Modern farms depend on consistent, reliable power. An Energy Storage System (ESS) offers a powerful solution for energy independence, but its long-term value hinges on one critical factor: battery lifespan. Premature degradation can undermine the entire investment. This case study examines a real-world example of a farm that significantly extended its ESS life by adopting a specific daily State of Charge (SOC) management strategy. By operating their LiFePO4 battery within a 30% to 90% SOC window, they unlocked substantial longevity gains and financial benefits.

The Farm's Energy Challenge

A farm's daily operations are energy-intensive. From running irrigation pumps to maintaining cold storage units, a stable power supply is not a luxury; it's a necessity for productivity and profitability. Interruptions can lead to crop loss and operational delays.

The High Stakes of Agricultural Power Needs

The energy demands on a farm are diverse and demanding. As noted in a report by the International Renewable Energy Agency (IRENA), agricultural value chains rely on equipment like water pumps and cold storage. For instance, a 5-tonne cold storage unit is crucial for preserving produce and securing better market prices. The farm in our case study faced similar demands, requiring consistent power for machinery that could not afford downtime. Their initial solar and storage setup was designed to meet these peak loads, but a major concern quickly emerged about the system's long-term durability.

Why a Standard ESS Setup Fell Short

Initially, the farm's ESS was configured to use the battery's full capacity, cycling from nearly 0% to 100% SOC daily. While this provided maximum available energy each day, it placed significant stress on the LiFePO4 battery cells. Projections based on this usage pattern indicated a shorter-than-expected operational life. The constant deep cycling would accelerate capacity fade, leading to a premature and costly battery replacement. The farm needed a smarter approach to protect its investment without compromising daily operations.

Implementing a Smart SOC Window

The solution was to shift from using the battery's full range to operating within a more conservative, optimized window. This strategy focuses on preserving battery health over maximizing single-cycle capacity.

What is a State of Charge (SOC) Window?

