Idling burns fuel, adds noise, and still may not keep batteries happy. Solar power paired with a marine energy storage system (ESS) can carry autopilot power and boat refrigeration for hours. You gain quiet, predictable energy and save engine hours.

Know the Loads That Drive Idling

Two steady consumers define daily energy on many sailboats and small cruisers: the autopilot and the fridge. Their draw swings with sea state and cabin temperature. Size solar and ESS to cover the worst day you expect, not the best day you wish for.

Autopilot power in real seas

Autopilot draw depends on hull, rudder, balance, and waves. Typical 12 V numbers for 28–38 ft boats:

- Flat water: 1–3 A (12–36 W)

- Moderate chop: 4–8 A (48–96 W)

- Heavy seas or poor balance: 9–15 A (108–180 W)

Trim, reef early, and align the sail plan to reduce steering work. Small changes here can cut autopilot power by 30–50%.

Boat refrigeration that stays cold

Most 12 V compressor fridges pull 3–6 A while running. Duty cycle runs 25–50% depending on insulation, ambient heat, and door openings. Daily energy is often 30–70 Ah (360–840 Wh). Improve seals, add shade, and pre-chill to lower duty cycle.

Daily energy picture

| Load | Calm Day | Mixed Seas | Notes |

|---|---|---|---|

| Autopilot | 2 A avg × 8 h = 192 Wh | 5 A avg × 10 h = 600 Wh | Power only while underway |

| Fridge | 4 A × 30% × 24 h = 346 Wh | 5 A × 40% × 24 h = 576 Wh | Improve insulation to lower duty |

| Total (typical day) | ~540 Wh | ~1,180 Wh | Excludes lights/instruments |

How Solar Covers Autopilot and Fridge Loads

Marine PV is modular and fits arches, davits, or hard tops. That flexibility suits small craft needs. As Energy.gov notes, PV scales down well and installs close to loads.

Yield math you can trust

Use conservative sun hours at sea and a derate for heat, flat mounting, and shading. A simple rule: daily Wh ≈ array W × peak sun hours × 0.55–0.65. For many mid‑latitude boats, plan for 3–5 sun hours afloat and a 0.6 derate.

| Array | 3 h PSH, 0.6 | 4 h PSH, 0.6 | 5 h PSH, 0.6 |

|---|---|---|---|

| 300 W | 540 Wh | 720 Wh | 900 Wh |

| 400 W | 720 Wh | 960 Wh | 1,200 Wh |

| 600 W | 1,080 Wh | 1,440 Wh | 1,800 Wh |

Match this to your daily load table. A 400 W array can often carry a fridge and light autopilot use on a mixed day. A 600 W array gives more headroom for clouds, motoring instruments, and overnight recovery.

Orientation and shading tactics

The IEA highlights that non‑equator orientation and smart system design can raise usable output in real settings by spreading generation over time and reducing clipping. See Next‑Generation Wind and Solar Power. On boats, you can mirror that effect by splitting panels port and starboard and wiring in parallel strings. This reduces partial shading losses from rigging and antennas.

Why MPPT and cabling matter

- Use an MPPT controller sized for array Isc × 1.25 and future expansion.

- Target less than 3% voltage drop from panels to MPPT and MPPT to battery. Upsize to 8 AWG or 6 AWG on longer runs.

- Keep the MPPT and high‑current cables away from compasses and autopilot sensors. Add ferrites to reduce EMI.

ESS Marine: LiFePO4 That Handles Daily Cycling

A marine ESS based on LiFePO4 offers high cycle life, fast charging, and stable voltage for autopilot power and boat refrigeration. Batteries, BMS, protection, and monitoring form a single system.

Right‑size usable energy, not nameplate

Plan around usable capacity. Many LiFePO4 banks deliver 80–90% depth of discharge. 12 V 200 Ah ≈ 2.4 kWh usable. Map runtime to your loads:

| Bank (12 V) | Usable kWh | Hours at 100 W avg | Hours at 200 W avg |

|---|---|---|---|

| 150 Ah | 1.8 | ~18 h | ~9 h |

| 200 Ah | 2.4 | ~24 h | ~12 h |

| 300 Ah | 3.6 | ~36 h | ~18 h |

For a day with ~1.1 kWh of loads, a 200 Ah bank gives comfortable margin overnight.

Charge and protect the bank

- MPPT bulk/absorb voltage: 14.0–14.4 V (follow the battery spec). Float can be low (13.4–13.6 V) or disabled if the BMS supports it.

- Fuse each source and load. Add a main disconnect. Size fuses to cable ampacity, not just device ratings.

- Use a DC‑DC charger or an alternator regulator compatible with LiFePO4 to avoid overvoltage.

