Perovskite solar cells are rapidly emerging as a highly efficient and potentially low-cost photovoltaic technology. Their impressive performance gains have generated significant excitement. However, this optimism is tempered by valid questions about their long-term sustainability and environmental impact. Separating the myths from the realities is crucial for understanding the future of this technology.

Unlike conventional energy sources, the negative externalities of solar technologies are comparatively small. Still, addressing sustainability concerns from the beginning is essential. This involves examining the entire perovskite material lifecycle, from raw material extraction to end-of-life recycling, to ensure this promising technology develops responsibly.

The Material Lifecycle of Perovskite Modules

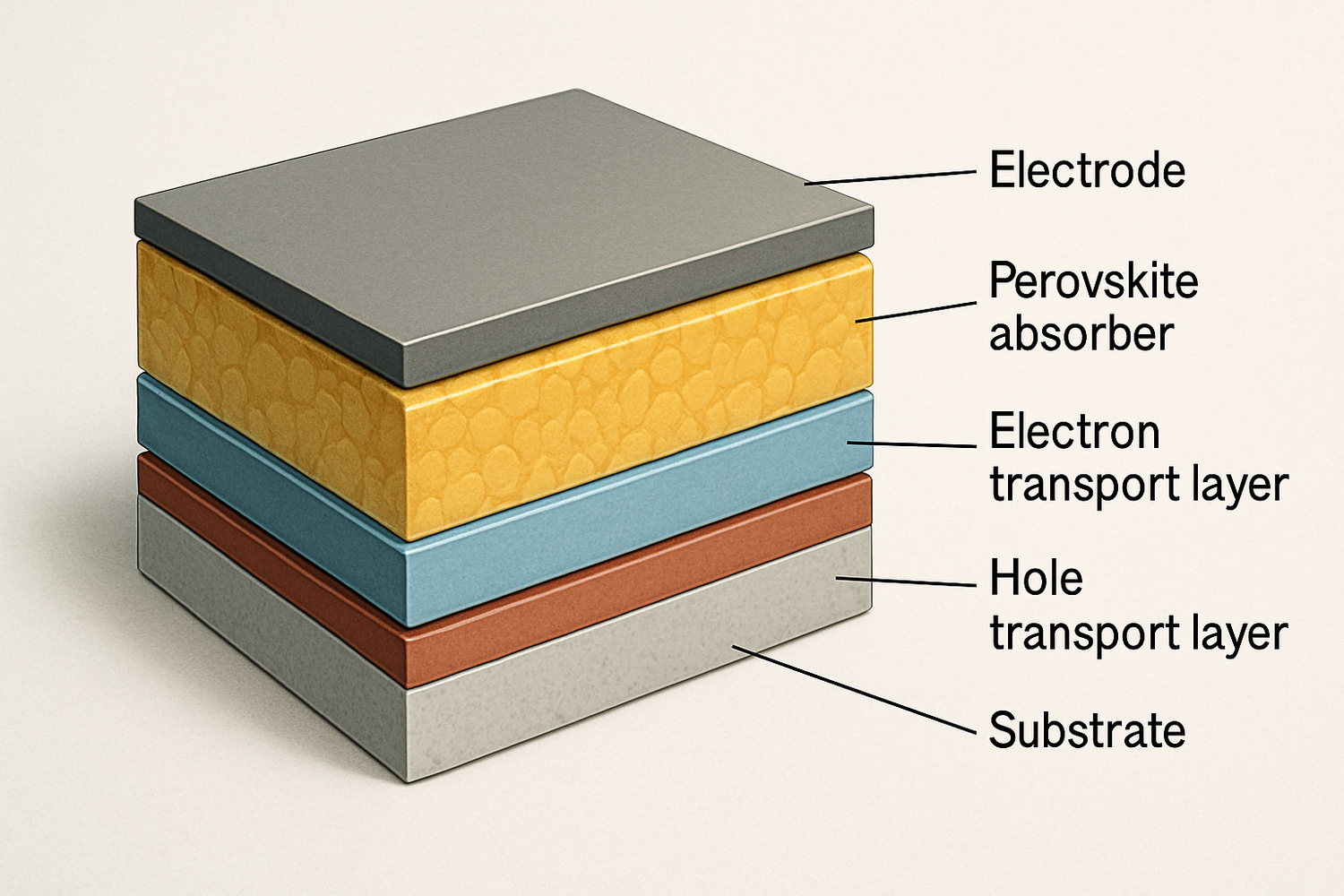

Understanding the sustainability of any solar technology begins with its lifecycle. For perovskites, this journey involves unique materials and manufacturing processes that differ significantly from traditional silicon-based panels, presenting both advantages and challenges.

Raw Material Sourcing and Concerns

The most discussed component in high-efficiency perovskite cells is lead. As a toxic heavy metal, its inclusion raises immediate environmental and health concerns. While the amount of lead in a single module is small—often around 0.4 g/m²—the potential for large-scale deployment necessitates careful management. Research has shown that discarded perovskite solar cells can be classified as hazardous waste due to lead leaching. However, the supply chain for perovskite materials is generally less energy-intensive than that for the high-purity silicon required for conventional panels.

Manufacturing and Energy Payback

One of the most significant sustainability advantages of perovskite technology is its low-energy manufacturing process. Unlike silicon, which requires high-temperature furnaces to create pure crystalline wafers, perovskites can be processed at much lower temperatures. This efficiency translates to a remarkably short energy payback time (EPBT)—the time a panel must operate to generate the amount of energy it took to produce it. Studies suggest the EPBT for perovskite cells can be as low as two to three months, a fraction of the one to two years typical for silicon panels. An analysis of all-perovskite tandem cells calculated an EPBT of just 0.35 years.

Unpacking the Primary Sustainability Risks

While the manufacturing advantages are clear, three primary risks dominate the sustainability conversation around perovskite modules: lead toxicity, operational stability, and end-of-life management. Addressing these challenges is fundamental to their widespread, responsible adoption.