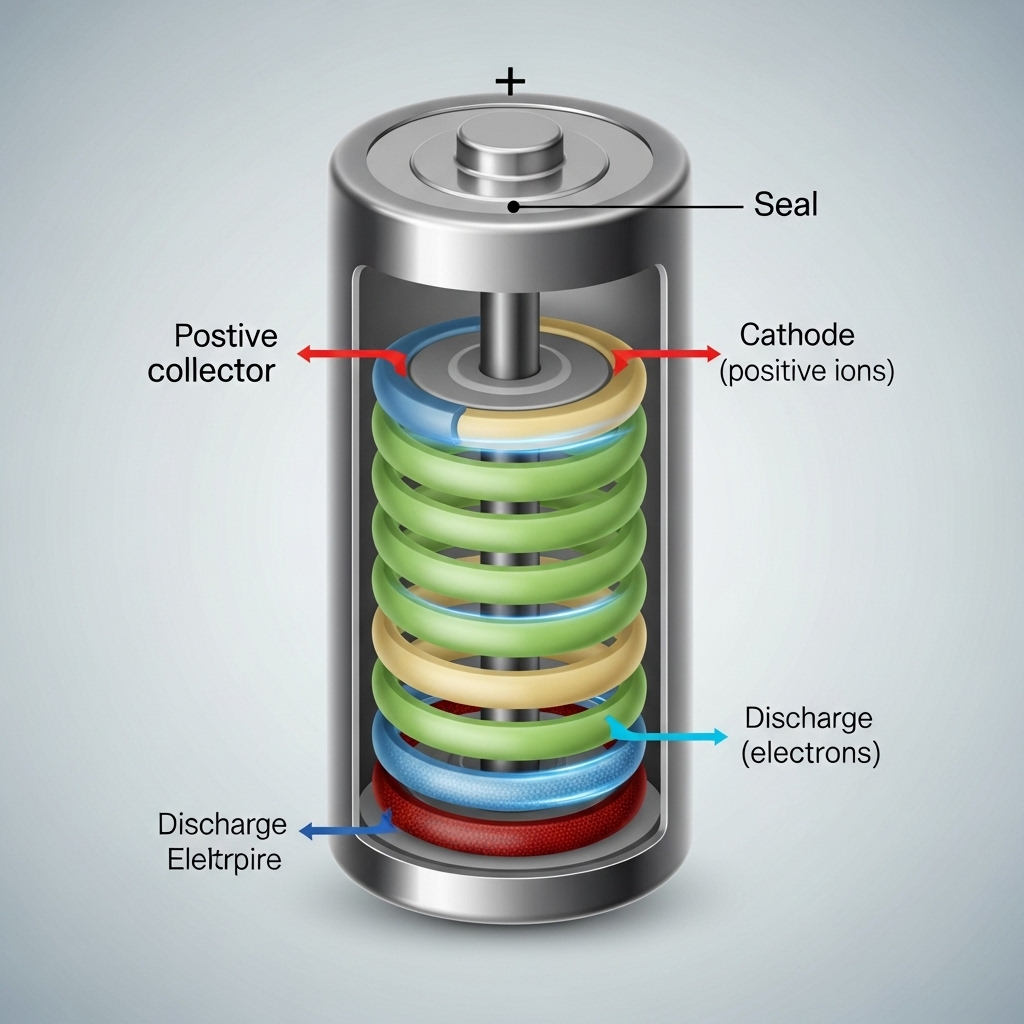

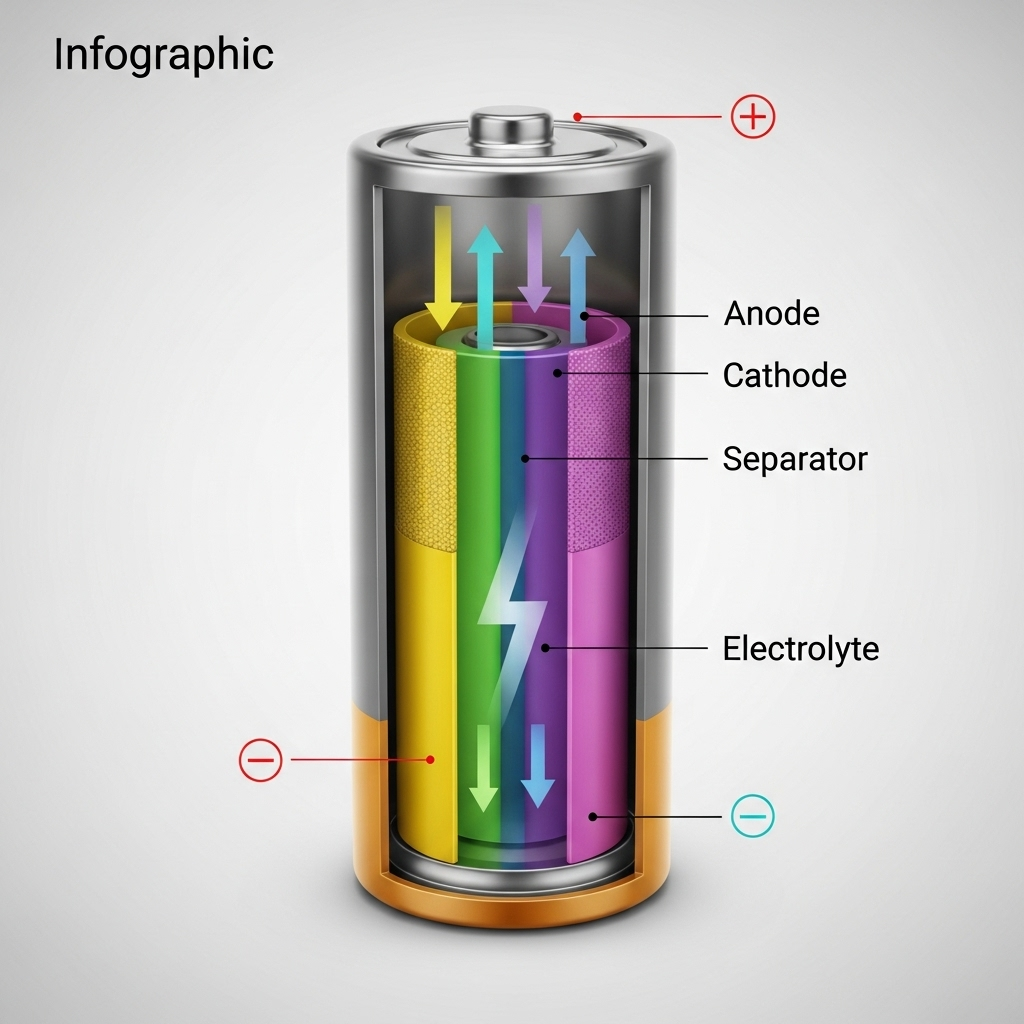

A State of Charge window is the defined operational range for your battery. Instead of charging to 100% and discharging to 0%, you program the system to operate between two set points, for example, 90% (as the upper limit) and 30% (as the lower limit). This practice avoids the electrochemical stress that batteries experience at the extreme ends of their charge spectrum. For LiFePO4 batteries, this is a particularly effective method for extending their cycle life.

