it recovers valuable raw materials, reduces the need for virgin material extraction, lowers manufacturing costs for new panels, decreases greenhouse gas emissions, prevents hazardous waste from entering landfills, and creates new jobs in the recycling sector.

Are all solar panels recyclable?

Most solar panels, particularly the dominant crystalline silicon type, are largely recyclable. However, the efficiency and extent of material recovery depend on the recycling technology used. Thin-film panels may require specialized recycling processes due to different material compositions, including potentially hazardous elements like cadmium telluride.

What is the projected economic value of recycled solar panel materials?

According to reports from IRENA and IEA-PVPS, the cumulative value of recoverable materials from end-of-life solar PV panels could exceed $15 billion globally by 2050. This represents a significant economic opportunity within the circular economy.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.