Outdoor lithium packs face two repeat offenders: water ingress and uncontrolled heat. Both raise the chance of shorts, corrosion, and gas release that can ignite. Battery Fire Prevention needs physical controls in the enclosure and smart logic in the BMS. This piece shares practical, field-tested methods to harden enclosures and program Smart BMS tactics for Lithium Battery Safety and Fire Mitigation Lithium without overcomplicating maintenance.

Why enclosure + BMS synergy reduces fire risk

Storage is scaling fast, and more units sit outside. Peaking duty grows, with many projects adding four to eight hour durations to shift solar output into the evening. This trend appears in the Southeast Asia Energy Outlook 2024, which highlights storage as secure capacity during peak hours. More outdoor packs raise the bar for moisture and heat control. Permitting points to fire safety and siting rules as a project constraint, noted in Renewable Power Generation Costs in 2024 from IRENA. Flexible assets like batteries already support system stability, stated in The Power of Transformation by IEA. Safer hardware and smarter controls keep that flexibility reliable at the edge of the grid.

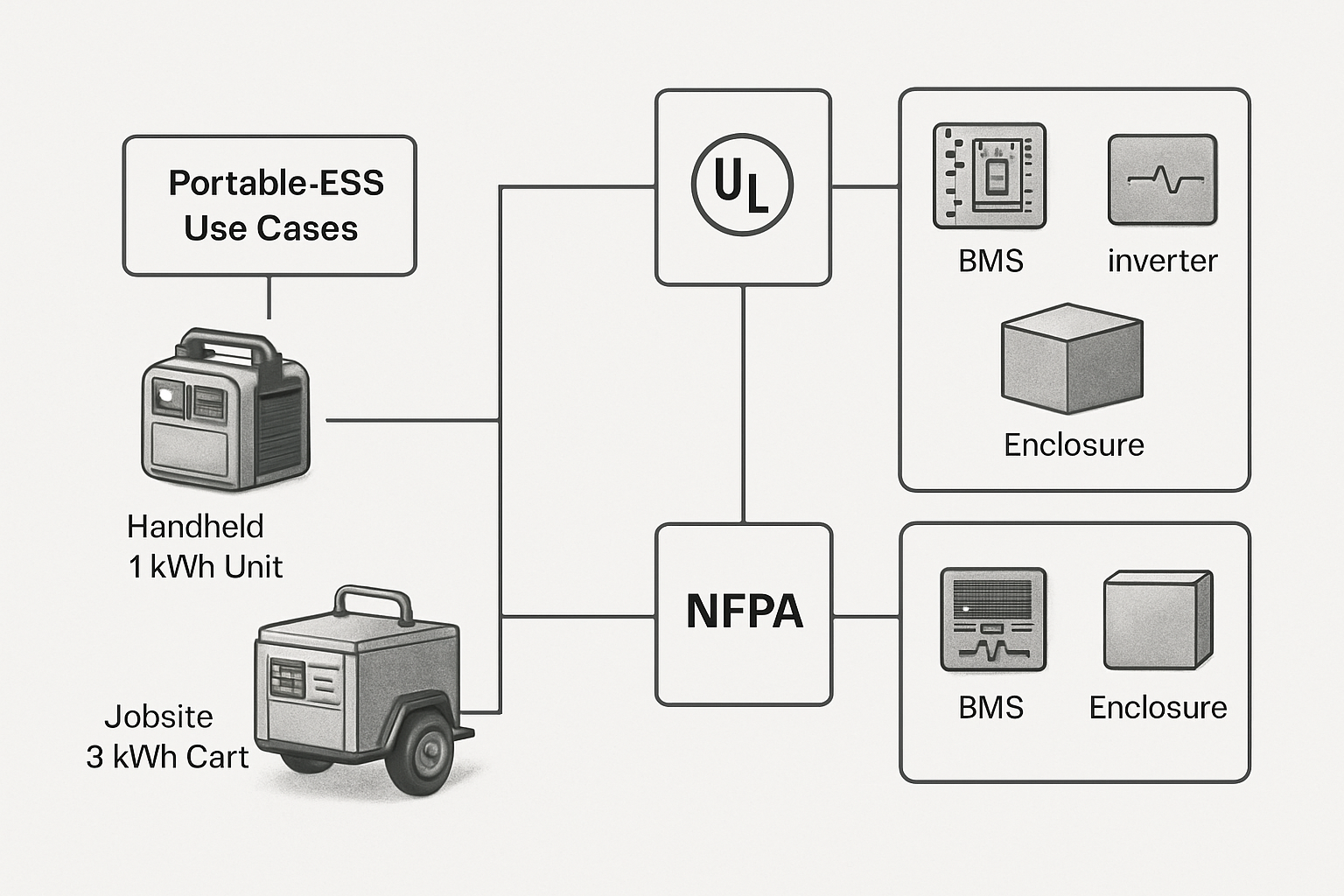

Weatherproof enclosures engineered for fire mitigation

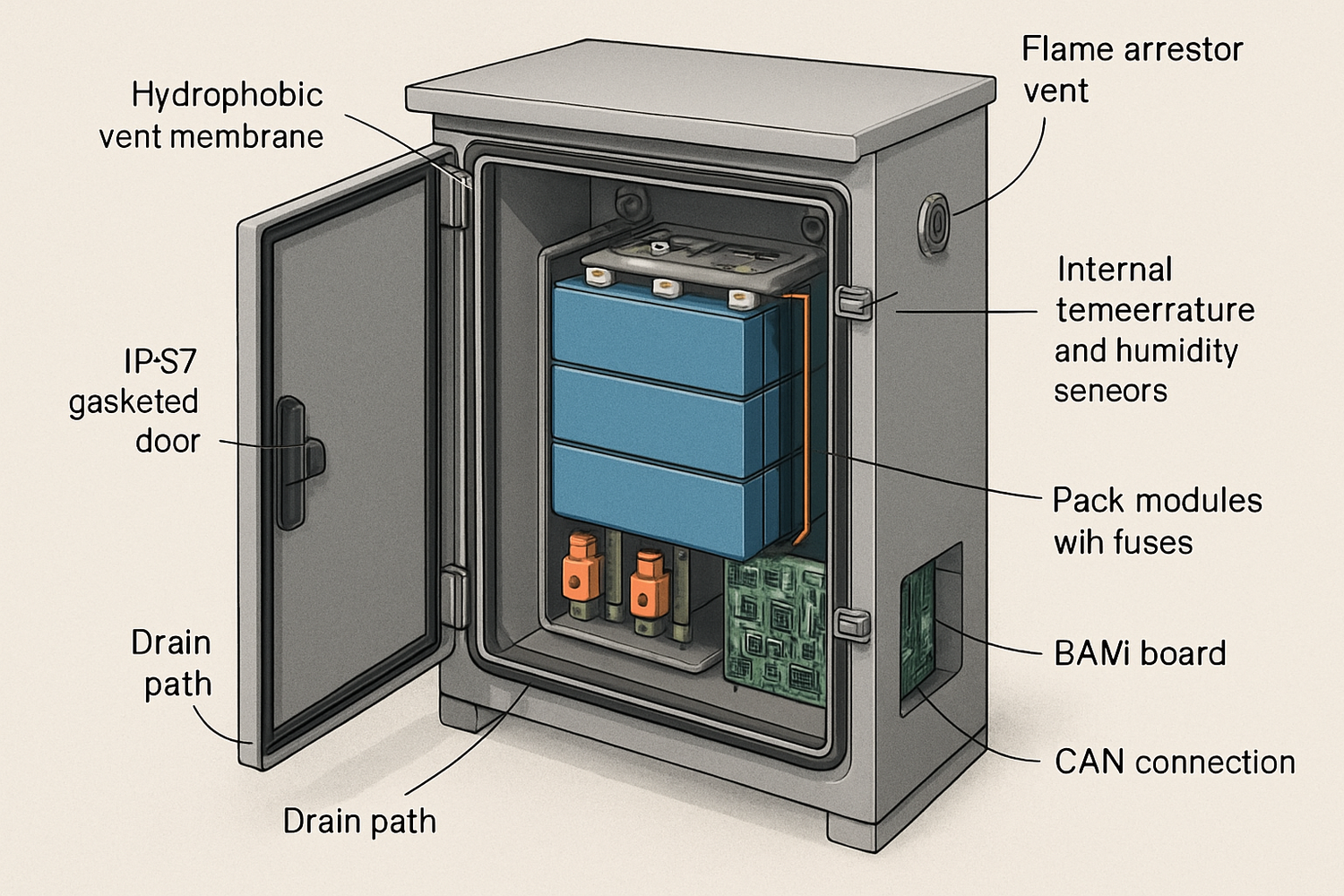

Ingress protection, materials, and cable entries

Moisture inside a pack is a slow fuse. Pick an IP rating that matches rain, wash-down, and flood risk. Seal all entries with rated glands and use UV-stable gaskets. Choose flame retardant interior plastics (UL 94 V-0 class) and non-dripping insulation. Place high-energy conductors along insulated raceways with clear labeling.

