The rapid expansion of solar energy is a major step toward a cleaner energy future. With this growth comes a critical responsibility: managing photovoltaic (PV) modules at the end of their operational life. Extended Producer Responsibility (EPR) and take-back programs are moving from niche concepts to mainstream policy. For PV module manufacturers, understanding and preparing for these regulations is no longer optional; it is a strategic necessity. This playbook offers a clear path for navigating the policy landscape and building a robust EoL management strategy.

Understanding Extended Producer Responsibility in the Solar Sector

EPR is a policy approach that assigns producers the physical or financial responsibility for the treatment or disposal of post-consumer products. It represents a fundamental shift in how we think about product lifecycles, moving the onus from taxpayers and municipalities to the companies that create the products.

The Core Principle of EPR

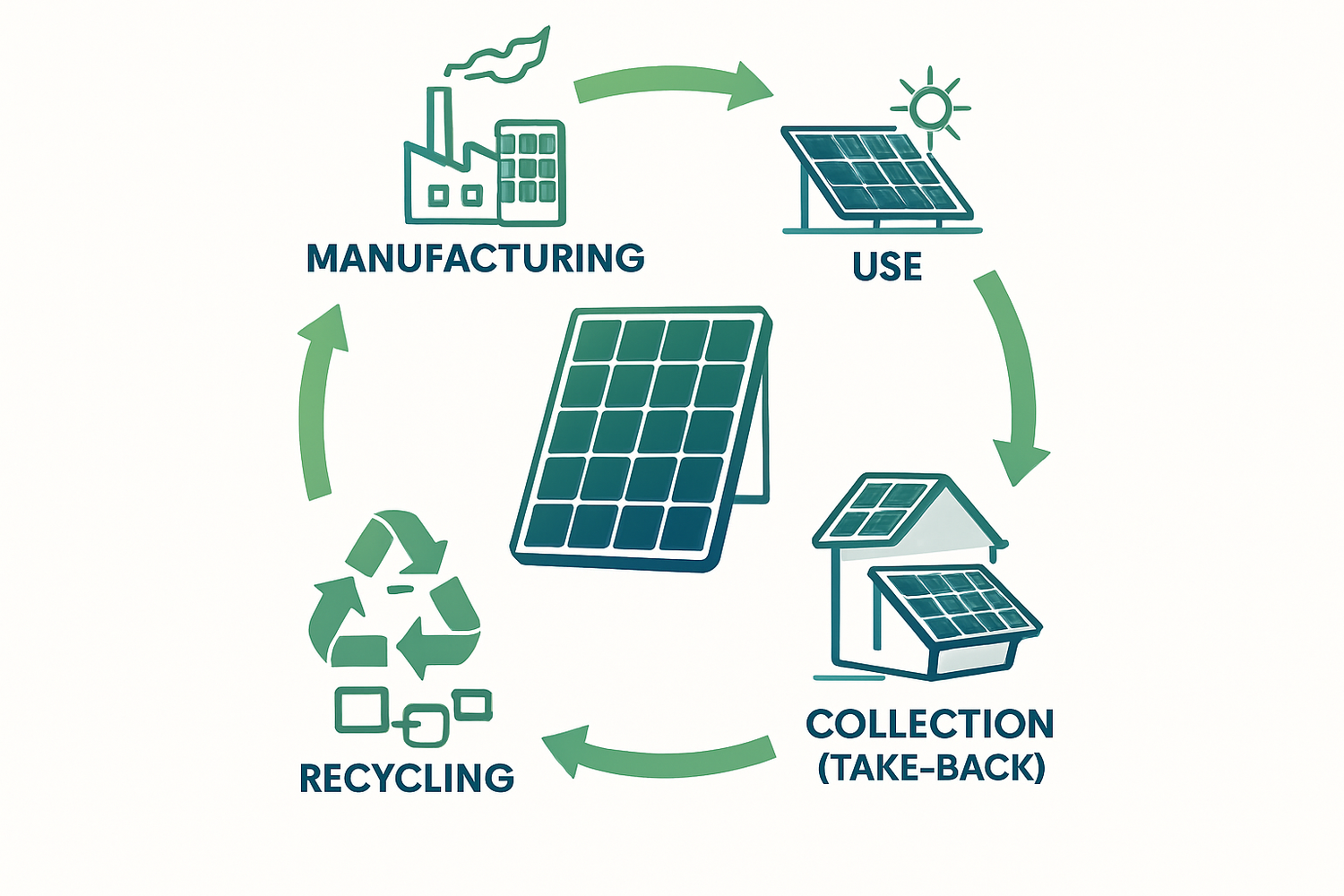

At its heart, EPR is designed to encourage more sustainable product design. As the International Energy Agency (IEA) notes in its Solar PV Global Supply Chains report, under an EPR scheme, producers have a direct incentive to improve module design for recycling because they bear the costs of the process. This encourages innovation in materials and construction, making panels easier to disassemble and their components simpler to recover. The goal is to create a closed-loop system where materials from old panels can be used to create new ones, fostering a true circular economy for solar.

Key Components of an EPR Framework

A comprehensive EPR framework typically includes several key elements. These often involve mandated collection targets to ensure a significant percentage of EoL modules are recovered. They also set specific recycling and material recovery rates to guarantee that collected panels are processed effectively. Furthermore, these frameworks must address the issue of "orphaned modules"—panels from manufacturers that are no longer in business. The IEA suggests that the cost of recycling these modules can be shared among remaining producers, sometimes supplemented by insurance or a joint liability scheme to ensure no panel is left behind.

