Environmental stress breaks solar assets more often than electronics do. The fix is simple: match hail rating, snow rating, and salt‑mist rating to the actual site. This raises uptime, protects ROI, and avoids preventable outages. Below is a practical, standards‑aligned way to set site‑specific ratings and stop failures.

What the ratings actually cover

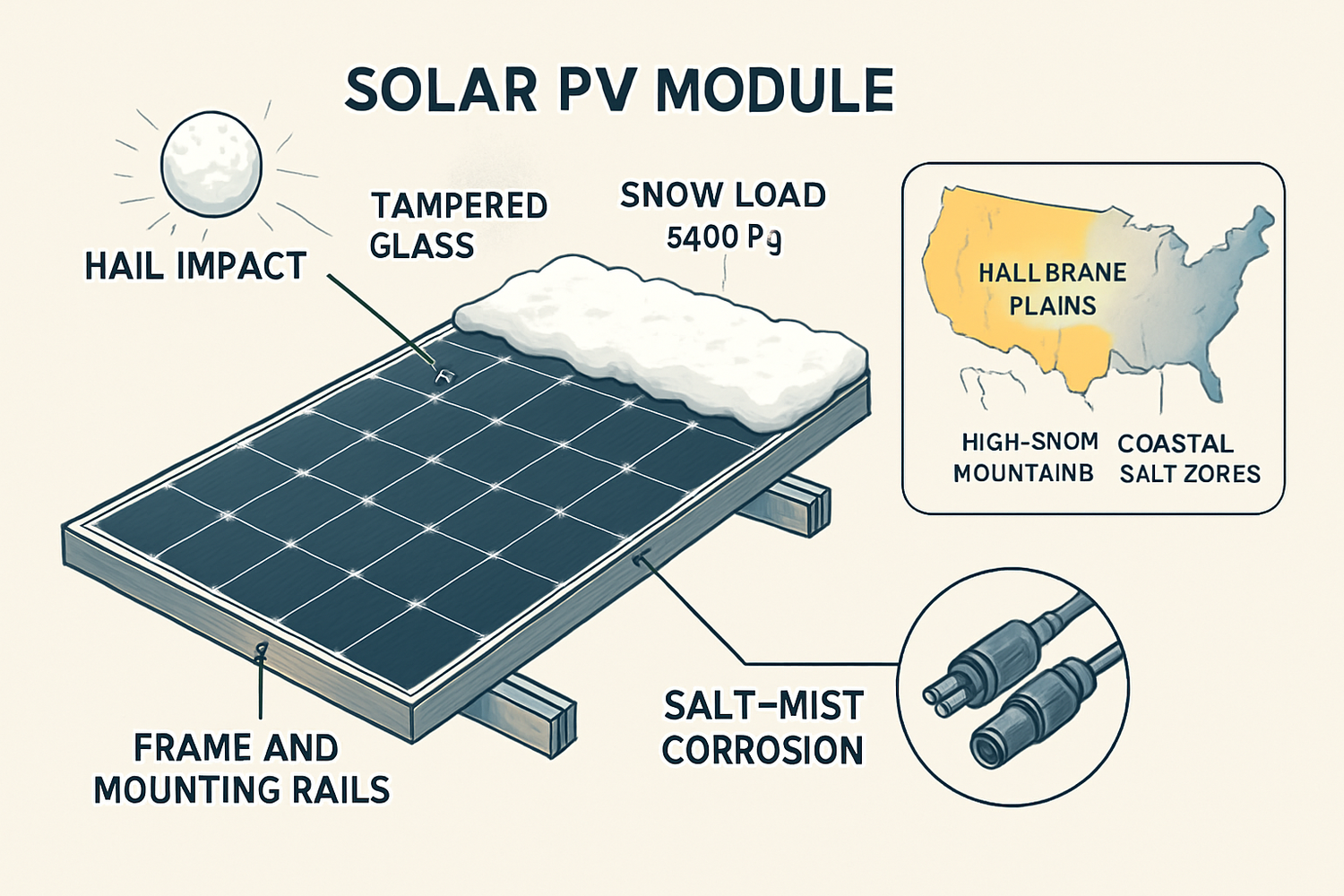

Hail rating

Standard qualification (IEC 61215 hail test) uses 25 mm ice balls at roughly 23 m/s across multiple impact points. This equates to about 2 J of kinetic energy per strike. Field storms can exceed this. Enhanced hail ratings test 35–55 mm ice at higher speeds. For reference, a 35 mm ice ball at 27 m/s carries about 7 J. If your site sits in a severe hail belt, specify the larger impact class and verify tempered glass thickness, frame rigidity, and interlayer (EVA/POE) choices.

