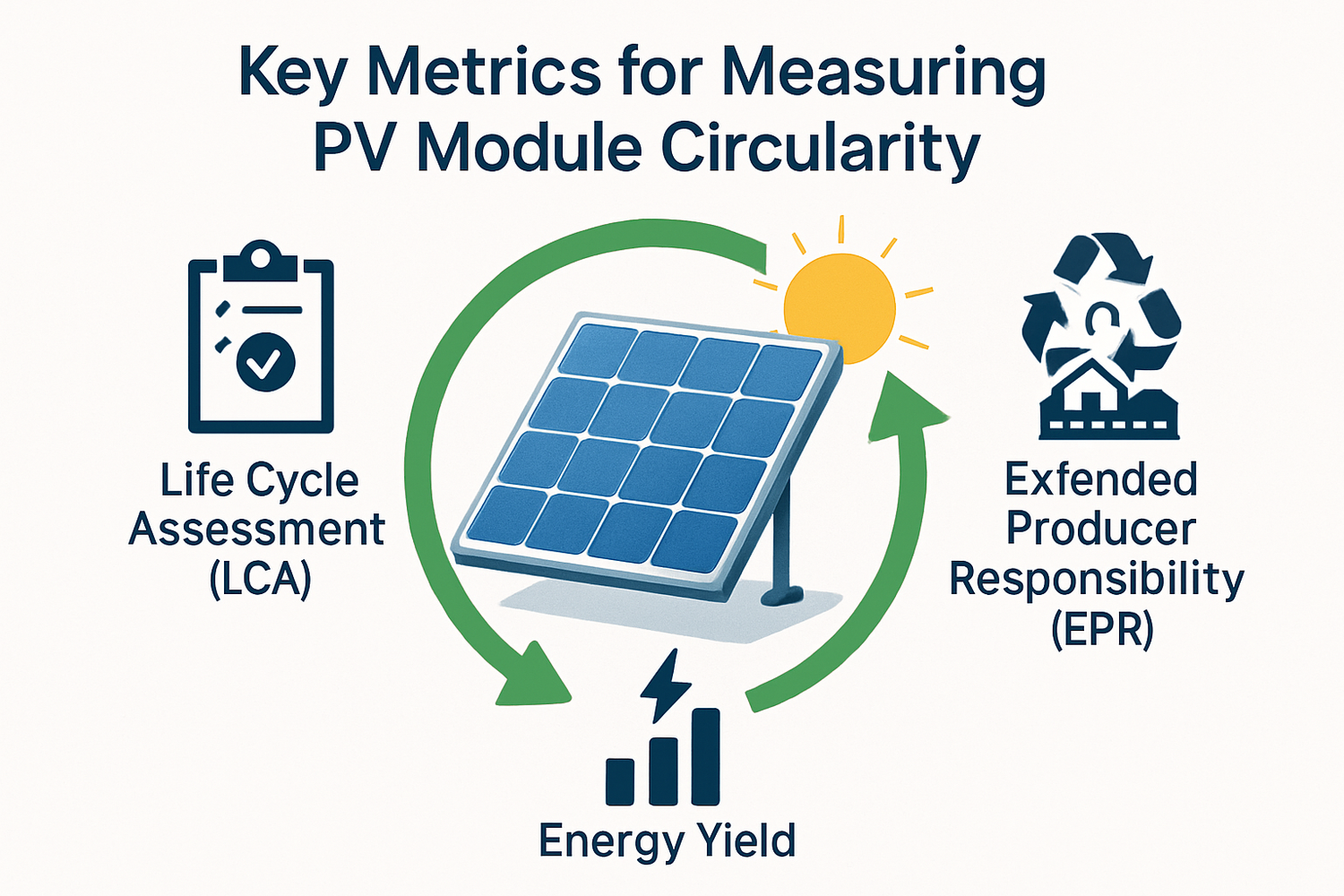

The solar industry is expanding at an unprecedented rate, making sustainability a central concern. As millions of panels are installed, the question of their end-of-life fate becomes critical. A circular economy offers a solution, but to manage it, we must first measure it. This requires moving beyond simple recycling percentages and adopting a more sophisticated set of metrics. Three powerful frameworks provide the necessary tools: Life Cycle Assessment (LCA), Extended Producer Responsibility (EPR), and Energy Yield.

Life Cycle Assessment (LCA): A Holistic View of Environmental Impact

A Life Cycle Assessment (LCA) provides a comprehensive environmental accounting for a PV module. It examines every stage, from raw material extraction and manufacturing to transportation, operational life, and final disposal or recycling. This complete picture helps identify the true environmental footprint.

Key Metrics in a PV Module LCA

An LCA evaluates several critical impact categories. The most prominent is the carbon footprint, often expressed as an energy payback period. This is the time a module must operate to generate the same amount of energy consumed during its production. According to research from the IEA, this period can be remarkably short. A study in the Solar PV Global Supply Chains report indicates that modules often offset their manufacturing emissions in just a few months. Other key LCA metrics include water consumption, resource depletion (especially for materials like silver and high-purity silicon), and ecotoxicity potential.

