Portable ESS packs are safer today because detection and control matured. The right Fire Detection Tools and BMS Tools can spot early warning signals, act in seconds, and avoid false trips that drain uptime. This review ranks practical options for lithium handling in compact systems, with measured trade-offs in latency, power draw, and reliability. It also ties choices to energy‑sector insights from the Solar Energy Perspectives, power system flexibility research, and energy transition outlooks.

What “fire detection” means in a portable ESS

Fire safety in ESS starts long before flames. The aim is to detect precursors and act early: heat rise at a cell tab, off‑gas in the enclosure, smoke in the exhaust path, pressure spikes, and abnormal acoustics. A layered approach reduces blind spots and false alarms while keeping quiescent current small for off‑grid duty.

Heat sensing on cells and hot spots

Use multiple NTC thermistors or digital temperature ICs at tabs and mid‑cell. They react in under a second and draw very little power. Thermal fuses add fail‑safe cutout. An IR thermopile can watch a cluster without contact, useful under compression plates. Heat sensors confirm a trend, but they detect later than off‑gas tools in some failure modes.

Off‑gas, HF/CO, and VOC sensing

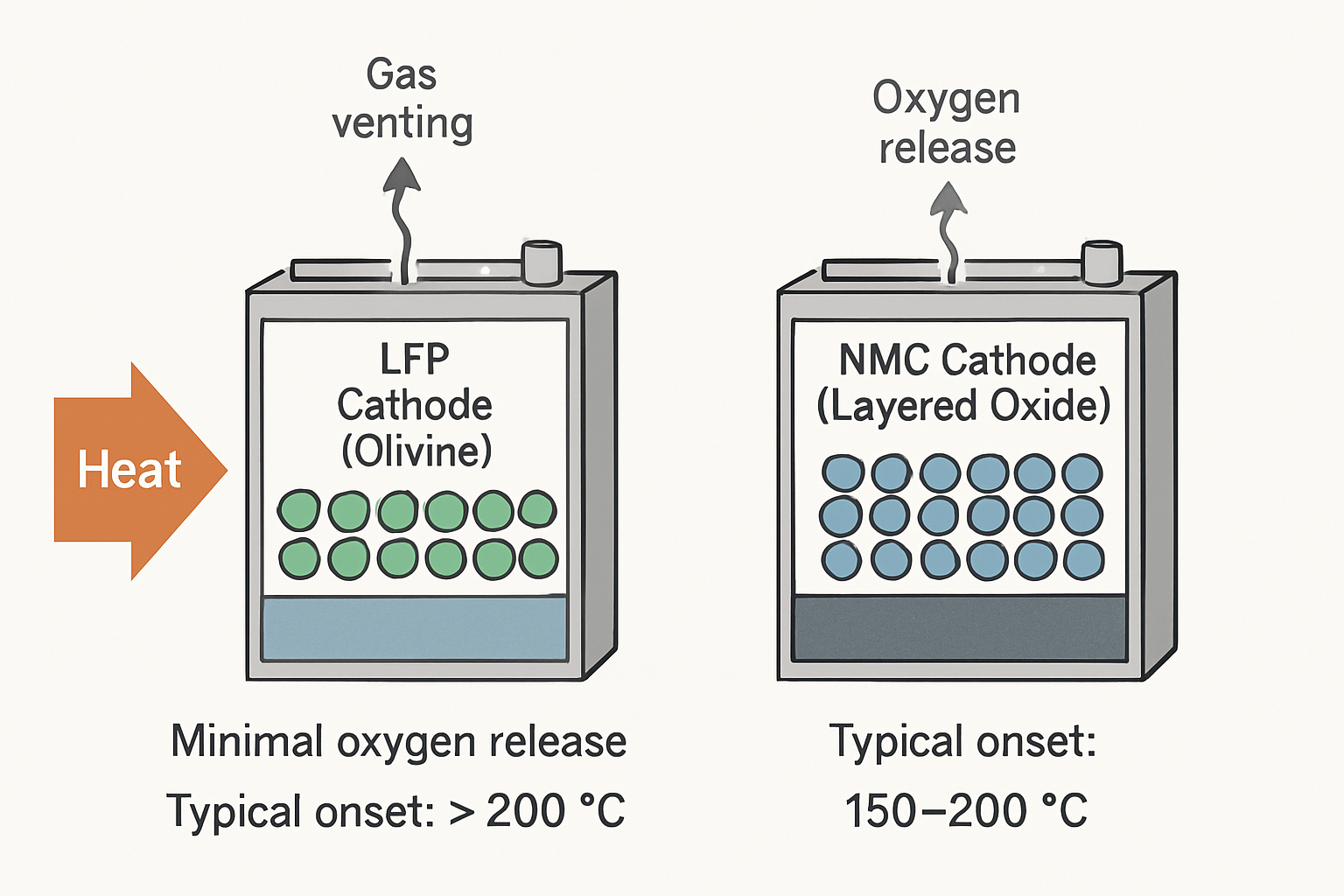

Early venting can precede thermal runaway. Electrolyte vapors and byproducts (HF, CO, VOCs, H2) appear first near vents and seams. Electrochemical sensors for HF or CO have low power draw and good selectivity, while metal‑oxide (MOX) VOC sensors detect a broader signature at the cost of higher power and warm‑up time. Off‑gas sensing often buys tens of seconds of lead time compared with temperature alone.

Smoke, pressure, and acoustic cues

Photoelectric smoke sensors capture smoldering and flaming phases in air passages. A small pressure transducer in a semi‑sealed enclosure flags rapid gas build‑up quickly. Acoustic methods can pick arcing or venting events, but they need careful filtering and are less common in compact kits.

Best‑fit tool categories and trade‑offs

The table below summarizes typical ranges for portable ESS integration. Values are representative, based on vendor datasheets and field use. Pick for your enclosure volume, duty cycle, and service environment.

| Tool category | Typical latency | Quiescent/active power | False alarm risk | Integration notes | Best use |

|---|---|---|---|---|---|

| NTC thermistor on cells | 0.2–1 s | <5 mW (depends on bias) | Low | Analog read; place at tabs and mid‑cell | Baseline heat trend and OTP cutback |

