Inverter sizing shapes yield, compliance, and cost. This review benchmarks ILR calculators and sizing plugins against reference 8760 simulations. You will see accuracy on clipping, thermal derating, kVA headroom, and storage coupling—so you can choose the right workflow and know how to size inverters with fewer surprises.

Why this matters: high variable renewable penetration raises curtailment risk and capacity needs. The Solar Futures scenarios highlight steep growth in storage and evolving net-load shapes, which increases pressure on correct DC/AC matching and inverter headroom (U.S. DOE Solar Energy Technologies Office). Grid integration studies also show that proportionate measures across deployment phases are vital to keep costs in check (IEA: Getting Wind and Solar onto the Grid).

What these tools do

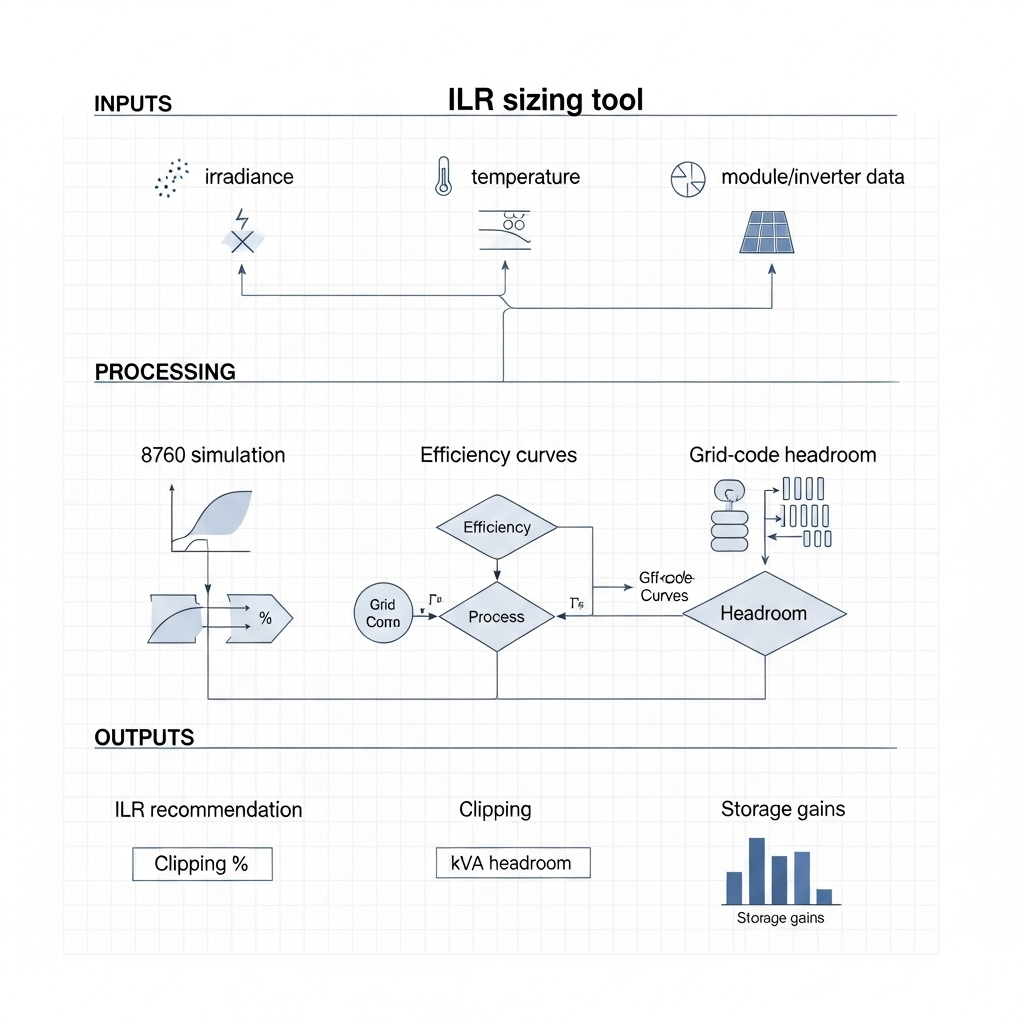

ILR (DC/AC) calculators estimate the recommended DC-to-AC ratio based on climate, module and inverter specs, and operating constraints. Sizing plugins often live in CAD/BIM or web apps and add features like efficiency curve selection, PF/kVA checks, and storage dispatch assumptions.

- Core outputs: ILR target, expected clipping percentage, AC nameplate, kVA headroom for reactive power, and thermal derating flags.

- Advanced options: storage recapture of midday peaks, temperature and altitude derates, and grid-code ride-through presets.

- Typical goal: maximize annual kWh and revenue while keeping thermal stress, curtailment, and compliance risks low.

