Lithium Iron Phosphate (LiFePO4) batteries are central to modern residential and off-grid energy storage systems. Their long lifespan and safety profile make them a preferred choice. But a critical question arises as their adoption grows: what happens when these batteries reach the end of their service life? The answer lies in creating a robust, closed-loop system for take-back and recycling. This approach not only addresses environmental concerns but also strengthens supply chain resilience by recovering valuable materials.

The Foundation: Why a Closed-Loop System Matters

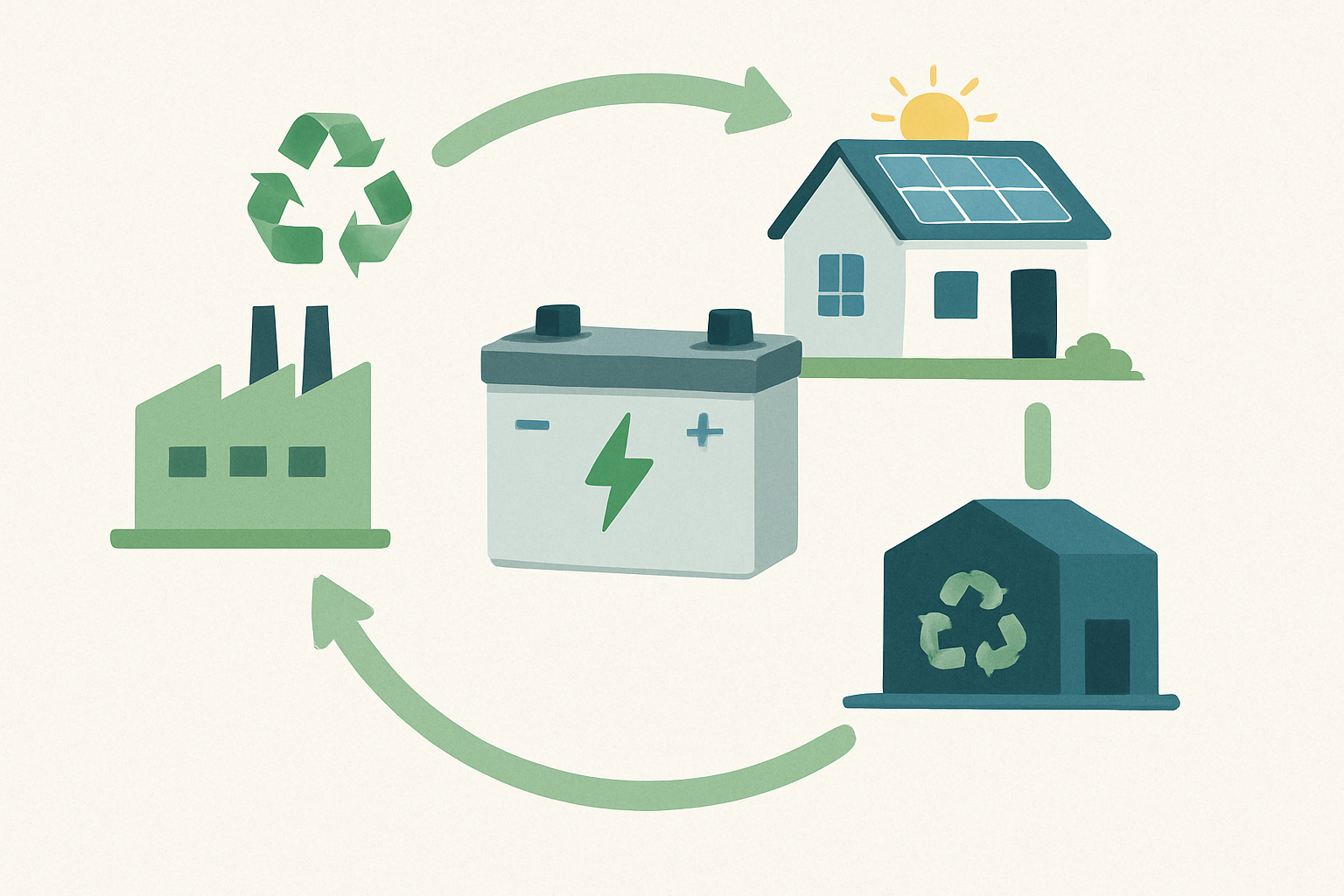

A closed-loop system, also known as a circular economy model, is designed to eliminate waste and keep materials in use. For LiFePO4 batteries, this means moving beyond simple disposal and creating a pathway where end-of-life products become the feedstock for new ones. This strategy is built on clear environmental and economic advantages.

Beyond Landfills: The Environmental Imperative

Improper disposal of any battery can pose environmental risks. A structured recycling loop ensures that valuable materials are recovered, not discarded. The process of creating new batteries from raw materials is energy-intensive. According to research, using recycled metals can significantly lower the environmental footprint. As detailed in the IEA's report, The State of Energy Innovation, recycled battery metals such as nickel, cobalt, and lithium can incur 80% less greenhouse gas emissions than primary materials produced from mining and refining. This makes battery recycling a powerful tool in reducing the overall carbon footprint of energy storage solutions.

Economic Viability and Supply Chain Resilience

The materials inside a LiFePO4 battery—lithium, iron, phosphate, copper, and aluminum—are valuable commodities. Creating a system to recover them establishes a reliable domestic source of raw materials. This reduces dependence on international mining operations, which can be subject to geopolitical instability and price volatility. The market for these recovered materials is growing, turning a potential waste stream into a revenue stream. A well-designed take-back program transforms end-of-life liabilities into tangible economic assets.

Blueprint for a Take-Back Program: A Step-by-Step Approach

Developing an effective take-back and recycling program requires careful planning and strategic execution. It involves designing products for easier end-of-life processing, establishing efficient logistics, and leveraging data to manage the entire lifecycle.