| Digital temp sensor (I2C/SPI) | 0.5–2 s | 1–3 mW | Low | Alert pins help low‑power wake | Precise logging and derating |

| IR thermopile (non‑contact) | 0.1–0.5 s | 10–20 mW | Medium (line‑of‑sight) | Avoid reflective views; add emissivity mask | Cluster scan under compression plate |

| Electrochemical HF sensor | 10–60 s to threshold | <1 mW (µA‑level) | Low–medium (calibration drift) | Needs periodic bump test; no heater | Early off‑gas warning in sealed packs |

| Electrochemical CO sensor | 10–40 s | <1 mW | Medium (combustion sources) | Filter for external CO sources | Smoldering/venting confirmation |

| MOX VOC sensor | 1–2 s after 5–60 s warm‑up | 60–150 mW (heater) | Medium (cleaners/solvents) | Duty‑cycle heater to save energy | Broad off‑gas pre‑alarm |

| Photoelectric smoke | 30–120 s | 10–50 mW | Medium (dust, insects) | Use bug mesh; auto‑clean pulse | Air‑path confirmation |

| Pressure transducer | <0.1 s | 5–20 mW | Low–medium (altitude swings) | Add slow compensation for ambient | Rapid vent spike detection |

Note: The US National Fire Protection Association rates hydrogen flammability at 4 (highest). That underscores the value of leak and off‑gas detection in enclosed spaces. While portable ESS do not store hydrogen, H2 can appear in some failure off‑gas mixes, so gas handling discipline matters.

What a “good” BMS toolset looks like

Effective BMS Tools do three jobs: measure accurately, decide quickly, and act safely. In portable ESS, keep it simple, power‑frugal, and visible to the user.

Core firmware and protections

- Cell supervision: 1–2 mV resolution with 1–10 Hz logging. Catch drift, not just trips.

- Balancing: passive for compact packs; thermal‑aware cutback to keep hotspots down.

- Protections: OVP/UVP, OCD/SCD, OTP/UTP, charge derating by temperature and SoC.

- Pre‑charge and contactor logic: current‑based verification with 100–300 ms timeouts.

- Data handling: ring buffer of events, last 100–1000 faults with timestamps.

Interfaces and field tools

- Comms: CAN or UART for inverters; BLE for user app. Broadcast key alarms within 100 ms.

- PC/mobile utility: live charts, CSV export, signed config profiles, and read‑only mode for end users.

- Bench aids: cell simulators, programmable PSU/load, and an isolated CAN adapter for safe fault injection.

Quiescent current matters in storage. Keep the BMS asleep under 200–500 µA, and wake to sample sensors in bursts. IEA’s Solar Energy Perspectives notes storage investments need daily use to pay off; low idle losses and robust monitoring extend service life and reduce safety incidents linked to degradation.