The Lead Conundrum: Toxicity and Leaching

The primary risk associated with perovskite modules is the potential for soluble lead compounds to leach into the environment. If a panel is damaged by severe weather or mishandled at its end of life, rainwater could carry lead into soil and groundwater. Studies have confirmed that under simulated rain conditions, a significant percentage of lead can be lost from damaged, unencapsulated cells. This reality underscores the critical need for robust encapsulation and effective end-of-life collection and recycling programs to prevent environmental contamination.

Module Stability and Longevity

Historically, perovskite cells have demonstrated shorter operational lifespans compared to the 25-30 year standard for silicon modules. This instability, particularly when exposed to moisture and heat, is a sustainability concern. A shorter lifespan means more frequent replacement, which increases the overall material consumption and waste generation over the long term. However, significant research progress is being made. According to a study in *The Role of Critical Minerals in Clean Energy Transitions*, machine learning and AI are being used to select more stable materials and improve module longevity, directly addressing this issue.

End-of-Life Management and Recyclability

With a shorter lifespan and toxic components, a clear plan for perovskite recycling is not just an option—it's a necessity. The good news is that perovskite modules are, in many ways, designed for easier disassembly than silicon panels. Research into perovskite recycling is advancing rapidly, with several effective methods already demonstrated. Recent studies have shown that new recycling processes using green solvents like water can recover nearly all materials for reuse in new, equally efficient cells. This creates a pathway for a closed-loop manufacturing system, a core principle of the circular economy.

Innovations Mitigating Environmental Impact

The scientific community is actively working to engineer solutions that mitigate the inherent sustainability risks of perovskite technology. These innovations focus on safer materials, improved durability, and a commitment to circular design principles from the very beginning.

Lead-Free Perovskite Alternatives

The most direct solution to the lead problem is to remove it entirely. Researchers are actively developing alternative perovskite formulations based on less toxic elements like tin. While these lead-free alternatives have not yet matched the efficiency and stability of their lead-based counterparts, progress is continuous and represents a vital path toward inherently safer perovskite technology.