Storage boosts self‑consumption and trims peaks. IRENA’s Innovation Outlook on Smart Charging reported self‑consumption rising from 49% to 62–87% and peak cuts of 27–67% with smart control and batteries. Boat charge controllers and BMS can apply similar logic: push solar to the bank at midday, schedule heavy draws then, and glide through the evening on stored energy.

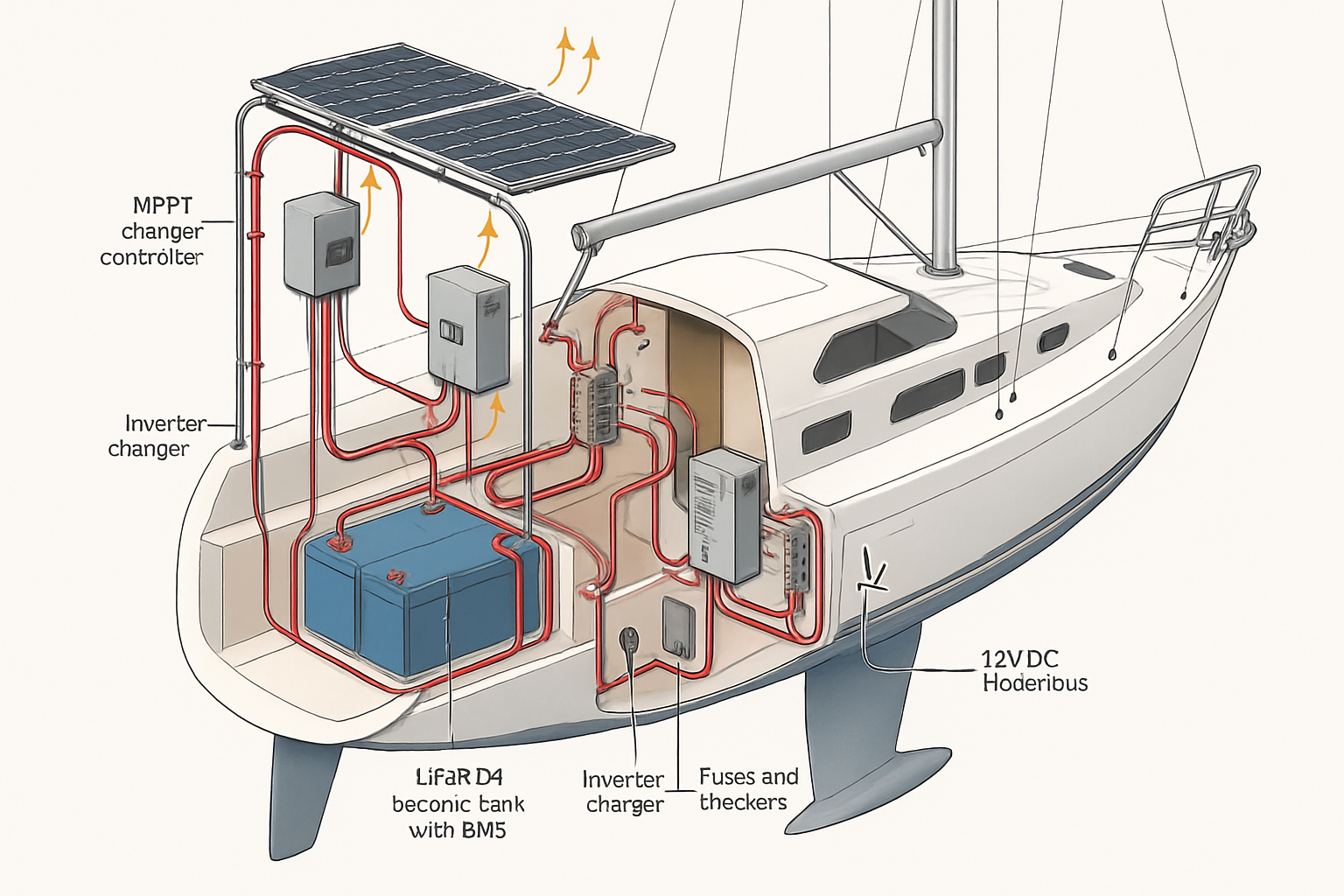

A simple, robust architecture

Panels → MPPT → LiFePO4 bank → DC bus to autopilot and fridge. Add an alternator input via DC‑DC as backup. Keep wiring short and dry. Protect sensors from magnetic fields. This layout reduces losses and prioritizes quiet solar first.

