Lithium-ion batteries power countless applications, from small electronics to large-scale energy storage systems. Yet, a common question arises: why do their prices vary so much? The answer lies deep within the battery cell itself, specifically in its chemical composition. The materials used to build a battery are the single largest factor determining its cost, performance, and safety. Understanding this chemistry breakdown is key to making an informed investment in your energy independence.

The Heart of the Battery: Why Cathode Chemistry Matters Most

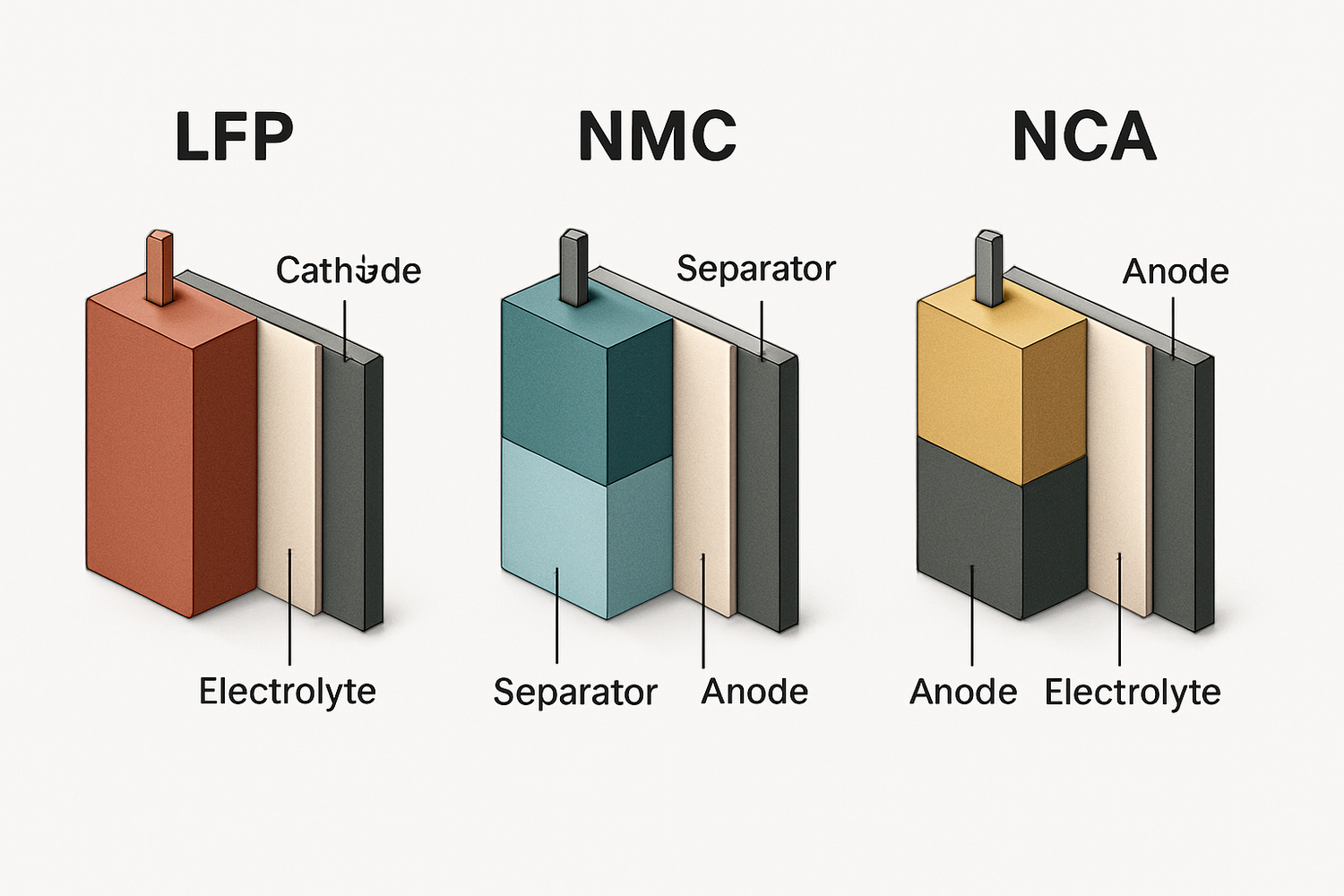

The cathode is a critical component of a lithium-ion battery, and the materials used here have the most significant impact on the final price. Different chemical combinations offer unique advantages, creating a trade-off between cost, energy density, and lifespan. According to a report from the IEA, raw materials can account for a substantial portion of production costs. For instance, in the European Union, about 45% of the cost of producing batteries comes from materials. This highlights why the choice of cathode chemistry is so pivotal.