Advanced Encapsulation and Sequestration

To prevent lead leakage from damaged modules, researchers are developing multi-layered encapsulation techniques that create a more robust barrier against the elements. Another innovative approach involves integrating lead-absorbing materials directly into the module's structure. These sequestration layers are designed to capture and bind any lead that might escape from the perovskite layer, effectively immobilizing the toxin within the panel even if it is severely damaged.

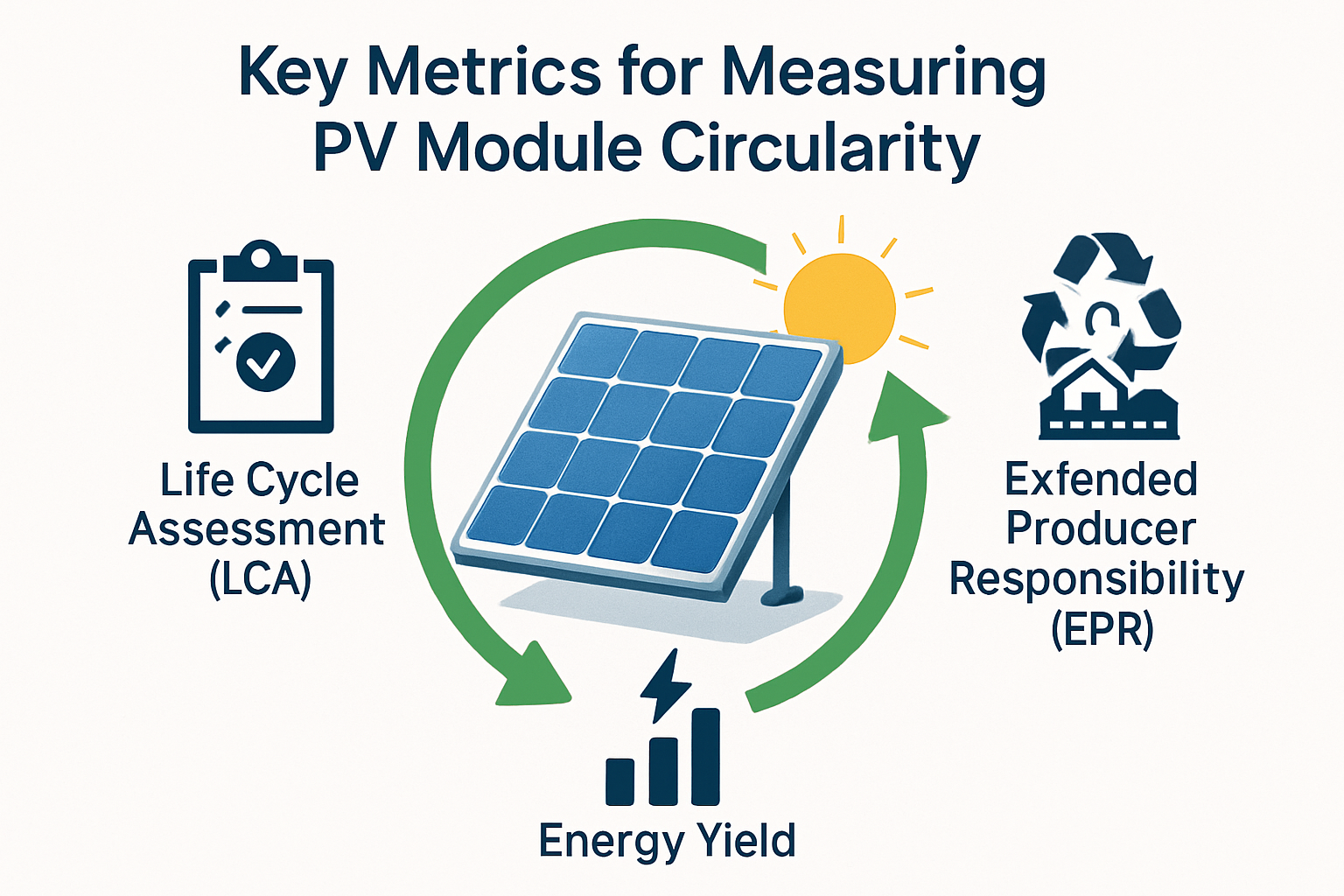

Designing for a Circular Economy

Perhaps the most powerful strategy is to design perovskite modules for circularity from the outset. This approach, known as Design for Circularity (DfC), involves choices that simplify end-of-life processing. As researchers from the National Renewable Energy Laboratory (NREL) have highlighted, this includes using reversible adhesives, avoiding hazardous materials like fluorinated backsheets, and designing modules that can be easily disassembled. By planning for repair, reuse, and recycling during the design phase, manufacturers can create a product that aligns with a sustainable, circular economic model, reducing waste and preserving valuable resources.

A Comparative Look: Perovskite vs. Silicon Sustainability

When evaluating sustainability, a direct comparison provides valuable context. Perovskite and silicon technologies each have distinct environmental profiles across their lifecycles.

| Sustainability Metric | Perovskite Modules | Crystalline Silicon Modules |

|---|---|---|

| Energy Payback Time (EPBT) | Very Low (0.3 - 0.5 years) | Low (1 - 2 years) |

| Greenhouse Gas Emission Factor | Very Low (approx. 11 g CO2-eq/kWh) | Low (approx. 25 g CO2-eq/kWh) |

| Primary Material Toxicity Risk | High (soluble lead) | Low (inert silicon, some lead in solder) |

| Recycling Potential | High (designed for disassembly, high recovery rates demonstrated) | Moderate (mature industry, but energy-intensive to separate materials) |

| Manufacturing Footprint | Lower energy and material inputs | Higher energy for silicon purification and wafering |

Data compiled from multiple lifecycle assessment studies.

A lifecycle study found that perovskite-on-silicon tandem modules could have a 6% to 18% lower environmental impact than conventional silicon modules over a 25-year lifetime, primarily due to their higher efficiency.