Stop Idling: Fuel, Power, and Cost Reality

Small marine diesels often burn 0.5–1.0 L/h at idle while delivering modest net charging once belt losses and low RPM limits kick in. Output can sit near 200–600 W DC sustained on typical setups. Fuel costs vary by port, as EIA market data shows over time. Solar has no fuel cost and minimal maintenance needs.

| Source | Typical Output | Operating Cost | Noise/Heat |

|---|---|---|---|

| Engine idling for charge | 200–600 W DC | Fuel 0.5–1.0 L/h + wear | High noise, hot cabin |

| 400 W marine solar | 0.7–1.2 kWh/day (at 3–5 PSH, 0.6 derate) | Zero fuel | Silent, cool |

| 600 W marine solar | 1.1–1.8 kWh/day | Zero fuel | Silent, cool |

The IEA documents steady PV cost declines and the value of pairing storage to match demand and shave peaks. See the full report for system integration insights. On a boat, that same pairing reduces engine starts and smooths state of charge swings.

Control Tactics That Stretch Solar and ESS

Run‑time strategy

- Prioritize fridge cooling midday. Lower the setpoint slightly in the afternoon to coast through evening.

- Use windvane sailing in steady conditions. Reserve autopilot for variable winds and close quarters.

- Hand steer during battery top‑off if clouds stack and you must preserve charge for the night.

Hardware tweaks that pay back

- Add insulation or a thermal curtain inside the fridge box. Even 10–15% duty drop is a daily win.

- Balance the boat. Reef earlier. Reduce autopilot hunting by tuning gain and counter‑rudder.

- Split arrays across two MPPT trackers if layout forces different orientations. This cuts mismatch loss, a tactic aligned with IEA’s emphasis on system‑friendly distributed PV.

Monitoring and alarms

Use a shunt‑based monitor to watch Ah and Wh, not just voltage. Set alarms at 20% state of charge for LiFePO4. Log daily solar yield. These small habits avoid guesswork and idle‑charging “just in case.”

Two Quick Scenarios

Underway day sail

35 ft sloop, mixed seas: Autopilot ~80 W avg for 6 h = 480 Wh. Fridge ~500 Wh. Total ~980 Wh. A 600 W array in 4 PSH with 0.6 derate yields ~1,440 Wh. You finish the sail with surplus to recharge the bank and anchor quietly.

At anchor overnight

Autopilot off. Fridge 400–600 Wh. Instruments and lights ~150 Wh. A 200 Ah LiFePO4 bank covers the night easily. Morning sun restores charge without starting the engine.

Installation Checklist

- Array: 400–600 W target if you rely on autopilot and fridge daily. Mount with airflow to limit heat losses.

- ESS marine: 12 V 200–300 Ah LiFePO4 with marine BMS and proper fusing.

- Charge: MPPT matched to array Voc/Isc, LiFePO4 charge profile, and remote temp sensor for current limiting if needed.

- Protection: ANL/MRBF fuses, main disconnect, tinned cable, drip loops, strain relief, clearly labeled bus bars.

- EMI: Separate power and nav wiring, twist pairs, ferrite cores near MPPT and alternator lines.

Policy and research bodies keep pointing to the same direction: distributed PV with storage raises self‑consumption and reliability. See IEA and IRENA. The same principles help a small craft sail more and idle less.

What this gives you

- Fewer engine hours and fuel stops

- Cold food and steady autopilot power without noise

- Predictable daily energy, logged and managed

Set the system up once. Then let the sun handle the routine.

Safety and Disclaimer

Work to marine electrical standards. If unsure, hire a qualified marine electrician. Fuse every positive conductor near the source. This material is for general information and does not constitute engineering, legal, or investment advice.

FAQ

How much solar power do I need for autopilot power and boat refrigeration?

Most boats that run both daily do well with 400–600 W. Use the tables above: estimate daily Wh for your autopilot and fridge, then size for 3–5 sun hours with a 0.6 derate.

Can Solar ESS for boat autopilot keep up on cloudy days?

Partially. The ESS covers gaps. Plan for 1–2 days of autonomy in the battery. Keep an alternator or shore charger as a backup for extended overcast.

Do I need a special MPPT profile for LiFePO4?

Yes. Set bulk/absorb ~14.0–14.4 V and a short absorb time. Float can be low or disabled per the battery spec. Always follow your battery manual.

Will MPPT or solar wiring interfere with my compass or autopilot?

It can if routed poorly. Separate high‑current cables from compasses and heading sensors. Twist pairs and add ferrites. Keep the MPPT away from nav gear.

Is solar cheaper than idling the engine?

Fuel costs and alternator output vary. Solar has no fuel cost and low upkeep. IEA and Energy.gov report sustained PV cost declines, which improves lifetime value onboard.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.