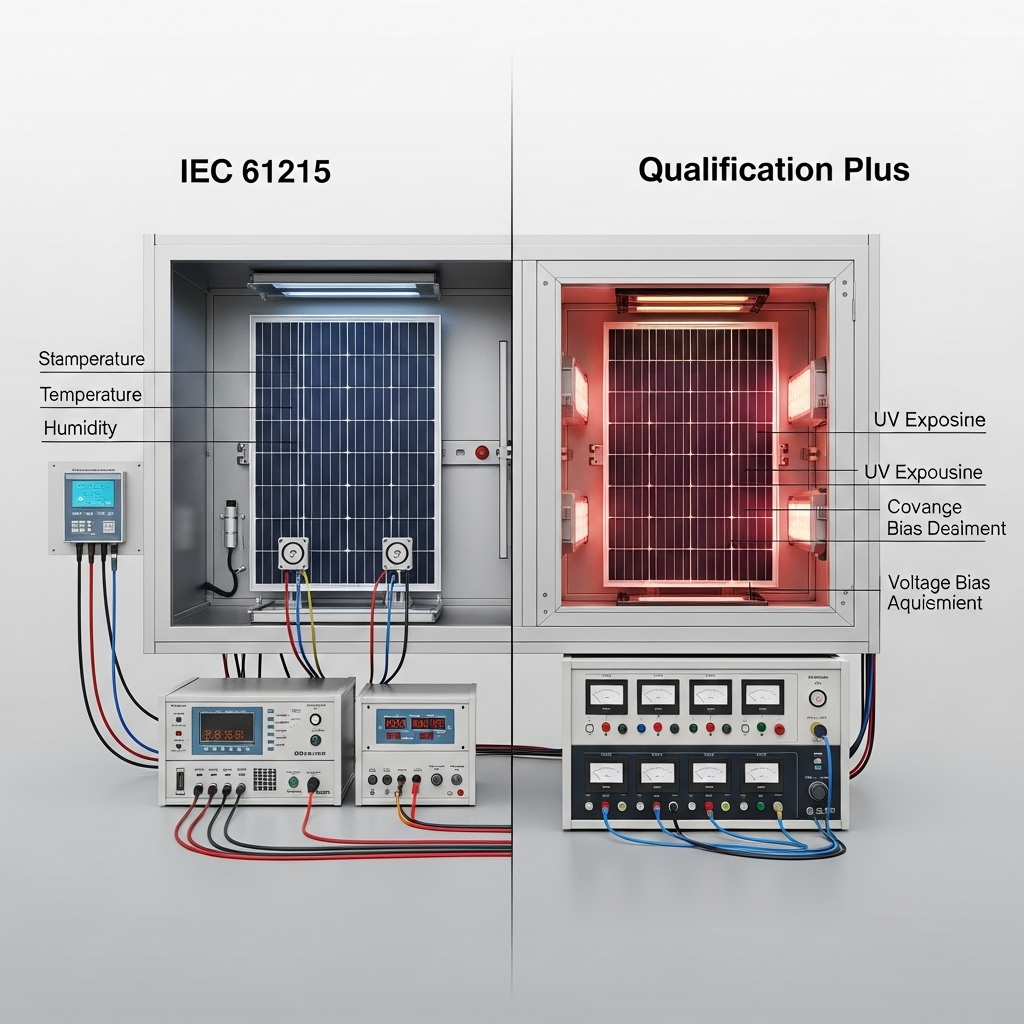

Navigating the stringent requirements of the IEC 61000 series for electromagnetic compatibility (EMC) is a critical step in bringing solar and energy storage systems to market. Formal certification can be a lengthy and expensive process. A failure at a certified test lab not only incurs re-testing fees but also introduces significant project delays. EMC pre-compliance kits offer a strategic advantage, allowing you to identify and resolve potential electromagnetic interference (EMI) issues during the design phase, long before you approach a formal test facility.

Why Pre-Compliance Testing is Non-Negotiable for PV and Storage Systems

In-house pre-compliance testing is more than a preliminary check; it's a fundamental part of a robust design and validation strategy. It empowers engineering teams to build products that are compliant by design, rather than fixing problems after the fact. This proactive approach is essential for managing the complex electronic environments of modern solar inverters and battery management systems.

The Staggering Cost of EMC Compliance Failures

Failing a formal EMC test at a third-party lab is a costly setback. Expenses include not only the lab fees, which can run into thousands of dollars per day, but also the engineering hours required to diagnose the problem, redesign the hardware, and produce new prototypes. These delays can cause you to miss market windows and put you behind schedule. As noted in IRENA's research on grid infrastructure, compliance tests are crucial throughout the planning, development, and implementation phases to mitigate risks. According to the publication Grid Codes for Renewable Powered Systems, combining strategies like type tests, on-site commissioning, and simulation is the most effective way to achieve grid code compliance.

Gaining Design Confidence and Accelerating Time-to-Market

Pre-compliance testing provides immediate feedback on your design choices. You can quickly assess the EMC impact of a new component, a change in the PCB layout, or a modification to the firmware. This iterative process builds confidence in the design's integrity and dramatically increases the likelihood of passing formal certification on the first attempt. This aligns with the principle that certification schemes increase trust through transparent and independent assessment.

Core Components of an Effective EMC Pre-Compliance Kit

A well-equipped pre-compliance setup does not need to replicate a multi-million dollar test lab. Instead, it focuses on providing actionable data to identify and troubleshoot EMI sources. A typical kit includes several key instruments.