Snow rating

Module mechanical load ratings are given in Pascals (Pa). A common front load is 5400 Pa (~113 psf), and rear load is 2400 Pa (~50 psf). Ratings are only valid with certified mounting patterns and clamp zones. Edge clamping vs. mid‑clamping changes strength. Include mounting layout in the specification so the snow rating applies to your actual installation.

Salt‑mist rating

Salt exposure accelerates corrosion in frames, fasteners, junction boxes, connectors, and cell metallization. IEC 61701 defines salt‑mist severity levels 1–6. Coastal or offshore locations often require Severity 6. For sites near intensive agriculture, consider ammonia resistance per IEC 62716 as well. Sealants, anodization grade, stainless steel fasteners (e.g., 316), and double‑glass constructions can raise resilience in harsh atmospheres.

Map site hazards to site‑specific ratings

Site hazard mapping comes first. Historical hail size distributions, design ground snow loads, and distance from shore guide the minimum ratings. Align ratings and mounting details with local building code and structural engineering. The aim is to keep safety factors above 1.5 for static loads and to reduce impact risk with operational strategies.

| Site condition | Trigger to act | Minimum ratings | Add‑ons that matter |

|---|---|---|---|

| Severe hail belt (large hail events common) | Frequent ≥35 mm hail in records or insurer maps | Enhanced hail rating ≥35 mm at elevated speed; robust frame and 3.2 mm glass | Tracker hail‑stow protocol; denser mid‑clamping; cell layout with more busbars to reduce crack impact |

| High snow load (mountain or cold continental) | Design ground snow load >30 psf (≈1.44 kPa) | Front load ≥5400 Pa with certified clamp zones and rail spacing | Tilt ≥30° where feasible; snow guards; stiff rails; verified load path to structure |

| Coastal marine air (onshore within ~5 km or offshore) | Salt spray visible or hardware shows rust in months | IEC 61701 Severity 6; sealed J‑boxes; UV‑resistant backsheets or glass‑glass | 316 SS fasteners; marine‑grade anodization; hydrophobic coatings; IP68 connectors |

| Agricultural or industrial atmospheres | Ammonia or chemicals in air | IEC 62716 ammonia resistance; robust encapsulant (POE favored) | Regular wash plans; gasketed combiner boxes; tinned copper conductors |

Design and O&M practices that reduce risk

Hail: structural and operational control

- Glass and frame: Choose 3.2 mm tempered glass and frames with strong corner keys. More frame screw points reduce torsion.

- Mounting: Prefer mid‑clamps at certified zones and adequate rail stiffness. Avoid overhangs that invite bending.

- Hail stow: For trackers, use a high‑tilt stow setting aligned with storm vectors. Automate with weather feeds and test the sequence each season.

Snow: keep loads predictable

- Geometry: Higher tilt helps shedding. Maintain row spacing for drifts and avoid trapping snow behind obstructions.

- Structural path: Confirm module‑to‑rail‑to‑purlin load paths for 5400 Pa front loads with the exact clamp layout.

- Operations: Clear critical accumulations at string combiner locations. Inspect for frame bowing after storms.

Salt‑mist: slow the corrosion clock

- Materials: 316 stainless hardware, thick anodization, sealed J‑boxes, and double‑glass modules decrease ingress.

- Interfaces: Use UV‑ and salt‑resistant cable jackets; apply dielectric grease on connectors if allowed by the datasheet.

- Maintenance: Rinse with fresh water per OEM guidance. Track insulation resistance and contact resistance over time.

Standards, data points, and why site matching works

Tailoring technology to site conditions is a recognized best practice. Getting Wind and Solar onto the Grid notes that avoiding poor siting decisions prevents technical issues and curbs outages through better planning. System Integration of Renewables highlights that deployment aligned with local conditions improves adequacy and reduces stress on assets. The Technology Roadmap – Solar Photovoltaic Energy 2010 reports that modern inverters and systems can support broader operating ranges, which helps O&M teams run protective stow or curtailment strategies during extreme events. Recent innovation tracking in The State of Energy Innovation points to ongoing material and reliability improvements, which you can leverage by specifying certified, current‑generation modules.

As deployment scales, small error rates add up. Public data from the EIA shows rapid PV capacity growth in multiple regions, which increases exposure to a wide range of climates. Global policy and market analysis from IRENA reinforces the value of quality assurance and standards in sustaining performance. For fundamentals and design resources, see the U.S. Department of Energy solar energy pages.