Applying LCA to Circularity

LCA data is fundamental to improving circularity. It pinpoints environmental "hotspots" in the value chain. For instance, if polysilicon production is the most energy-intensive stage, efforts can be focused on using lower-carbon manufacturing processes or incorporating recycled silicon. An LCA can quantitatively demonstrate how using recovered materials or designing a module for easier disassembly reduces its overall environmental impact, providing a clear business case for circular design.

Extended Producer Responsibility (EPR): Policy as a Driver for Circularity

Extended Producer Responsibility (EPR) is a policy principle that assigns manufacturers the financial and operational responsibility for their products at the end of their life. This approach incentivizes producers to design products that are more durable, repairable, and recyclable. It shifts the burden of waste management from municipalities and taxpayers to the companies that create the products.

Measuring Success in EPR Programs

The effectiveness of an EPR scheme is measured through specific, quantifiable metrics. These metrics provide clear targets for the industry and allow regulators to track progress toward circular economy goals.

- Collection Rate: This measures the percentage of PV modules that reach their end-of-life in a given period that are successfully collected through official take-back schemes. A high collection rate is the first step to preventing panels from ending up in landfills.

- Recycling Rate: This refers to the percentage of the collected mass that is sent to a recycling facility and processed, rather than being landfilled or incinerated.

- Material Recovery Rate: This is a more granular metric that measures the percentage of specific materials—such as glass, aluminum, silicon, silver, and copper—that are successfully recovered from the recycling process and made available for re-entry into the economy.

Comparing End-of-Life Metrics

The distinction between these rates is important. A program might have a high collection rate but a low material recovery rate if the recycling technology is inefficient. True circularity depends on maximizing all three.

| Metric | Description | Example Target |

|---|---|---|

| Collection Rate | Percentage of end-of-life modules collected | 85% |

| Recycling Rate | Percentage of collected weight sent to recycling | 95% |

| Material Recovery Rate (Silicon) | Percentage of silicon recovered from recycled modules | 90% |

Energy Yield and Performance: The Use Phase of Circularity

Circularity is not just about end-of-life. It also involves maximizing the value and lifespan of products during their use phase. For a PV module, its primary function is to generate clean energy. Therefore, its energy yield and long-term performance are direct measures of its resource efficiency.

Why Energy Yield is a Circularity Metric

A durable, high-performing module that generates more electricity over its lifespan embodies the core circular principle of "slowing the loop." The more energy a single panel produces, the more value is extracted from the materials and energy invested in its creation. A module that degrades slowly and lasts for 30 or 40 years has a much higher circularity value than one that fails after 15 years, even if both are fully recyclable.

Factors Influencing Long-Term Yield

Several factors contribute to a module's lifetime energy production. The annual degradation rate is a primary concern; a lower rate ensures sustained high performance. Technologies like bifacial cells, which capture light on both sides, and single-axis trackers significantly boost energy yield over the system's life. As noted by the U.S. Department of Energy, these technologies are becoming mainstream because they increase the amount of light reaching the modules, thereby raising the overall energy output of the PV fleet. Reliability is also crucial, as modules that are less prone to failures like hotspots or backsheet cracking require fewer replacements and contribute to a longer, more productive operational life.

A Comprehensive Approach to Circularity

No single metric can capture the full picture of PV module circularity. A truly sustainable approach requires integrating insights from all three frameworks. LCA provides the environmental baseline, EPR metrics track end-of-life effectiveness, and energy yield data measures in-use efficiency. By combining these perspectives, manufacturers, developers, and policymakers can make more informed decisions that drive the solar industry toward a genuinely circular future. This holistic measurement is the foundation for building a resilient and sustainable energy system for generations to come.

Frequently Asked Questions

What is the difference between recycling rate and material recovery rate?

The recycling rate measures the total weight of a product that enters the recycling process. The material recovery rate is more specific; it measures the percentage of individual materials (like silver or silicon) that are successfully extracted and purified from the recycled product for reuse.

How does a high energy yield contribute to PV module circularity?

A high energy yield over a long operational life maximizes the value derived from the initial resource investment. It means more clean energy is produced per panel, extending its useful life and delaying the need for replacement and recycling. This aligns with the circular economy principle of keeping products in use for as long as possible.

Is LCA a mandatory requirement for selling solar panels?

Mandatory LCA requirements vary by region and specific regulations. In some markets, like the European Union, environmental product declarations based on LCA data are becoming more common for public procurement and green building certifications. While not universally mandatory, it is a growing expectation for demonstrating environmental performance.

Disclaimer: This article is for informational purposes only and does not constitute financial or legal advice. Please consult with a qualified professional for guidance on specific situations.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.