Key Takeaways

- Undersizing typically stems from missing load profiling, unrealistic depth‑of‑discharge (DoD) assumptions, ignoring temperature/c‑rate limits, or overlooking round‑trip losses.

- Right‑sizing starts with a critical‑loads list, a realistic outage profile, and tariff rules that shape self‑consumption vs export.

- Document assumptions and stress‑test them. Batteries that look adequate at 25°C may underperform at winter temperatures or at high discharge rates.

Common Sizing Mistakes and How to Avoid Them

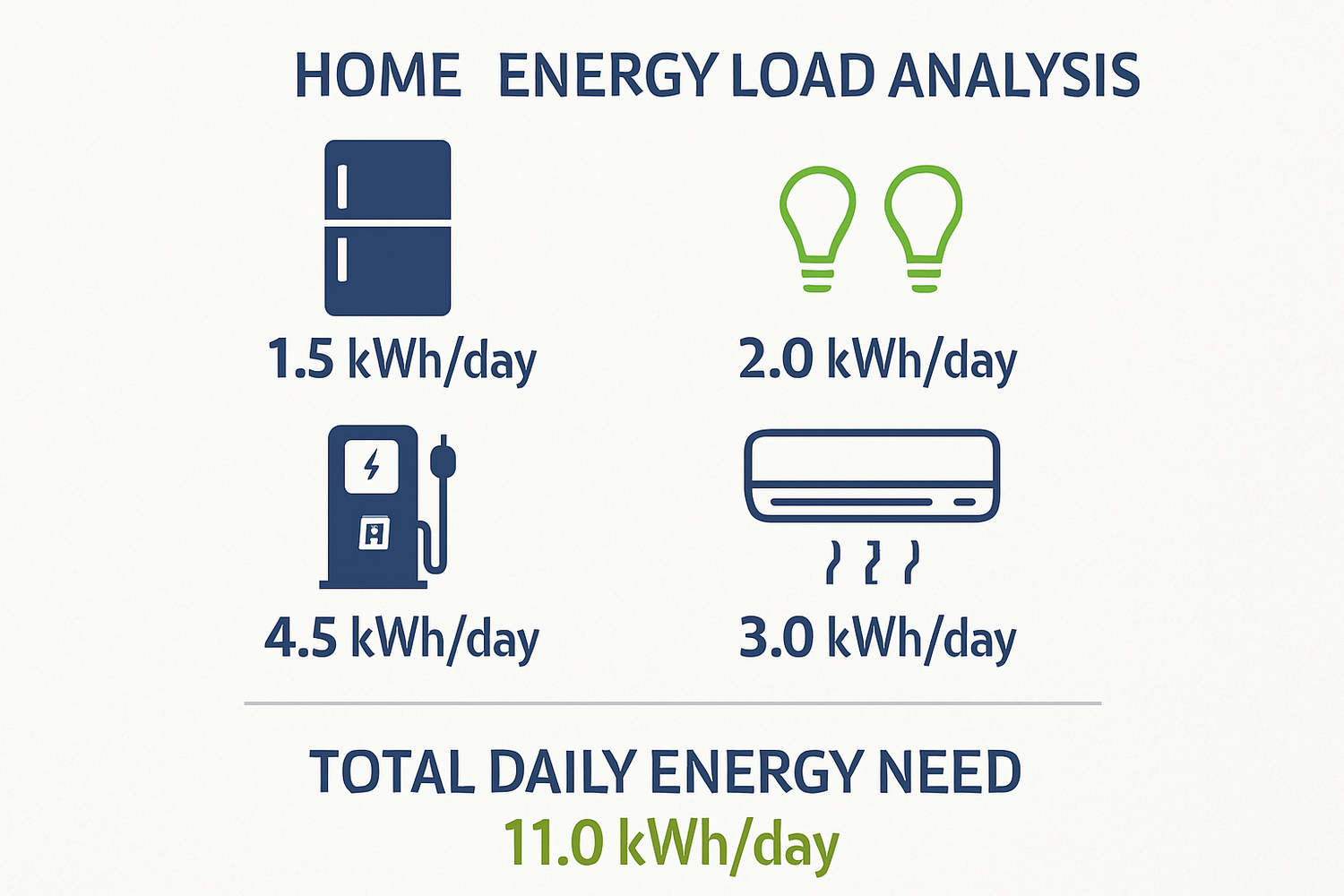

- No load profile: Estimating with averages hides peaks. Collect device wattage and hours/day; confirm starting surges (motors, pumps).

