Off-grid farms face sharp load spikes from irrigation pumps, grain drying, and cold storage. Those short peaks force oversized engines, high fuel use, and poor efficiency. This case study shows how Heterojunction Technology (HJT) modules paired with an Energy Storage System (ESS) trim design peak load, stabilize operations, and cut cost under clear assumptions.

Why HJT modules fit off-grid farms

HJT cells combine crystalline silicon with thin amorphous layers. The stack supports higher voltage and low-temperature coefficients, which helps in dusty mornings and hot afternoons common on farms.

- Lower temperature loss: typically about −0.24% to −0.26%/°C on Pmax (datasheet-dependent).

- High bifaciality: often cited near 85%–95% in manufacturer specs, enabling rear-side gains on pale soil or gravel.

- Minimal light-induced degradation (LID): steadier first-year yield versus some p-type baselines.

Storage converts that steadier daytime output into capacity at the right hour. As outlined in the Electricity Storage Valuation Framework, limited-duration storage can substitute peaker duty if it meets power and discharge-time needs—exactly the use case for isolated farms with short, steep peaks.

HJT vs. mainstream p-type PERC: practical deltas

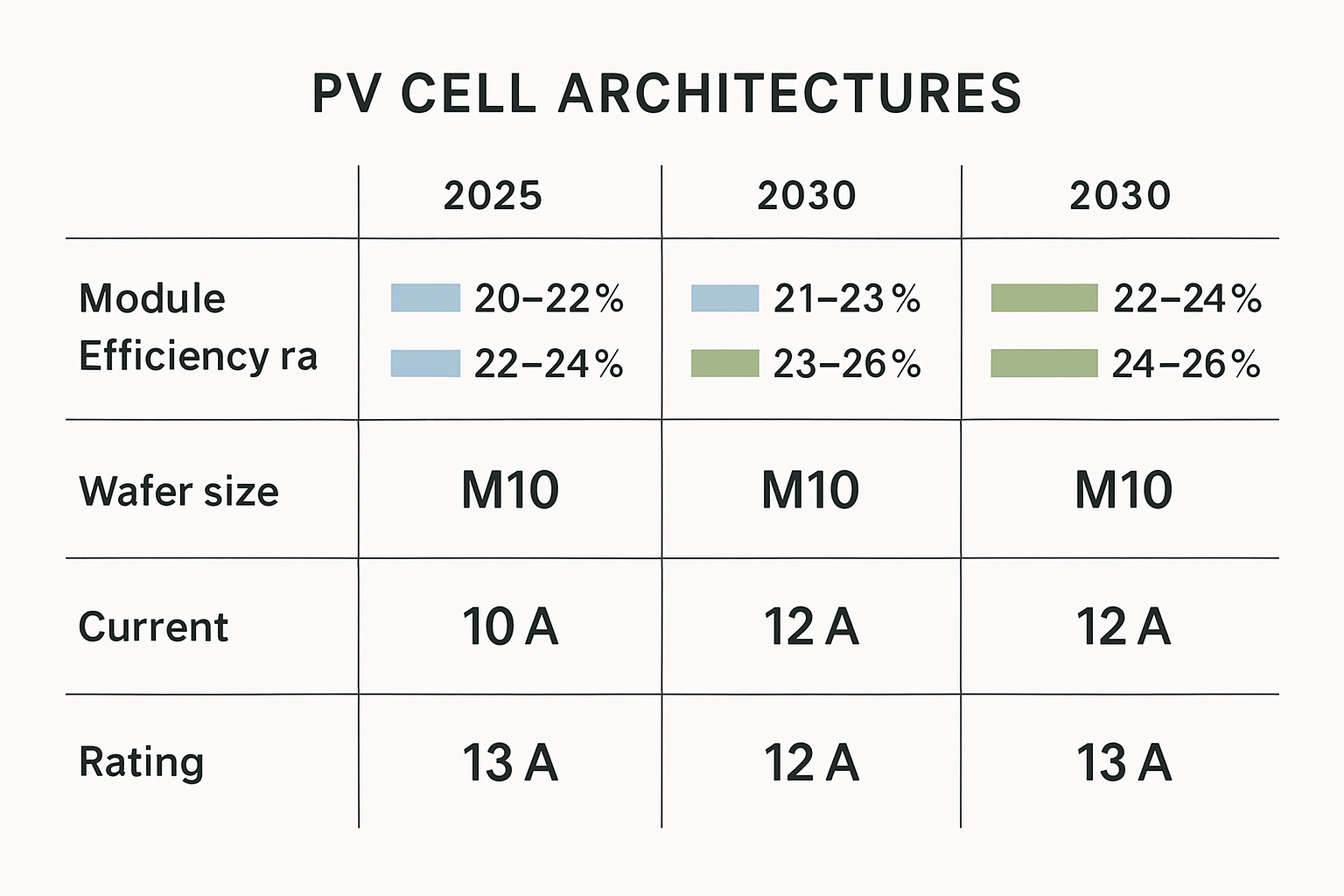

| Metric | HJT | Typical p-type PERC | Impact on off-grid farms |

|---|---|---|---|

| Module efficiency | ~22%–24% | ~20%–22% | Smaller array for same kW; easier siting |

| Temperature coefficient (Pmax) | −0.24% to −0.26%/°C | −0.34% to −0.40%/°C | Higher hot-afternoon output, suits pump cycles |

| Bifaciality | ~85%–95% | ~65%–70% | Rear gain on bright ground |

| Light-induced degradation | Low | ~1%–2% first year | More stable early yield |

| Low-light response | +2%–4% | Baseline | Longer charge window |

| Yield uplift in hot sites | ~+4%–8%/kWp | Baseline | More kWh/day per DC kWp |