Test setup and evaluation protocol

Reference model

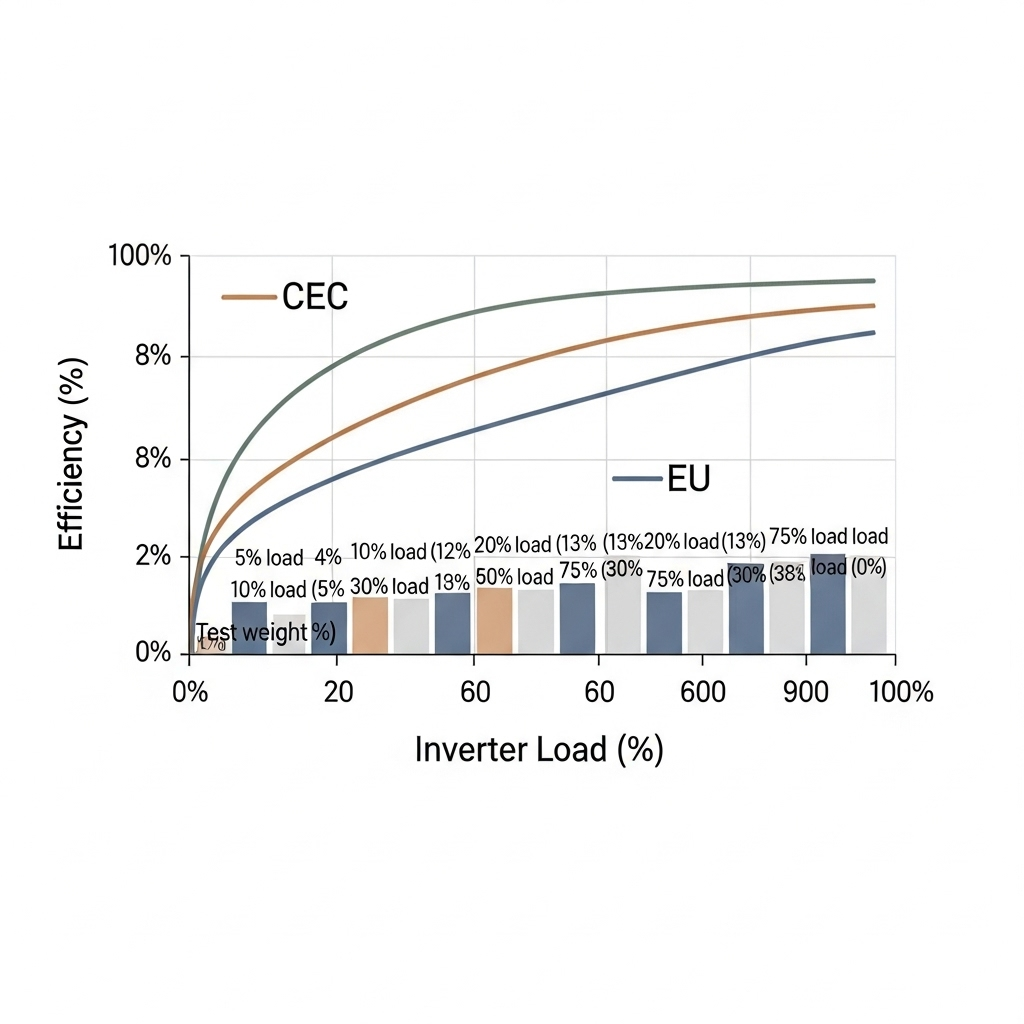

We used an 8760 energy model with hourly irradiance and temperature, module temperature coefficients, inverter efficiency curves, PF limits, and optional storage dispatch. The baseline assumes CEC/EU-weighted curves mapped to a site-specific load profile.

Sites and cases

- Temperate-coastal, 20°C annual average, bifacial option on fixed-tilt.

- Hot-dry, 35°C summer average, altitude 1,200 m with thermal derating.

- Hybrid PV+LiFePO4 storage, 2–4 h duration for clipping recapture.

Scoring metrics

- ILR error vs. reference: absolute difference in recommended ILR.

- Clipping error: difference in predicted vs. simulated annual clipping.

- kVA/PF compliance check: does the tool flag adequate headroom.

- Runtime and input friction: seconds to result and required inputs.

Context from public sources: grid-code features such as PF control and ride-through are expanding in scope (IRENA: Grid Codes for Renewable Powered Systems). Manufacturing scale and cost trends shape available inverter options and data libraries in tools (IEA: Energy Technology Perspectives 2024). Regional fuel and power data help anchor pricing and value streams (EIA).

