Generating solar energy is about more than just peak efficiency ratings. The true measure of a solar system’s value lies in the total kilowatt-hours (kWh) it delivers over its lifetime. This consistent energy output directly impacts your savings and progress toward energy independence. While external factors like sun exposure and installation quality play a role, the fundamental design choices within the solar panel itself significantly influence how much electricity you harvest. This article explores key panel design features that contribute to greater real-world energy production.

Cell Technology and Architecture: The Foundation of Output

The type of photovoltaic cell and its architectural layout are primary drivers of a panel’s ability to convert sunlight into usable electricity.

Advancing Electron Capture: PERC, TOPCon, and HJT

Innovations in cell technology aim to capture more light and reduce energy losses. PERC (Passivated Emitter Rear Cell) adds a passivation layer to the cell’s rear that reflects unused light back into the absorber, improving conversion. TOPCon (Tunnel Oxide Passivated Contact) further enhances charge transport and reduces recombination, while Heterojunction Technology (HJT) combines amorphous and crystalline silicon to maintain strong performance at elevated temperatures. In today’s market, module efficiencies commonly cluster in the low-20% range, with TOPCon and HJT tending to edge above PERC; always confirm with product datasheets and third-party tests.

Bifacial Design: Capturing Light from Both Sides

Bifacial modules harvest light from the front and rear surfaces. Gains depend on ground reflectivity (albedo), height, tilt, and tracking. Field studies show single-digit gains are common at moderate albedo, and in optimized single-axis tracked layouts, energy yield can be substantially higher compared with fixed-tilt monofacial arrays (reported up to ~35%). See technical guidance from PV programmes for design specifics: IEA PVPS Task 13 bifacial & tracking and a meta-analysis in Joule (2020).

Module Construction: Enhancing Durability and Performance

Beyond the cells themselves, the module’s physical build affects long-term yield and resilience.

Half-Cut Cells and Multi-Busbar (MBB) Technology

Cutting standard cells into halves lowers current per cell, which reduces resistive (I²R) losses and improves shade tolerance at the string level. Laboratory and field analyses find measurable power gains from half-cell layouts, especially at higher irradiance; see technical reviews such as PV-Tech: half-cell modules. MBB increases the number of current-collecting busbars, shortening carrier paths and reducing series resistance; see Fraunhofer CSP & SCHMID on MBB.

Encapsulation and Glass Technology

Encapsulant choice influences moisture ingress, ion migration, and long-term stability. Polyolefin elastomers (POE) generally exhibit higher volume resistivity than EVA in studies, which is associated with improved resistance to potential-induced degradation (PID); see Spinella et al., 2022 and Task-13 reliability notes (IEA PVPS 2025). Cover glass matters too: low-iron glass with durable anti-reflective coatings can raise transmittance by several percent; see materials research like Zäll 2023.

Temperature Management: Maintaining Peak Performance

Solar modules are rated at 25 °C (77 °F). Above that, output declines according to the temperature coefficient of power. NREL references indicate a typical coefficient around −0.5%/°C for older crystalline silicon assumptions, with newer modules often performing better; see NREL PVWatts v5 and explanatory notes (NREL 2016). Practically, designs that allow airflow (standoff mounting, ventilated racking) and thermally sensible backsheets/frames help moderate operating temperature and preserve kWh output.

Quality Control and Degradation Mitigation: Long-Term Yield

Consistent yield over decades depends on robust quality control and mitigating known degradation modes. PID risks are context-specific (system voltage, humidity, temperature, materials), and are mitigated through higher-resistivity encapsulants, glass choices, and grounding practices; see IEA PVPS Task 13. Selecting modules with third-party certifications and clear power warranties supports predictable lifetime energy.

| Technology | Typical Module Efficiency (Indicative) | Key Design Advantage | Benefit for kWh Yield |

|---|---|---|---|

| PERC | ~20–22% | Rear-side passivation | Improved absorption, reduced recombination |

| TOPCon | ~21–23.5% | Tunnel-oxide passivated contacts | Higher efficiency, strong low-light behavior |

| HJT | ~21.5–24% | Amorphous + crystalline silicon stack | Efficiency headroom; stable at higher temps |

| Bifacial (design) | Design-dependent gain | Dual-side capture | Extra rear-side yield; larger with tracking |

Note: Ranges are indicative and vary by product and test method; verify with manufacturer datasheets and accredited tests.