The Path to Sustainable Perovskite Technology

Perovskite solar technology holds immense promise, but its path to commercial success must be paved with a commitment to sustainability. The risks, particularly concerning lead toxicity and module stability, are real and require diligent engineering and robust regulatory frameworks. However, the challenges are not insurmountable.

The inherent advantages of low-energy manufacturing and high potential for recyclability provide a strong foundation for a sustainable lifecycle. Through continued innovation in lead-free materials, advanced encapsulation, and a steadfast focus on circular design, perovskite modules can evolve into a technology that is not only highly efficient but also environmentally responsible. As noted in the *Solar PV Global Supply Chains* report by the IEA, developing and strengthening recycling capabilities is crucial for managing future solar waste and creating a secure secondary source of materials.

Frequently Asked Questions

Are perovskite solar panels toxic?

The most efficient perovskite solar panels currently contain a small amount of water-soluble lead, which is a toxic substance. The primary risk is not during normal operation but if the panel is damaged or improperly disposed of, which could allow lead to leach into the environment. Researchers are mitigating this risk through robust encapsulation, built-in lead-absorbing layers, and developing lead-free alternatives.

Can perovskite modules be recycled?

Yes, and they show great promise for highly efficient recycling. Because of their layered structure, perovskite modules can be designed for easier disassembly than conventional silicon panels. Studies have demonstrated recycling processes that can recover up to 99.97% of the materials, which can then be used to manufacture new cells with comparable performance.

How does the environmental impact of perovskite compare to silicon panels?

Perovskite panels have a significantly lower manufacturing footprint, requiring less energy to produce, which gives them a much shorter energy payback time. However, they present a higher toxicity risk due to the use of lead. Overall lifecycle assessments suggest that high-efficiency perovskite-on-silicon tandem modules can have a lower long-term environmental impact than silicon-only panels, provided they achieve a long operational lifetime and are properly recycled.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.