The initial price of a solar inverter is only the first chapter in its financial story. To truly understand the value of your solar investment, you must look at the Total Cost of Ownership (TCO). This metric provides a complete picture, encompassing not just the purchase price but all costs incurred over the system's entire lifespan. This analysis moves beyond simple price tags to compare the lifecycle costs of the three primary inverter technologies: traditional string inverters, microinverters, and DC power optimizers.

Deconstructing Inverter TCO: More Than Just the Sticker Price

A comprehensive TCO analysis evaluates every financial aspect of an inverter system, from installation to decommissioning. It breaks down into three core components: initial spending, ongoing operational costs, and the financial value of the energy it produces.

Initial Capital Expenditure (CapEx)

Capital expenditure is the upfront cost to purchase and install the system. This includes the inverter hardware, mounting equipment, and all associated labor. Generally, string inverters present the lowest initial hardware cost on a per-watt basis. Module-Level Power Electronics (MLPE), which include both microinverters and power optimizers, typically require a higher initial investment due to the component-level hardware installed at each panel.

Operational Expenditure (OpEx)

Operational expenditure covers all the costs required to keep the system running efficiently. This includes scheduled maintenance, system monitoring, and the eventual cost of repairs or replacements. The type of inverter technology directly influences these long-term costs. For example, the granular, panel-level monitoring provided by MLPE systems can reduce troubleshooting time and expense compared to the string-level diagnostics of a standard string inverter.

Performance and Energy Yield

Energy yield is the total amount of electricity your system produces over its lifetime. This is arguably the most critical factor in your TCO, as higher production translates directly to greater savings and a faster return on investment. Factors like partial shading, panel soiling, or module mismatch can significantly reduce the output of a standard string inverter. MLPE technologies are designed to mitigate these issues by optimizing the performance of each individual panel, often leading to a higher lifetime energy harvest in installations with complex conditions.

A Data-Driven Comparison of Lifecycle Costs

Each inverter technology presents a unique TCO profile. The optimal choice depends on the specific characteristics of the installation site and the financial goals of the system owner.

