Solar energy continues its rapid expansion, driving significant investments and capacity additions globally. China alone added over 100 GW of solar PV capacity in 2022, marking a nearly 70% increase from 2021. Europe, India, and Brazil also saw annual installations rise by 40% or more. This impressive growth underscores the critical need for robust quality assurance (QA) in PV modules. A well-structured PV Module Quality Assurance Plan is not just a technical requirement; it is a cornerstone for securing the financial viability and long-term performance of any solar project. In 2025, with evolving technologies and market dynamics, a comprehensive and forward-looking QA strategy is more crucial than ever.

The Foundation of Bankable PV Module QA

Defining Bankability in Solar Projects

Bankability refers to a project's ability to secure financing from lenders and investors. For solar projects, this means demonstrating a high degree of certainty regarding long-term performance, reliability, and return on investment. PV modules represent a significant portion of a solar project's capital expenditure. Their quality directly impacts energy yield, operational costs, and overall project lifespan. Investors require assurance that the modules will perform as expected over their decades-long operational life. A strong PV Module Quality Assurance Plan provides this confidence, mitigating risks associated with premature degradation, unexpected failures, and underperformance.

Beyond Basic Compliance: Why Standard Tests Fall Short

Standard certifications, such as those based on IEC 61215, 61646, and 62108, establish a baseline for PV module safety and performance. These tests are foundational. However, they often fall short in predicting long-term performance or differentiating product quality under real-world operating conditions. For instance, while useful for basic compliance, current IEC tests may not fully predict long-term durability against extreme heat, abrasive dust, and high humidity in harsh desert climates. This highlights the critical need for enhanced real-world testing. This gap necessitates a more rigorous approach to quality assurance, moving beyond mere compliance to proactive risk management and performance optimization.

Key Pillars of a Robust QA Plan for 2025

Advanced Testing Protocols and Beyond-IEC Standards

A bankable PV Module QA Plan incorporates advanced testing protocols that go beyond the minimum IEC requirements. These include:

- Accelerated Stress Testing: Exposing modules to extreme conditions (e.g., higher temperatures, humidity, UV radiation, mechanical loads) for extended periods helps reveal potential weaknesses not captured by standard tests.

- Climate-Specific Stress Screening: Generic PV testing often fails to predict solar panel durability in diverse climates. Tailored testing protocols, considering factors like localized heat, UV, and humidity, ensure long-term performance and reliability in specific deployment environments.

- Electroluminescence (EL) and Infrared (IR) Imaging: These techniques detect micro-cracks, hot spots, and cell defects that can lead to significant power loss over time, often before they become visible.

- Potential Induced Degradation (PID) and Light Induced Degradation (LID) Testing: Specific tests to measure and mitigate these common degradation mechanisms are crucial for long-term performance.

Supply Chain Vigilance and Manufacturer Audits

The quality of a PV module begins with its components and manufacturing process. A robust QA plan includes:

- Supplier Qualification: Rigorous vetting of cell, glass, encapsulant, and backsheet suppliers.

- Factory Audits: Regular, unannounced inspections of manufacturing facilities to ensure adherence to quality control processes, material traceability, and ethical labor practices.

- In-line Quality Control: Verification of quality checks at various stages of the production line, from raw material inspection to final module assembly.

- Pre-shipment Inspection: A final inspection of modules before they leave the factory to confirm visual quality, packaging, and quantity.

Data-Driven Performance Monitoring and Field Validation

Once installed, continuous monitoring and validation are essential:

- Performance Ratio (PR) Analysis: Regularly comparing actual energy output to expected output, adjusted for environmental conditions, helps identify underperforming modules or system issues.

- Degradation Rate Tracking: Monitoring how quickly module performance declines over time provides valuable data for future project planning and warranty claims.

- Field Electroluminescence/Infrared Inspections: Periodic on-site inspections can detect issues that develop after installation, such as snail trails, delamination, or cell damage from environmental factors.