- Assuming 100% usable capacity: Respect DoD, reserve, and BMS limits. Many warranties state usable energy and cycle limits explicitly.

- Ignoring round‑trip losses: Include inverter and battery losses when calculating delivered kWh.

- Overlooking c‑rate and power limits: kWh capacity does not guarantee kW output. Check continuous and surge ratings.

- Not accounting for temperature: Cold reduces available power and charge acceptance; heat accelerates aging. Use the datasheet’s temperature curves.

- Skipping replacements: Inverters rarely match module life. Budget replacements and warranty logistics.

- Tariff blindness: Export limits, TOU rates, and demand charges reshape economics and sizing priorities.

Design Math You Can Reproduce

Step 1 — Critical Energy (kWh)

Sum of each device’s watts × hours needed during the target outage window.

E_crit (kWh) = Σ (Watts_i × Hours_i) ÷ 1000

Step 2 — Required Battery Energy

Include reserve, losses, and temperature derate.

E_required = E_crit ÷ (Usable_Fraction × RoundTrip_Eff × Temp_Factor)

- Usable_Fraction ≈ allowed DoD (e.g., 0.8 for 80% DoD) × BMS availability.

- RoundTrip_Eff typical 0.85–0.95 depending on hardware.

- Temp_Factor 0.85–0.95 if cold reduces usable energy/power.

Step 3 — Power Check (kW)

Verify continuous and surge power meet peak load and motor starts. If not, upsize inverter or add soft‑start/priority control.

Step 4 — Solar Contribution

For daytime/winter scenarios, estimate PV charging to extend runtime. Account for shading, tilt, and seasonal irradiance.

Worked Example (Illustrative)

Adjust to your site and equipment datasheets.

| Input | Assumption |

|---|---|

| Critical loads | Fridge 150 W × 12 h; Lights 80 W × 6 h; Wi‑Fi/Router 15 W × 18 h; Well pump 800 W × 1 h (intermittent) |

| Target outage window | 24 hours |

| PV contribution during outage | Winter day, estimated 2.5 kWh |

| Usable fraction | 0.8 (80% DoD allowed by warranty) |

| Round‑trip efficiency | 0.9 |

| Temperature factor | 0.9 (cold derate) |

Energy need: (150×12 + 80×6 + 15×18 + 800×1) Wh = 3,890 Wh ≈ 3.89 kWh.

Subtract winter PV 2.5 kWh → net battery energy ≈ 1.39 kWh.

Required battery: 1.39 ÷ (0.8 × 0.9 × 0.9) ≈ 2.15 kWh. Round up for uncertainty and future load growth (e.g., 3–5 kWh minimum) and check power rating for the well pump surge.