String Inverters: The Cost-Effective Workhorse

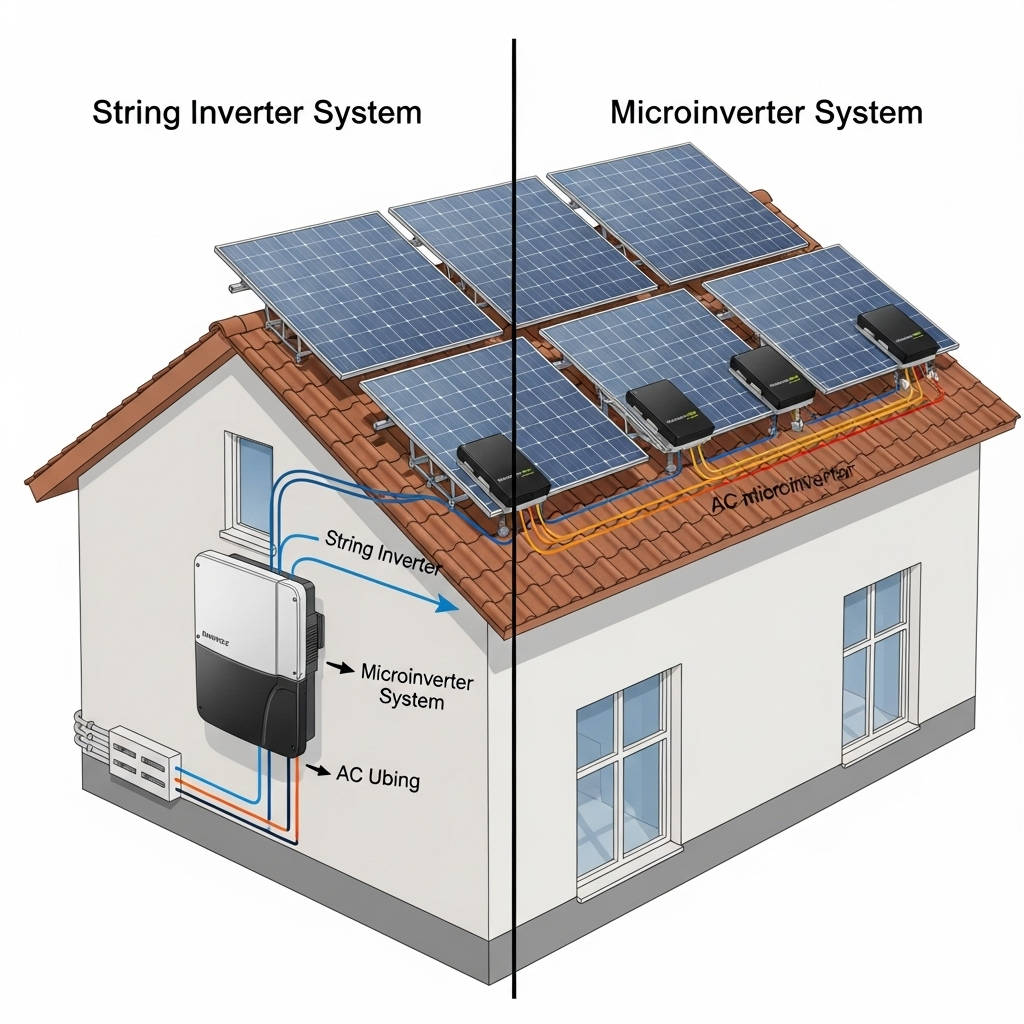

The primary advantage of a string inverter is its low upfront cost. However, its TCO can increase over time. Because all panels are wired in a series, the entire string's output is limited by the lowest-performing panel. Furthermore, a failure in the central inverter will take the entire solar array offline until it is repaired or replaced. This technology is best suited for large, unshaded roofs where all panels are on the same plane and receive uniform sunlight.

Microinverters: Maximizing Yield at the Module Level

Microinverters carry the highest initial CapEx, but they can deliver a lower TCO in many scenarios. By converting DC to AC power at each panel, they ensure that shading or a malfunction on one panel does not affect the rest of the system. This leads to maximum energy harvest and system uptime. With warranties that often match the 25-year life of the solar panels, they minimize replacement costs. This makes them ideal for complex roofs with multiple angles, orientations, or intermittent shading.

Power Optimizers: A Hybrid Approach

Power optimizers offer a middle ground. They pair DC optimizers at each panel with a central string inverter. This configuration provides the shade mitigation and panel-level monitoring benefits of MLPE while maintaining a slightly lower upfront cost than a full microinverter system. The main TCO consideration is the dual-component nature; while the optimizers have a long warranty, the central inverter will likely need replacement after 10-15 years, creating a future expense that must be factored into the lifecycle cost calculation.

Quantifying the Financial Impact: Key TCO Variables

Several specific factors have a significant, quantifiable impact on the long-term cost of an inverter system. Analyzing these variables is key to making an informed decision.

Inverter Replacement Schedule and Costs

The expected lifespan and warranty of an inverter are critical to its TCO. A shorter warranty means you will likely bear the full cost of replacement. Labor costs for replacement should also be considered, as replacing a single microinverter may be less labor-intensive than replacing a large, heavy string inverter.

| Inverter Type | Typical Warranty | Primary Replacement Component | Expected Replacement Cycle |

|---|---|---|---|

| String Inverter | 10-12 Years | Central Inverter Unit | Every 10-15 Years |

| Microinverter | 25 Years | Individual Microinverter Unit | As needed (per unit failure) |

| Power Optimizer System | Optimizers: 25 Years Inverter: 10-12 Years |

Central Inverter Unit | Inverter every 10-15 Years |

The Value of Granular Monitoring

The ability to monitor the performance of each individual solar panel is a powerful tool for reducing long-term O&M costs. MLPE systems provide this data, allowing system owners to pinpoint underperforming panels quickly. This precision reduces diagnostic time for technicians and ensures that issues are resolved before they significantly impact energy production. String-level monitoring can only indicate a problem within a group of panels, requiring more extensive on-site investigation.

System Uptime and Reliability

System uptime is a direct contributor to your return on investment. A string inverter represents a single point of failure; if it goes down, 100% of your energy production stops. In a microinverter system, the failure of a single unit only impacts the output of one panel, allowing the rest of the system to continue operating normally. This inherent redundancy in MLPE architecture leads to higher overall system availability and a more reliable energy yield over the long term.

Beyond the Numbers: Future-Proofing Your Investment

TCO is not just about historical costs; it's also about preparing for the future. Technology choices made today will affect your system's adaptability and value for decades to come.

Scalability and System Expansion

If you plan to expand your solar array in the future, MLPE systems offer a distinct advantage. Microinverters allow you to add one or more panels easily without concerns about matching the specifications of older panels. Expanding a string inverter system can be more complex and may even require a costly inverter replacement if the existing unit cannot handle the additional capacity.