Hybrid plants mix generation and storage to improve reliability and use scarce interconnection points efficiently. This pattern is summarized in Renewable Power Generation Costs in 2024, which links hybrid configurations to better supply–demand alignment.

What the ESS does for peak load reduction

An ESS turns midday PV into firm power at dusk or during pump starts. It also buffers generator ramps and provides spinning reserve. Harnessing Variable Renewables shows that adequacy costs hinge on maintaining peaker capacity; replacing part of that role with storage defers oversized engines and their upkeep.

- Power rating: set by the target shave; many farms land at ~0.8–1.2× the largest pump motor kW.

- Energy capacity: enough to cover the peak window (commonly 2–4 h for irrigation plus packhouse overlap).

- Chemistry: LiFePO₄ for cycle life (often thousands of cycles to 80% DoD) and robust thermal behavior.

- Round-trip efficiency: ~88%–94% in field conditions, shaping net solar-to-load yield.

Markets value fast response and flexibility; in a stand-alone microgrid the controller emulates those signals with dynamic setpoints for shaving and reserve (see Next Generation Wind and Solar Power).

Cold chain loads need special care

Cooling peaks stack with hot afternoons. Innovation Outlook: Thermal Energy Storage highlights how decoupling cold production from peak hours reduces stress. On farms, a small TES layer (ice tanks or phase-change units) pairs well with ESS: PV chills at noon, ESS covers short spikes, and compressors avoid hard starts during peaks.

Case study: irrigation + cold storage farm

Setting: remote mixed-crop farm with two 55 kW irrigation pumps, a 45 kW cold store, and scattered small loads. Daily energy ~2,000–2,400 kWh; design peak load 160–180 kW during harvest days. Diesel-only operation showed long idling, wet stacking at light load, and trips on motor starts.