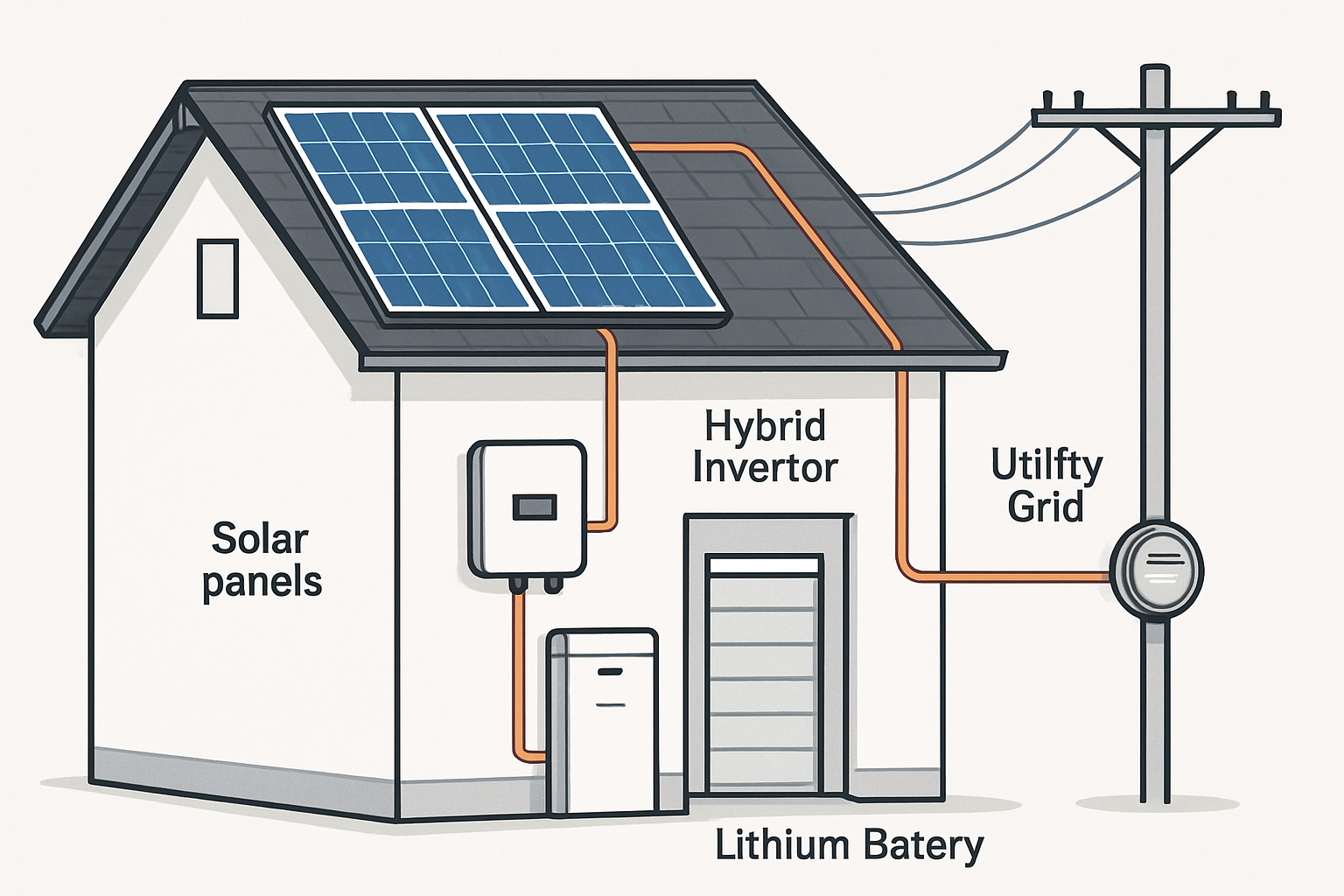

Integration Options

- Hybrid all‑in‑one: Compact, coordinated control; verify certifications and utility acceptance.

- AC‑coupled retrofit: Flexible; extra conversions reduce net delivered kWh.

- DC‑coupled: Efficient PV charging; best planned at initial install.

Safety, Codes, and Interconnection

Follow applicable codes and listings. In North America, designers commonly reference NEC 690/705 (PV and interconnections), UL 1741 (inverters), UL 9540/9540A (ESS safety evaluation), and NFPA 855 (energy storage placement and fire protection). Your local Authority Having Jurisdiction (AHJ) and utility interconnection team have the final say. Always use listed equipment and follow manufacturer instructions.

Owner Checklist

- 12 months of bills; tariff and export rules; outage history.

- Critical‑loads list with watts and hours; acceptable runtime target.

- Roof/space photos and main panel rating; preferred circuits for backup.

- Equipment models, warranties (throughput MWh, cycle life, DoD), and certifications.

- Plan for monitoring, maintenance, and potential inverter replacement.

What to Ask Your Installer

- How were loads and autonomy calculated? Can I see the worksheet?

- What derates were used for temperature, round‑trip efficiency, and DoD?

- Which codes/standards and AHJ requirements are you designing to?

- What is the expected lifecycle cost (including replacements) and warranty process?

References for Verification

- International Energy Agency (IEA) and IEA PVPS publications on PV and storage.

- U.S. Department of Energy (DOE) consumer and technical guides on residential storage.

- National Renewable Energy Laboratory (NREL) resources on system design and performance.

- UL 9540/9540A, UL 1741, NFPA 855, NEC Articles 690/705 for safety and interconnection.

- Manufacturer datasheets for usable energy, DoD limits, temperature curves, and power ratings.

Plain‑Language Disclaimer

This article is educational and not legal, engineering, or financial advice. Codes, incentives, tariffs, and product specifications change over time. Work with qualified professionals and follow manufacturer instructions and your local requirements.

Attribution

Adapted from an earlier version on your site titled “Stop Undersizing Batteries — ESS Design Mistakes to Avoid,” revised for clarity, neutrality, and verifiability.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.