Step 1: Designing for Disassembly

The recycling process begins on the design floor. Batteries engineered for easy disassembly can dramatically lower the cost and complexity of recycling. This involves using fasteners instead of strong adhesives, standardizing cell formats, and clearly labeling components. As noted in the IEA's analysis, The Role of Critical Minerals in Clean Energy Transitions, the current design of many battery packs is not optimized for easy disassembly. A more standardized design with recycling in mind will allow for easier and more automated processes, improving the efficiency of material recovery.

Step 2: Establishing Efficient Collection Channels

The logistics of getting batteries from the user back to a recycling facility is a major hurdle. A successful program requires a multi-channel approach. This includes partnering with solar installers, who are often the first point of contact for decommissioning old systems. Other channels can include working with electronics waste collection centers and dedicated drop-off locations. Clear guidance on the safe collection, storage, and transport of end-of-life batteries is crucial for all stakeholders involved.

Step 3: Data Management and Traceability

Knowing where every battery is and its current state of health is key to an efficient loop. Implementing traceability systems, such as QR codes or embedded RFID chips, allows a battery's journey to be tracked from manufacturing to end-of-life. This data helps predict when batteries will need replacement, streamlines collection efforts, and provides recyclers with vital information about the battery's chemistry and construction, making the recovery process safer and more effective.

The Recycling Process: From Used Battery to Raw Material

Once a battery is collected, it enters a sophisticated process to reclaim its core components. This involves careful disassembly, material separation, and refining to produce high-purity raw materials ready for manufacturing new products.

Decommissioning and Disassembly

The first step at a recycling facility is to safely decommission the battery. This involves discharging any residual energy and conducting safety checks. The battery pack is then disassembled, either manually or through automated systems, to separate the individual cells, battery management system (BMS), wiring, and casing. Each component stream is then directed to its respective recycling pathway.

