In solar energy systems, safety and grid stability are paramount. Two standards, IEEE 1547 and NEC Article 690, provide the foundational rules for achieving these goals. IEEE 1547 dictates how systems connect to the electrical grid, while NEC 690 ensures the installation is electrically safe. A critical challenge arises at the intersection of these two standards: the interaction between inverter-generated harmonics and Arc-Fault Circuit Interrupter (AFCI) devices. This alignment is crucial for preventing system downtime and ensuring operational integrity.

Understanding Harmonics in Solar PV Systems

Modern solar installations rely on inverters to convert DC power from panels into usable AC power. This conversion process, while efficient, is not perfect and can introduce distortions into the electrical grid. These distortions are known as harmonics.

What Are Harmonics and Why Do They Matter?

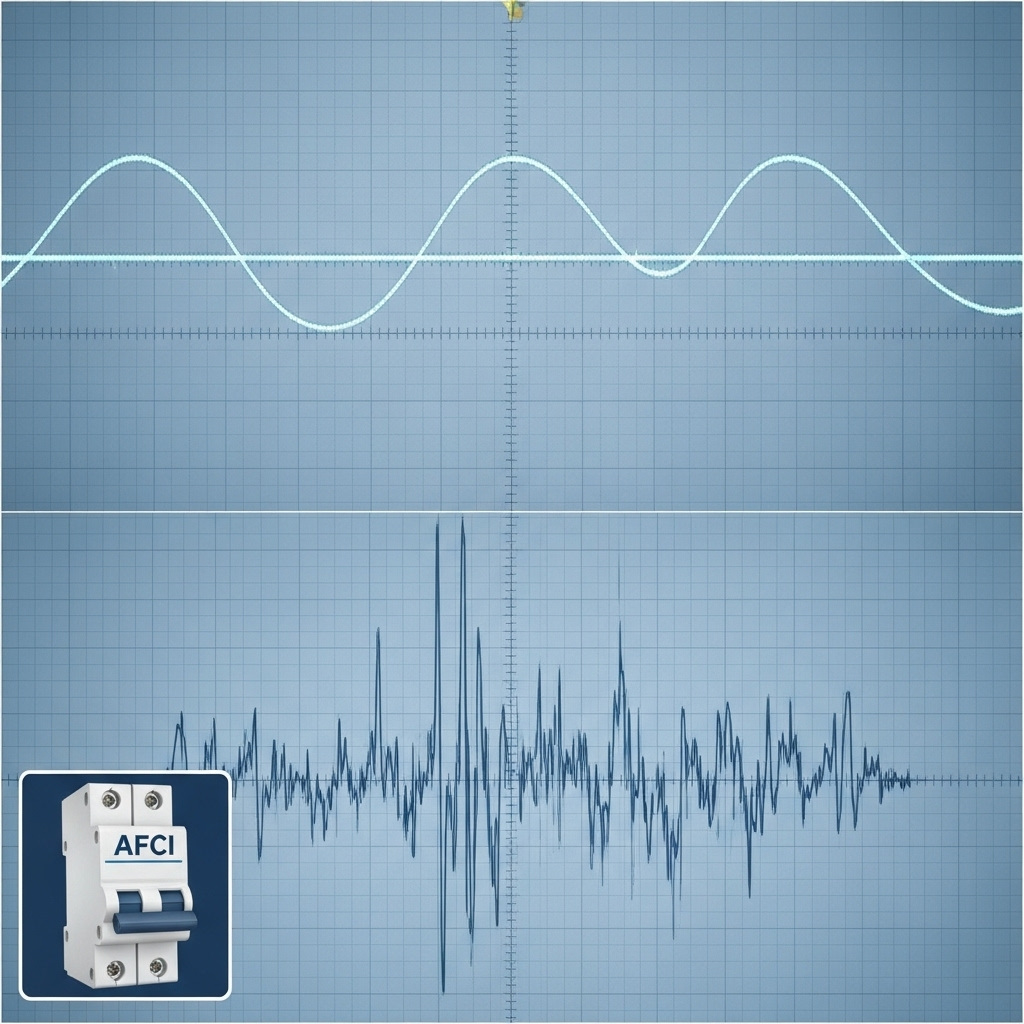

Harmonics are electrical voltages and currents that operate on a frequency that is a multiple of the fundamental frequency. In simple terms, they are a form of electrical 'noise' that distorts the clean, smooth sine wave of AC power. This noise is primarily generated by power electronic devices, with solar inverters being a common source. According to the International Renewable Energy Agency's research in Grid Codes for Renewable Powered Systems, these distortions can even include interharmonics, which are not integer multiples of the fundamental frequency and can cause issues like flicker. Unchecked harmonics can lead to overheating in equipment, reduced system efficiency, and interference with sensitive electronics.

IEEE 1547 and Harmonic Distortion Limits

IEEE 1547 is the definitive standard for interconnecting Distributed Energy Resources (DER), including solar PV systems, with the electric grid. A key function of this standard is to set strict limits on the amount of harmonic distortion a system can export to the grid. This ensures that individual solar installations do not collectively degrade the power quality for all utility customers. The standard provides specific limits for Total Harmonic Distortion (THD) as well as for individual harmonic orders. Adherence to these limits is mandatory for grid-tied systems to maintain a stable and reliable power supply. Below is a table illustrating typical harmonic distortion limits.

| Standard Type | Harmonic Order (h) | Distortion Limit | Total Harmonic Distortion (THD) |

|---|---|---|---|

| IEEE 1547 | Odd (3 ≤ h ≤ 9) | <4% | <5% |

| IEEE 1547 | Odd (11 ≤ h ≤ 15) | <2% | <5% |

| IEEE 1547 | Odd (17 ≤ h ≤ 21) | <1.5% | <5% |

| IEEE 1547 | Odd (23 ≤ h ≤ 33) | <0.6% | <5% |

| IEEE 1547 | Even (2 ≤ h ≤ 8) | <1% | <5% |

The Role of AFCI in NEC 690 for PV Safety

While IEEE 1547 manages grid interaction, NEC Article 690 focuses on protecting property and personnel from electrical hazards originating within the solar installation itself. One of its most critical safety requirements is the use of arc-fault protection.