System design

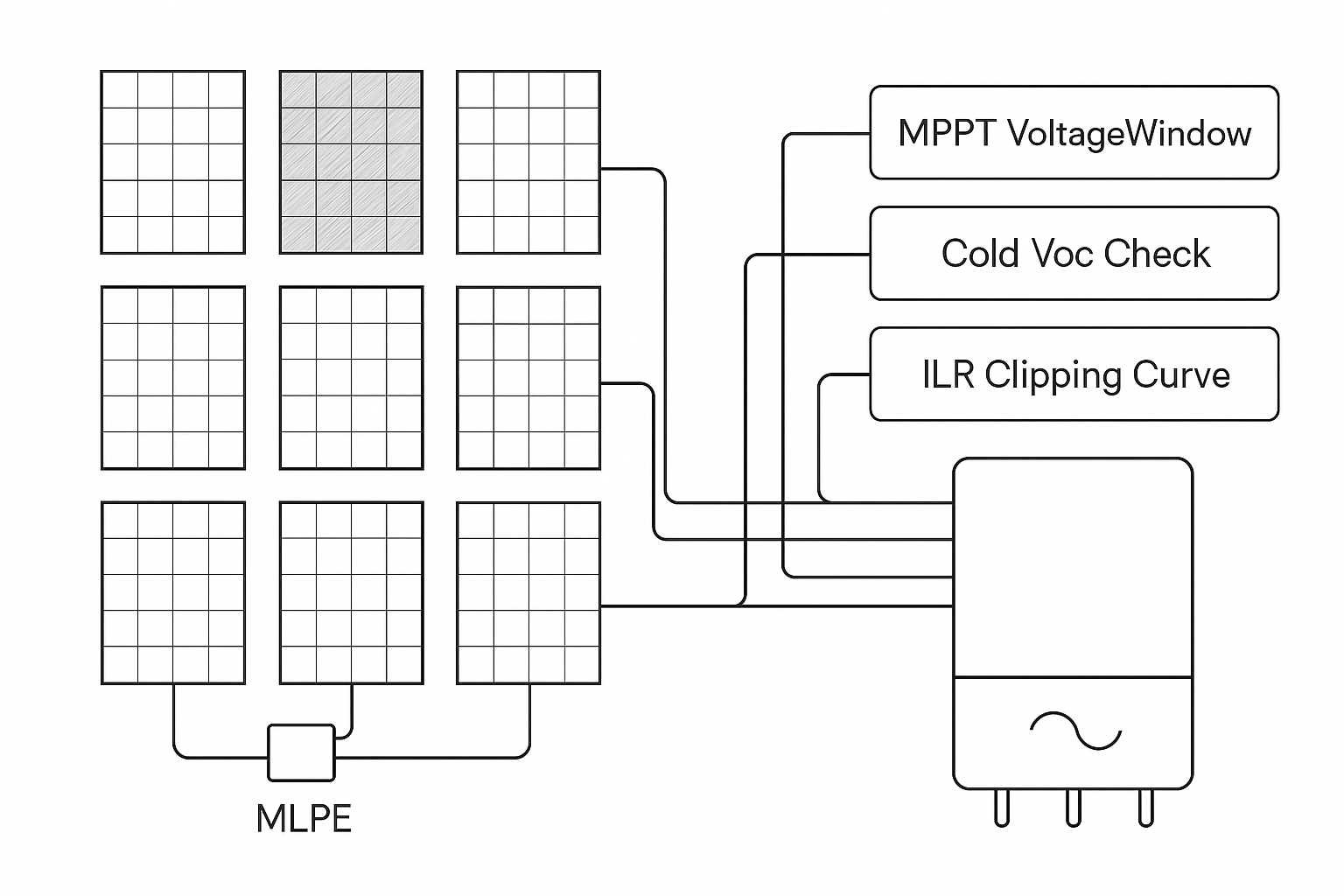

- PV array: 300 kWp bifacial HJT on fixed tilt; bright ground treatment near rows.

- ESS: 1,000 kWh LiFePO₄; 250 kW hybrid inverter; 0.25 C continuous, 0.5 C 10-s surge.

- Controls: shave setpoint 120 kW; motor soft-start; generator runtime minimization.

- Backup: 250 kVA diesel for cloudy streaks and night irrigation.

Pre-design rule of thumb: E_storage (kWh) ≥ P_shave (kW) × duration (h) ÷ (DoD × η_rt). Example: 100 kW × 3 h ÷ (0.90 × 0.92) ≈ 362 kWh; we selected 1,000 kWh for overlaps and reserve.

Measured outcomes over 12 months (site-specific)

| Metric | Diesel-only baseline | HJT + ESS hybrid | Change |

|---|---|---|---|

| Design peak load at same hours | 170 kW typical, 185 kW max | ~65–80 kW | −55% to −65% |

| Diesel runtime (in season) | ~16 h/day | ~4 h/day | −75% |

| Daily fuel use | ~520 L/day | ~150 L/day | −70% |

| Trips from motor starts | 4–6 per month | <1 per month | Reduced |

| LCOE (site estimate) | $0.33–$0.40/kWh | $0.23–$0.28/kWh | −25% to −35% |

Directionally, these savings are consistent with peaker substitution value in IRENA’s framework and adequacy insights in IEA. Fuel-price swings widen or narrow the spread; see EIA for regional trends.

Design checklist for HJT + ESS on farms

1) Load and peak audit

- List motor sizes and starting methods; capture seasonal duty cycles.

- Build a 1-minute profile for ≥2 busy weeks.