Closed-Loop vs. Open-Loop Recycling

Recycling can follow two primary pathways: closed-loop or open-loop. The ultimate goal is a closed-loop system, where recovered materials are used to manufacture the same product—in this case, new LiFePO4 batteries. An open-loop system uses the materials for different, often lower-value, applications. Both have their place, but a closed-loop approach delivers greater environmental and supply chain benefits.

| Feature | Closed-Loop Recycling | Open-Loop Recycling |

|---|---|---|

| Objective | Recover materials to produce new batteries. | Recover materials for use in other industries. |

| Material Value | Maintains high value of specialized materials like purified lithium and graphite. | Materials may be downcycled into lower-value applications (e.g., slag for concrete). |

| Supply Chain Impact | Directly reduces need for virgin raw materials for batteries. | Reduces need for raw materials in other sectors. |

| Example | Recovered lithium carbonate is used to create new LiFePO4 cathodes. | Recovered aluminum casing is used to make beverage cans. |

A successful real-world example of a closed-loop initiative is the technology consortium formed by BMW, Umicore, and Northvolt. As described in a 2018 announcement, this project aims to create a sustainable life cycle for battery cells where end-of-life batteries from vehicles are collected, recycled, and the recovered materials are used to produce new battery cells for the same manufacturer.

Overcoming Hurdles in the Recycling Loop

While the vision for a circular battery economy is clear, several challenges must be addressed. These include navigating complex regulations and overcoming technological and economic barriers that can hinder the efficiency and scalability of recycling operations.

Navigating Regulatory Complexities

The transportation of end-of-life lithium-ion batteries is often classified as moving hazardous materials, subjecting it to strict regulations. These regulations can vary significantly between regions and countries, creating logistical bottlenecks. Harmonizing these rules and creating clear, consistent guidelines for the international movement of batteries for recycling is essential to building a seamless global recycling network.

Technological and Economic Challenges

Recycling technology is continuously improving, but challenges remain. The diversity of battery designs and chemistries can complicate the recovery process. Furthermore, the economic viability of recycling often depends on the market price of virgin materials. When raw material prices are low, the economic incentive to recycle can decrease. Continued investment in research and development is needed to improve recovery rates and lower the costs of recycling, making it consistently competitive with primary production.

The Path Forward: A Circular Economy for Energy Storage

Building a LiFePO4 take-back and recycling loop is not just an environmental obligation; it is a strategic business decision. It strengthens brand reputation, enhances supply chain security, and unlocks new economic value. By designing for disassembly, creating efficient collection networks, and investing in advanced recycling technologies, the energy storage industry can lead the transition to a true circular economy. This ensures that the clean energy solutions of today do not become the waste problem of tomorrow, paving the way for a genuinely sustainable energy future.

Frequently Asked Questions

What makes LiFePO4 batteries a good candidate for recycling compared to other lithium-ion chemistries?

LiFePO4 batteries do not contain cobalt or nickel, which are valuable but also hazardous materials found in other chemistries like NMC or NCA. The absence of cobalt simplifies the recycling process. Additionally, the core materials—lithium, iron, and phosphate—are abundant and can be recovered with high efficiency through modern recycling techniques like hydrometallurgy.

As a homeowner, how can I participate in a battery take-back program?

The best first step is to contact the installer or manufacturer of your energy storage system. They should provide specific instructions for end-of-life management. As take-back programs become more common, you may also find information through local e-waste recycling centers or municipal waste authorities who can direct you to certified battery recyclers.

What is the difference between battery reuse and battery recycling?

Reuse, often called second-life application, involves repurposing a battery that no longer meets its original performance standards for a less demanding application. For example, an EV battery might be used for stationary energy storage. Recycling is the process of breaking down the battery into its fundamental chemical components to be used as raw materials for manufacturing new products, including new batteries.

Are there safety concerns when transporting old LiFePO4 batteries for recycling?

Yes, all lithium-ion batteries must be handled with care, even at the end of their life, as they can still hold a residual charge. It is important to follow specific guidelines for packaging and transport to prevent short circuits or physical damage. Certified recyclers and logistics partners are trained to handle these materials safely and in compliance with transportation regulations.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.