Preventing Fire Hazards with Arc-Fault Protection

An arc fault is a dangerous electrical condition where current flows through an unintended path, often through the air, creating a high-intensity discharge. In a PV system, this can be caused by damaged wiring, loose connections, or insulation failure. The resulting arc can reach extremely high temperatures, posing a significant fire risk. NEC 690 mandates the use of AFCI technology to detect these conditions and de-energize the circuit before a fire can start, dramatically improving the safety profile of solar installations.

How AFCI Devices Detect Arc Faults

AFCI devices are sophisticated electronic circuits that continuously monitor the electrical waveform. They are programmed to recognize the unique, irregular signatures and high-frequency noise characteristic of a dangerous arc fault. When such a signature is detected, the AFCI trips the circuit almost instantaneously, cutting off the flow of electricity. This sensitivity is key to their effectiveness but also creates a potential conflict with the normal operation of some solar inverters.

The Conflict: When Harmonics Trigger AFCI Nuisance Tripping

The primary challenge in aligning IEEE 1547 and NEC 690 lies in the sensitive nature of AFCIs and the harmonic 'noise' produced by inverters. While this noise is typically within the limits set by IEEE 1547, it can sometimes be misinterpreted by an AFCI as a hazardous arc fault.

Why Inverter Harmonics Can Mimic Arc Faults

Modern solar inverters use high-frequency switching to efficiently manage power, particularly for functions like Maximum Power Point Tracking (MPPT). This rapid switching, while essential for performance, generates electrical noise and harmonic currents as a byproduct. The frequency and amplitude characteristics of this operational noise can closely resemble the signatures that an AFCI is designed to detect as an arc fault. This overlap can lead the AFCI to trip the system, even when no actual danger is present. This phenomenon is commonly referred to as nuisance tripping or false tripping.

Consequences of Nuisance Tripping

Nuisance tripping is more than a minor inconvenience. It results in unexpected system shutdowns, leading to a direct loss of energy production and financial returns. For installers, it means costly and time-consuming service calls to diagnose a problem that isn't a true safety hazard. For system owners, it can erode confidence in the reliability of their solar investment. Differentiating between a nuisance trip and a genuine arc fault requires careful diagnostics, making system reliability a primary concern.

Strategies for Aligning Harmonics and AFCI Protection

Resolving the conflict between inverter harmonics and AFCI sensitivity requires a multi-faceted approach, focusing on component selection, system design, and ongoing maintenance.

Selecting Compliant Inverters and Components

The first line of defense is to select inverters that are not only certified to the latest IEEE 1547 standards but are also specifically designed and tested for compatibility with AFCI devices. Manufacturers are increasingly aware of this issue and are developing inverters with advanced filtering and software algorithms to minimize harmonic noise that could cause false trips. Evaluating the technical specifications of all system components is vital. A comprehensive understanding of solar storage performance can provide crucial insights into how different components interact, helping you choose equipment that promotes a stable and reliable system.

Proper System Design and Installation Practices

High-quality system design and meticulous installation are critical. Best practices include maintaining proper separation between DC and AC conductors to prevent inductive interference. Using shielded wiring for critical circuits can also help contain electrical noise. Furthermore, ensuring all electrical connections are secure and properly torqued minimizes the potential for both real arc faults and sources of electrical noise. A well-executed grounding system is also fundamental to providing a path for stray currents and reducing system-wide noise.

The Importance of Firmware and Software Updates

Inverter technology is constantly evolving. Manufacturers frequently release firmware updates that can refine the inverter's operating parameters, improve its harmonic profile, and enhance its compatibility with AFCI technology. Regularly checking for and applying these updates is a simple yet effective way to ensure the system is operating with the latest optimizations. These updates can often resolve nuisance tripping issues without requiring any physical changes to the hardware.

A Forward Look at Standards and Technology

Achieving harmony between the grid stability goals of IEEE 1547 and the safety mandates of NEC 690 is essential for the continued growth of the solar industry. The solution is not to compromise on either safety or performance but to advance technology and practices to meet both standards seamlessly. Through the selection of advanced, compliant inverters, adherence to rigorous design and installation standards, and diligent system maintenance, installers and system owners can build solar energy systems that are safe, reliable, and efficient grid assets for years to come.

Frequently Asked Questions

What is the main difference between IEEE 1547 and NEC 690?

IEEE 1547 primarily governs how distributed energy resources, like solar PV systems, interconnect and interact with the electric grid, focusing on grid stability and power quality. NEC 690, part of the National Electrical Code, focuses on the electrical safety of the solar installation itself, covering wiring, overcurrent protection, grounding, and devices like AFCIs.

Can I disable the AFCI to prevent nuisance tripping?

Disabling a required safety device like an AFCI is a violation of the NEC and creates a significant fire risk. It is not a recommended or permissible solution. The proper approach is to diagnose and resolve the root cause of the tripping, which may involve component selection, installation adjustments, or firmware updates.

Are all solar inverters compatible with all AFCI devices?

Not necessarily. Compatibility can vary, and it is important to consult manufacturer documentation for both the inverter and the AFCI device. Modern inverters are increasingly designed and tested for compatibility, but issues can still arise, especially with older equipment or mismatched components. Selecting components that are listed and tested as a system is the best practice.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.