Nickel-Manganese-Cobalt (NMC): The High-Energy Contender

NMC batteries are known for their high energy density, which means they can store a lot of energy in a small, lightweight package. This makes them a popular choice for applications where space and weight are primary concerns. However, this performance comes at a price. The key ingredients, nickel and especially cobalt, are expensive and have volatile supply chains. In recent years, manufacturers have worked to reduce cobalt content, leading to nickel-rich chemistries like NMC 811 (8 parts nickel, 1 part manganese, 1 part cobalt). As detailed in the IEA's The Role of Critical Minerals in Clean Energy Transitions, this trend away from cobalt has, in turn, placed greater pressure on nickel supplies, influencing its price and availability.

Lithium Iron Phosphate (LFP): The Safe and Stable Alternative

Lithium Iron Phosphate (LFP) batteries offer a different set of advantages. They do not contain cobalt or nickel, instead relying on iron and phosphate, which are far more abundant and less expensive. This fundamental difference in materials makes LFP batteries significantly more affordable. The IEA's Energy Technology Perspectives 2024 report notes that LFP batteries can cost up to 30% less than their high-nickel NMC counterparts. Beyond cost, LFP chemistry provides superior thermal stability, making the batteries safer and less prone to overheating. They also boast a longer cycle life, meaning they can be charged and discharged more times before their capacity degrades, offering excellent long-term value for stationary applications like home energy storage.

Nickel-Cobalt-Aluminum (NCA): Power-Packed Performance

Similar to NMC, NCA batteries offer high energy density and impressive power output. They use aluminum as a stabilizing agent instead of manganese. While they deliver excellent performance, they share the same cost challenges as NMC due to their reliance on nickel and cobalt. The price of these batteries is closely tied to the commodity markets for these two critical minerals, making them a premium option in the energy storage landscape.

Beyond the Cathode: Other Key Cost Components

While the cathode is the primary cost driver, other parts of the battery also contribute to the final price. These components are essential for the battery's function and safety, and their material and manufacturing costs add up.

Anode Materials: The Graphite Standard

The anode in most lithium-ion batteries is made of graphite. It plays the crucial role of holding lithium ions when the battery is charged. The cost of the anode depends on whether natural or synthetic graphite is used, with synthetic graphite generally being more expensive but offering more consistent performance and a longer lifespan. The processing and purification of graphite also add to the overall cost of the battery cell.

Electrolyte and Separator

The electrolyte is the medium that allows lithium ions to flow between the cathode and anode, while the separator is a physical barrier that prevents the two electrodes from touching and short-circuiting. The electrolyte is typically a lithium salt dissolved in an organic solvent. The separator is a microporous polymer membrane. While these components represent a smaller fraction of the total cost compared to the cathode, their quality is vital for the battery's safety and performance.

A Comparative Look at Battery Chemistries

Choosing the right battery chemistry involves balancing performance needs with budget constraints. The table below provides a simplified comparison of the three major cathode types used in solar and energy storage systems.

| Feature | NMC (Nickel-Manganese-Cobalt) | LFP (Lithium Iron Phosphate) | NCA (Nickel-Cobalt-Aluminum) |

|---|---|---|---|

| Relative Cost | High | Low | High |

| Energy Density | High | Moderate | Very High |

| Cycle Life | Good (2000-3000 cycles) | Excellent (4000-6000+ cycles) | Good (2000-3000 cycles) |

| Safety | Good | Excellent | Good |

| Key Materials | Nickel, Manganese, Cobalt, Lithium | Iron, Phosphate, Lithium | Nickel, Cobalt, Aluminum, Lithium |

Market Dynamics and Their Impact on Your Wallet

The price you pay for a lithium-ion battery is not just about the raw materials. Global market forces, manufacturing efficiency, and technological advancements all play a significant role in the final cost.

Raw Material Supply Chains

The geographic concentration of critical minerals like lithium, cobalt, and nickel creates supply chain vulnerabilities. As the IEA highlights in its analysis, these materials are often extracted and processed in a small number of countries. Any disruption, whether from geopolitical events or logistical challenges, can lead to price spikes. This volatility is a key reason why many manufacturers are increasingly turning to LFP chemistry to create more stable and predictable pricing for consumers.