Helpful calculations

- Converting ratings: 5400 Pa ≈ 113 psf. 2400 Pa ≈ 50 psf.

- Simple safety factor: If roof snow load on the module is 30 psf, a 113 psf front rating gives a static safety factor ≈ 3.8. Aim for ≥1.5 after accounting for clamps and rails.

- Hail energy: 25 mm at 23 m/s ≈ 2 J; 35 mm at 27 m/s ≈ 7 J. Larger ice increases damage steeply. Use enhanced hail ratings in large‑hail regions.

Procurement checklist for site‑specific ratings

- State the required hail rating (ice diameter and speed), snow rating (Pa front/rear), and salt‑mist severity (IEC 61701 level) on drawings and in the module data sheet requirement.

- Lock the bill of materials (glass thickness, frame alloy, encapsulant type, backsheet or glass‑glass). Require third‑party certificates for the exact BOM.

- Specify clamp zone, clamp type, rail gauge, and torque values. Ask the module supplier to sign off on the mounting layout.

- For hail belts, require a tracker hail‑stow method statement and a test of the automated trigger at site.

- For coastal sites, require corrosion‑resistant fasteners and a maintenance plan for rinsing and inspection.

Cost and risk: a quick look

Enhanced hail and salt packages often add a small premium compared with the potential loss from a single storm. Even a modest increase in module and mounting cost can be justified if it avoids widespread glass breakage, PID from moisture ingress, or corrosion‑driven downtime. The key is local hazard data plus standards‑based specifications, rather than generic ratings.

Real‑world application examples

- Great Plains utility site: Enhanced hail rating (≥35 mm), 3.2 mm glass, dense mid‑clamping, and automated hail stow cut breakage rates in past seasons. Insurance terms improved after documented stow drills.

- Alpine C&I roof: Snow rating 5400 Pa, verified clamp zones, rail span reductions, and thermal breaks at penetrations limited frame bending. Post‑storm IR scans showed no cell hot spots.

- Coastal microgrid: Salt‑mist Severity 6 modules, 316 SS hardware, glass‑glass, and quarterly fresh‑water rinses stabilized insulation resistance. Connectors stayed within milliohm targets across two years.

Practical tender language you can reuse

“Modules shall be certified to IEC 61215/IEC 61730 and meet: (a) Hail impact class: ≥mm at m/s; (b) Mechanical load: ≥5400 Pa front, ≥2400 Pa rear for the specified clamp pattern; (c) Salt‑mist resistance: IEC 61701 Severity . Supplier shall lock BOM and provide certificates for the exact BOM. Mounting layout and clamp zones must be approved in writing by the module supplier. For tracker sites in hail regions, supplier shall provide a documented hail‑stow method and validate automated stow prior to COD.”

Pair these specifications with resilient power electronics and storage to sustain operations during protective stows, curtailment, or grid events. DOE and IEA materials (DOE solar; IEA roadmap) provide helpful context for control strategies.

Key takeaways

- Stop failures by matching hail, snow, and salt‑mist ratings to the site, not a generic spec.

- Translate hazards into specific numbers: hail ice size/speed, Pa loads, IEC 61701 severity level.

- Tie ratings to mounting, clamp zones, and O&M plans. Ratings alone are not the full story.

Disclaimer: Engineering and code topics herein are for general information only and do not constitute design, legal, or insurance advice.

FAQ

How high should my hail rating be in large‑hail regions?

Target ≥35 mm ice at elevated speeds with certification evidence. Combine this with sturdy frames, certified clamp zones, and a tracker hail‑stow program to reduce risk.

Is a 5400 Pa snow rating always enough?

Often yes, if the clamp pattern and rail spans match the certification. Check your site’s design snow load, tilt, drift potential, and keep a safety factor ≥1.5 for static load.

How close to the shore justifies IEC 61701 Severity 6?

As a rule of thumb, within ~5 km of open coast or any site with visible salt spray. For harbors or offshore, Severity 6 is standard practice. Inland brackish lakes may need similar care.

Does bifacial change these requirements?

The environmental ratings still apply. Verify rear mechanical load limits and ensure frames and clamps support the certified loads. For coastal sites, rear glass helps with salt ingress.

Do operations really matter if I pick strong hardware?

Yes. Hail stow, snow management, and corrosion maintenance cut risk significantly. Standards validate strength; operational discipline keeps assets within those limits.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.