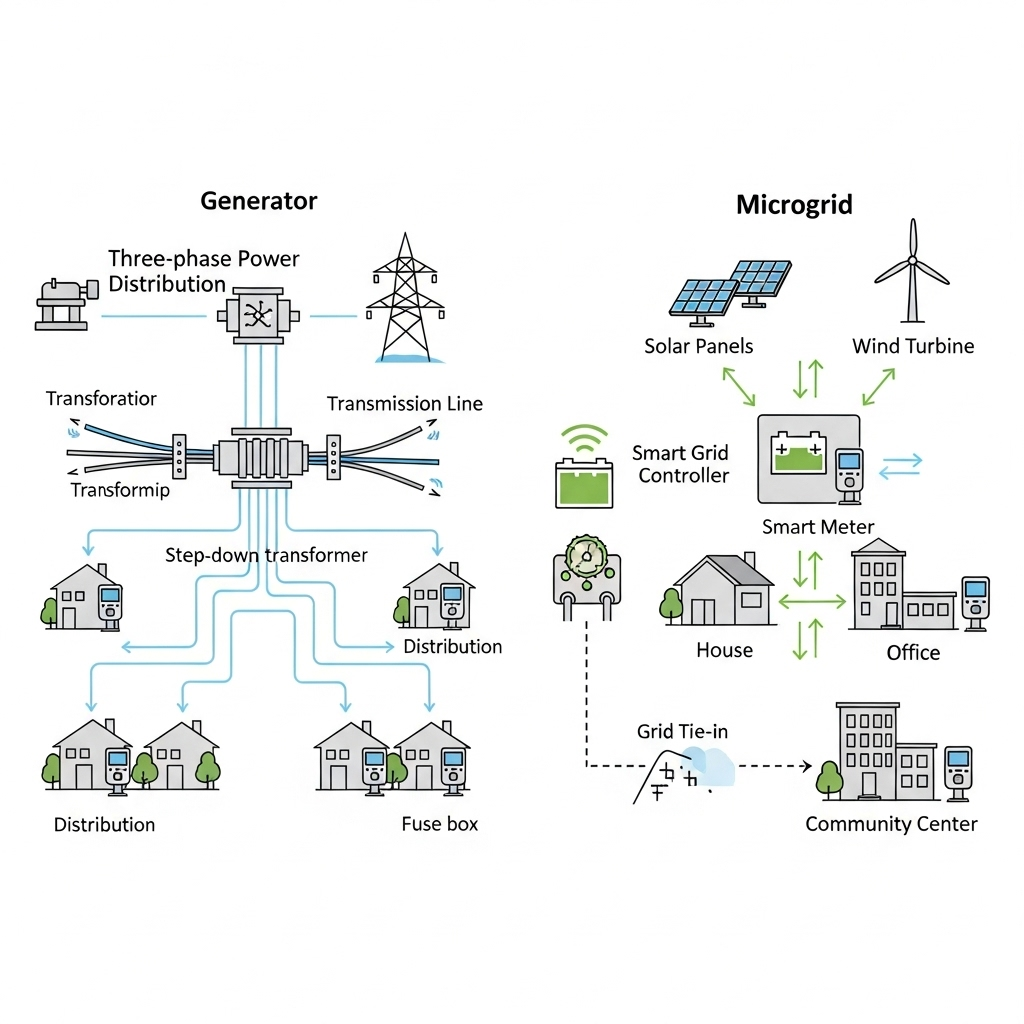

Integration with Energy Storage

As energy storage becomes more common, inverter compatibility is crucial. The choice between AC-coupled and DC-coupled battery systems is tied to your inverter topology. The efficiency and performance of a combined solar-plus-storage system are heavily influenced by this pairing. For a deeper analysis of how inverter choices affect battery performance, understanding the metrics in this ultimate reference on solar storage performance is crucial.

Evolving Safety and Grid Codes

Safety regulations, such as rapid shutdown requirements for firefighters, are now standard in many regions. MLPE technologies typically have this capability integrated at the module level. String systems often require additional components to achieve compliance, adding cost and complexity. Furthermore, as the Next Generation Wind and Solar Power report from the IEA highlights, modern grid codes increasingly require inverters to provide advanced grid support functions, making sophisticated inverter technology a more future-proof investment.

Making the Right Choice for Your Project

Ultimately, the lowest Total Cost of Ownership is not tied to a single technology but to the right technology for a specific application. A data-driven TCO analysis reveals that while string inverters are excellent for simple, unshaded installations, the superior energy yield and reliability of microinverters and power optimizers often provide greater long-term value for more complex projects. By looking beyond the initial price and modeling the full lifecycle costs, you can select an inverter solution that maximizes both performance and financial returns for years to come.

Frequently Asked Questions

Is the higher upfront cost of microinverters ever worth it?

Yes, especially for roofs with shading or multiple orientations. The increased energy yield over 25 years can often offset the higher initial investment, resulting in a lower TCO.

How often do solar inverters need to be replaced?

String inverters typically have a lifespan of 10-15 years. Microinverters and power optimizers are designed to last the life of the solar panels, often coming with 25-year warranties. However, the central inverter in an optimizer system will still need replacement.

Does TCO account for inverter efficiency?

Absolutely. Inverter efficiency is a key component of the 'Performance and Energy Yield' factor within the TCO calculation. Higher efficiency translates directly to more energy harvested and a better return on investment over the system's life.

Can I mix different inverter types in one system?

Generally, this is not recommended. Systems are designed to work with a single, consistent inverter topology. Mixing types can lead to compatibility issues, void warranties, and complicate monitoring and maintenance.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.