Why latency and robustness beat raw sensitivity

Short response time plus credible context beats a single ultra‑sensitive sensor. The blend below yields fast action and few false alarms in portable enclosures:

- Primary sensors: NTCs on cells, a pressure transducer in the main cavity.

- Early off‑gas: electrochemical HF or CO near the cell vent path.

- Confirmation: a small photoelectric smoke head in the exhaust path or fan outlet.

IEA flexibility research shows that fast ramps and transient operation stress hardware. Portable ESS face similar stress during inrush, rapid load steps, or regen. That argues for BMS limits on current slew rate and for thermal rate‑of‑rise alerts, not just absolute limits.

Practical integration patterns

Sensor placement that actually works

- Put off‑gas sensors where air first flows from the cell bay. Avoid intake leaks that dilute readings.

- Use two NTCs per 4–6 cells, one at a tab, one mid‑cell. Add a sensor on the MOSFET or relay board.

- Pressure sensor on the largest cavity; compensate for altitude with a slow filter.

- Shield MOX sensors from solvent exposure during service. Add a warm‑up timer on wake.

Decision logic you can defend

- Voting: trip only if two different modalities agree (e.g., pressure spike + VOC rise).

- Rate‑of‑change: alert if dT/dt > 2–5 °C/min while pack current is low; that suggests internal heat.

- Context: ignore smoke if fan is off and pressure is steady; sample again in 2 s.

- Actions: stop charge, limit discharge, open contactor if pressure continues to climb, then notify the user.

IRENA’s Malaysia Energy Transition Outlook quantifies demand‑side measures that cut balancing needs by about 5%. In small ESS fleets, that kind of smart control only works if devices stay safe under dynamic profiles. Sensor fusion and staged actions keep safety margins while enabling flexibility.

Evaluation checklist and test cases

Here’s a concise plan to verify Fire Safety ESS features without exotic labs:

- Heat ramp: apply a controlled 2–5 °C/min rise at a cell tab; confirm dT/dt alarm in 30–60 s.

- Off‑gas proxy: a tiny droplet of ethyl acetate near the vent path; confirm VOC pre‑alarm without tripping final shutdown. Ventilate well.

- Pressure step: inject 10–30 mbar with a syringe into a test port; confirm sub‑100 ms detection.

- Fan smoke: safe smoke tester at the outlet; confirm confirmation alarm, not the first‑stage trigger.

- Current slew: command a 0–1C load step; verify BMS limits di/dt and logs the event.

Keep calibration logs. Electrochemical cells drift over months; MOX sensors drift with exposure. Set maintenance reminders in firmware. For user safety prompts, keep messages short and actionable: “Venting detected. Move unit outdoors. Do not charge. Contact service.”

Why this matters beyond a single device

Field fleets run in hot sheds, vans, and cabins. DOE resources stress reliability and safe integration across solar and storage. Robust detection and a capable BMS keep uptime high and reduce service calls. Across many units, fewer thermal events mean less downtime during peak solar hours, better customer trust, and cleaner data for continuous improvement.

Recommended baseline for 2025 portable ESS

- Sensors: 2× NTC per module, 1× HF or CO sensor, 1× pressure transducer, 1× photoelectric smoke head.

- Latency: sub‑100 ms detection for pressure spikes, sub‑1 s for heat rise, sub‑60 s for off‑gas.

- BMS: 1–10 Hz logging, signed configs, di/dt limiting, staged responses, and user notifications.

- Power: total safety overhead < 250 mW average with duty‑cycled MOX; sleep current < 500 µA.

These numbers are practical for compact packs and align with wider energy‑system needs. IEA notes storage must operate daily to deliver value, and that pushes for durable, low‑loss safety layers. The IEA flexibility annex also highlights wear from transients, supporting derating and staged shut‑downs inside the BMS.

Final take

For portable ESS, the best fire detection stack is simple and layered: temperature + pressure for speed, off‑gas for early warning, smoke for confirmation. Pair it with a BMS that logs at human‑readable rates, limits current slew, and communicates clearly to users. You get fewer false trips, faster safe actions, and better lithium handling in everyday use.

Safety note

Work on lithium systems involves risk. Procedures here are for trained personnel with proper PPE and ventilation. This content is not legal advice.

References

- International Energy Agency — Solar Energy Perspectives. Storage roles, economics, and daily use context.

- International Energy Agency — Status of Power System Transformation 2018: Technical Annexes. Hardware stress from flexible operation.

- International Renewable Energy Agency — Malaysia Energy Transition Outlook (2023). Demand‑side measures and system planning.

- U.S. Department of Energy — Solar Energy. Reliability and safety resources for solar‑storage integration.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.