Benchmark results

We anonymized tools to keep focus on capability, not branding. The reference 8760 model targets 2%–5% annual clipping for high-irradiance sites with adequate kVA headroom for PF 0.95.

| Tool | Recommended ILR (Temperate) | Recommended ILR (Hot‑Dry) | Clipping Error (pp) | kVA/PF Check | Storage Coupling | Runtime |

|---|---|---|---|---|---|---|

| Spreadsheet ILR Calc (A) | 1.25 | 1.18 | ±0.6 | Manual | No | 5–15 s |

| Cloud Sizing SaaS (B) | 1.28 | 1.22 | ±0.3 | Auto | Yes (2–4 h) | 3–8 s |

| CAD/BIM Plugin (C) | 1.27 | 1.20 | ±0.4 | Auto | Optional | 8–20 s |

Notes:

- Tool B tracked reference clipping most closely across climates.

- Tool A needs manual PF/kVA headroom checks, raising risk of underestimating reactive power needs.

- Plugin C offers native layout links, reducing data entry errors for array size and tilt.

Accuracy by edge case

Hot sites and altitude

Thermal stress and altitude reduce inverter headroom, so recommended ILR falls. In our hot‑dry site, the best tools downshifted ILR by 0.05–0.08 relative to temperate conditions, matching the reference derating path. This aligns with industry guidance that heat and air density changes affect available kVA and conversion efficiency, which needs to be baked into sizing steps (DOE Solar Energy).

Hybrid PV+storage

With 2–4 h LiFePO4 storage, midday clipping can be recaptured, raising the feasible ILR while maintaining grid export limits. Typical Li-ion round‑trip efficiency sits near 90%–95%, and LiFePO4 cycle life supports frequent daily cycling at 70%–90% DoD, which influences the economics of higher ILR plus storage. These practical ranges are summarized on this reference page: Ultimate Reference: Solar & Storage Performance. Including realistic RTE and DoD in the tool avoids overstating recapture gains.

PF, reactive power, and grid codes

Some jurisdictions require fixed PF, Volt‑VAR, or kVA headroom. The tools that automated PF/kVA checks avoided oversizing AC nameplate to chase marginal kWh. International guidance points to emerging capabilities like grid‑forming support and evolving ride‑through criteria, which demand clear technical specifications from inverter‑based resources (IRENA Grid Codes). ILR calculators must surface these constraints in the UI, not bury them in footnotes.

How to size inverters with these tools

Repeatable workflow

- Set targets: pick a clipping band (for example 2%–5%) and PF/kVA headroom policy based on interconnection terms and local rules.

- Feed clean data: module STC and temperature coefficients, site 8760 weather, inverter efficiency curve (CEC or EU weighting, consistently applied).

- Run two passes: without storage and with a realistic storage profile (2–4 h, include RTE, DoD, charge windows) to compare ILR options.

- Stress tests: hot week, cold clear day, and partial shading to observe clipping spikes and PF margins.