Maximizing Your Energy Harvest

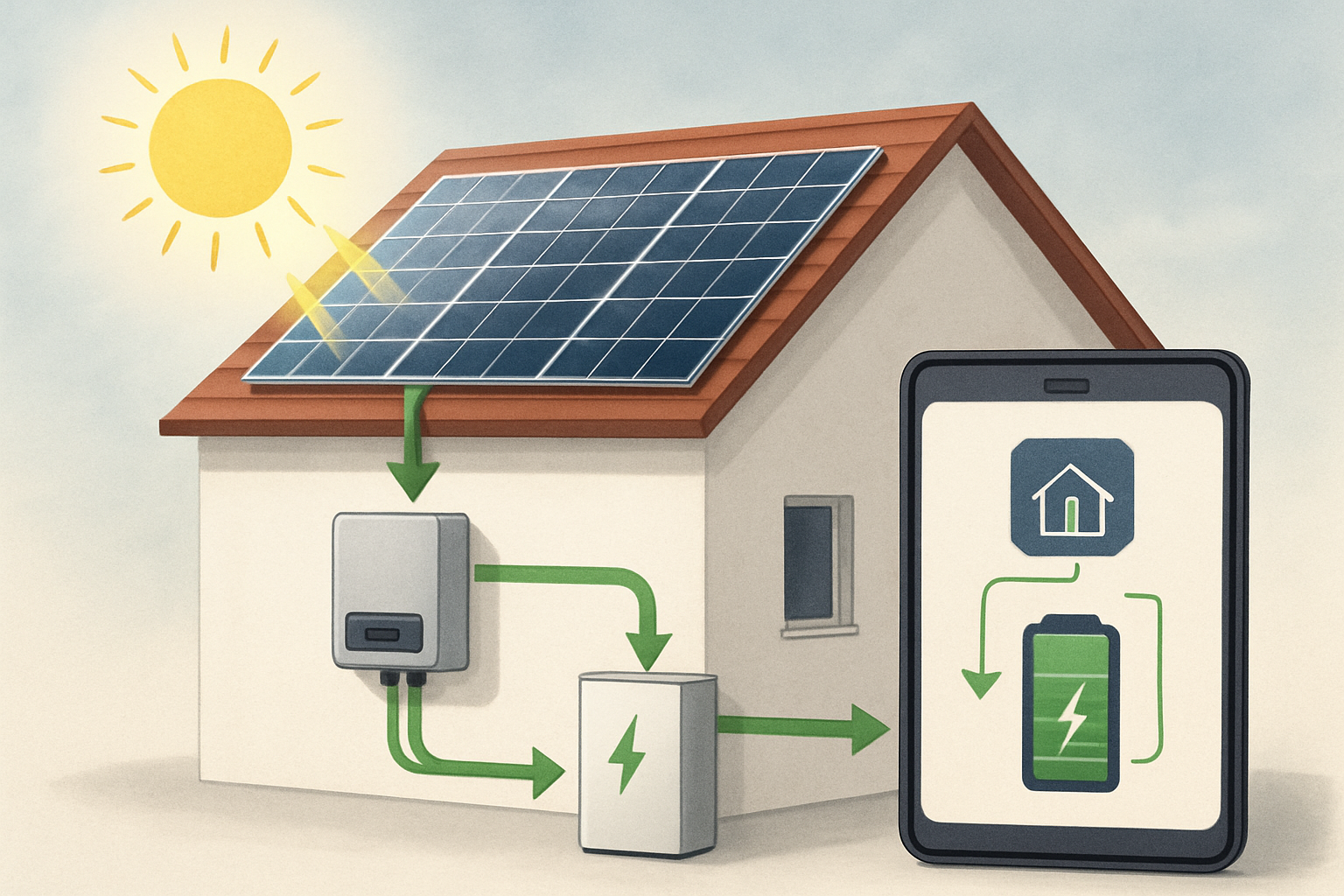

Solar PV’s rapid scale-up reinforces why design for yield matters. In 2023, global solar generation rose by a record ~320 TWh (+25%) to about 5.4% of world electricity, according to the International Energy Agency (IEA). In 2024, solar added roughly another ~480 TWh and reached ~7% of global electricity (IEA Electricity 2025). Choosing modules with yield-oriented designs—and integrating them with efficient inverters and appropriately sized storage—turns those technology gains into everyday kWh on your meter.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.