The Rationale for a 30–90% SOC Window

Operating a LiFePO4 battery at very high or very low states of charge accelerates degradation. At high SOC levels (above 90-95%), materials within the cathode can experience structural stress. At low SOC levels (below 20-30%), the risk of other side reactions increases. By keeping the battery within a 'sweet spot' of 30% to 90%, you significantly reduce these stressors. This results in a much higher number of completed charge-discharge cycles before the battery's capacity degrades to its end-of-life threshold (typically 80% of its original capacity).

The Results: Measurable Longevity Gains

By reprogramming the farm's inverter and Battery Management System (BMS) to enforce the 30-90% SOC window, the team was able to track and confirm substantial improvements in the battery's health and projected lifespan.

The Data: Before and After Comparison

The impact of this simple adjustment was profound. The data collected showed a dramatic difference in projected performance and cost between the standard full-cycle approach and the optimized SOC window strategy.

| Metric | Standard 0-100% SOC Window | Optimized 30-90% SOC Window |

|---|---|---|

| Depth of Discharge (DoD) | ~100% | 60% |

| Projected Lifespan (Cycles) | ~3,000 | 6,000+ |

| Estimated Annual Capacity Loss | ~3-4% | ~1-1.5% |

| Projected System Lifespan | 7-8 years | 15+ years |

The Financial Impact of Smart Management

The extended lifespan translates directly into significant financial savings. By more than doubling the battery's projected operational life, the farm effectively delayed a major capital expenditure on a replacement system. This dramatically improves the Levelized Cost of Energy (LCOE) and the overall return on investment. As the International Energy Agency (IEA) has pointed out, factors that improve project economics are critical for wider adoption. While they focus on financing, operational strategies like SOC management offer a direct way for owners to enhance the financial viability of their systems. This proactive management ensures the storage system remains a valuable asset, capable of providing services like peak shaving for a much longer period, a concept highlighted in IRENA's framework for electricity storage valuation.

Applying This Strategy to Your System

The success of this farm's experience offers a valuable lesson for other ESS owners. Adopting a similar strategy can help you get the most out of your battery investment.

Is a Narrow SOC Window Right for You?

This strategy involves a trade-off: you gain longevity at the expense of daily usable capacity. For a 10 kWh battery, a 30-90% window provides 6 kWh of energy per cycle. This is ideal for systems with daily cycling patterns, such as solar self-consumption, where you consistently charge during the day and discharge in the evening. For a system designed purely for infrequent emergency backup, you might prioritize having 100% of the capacity available, but even then, holding the battery at 90% instead of 100% can reduce calendar aging.

How to Determine Your Optimal Window

Your optimal SOC window depends on your battery chemistry, daily energy needs, and primary goals. LiFePO4 chemistry is highly responsive to this strategy. Analyze your daily consumption to see if a 60-70% operational capacity is sufficient. If so, implementing a conservative SOC window is a powerful way to boost longevity. For a deeper look at the various factors that influence battery health and output, the ultimate reference on solar storage performance offers extensive data and benchmarks that can help you fine-tune your system's parameters for optimal results.

A Smarter Approach to Energy Independence

This case study demonstrates that intelligent system management is just as important as high-quality hardware. By implementing a 30-90% SOC window, the farm transformed its ESS from a simple power source into a durable, long-term asset. This approach not only saved money but also aligned with broader goals of sustainability. Extending the life of a battery is the first and most impactful step in reducing waste and promoting a circular economy for solar technologies, a key consideration for the future as outlined in the U.S. Department of Energy's Solar Futures Study. True energy independence is achieved not just by installing a system, but by operating it wisely for maximum value and lifespan.

Frequently Asked Questions

Will a 30-90% SOC window void my battery warranty?

Generally, no. This practice is less stressful for the battery and is often encouraged. Most warranties are based on total energy throughput or a set number of cycles, and this method helps you stay within those limits for a longer period. Always confirm with your specific manufacturer's warranty documentation.

How much usable capacity do I lose with this strategy?

You are operating within 60% of the battery's nameplate capacity on a daily basis (90% minus 30%). For a 10 kWh battery, this provides 6 kWh of usable energy per cycle. The key benefit is that you can perform many more of these cycles. The full capacity is typically still available if you need to manually override the settings for an emergency.

Can I apply this to other battery chemistries like lead-acid or NMC?

The core principle of avoiding the extremes of charge and discharge applies to most battery types, but the optimal SOC windows vary. This case study focuses on LiFePO4 (Lithium Iron Phosphate) batteries, which are particularly well-suited for this kind of cycle management. Other chemistries, like NMC or lead-acid, have different degradation mechanisms and optimal operating ranges.

Is this difficult to set up?

For most modern energy storage systems, setting SOC limits is a basic function within the inverter or Battery Management System (BMS) software. It is usually a simple parameter change in the user settings menu. You can consult your system's manual or speak with your installer for specific instructions on how to adjust these limits.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.