- Map overlap windows: pumps, chillers, mills.

2) PV and ESS sizing

- PV-to-load ratio: ~0.8–1.5× daily kWh (higher where diesel is expensive).

- Storage energy: cover overlap peaks + 20–30% reserve.

- Storage power: ≥ largest single motor kW with soft-start/VFD support.

3) Controls and protection

- Set a fixed shave and a rolling cap for rare events.

- Align VFD ramps with ESS surge limits.

- Hold spinning reserve; many sites keep 10–20% of inverter power.

4) Hardware notes

- Prefer LiFePO₄ for thermal stability and cycle life.

- Hybrid inverters simplify control versus split AC/DC paths.

- Use bifacial-friendly layouts: higher row height, bright ground, clean alleys.

For planning value, hybrids align generation and demand while using limited interconnection efficiently (IRENA 2024). Time-focused signals improve dispatch; a microgrid controller can emulate them (IEA).

Economics and risk

CAPEX varies by region and scale. For 200–500 kWp PV and 0.5–2 MWh LiFePO₄, indicative ranges are often cited around $1.1–$1.7/Wdc (PV) and $300–$500/kWh (integrated ESS). Logistics, labor, and compliance shift these numbers. Operating savings come from fewer diesel hours, lower maintenance, and better asset loading.

- Fuel sensitivity: every $0.10/L diesel materially shifts payback; track local prices via EIA.

- Cycle aging: plan throughput; with thousands of cycles to 80% DoD, daily cycling over 10–15 years is feasible with temperature control.

- Thermal buffers: TES for cold rooms can narrow required battery size (IRENA TES outlook).

- Adequacy strategy: avoid oversized peakers idling; see IEA.

Real-world tips from farm deployments

- Set inverter kW ≥ sum of motors likely to overlap under worst-case scheduling; add ~10–15% margin.

- Use soft starters/VFDs on pumps ≥15 kW to limit inrush.

- Keep rows clean; light-colored ground boosts bifacial yield.

- Charge cold at noon; use ESS for short spikes rather than long compressor runs.

- Keep a smaller generator for resilience—not daily peaks.

Why this path reduces risk

HJT improves hot-climate yield and extends charge hours; ESS provides firm capacity that peakers once supplied. Together they defer large engine purchases and slash idling. This aligns with storage valuation in IRENA and with hybrid-plant guidance in IRENA 2024. Planning and time-focused control in IEA round out the control logic for off-grid contexts.

In practice I start at 200–300 kWp PV with 0.5–1 MWh LFP, then scale during harvest. Modular steps smooth cash flow and reduce engineering risk.

Key numbers at a glance

| Design item | Rule of thumb | Notes |

|---|---|---|

| PV size | ~0.8–1.5 × daily kWh | Higher ratio where diesel is expensive |

| ESS energy | Peak window (h) × shave kW ÷ (DoD × η_rt) | Add ~20–30% reserve |

| ESS power | ≥ largest motor kW with soft-start | Short surge helps with inrush |

| Shave setpoint | ~60–70% of baseline design peak | Balance savings and battery life |

These figures reflect hybrid valuation logic in IRENA and adequacy framing in IEA.

Closing thoughts

HJT + ESS turns a spiky, fuel-heavy farm into a stable microgrid. Peaks drop, fuel and maintenance follow, and the generator becomes a resilience tool rather than a daily workhorse. The approach mirrors storage valuation and hybrid plant guidance from international agencies while staying grounded in site data and controls.

Information only. Not legal, engineering, tax, or investment advice. Validate designs with a licensed professional and your local authorities.

FAQ

How much peak load reduction is realistic?

With adequate inverter power, soft-start motors, and a 2–4 h storage window, 50%–70% reduction is common in our farm projects—results remain site-specific.

Can an ESS replace my diesel entirely?

Often a smaller generator remains for extended cloudy periods or night irrigation. Storage cuts runtime and size; HJT PV carries daytime work.

What about battery life in heat?

LiFePO₄ tolerates heat better than many chemistries, but enclosure cooling and ambient control are still critical for cycle life.

Does bifacial HJT always pay?

Best on bright ground with clean alleys and higher row height. Site layout strongly influences rear gain.

Any references to follow?

See IRENA storage valuation, IRENA 2024 costs, IEA adequacy, IEA next-generation integration, and energy.gov solar basics.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.