- Doors and seams: Continuous EPDM or silicone gaskets with compression stops. Avoid sharp bends that crush seals.

- Cable glands: IP68/69K glands with anti-wick inserts. Add external drip loops to DC and PV leads.

- Drainage: One-way drains at the lowest point. Keep them shielded from splash and road spray.

- Fasteners: Stainless steel with anti-galvanic washers. Corrosion can become a hot spot under load.

| Use case | Suggested IP / NEMA | Key features | Fire mitigation angle |

|---|---|---|---|

| Light rain, sheltered patio | IP54 / NEMA 3R | Drip shields, gasketed door, screened vents | Keeps wind-driven rain off live parts; reduces corrosion |

| Heavy rain, hose spray | IP65–IP66 / NEMA 4 | Sealed seams, rated glands, no open vents | Blocks water jets that can track across busbars |

| Temporary immersion risk | IP67 / NEMA 6 | Immersion-rated seals, pressure-comp vents | Limits shorts during flash floods; vent equalizes pressure |

| Coastal salt fog | IP66–IP67 / NEMA 4X | Corrosion-resistant hardware, coated internals | Slows conductive paths from salts; preserves creepage |

Note: IP67 targets 30 minutes at 1 m immersion; verify the full assembly, not just parts.

Vent membranes, pressure relief, and gas handling

Even a sealed box breathes with daily temperature swings. Add a hydrophobic membrane vent to cut pressure cycling while blocking liquid water. Install a dedicated pressure relief with a flame arrestor for rare high-rate venting events. Separate the normal breather and the emergency relief. Avoid routing relief into occupied spaces.

- Place vents high for gas and low for drainage. Use baffles to avoid direct splash.

- Route emergency relief toward a safe standoff zone with no ignition sources.

- Label relief paths. First responders need a quick read of gas flow direction.

Condensation control and thermal moderation

Condensation triggers tracking, then carbonization, then arcs. Control humidity and surface temperatures inside the box.

- Humidity: Add desiccant packs with visible status cards. Replace on a service schedule.

- Heat: Use reflective finishes, exterior sun shields, and standoff brackets to promote airflow. Dark boxes run much hotter in direct sun.

- Night cool-down: Add a small duty-cycle heater or heat mat to stay a few degrees above dew point during cold nights after hot days.

Simple check: If ambient is 35°C at 85% RH (dew point near 31°C) and the pack cools to 29°C after sunset, expect condensation. Keep the interior at least 3–4°C above the dew point using low-power heating and control logic.

Smart BMS tactics that cut ignition risk

Staged limits that adapt to heat, voltage, and SoC

Smart BMS Tactics shine with staging. Instead of a single trip, use steps that shave risk earlier and avoid stress spikes.

- Temperature derating: Start reducing charge current well below the high-temp cutoff. Ramp down with a gentle slope.

- SoC windows: Narrow the top-end window on very hot days to reduce cell pressure and heat at the knee of the curve.

- Voltage alarms: Warn early on any cell drift. Open contactors only after current has been pulled to a safe low level.

Balancing without heat build-up

Passive balancing can create heat in a tight enclosure. Schedule balance activity at moderate SoC and temperature. If the pack is hot, pause balancing and let the enclosure cool. Treat long-duration float near the upper knee as an exception, not a daily habit.

Fuses, contactors, and arc risk reduction

- Precharge: Always precharge large input capacitors to limit inrush and prevent contactor welding.

- Segmentation: Use module-level fuses and busbar covers. A single damaged module should not feed a fire in another bay.

- Pyro-fuse or fast HV fuse: Keep a last-resort device with a known clearing curve.

- Ground fault detection: Trip on low-level leakage to stop slow, heating faults.

| Event | Detection source | Stage 1 action | Stage 2 action | Stage 3 action |

|---|---|---|---|---|

| Rapid temp rise in a module | Dual sensors + rate-of-rise | Cut charge to 0, limit discharge | Open contactor after current ramps down | Trigger relief alarm; notify site |

| Moisture ingress detected | RH sensor + leak probe | Reduce power, pause balancing | Isolate affected string | Lockout and service ticket |

| Off-gas or smoke | Electrochemical sensor or photo | Zero charge, force fan/vent path | Open both poles | Trigger external alarm and signage |

| Ground fault current | High-Z monitor | Alert and derate | Open charge side | Open both sides |

Pair sensors with cross-checks to cut false trips. Example: require RH spike plus door-ajar signal to confirm a rain event during service.