Spectrum Analyzers and EMI Receivers

The spectrum analyzer is the cornerstone of any EMC toolkit. It captures and displays the frequency and amplitude of electromagnetic signals, allowing you to see the noise your product is emitting. An EMI receiver is a specialized type of spectrum analyzer with specific detectors (like Peak, Quasi-Peak, and Average) required by EMC standards, but a general-purpose spectrum analyzer is often sufficient for pre-compliance work.

Near-Field Probes

While an antenna in a shielded chamber measures far-field emissions (what the regulatory bodies care about), near-field probes are your diagnostic tools. These handheld probes act like EMI stethoscopes, allowing you to 'sniff' out the exact sources of noise on a circuit board, such as noisy traces, leaky connectors, or poorly shielded components. This is invaluable for pinpointing where a fix is needed.

LISNs and Current Probes

A Line Impedance Stabilization Network (LISN) is used for testing conducted emissions—the noise that travels back onto the power lines. It provides a stable impedance and a port to measure the noise generated by your device. Current probes clamp around cables to measure the common-mode currents that are often a source of radiated emissions.

ESD Guns and Surge Generators

Immunity testing is the other half of EMC compliance. You must ensure your product can withstand external electromagnetic phenomena. An ESD (Electrostatic Discharge) gun, a key tool for IEC 61000-4-2 compliance, simulates the static shock from a human touch. Surge generators test the device's ability to survive voltage spikes on the power lines, a common occurrence in real-world grid conditions.

A Practical Workflow: Using a Pre-Compliance Kit for IEC 61000

A structured approach to testing ensures repeatable and useful results. The goal is to create a baseline measurement and then systematically test for both emissions and immunity.

Step 1: Establishing a Baseline and Test Environment

Your test environment should be as quiet as possible. Find an area away from other electronic equipment. Take a baseline scan with your spectrum analyzer and antenna to understand the ambient RF noise. This baseline will be subtracted from your device's emission measurements.

Step 2: Radiated Emissions Scans

Place an antenna a set distance from your device (e.g., 1 or 3 meters) and connect it to the spectrum analyzer. Power on your device and run it through its various operating modes. Compare the measured peaks against the appropriate IEC 61000 limits. If you find emissions that are over the limit, use near-field probes to locate the source on the PCB.

Step 3: Conducted Emissions Testing

Place a LISN between your device's power source and the device itself. Connect the LISN's measurement port to the spectrum analyzer. This setup allows you to measure the noise the device is putting back onto the power cord, ensuring it doesn't interfere with other devices on the grid.

Step 4: Immunity Testing for Robustness

Use an ESD gun to apply controlled static discharges to various points on the product's enclosure, connectors, and buttons, as specified in IEC 61000-4-2. Monitor the device for any resets, lockups, or malfunctions. Similarly, use a surge generator on the AC input to test for resilience against power line disturbances.

Interpreting Results and Making Design Improvements

The data from your pre-compliance kit is only useful if you can translate it into actionable design changes. This is where engineering expertise comes into play.

Correlating Pre-Compliance Data with Standard Limits

Create a spreadsheet to log your measurements and compare them against the limits defined in the relevant IEC 61000 standard. Remember to account for the differences between your setup and a certified lab (e.g., antenna factors, cable loss). The goal isn't to get a perfect measurement but to identify problem frequencies with enough margin for error.

Common Mitigation Techniques

If you identify excessive emissions, common solutions include adding shielding to enclosures or cables, placing ferrite beads on power and data lines, improving the grounding scheme, or adding filter components to the PCB. For immunity failures, you might need to add transient voltage suppressors (TVS diodes) or improve the electrical isolation of sensitive circuits.

The Role of System Performance Metrics in Compliance

EMC issues can sometimes manifest as subtle performance degradations rather than outright failures. It is crucial to monitor key performance indicators during immunity testing. For a solar and storage system, this means tracking metrics like inverter efficiency, battery charge/discharge rates, and communication stability. A deep understanding of these metrics, as outlined in the ultimate reference for solar storage performance, provides a more complete picture of your system's robustness and its ability to function reliably in a noisy electromagnetic environment.

A Final Checkpoint

EMC pre-compliance testing is an indispensable strategy for any company developing solar and energy storage products. By investing in a basic pre-compliance kit and integrating testing into the design cycle, you can avoid costly delays, reduce financial risk, and bring a more reliable product to market faster. It transforms the certification process from an unpredictable hurdle into a final, confident verification of a well-engineered product. As stated by IRENA, ensuring devices do not adversely interfere with other electronics is a key element of quality infrastructure. The publication Quality infrastructure for smart mini-grids highlights that compliance with standards like IEC 61000 reduces risk for system operators and end-users alike.

Frequently Asked Questions

What is the difference between EMC pre-compliance and full compliance testing?

Pre-compliance testing is an in-house engineering tool used to identify and fix potential EMC issues during product development. It uses simplified setups to get directional data. Full compliance testing is a formal process conducted by an accredited, third-party laboratory with highly controlled environments and calibrated equipment to certify that a product officially meets all legal requirements of standards like the IEC 61000 series.

Can I build a DIY EMC pre-compliance kit?

Yes, to an extent. While high-end spectrum analyzers are expensive, more affordable options are available. You can also build your own near-field probes and LISNs. A DIY approach is excellent for gaining insights and solving many common EMI problems, though it may lack the accuracy of professional equipment. The key is to get usable data to make informed design decisions.

How much can a pre-compliance kit save my project?

The savings can be substantial. A single failed compliance test can cost between $10,000 and $20,000 in lab fees, engineering time, and prototype revisions. A pre-compliance kit, which can be assembled for a fraction of that cost, can help you avoid multiple failures. The return on investment is often realized by preventing just one failed certification attempt.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.