Navigating Emerging Technologies and Market Dynamics

Quality Assurance for Bifacial and Perovskite Modules

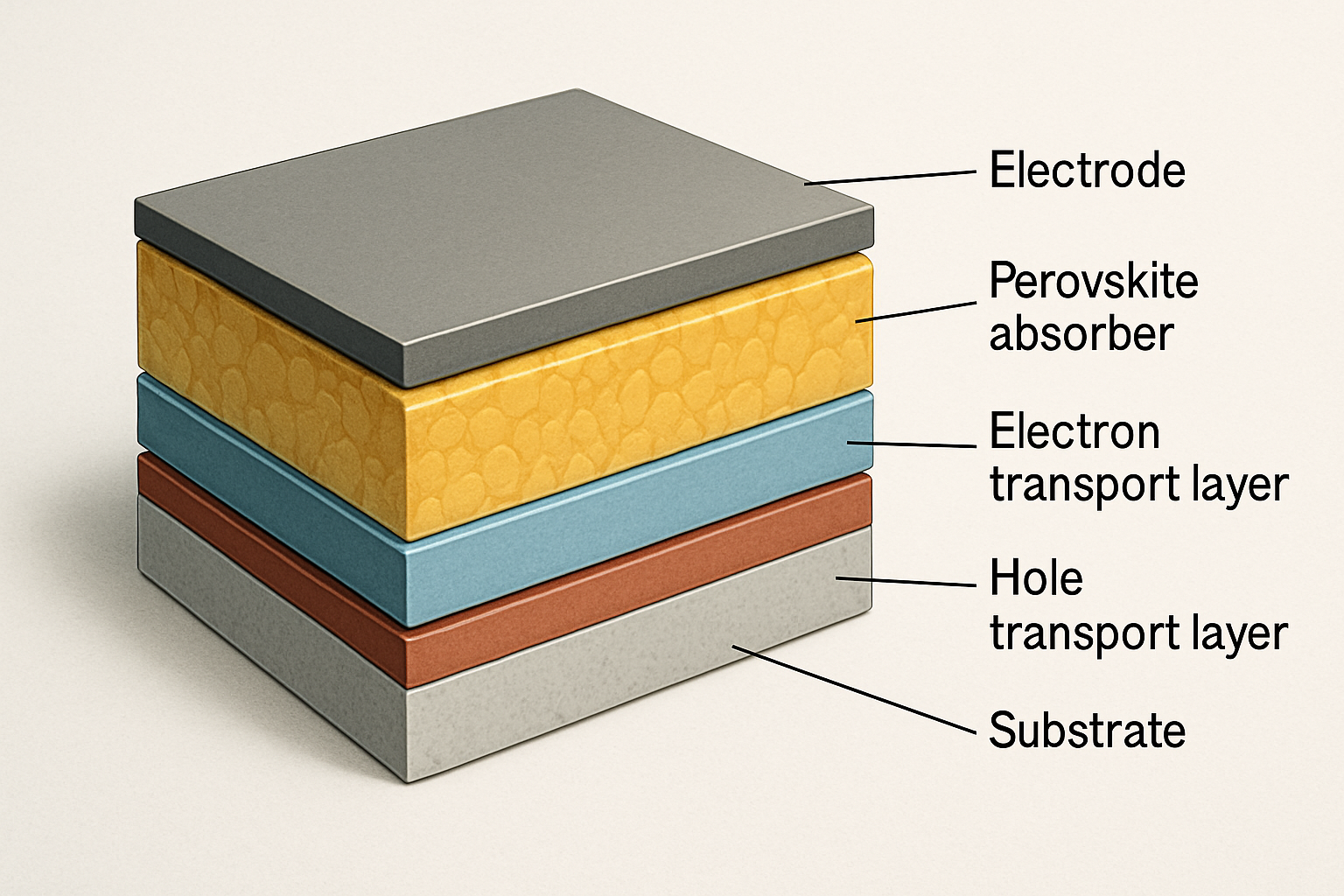

New technologies introduce new QA considerations:

- Bifacial Modules: These panels capture light from both sides, boosting energy yield. Testing protocols must account for factors like albedo and rear-side irradiance to accurately predict performance gains. Specialized tests predict yield gains for bifacial panels.