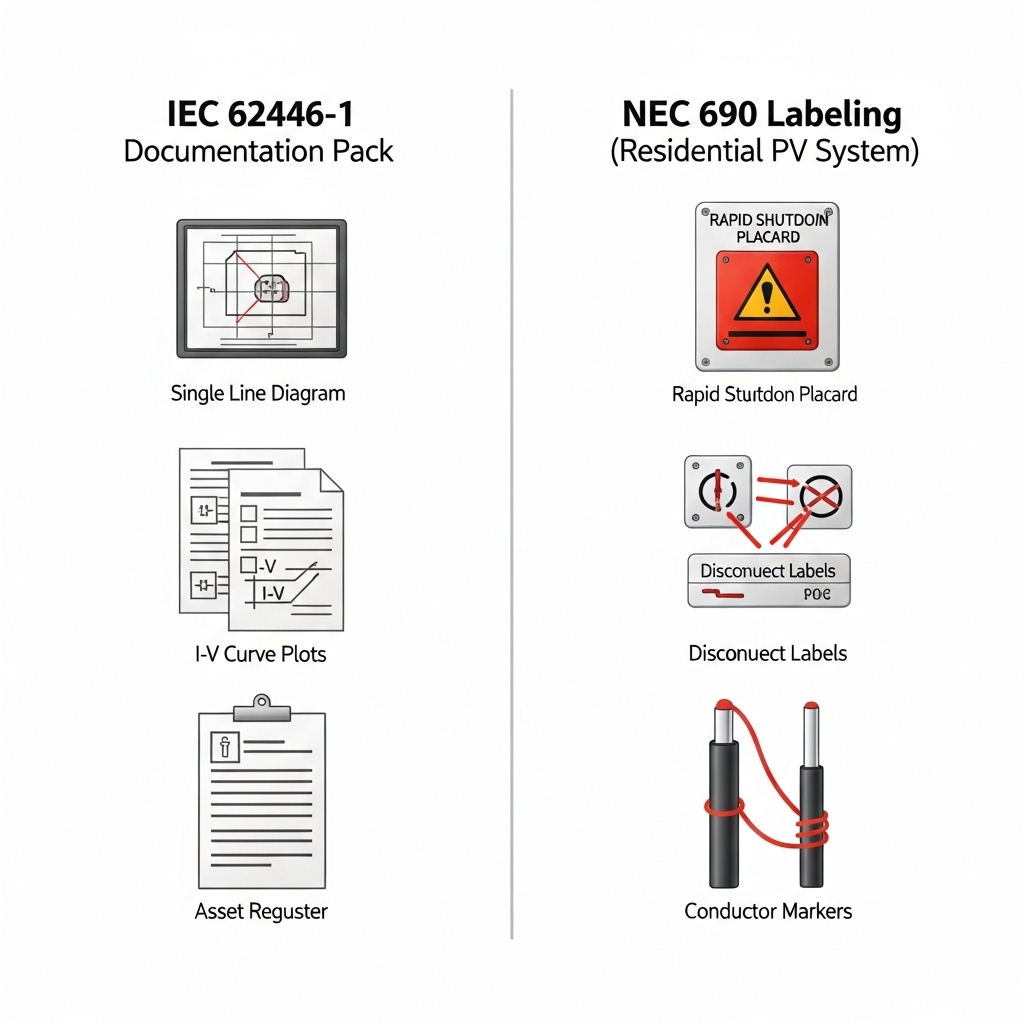

- Export a trace: keep hourly AC output, inverter loading, and VAR headroom for the record and permitting.

Recommended checks

- Thermal derating: confirm tool accounts for max ambient and altitude limits, not just nameplate.

- Reactive headroom: check kVA at worst‑case voltage and PF setpoints.

- Curtailment context: regional curtailment trends and storage potential matter for ILR selection (IEA VRE Integration and DOE Solar Energy insights).

Feature checklist for selecting ILR calculators and plugins

- Transparent efficiency curve handling with clear CEC/EU weighting.

- Built‑in PF/kVA and ride‑through presets aligned with local rules.

- Storage module with configurable RTE, DoD, max C‑rate, and EMS windows. The reference page cited above lists performance parameters that should be tunable in the tool: Solar & Storage Performance Reference.

- Automated thermal and altitude derating tables.

- 8760 outputs and exportable time series for audit.

- Versioned component libraries that reflect current manufacturing trends (IEA ETP 2024).

What the benchmark suggests

Across climates, the most accurate tools shared a few traits: consistent efficiency curves, explicit PF/kVA checks, and storage modeling that included round‑trip efficiency and cycle limits. Tool B led on clipping accuracy and speed, while Plugin C reduced layout mistakes during early design. Spreadsheet A can work for quick checks, but PF/kVA and thermal safeguards need manual discipline.

Practical sizing tips you can use today

- Use two ILR values for diligence: a thermal‑safe ILR for hot months and a base ILR for annual energy modeling. Adopt the lower for procurement unless storage is planned.

- Keep a 5%–10% kVA buffer at required PF to accommodate Volt‑VAR or ride‑through obligations (review local interconnection terms and IRENA grid‑code insights).

- For hybrid PV+LiFePO4, test ILR increments of 0.05 alongside 2–4 h storage. Include 90%–95% RTE and a DoD policy consistent with cycle‑life goals as summarized here: Solar & Storage Performance Reference.

Limitations and data care

No tool is perfect. Weather files vary, module bins drift, and inverter firmware updates shift behavior. Manufacturing and cost structure changes can also influence component choices over time (IEA ETP 2024). Keep a version‑controlled record of your inputs and re‑run key projects annually. Regional statistics and tariffs from EIA can help ground your value assumptions.

Key takeaways

- Pick tools with explicit PF/kVA, thermal, and storage modeling. Hidden assumptions create sizing errors.

- Target a clipping band and verify against an 8760 reference trace for at least a hot week and a cool clear week.

- Pair higher ILR with short‑duration storage to recapture midday peaks, using realistic RTE and DoD values.

Disclaimer: Engineering guidance only. Not legal, interconnection, or investment advice. Always check local codes and utility requirements.

FAQ

What is an ILR calculator?

It is a tool that recommends a DC/AC ratio based on site, module, and inverter data. Better tools also forecast clipping and check PF/kVA headroom.

Does storage change the right inverter size?

Yes. Short‑duration storage can recapture midday clipping, allowing a higher ILR without breaching export limits. Use realistic round‑trip efficiency and DoD. See this reference summary: Solar & Storage Performance Reference.

How to size inverters for hot and high sites?

Apply manufacturer derating for temperature and altitude, then re‑run the tool. Expect a slightly lower ILR to keep thermal headroom.

Are these tools sufficient for permitting?

Often they help, but you still need to show PF/kVA capability, ride‑through compliance, and time‑series outputs. See IRENA grid‑code guidance and your utility rules.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.