The performance and longevity of an Energy Storage System (ESS) depend heavily on one critical factor: temperature. Effective thermal management is not just a feature; it’s the foundation of a reliable and safe energy solution. As the core of your system, the batteries need to operate within a specific temperature range to deliver optimal output and reach their expected lifespan. This brings us to a central question in ESS design: what is the best way to maintain that optimal temperature? The two primary methods are active liquid cooling and traditional air cooling. Each approach has distinct mechanisms, benefits, and ideal use cases. Understanding these differences is key to safeguarding your energy investment.

Why Temperature Control is Crucial for Your ESS

An ESS is a sophisticated system, and its lithium-ion batteries, particularly robust chemistries like Lithium Iron Phosphate (LiFePO4), are sensitive to their operating environment. Consistent, controlled temperatures are directly linked to the system's health, safety, and financial return.

Impact on Battery Lifespan and Performance

Extreme temperatures, both high and low, degrade battery cells. High temperatures accelerate chemical reactions inside the battery, leading to a faster loss of capacity and a shorter overall lifespan. Conversely, very low temperatures can hinder performance, reducing the available power. By maintaining a stable, optimal temperature, a thermal management system ensures you get the maximum number of cycles and the full value from your batteries.

Safety Risks of Overheating

The most significant risk associated with poor thermal management is thermal runaway. This is a chain reaction where an increase in temperature causes the system to release energy, which in turn increases the temperature further, potentially leading to fire. A robust cooling system is the first line of defense against such events, actively removing heat to keep cell temperatures well within safe operating limits.

Maintaining Optimal Operating Temperatures

Most LiFePO4 batteries perform best between 15°C and 35°C (59°F and 95°F). An effective ESS cooling solution is designed to keep the battery module consistently within this range, regardless of external weather conditions or how hard the system is working during charging and discharging cycles.

The Fundamentals of Air Cooling for ESS

Air cooling is a common and straightforward method for managing heat in electronic systems, including energy storage. It relies on the simple principle of using air to transfer heat away from the battery cells and out of the enclosure.

How It Works: Convection and Forced Air

Air cooling systems can be passive or active. Passive systems use natural convection, where hot air rises and is replaced by cooler air. Active air cooling, which is more common in ESS, uses fans to force air circulation. These fans pull cooler ambient air into the ESS cabinet, blow it across the surface of the battery modules, and exhaust the heated air. This constant airflow prevents heat from building up.

Advantages: Simplicity and Lower Initial Cost

The primary appeal of air cooling is its simplicity. The design involves fewer components—mainly fans, vents, and filters—which makes it easier to install and maintain. This simplicity generally translates to a lower upfront cost compared to more complex liquid cooling systems, making it an attractive option for smaller-scale or budget-conscious projects.

Limitations: Inefficiency in High-Density or Hot Environments

Air cooling has its limits. Air has a much lower heat capacity than liquid, meaning it cannot absorb and transfer heat as efficiently. In high-density ESS where many batteries are packed closely together, or in regions with high ambient temperatures, air cooling systems may struggle to remove heat fast enough. This can force the system to reduce its power output (derate) to prevent overheating.

How Active Liquid Cooling Steps Up the Game

For high-performance and large-scale applications, active liquid cooling offers a more powerful and precise thermal management solution. This method uses a coolant to absorb heat directly from the batteries and transport it away.