- Perovskite Modules: While offering high efficiency and flexibility, perovskite modules have unique vulnerabilities to moisture and UV light. A robust durability testing roadmap beyond current IEC standards is critical for their bankability, building investor confidence and ensuring long-term performance.

Impact of Global Market Trends on QA Strategies

Global market trends significantly influence QA strategies:

- Cost Pressures: Global solar PV module prices experienced fluctuations, falling to a low in Q3 2020 before rising by 20% in Q4 2022 due to material and labor market tightness. However, prices began to decline in early 2023 as input costs, such as solar-grade silicon and wafers, decreased and manufacturing capacity expanded, particularly in Asia. These fluctuations necessitate vigilant QA to ensure cost reductions do not compromise quality.

- Supply Chain Resilience: Geopolitical events and trade policies can disrupt supply chains. A robust QA plan includes strategies for diversifying suppliers and verifying the quality of modules from various regions.

- Policy and Regulatory Shifts: Ambitious new policies, such as the Inflation Reduction Act in the United States and the EU's increased renewable target of 42.5% by 2030, are accelerating clean power investments. These policies often come with new standards or incentives for domestic manufacturing, impacting QA requirements.

Implementing and Maintaining Your QA Plan

Building an Internal QA Framework

Developing an in-house QA framework empowers you to maintain control over module quality. This involves:

- Establishing Clear Specifications: Define precise technical and performance requirements for all PV modules.

- Developing Standard Operating Procedures (SOPs): Document every step of your QA process, from procurement to installation and monitoring.

- Training Personnel: Ensure your team possesses the necessary expertise in PV technology, testing methods, and quality control.

- Investing in Equipment: Acquire essential tools for visual inspection, electrical testing, and basic diagnostic checks.

Partnering with Independent Experts

Collaborating with third-party testing labs and consultants offers invaluable benefits:

- Specialized Expertise: Independent labs provide advanced testing capabilities and deep technical knowledge. For example, labs rigorously qualify PV modules, ensuring their reliability and longevity.

- Impartial Verification: Third-party validation adds credibility to your QA efforts, providing unbiased assessments of module quality.

- Risk Mitigation: External experts can identify potential issues early, helping you avoid costly failures and disputes.

Securing Your Solar Investment

Building a bankable PV Module QA Plan in 2025 is a strategic imperative for any solar project developer or investor. It moves beyond basic compliance, embracing advanced testing, vigilant supply chain management, and continuous performance monitoring. By implementing these robust quality assurance strategies, you ensure the long-term reliability and financial viability of your solar assets. This commitment to quality ultimately contributes to a more resilient energy landscape and helps you achieve energy independence with confidence.

Frequently Asked Questions

What does "bankability" mean for PV modules?

Bankability for PV modules refers to their ability to provide sufficient confidence to financial institutions and investors that they will perform reliably over their warranted lifetime. This ensures the project's projected energy output and financial returns are met, making the project attractive for financing.

How do 2025 solar standards influence PV module QA?

While core IEC standards remain, 2025 solar standards emphasize more rigorous, climate-specific, and advanced testing protocols. This reflects the need for greater durability and performance predictability as solar deployments expand into diverse and challenging environments. New standards also address emerging technologies like bifacial and perovskite modules.

What are the risks of a poor PV module QA plan?

A weak QA plan can lead to significant risks, including premature module degradation, unexpected power losses, increased maintenance costs, and potential project failures. These issues directly impact financial returns, diminish investor confidence, and can result in costly warranty claims or legal disputes.

How can advanced testing improve project returns?

Advanced testing protocols identify potential module weaknesses before deployment, preventing costly failures and ensuring consistent high performance. By reducing degradation rates and maximizing energy yield over the project's lifespan, advanced testing directly contributes to higher, more predictable financial returns and enhances the overall bankability of your solar investment.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.