Coordinating enclosure sensors and BMS logic

Make the box part of the control loop

Feed enclosure data to the BMS and to the inverter. Use that data to avoid stress, not only to react after an incident. Link door switches, leak probes, humidity sensors, and temperature points into a single status map. The BMS can then cap power, pause charging, or schedule thermal holds to dry out the interior.

- Door open: reduce current to service-safe levels; block remote starts.

- High RH for 30 minutes: hold SoC below the top knee; allow internal heaters to run.

- Condensate reached the drain: trigger a maintenance ticket and photograph request.

Demand response can also help. Smart charge scheduling reduces heat during grid peaks and gives the enclosure time to cool. Innovation Outlook: Smart charging for electric vehicles from IRENA shows how smart controls shift load and improve flexibility. The same logic helps packs run cooler and safer.

Siting, operations, and traceability

Right place, right clearances

Provide shade, airflow, and standoffs from walls. Keep intakes off the ground to reduce splash. Avoid roof edges where horizontal rain hits hardest. Permitting teams often cite fire safety and land-use limits, a theme documented by IRENA’s cost trends. Good siting lowers both risk and friction with authorities.

Labels, QR, and the battery passport

Clear labeling speeds safe service and emergency response. Include chemistry, SoC at storage, vent directions, and disconnect locations. Traceability is rising. The “battery passport” concept from the Global Battery Alliance, referenced in The Role of Critical Minerals in Clean Energy Transitions, supports data sharing on chemistry and state-of-health. This improves Lithium Battery Safety during transport, service, and recycling. It also helps teams spot packs that need stricter handling.

Maintenance that actually gets done

- Quarterly: Inspect gaskets, glands, drains, vent membranes; replace desiccant; run door and leak sensor checks.

- Seasonal: Update BMS derating tables for hot and wet seasons. Validate relief paths remain clear.

- Annual: Pull logs on thermal events and alarms. Review against site weather data. Tune setpoints.

Growth in solar-plus-storage increases outdoor duty. DOE’s solar energy resources highlight this transition and the role of storage in reliability (U.S. DOE Solar Energy). More cycles and harsher environments make these checks pay off.

Field-proven quick wins

- Add a hydrophobic vent plus a separate burst disk. Pressure cycling drops and seals live longer.

- Repaint dark boxes to a reflective finish. Peak internal temps fall by several degrees in summer.

- Stage BMS limits 5–10°C below hard cutoffs. Faults become calm derates instead of shocks.

- Log RH and dew point inside the box. Heaters only run when needed, saving energy.

Why this matters for grid value

Storage supports evening peaks and reduces curtailment of solar, a point noted across IEA and IRENA system reports. Higher availability and fewer fire events preserve that value. Fewer thermal alarms also cut truck rolls. Reduced downtime matters as the fleet grows, a theme raised by the IEA flexibility analysis and the Southeast Asia Energy Outlook 2024.

Takeaway

Weatherproof Enclosures block the triggers. Smart BMS Tactics remove the stress. Together they reduce ignition risk, limit damage, and shorten recovery. Pick an enclosure rating that matches actual splash and flood exposure. Add vents that breathe without leaking. Program staged limits and early derates. Tie enclosure sensors into control actions. Then maintain the simple stuff: gaskets, drains, labels, and logs.

References

- IEA. The Role of Critical Minerals in Clean Energy Transitions. Notes the battery passport concept and how better data improves safety and recycling.

- IEA. Southeast Asia Energy Outlook 2024. Highlights storage durations and the role of batteries in evening peaks.

- IRENA. Renewable Power Generation Costs in 2024. Points to permitting and urban fire safety codes as siting constraints for projects.

- IEA. The Power of Transformation. Explains how storage adds flexibility and supports secure operation.

- IRENA. Innovation Outlook: Smart charging for electric vehicles. Shows how smart control shifts load, a tactic that also reduces pack heat.

- U.S. Department of Energy. Solar Energy. Background on the rise of solar and the growing role of storage for reliability.

Safety note: This content supports safe design and operation but does not replace codes, standards, or authority approvals. Non-legal advice.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.