The Global Regulatory Landscape

The European Union has been a forerunner in this area, implementing PV-specific waste regulations under its Waste Electrical and Electronic Equipment (WEEE) Directive. This directive mandates the recycling of all solar modules sold in the EU. However, the regulatory environment varies significantly across the globe. According to the IEA, many major markets, including the United States, China, and India, still lack specific regulations for EoL PV modules. In these regions, panels are often managed under general hazardous or non-hazardous solid waste frameworks, which may not be optimized for the unique materials found in solar panels.

Designing an Effective Take-Back Program

A successful take-back program requires careful planning around logistics, financing, and partnerships. It is the operational arm of an EPR strategy, turning policy requirements into a functional system that benefits both the business and the environment.

The Logistics of Reverse Supply Chains

Setting up a reverse supply chain is a critical first step. Manufacturers can consider several collection models. These include establishing designated drop-off points, creating a mail-back system for smaller quantities, or collaborating with installers who are often the first point of contact when a system is decommissioned. The efficiency of this network is paramount; a well-organized reverse logistics system minimizes transportation costs and improves the overall viability of the program.

Financial Mechanisms to Fund Your Program

Funding is a central consideration for any take-back initiative. Manufacturers have several options to finance the collection and recycling of their products. Choosing the right model depends on market regulations, business strategy, and customer expectations.

| Funding Model | Description | Advantages | Disadvantages |

|---|---|---|---|

| Visible Fee | A separate fee is added at the point of sale, explicitly covering future recycling costs. | Transparent for the consumer; creates a dedicated funding stream. | May negatively impact price competitiveness if not mandated industry-wide. |

| Internalized Cost | The cost of recycling is integrated into the overall product price. | Simple for the consumer; avoids a separate line-item fee. | Less transparent; requires accurate long-term cost forecasting. |

| Producer Responsibility Organization (PRO) | Manufacturers pay fees to a third-party PRO, which manages compliance and recycling operations for them. | Reduces administrative burden; leverages economies of scale. | Less direct control over the process; fees are an ongoing operational cost. |

Partnering for Success

Few manufacturers have the in-house expertise to manage the entire recycling process. Partnering with specialized recycling companies is essential to achieve high material recovery rates. These partners have the technology and processes to safely extract valuable materials like silver, copper, aluminum, and high-purity silicon. Additionally, joining a Producer Responsibility Organization (PRO) can streamline compliance. A PRO acts as a collective system, managing reporting, logistics, and recycling on behalf of its member companies, allowing manufacturers to focus on their core business.

The Business Case for Proactive EoL Management

Embracing EPR and take-back programs is more than a compliance exercise. It is a strategic decision that can deliver significant business value, enhance brand reputation, and build a more resilient company for the future.

Turning Responsibility into Opportunity

A commitment to EoL management sends a powerful message to customers, investors, and regulators. It demonstrates environmental stewardship and positions a brand as a leader in the sustainable energy transition. This can be a strong differentiator in a competitive market. Furthermore, the design challenges posed by EPR can spur innovation. Developing modules that are easier to repair, refurbish, or recycle can lead to more efficient manufacturing processes and new intellectual property.

Enhancing Supply Chain Resilience

The global solar supply chain is highly concentrated, as detailed in the IEA's Solar PV Global Supply Chains report. Recovering raw materials from EoL panels creates a valuable secondary source of materials. This reduces dependence on virgin resources, which can be subject to price volatility and geopolitical risks. Building a domestic source of recycled materials strengthens supply chain security and contributes to a more self-sufficient and circular solar industry.

Mitigating Future Risks

The trend toward greater environmental regulation is clear. Landfilling solar panels is likely to become more restricted and costly over time. By establishing a robust take-back and recycling program now, manufacturers can get ahead of future regulations. This proactive stance helps avoid the potential financial penalties and operational disruptions that come with reactive, last-minute compliance efforts. It is an investment in long-term operational stability.

A Final Perspective

Extended Producer Responsibility is reshaping the solar industry's obligations. For PV module manufacturers, this evolution presents a choice: view it as a regulatory burden or embrace it as a strategic opportunity. By proactively developing take-back programs, investing in circular design, and building strong partnerships, companies can do more than just comply with new rules. They can enhance their brand, strengthen their supply chains, and lead the way in building a truly sustainable and circular solar economy for generations to come.

Frequently Asked Questions

What is the main difference between EPR and a simple take-back program?

A take-back program is the logistical process of collecting a product at its end-of-life. Extended Producer Responsibility (EPR) is the policy principle that makes the manufacturer responsible for that process. EPR is the 'why' (the policy), while the take-back program is the 'how' (the operation).

Who pays for the recycling of solar panels under an EPR scheme?

Under EPR, the financial responsibility rests with the producer. This cost can be managed in several ways: by incorporating it into the product's price, by charging a visible recycling fee to the consumer at the time of purchase, or by paying fees to a collective organization that manages the recycling.

What happens to 'orphaned' solar panels from companies that are no longer in business?

Well-designed EPR systems have mechanisms to manage orphaned products. This is often achieved through a collective fund that all active producers pay into. This fund is then used to cover the costs of collecting and recycling panels from defunct companies, ensuring no module is left behind.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.