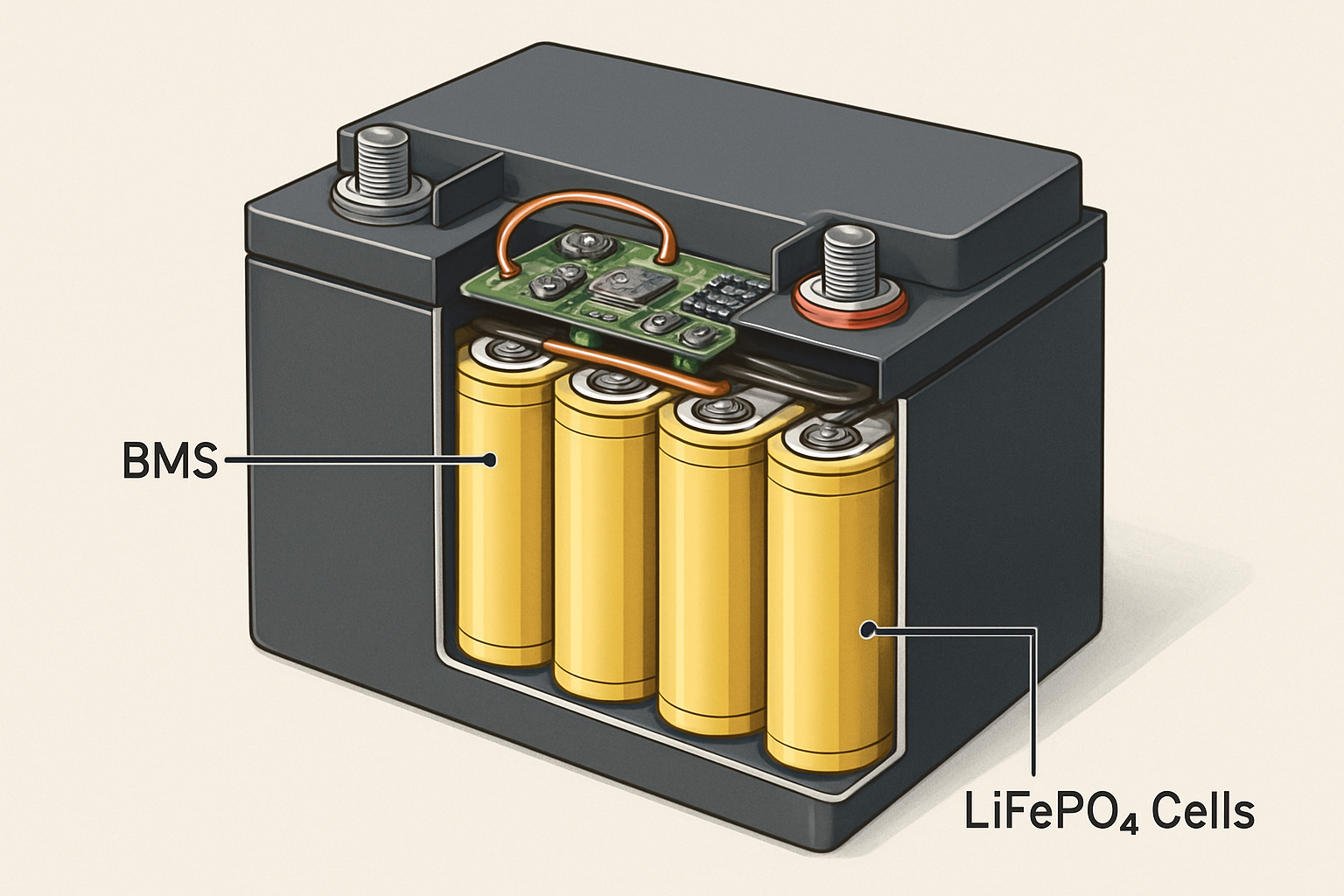

Manufacturing Scale and Innovation

The rapid expansion of battery manufacturing facilities, often called gigafactories, has created economies of scale that help drive down production costs. Automation, improved cell design, and more efficient production techniques all contribute to lower prices. Furthermore, innovations in battery management systems (BMS) enhance performance and longevity. A deeper understanding of metrics like C-rate and Depth of Discharge, as detailed in this guide on solar storage performance, helps in selecting a battery that offers the best value for its specific application.

Putting It All Together

The price of a lithium-ion battery is a direct reflection of its internal chemistry and the global forces that shape the materials market. For home energy storage and off-grid solar solutions, the choice often narrows down to a practical trade-off. NMC and NCA offer higher energy density, which can be an advantage in space-constrained installations. However, LFP batteries provide a compelling combination of lower cost, enhanced safety, and a much longer operational life, making them an excellent investment for stationary storage. By understanding what is inside your battery, you can better appreciate its value and choose the solution that best aligns with your energy goals and budget.

Frequently Asked Questions

Why are LFP batteries often cheaper?

LFP batteries are generally more affordable because they use iron and phosphate for their cathode. These materials are significantly more abundant, easier to source, and less expensive than the cobalt and high-purity nickel required for NMC and NCA batteries. This material advantage directly translates to a lower manufacturing cost and final price for the consumer.

Is a more expensive battery always better?

Not necessarily. The 'best' battery is the one that is most suitable for the intended application. For a stationary home energy storage system, the superior safety, long cycle life, and lower cost of an LFP battery often make it a better long-term value than a more expensive, high-energy-density NMC battery. The priority for home storage is typically reliability and safety over saving a few inches of space.

How will battery prices change in the future?

The long-term trend for lithium-ion battery prices is downward. This is driven by continuous improvements in manufacturing efficiency, economies of scale, and ongoing research and development. While short-term price fluctuations can occur due to raw material costs, the overall trajectory points toward more affordable energy storage solutions as technology matures and new, more sustainable chemistries are developed.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.