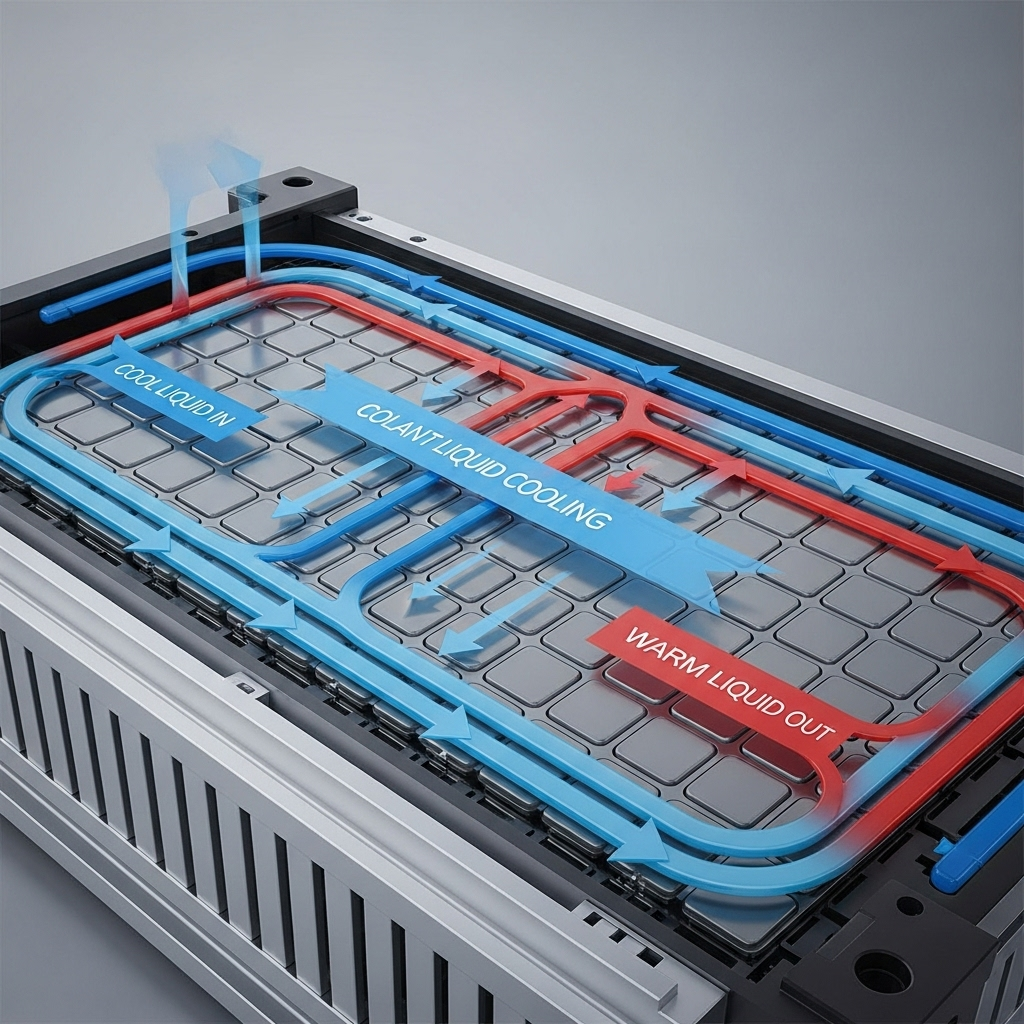

The Mechanism: Circulating Coolant for Direct Heat Transfer

An active liquid cooling system circulates a specialized coolant (often a water-glycol mixture) through pipes or cold plates that are in direct contact with the battery modules. The liquid absorbs the heat from the cells, then flows to a heat exchanger or radiator, where the heat is released into the ambient air, away from the ESS. The now-cooled liquid then circulates back to the batteries to repeat the process. This closed-loop system is highly efficient at targeted heat removal.

Key Benefits: Superior Heat Dissipation and Efficiency

The main advantage of liquid cooling is its superior thermal performance. Liquids can absorb and transfer significantly more heat than air, allowing the system to maintain a stable temperature even under heavy loads or in hot climates. This efficiency also means the cooling system itself can consume less energy than a large bank of high-speed fans, improving the overall round-trip efficiency of the ESS.

Scenarios Where Liquid Cooling Excels

Active liquid cooling is the preferred choice for utility-scale energy storage projects, commercial installations with high power demands, and any ESS deployed in a hot climate. Its ability to precisely manage temperatures ensures maximum performance and system longevity, justifying the higher initial investment for these critical applications.

A Direct Comparison for Your ESS

Choosing between air and liquid cooling requires a clear look at how they stack up across several key metrics. The best choice depends entirely on the specific requirements of your project, including scale, location, and performance expectations.

| Feature | Air Cooling | Active Liquid Cooling |

|---|---|---|

| Cooling Efficiency | Moderate | Very High |

| System Complexity | Low | High |

| Upfront Cost | Lower | Higher |

| Operating Cost | Can be high due to fan power | Generally lower due to pump efficiency |

| Noise Level | Can be high from fans | Very low |

| Footprint | Can require more space for airflow | More compact and power-dense |

| Performance in Hot Climates | Limited; may lead to derating | Excellent |

Performance in Extreme Conditions

In arid climates, air-based cooling is a mature technology for some applications. As noted in the IEA's Solar Energy Perspectives report, dry cooling is often used for steam plants. However, for high-density battery systems, its effectiveness wanes as ambient temperatures rise. Liquid cooling, by contrast, provides consistent performance even when the outside temperature is high, preventing the system from having to limit its output to protect the batteries.

Cost Over the System's Lifetime

While air cooling has a lower initial purchase price, the total cost of ownership can sometimes be higher. This can be due to increased energy consumption from fans or revenue loss if the ESS has to derate frequently in warm weather. Liquid cooling's higher upfront cost can be offset by improved system efficiency, longer battery life, and sustained peak performance, offering a better long-term return on investment for demanding applications.

Ensuring the Longevity of Your Energy Investment

Ultimately, the choice between active liquid cooling and air cooling is a strategic decision about how to best protect your energy asset. There is no single answer that fits every situation. For a residential ESS in a moderate climate, a well-designed air cooling system is often a perfectly suitable and cost-effective solution. It provides the necessary protection without the complexity and cost of a liquid-based system. For larger commercial systems, utility-scale projects, or any installation in a challenging climate, active liquid cooling is a superior technology. Its ability to efficiently manage heat under demanding conditions ensures the system operates at its full potential and maximizes battery lifespan. While thermal management is a critical piece of the puzzle, understanding the full picture is essential. To learn more about other key factors, you can find a comprehensive overview of solar storage performance that covers efficiency, depth of discharge, and more. Making an informed choice on cooling technology ensures your energy storage system remains a reliable, high-performing asset for years to come.

Frequently Asked Questions

Is liquid cooling for an ESS dangerous?

Modern liquid cooling systems for ESS are designed with safety as a top priority. They are factory-sealed, closed-loop systems that use non-conductive, specialized coolants. Multiple safeguards are in place to prevent and contain leaks, making them a very safe and reliable technology used in many high-stakes industries.

Does air cooling consume a lot of energy?

The energy consumption of an air cooling system depends on its size and the ambient temperature. In hot conditions or during heavy system use, the fans may need to run at high speeds for extended periods, which can consume a noticeable amount of energy. In comparison, the pumps used in a liquid cooling system are often more energy-efficient for the amount of heat they move.

How does ambient temperature affect my choice of ESS cooling?

Ambient temperature is one of the most important factors. If your ESS will be installed in a location where temperatures regularly exceed 30°C (86°F), active liquid cooling is strongly recommended. An air cooling system in such an environment may struggle to keep the batteries cool enough, leading to reduced performance and accelerated aging of the cells.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.