An inverter that runs too hot is more than an inconvenience; it's a direct threat to your energy system's performance and longevity. Heat is the primary enemy of electronics, and in an inverter, excess heat is a clear sign of wasted energy. The root cause often lies in power losses during the DC-to-AC conversion process. By carefully selecting the modulation strategy, you can directly tackle these losses, leading to a cooler, more efficient, and more reliable inverter.

Understanding and controlling these internal power losses is not just about incremental gains. It's about ensuring your system delivers its expected output year after year. This involves looking closely at how the inverter's internal switches are controlled—the very essence of modulation.

Understanding the Sources of Inverter Losses

Every watt of energy lost within an inverter is converted into heat. These losses primarily fall into two categories: conduction and switching. Minimizing both is the key to preventing overheating and maximizing energy output.

Conduction Losses: The Constant Drain

Conduction losses occur when electricity flows through the inverter's semiconductor switches (like IGBTs or MOSFETs) while they are in the 'on' state. Think of it as electrical friction. These losses are determined by the device's internal resistance and the amount of current passing through it. While they are an inherent part of the process, choosing advanced switching devices with lower on-resistance can help reduce them.

Switching Losses: The High-Frequency Challenge

Switching losses are generated during the tiny fractions of a second when the semiconductor switches transition between on and off. Each time a switch turns on or off, a brief period of high voltage and high current overlap occurs, creating a pulse of energy loss. When multiplied by tens of thousands of times per second (the switching frequency), these small losses add up to a significant amount of heat. This is the area where modulation techniques have the most profound impact.

Other Minor Losses

Beyond the main two, other factors contribute to energy loss. These include the power needed to operate the control circuits (quiescent losses), the energy used to open and close the semiconductor gates (gate drive losses), and losses in passive components like inductors and capacitors. While smaller, they are still part of the overall efficiency equation.

Core Modulation Techniques and Their Impact on Efficiency

Pulse Width Modulation (PWM) is the technique used to chop the DC voltage into variable-width pulses that, when averaged, create an AC sine wave. The specific PWM strategy determines how and when the switches operate, directly influencing switching losses.

Sinusoidal PWM (SPWM): The Industry Standard

Sinusoidal PWM is a straightforward and widely used method. It works by comparing a target sine wave with a high-frequency triangular carrier wave to generate the switching signals. While SPWM produces a high-quality output waveform with low distortion, its continuous switching action in all phases results in relatively high switching losses, making it less efficient than more advanced methods.

Space Vector PWM (SVPWM): A More Efficient Approach

Space Vector PWM takes a more intelligent approach. Instead of treating each of the three phases independently, it considers them as a single rotating vector. By using a more optimized switching sequence, SVPWM can produce the same quality AC waveform with fewer switching transitions per cycle. This directly translates to lower switching losses and better utilization of the DC input voltage, boosting overall efficiency by a noticeable margin.

Discontinuous PWM (DPWM): Minimizing Switching Events

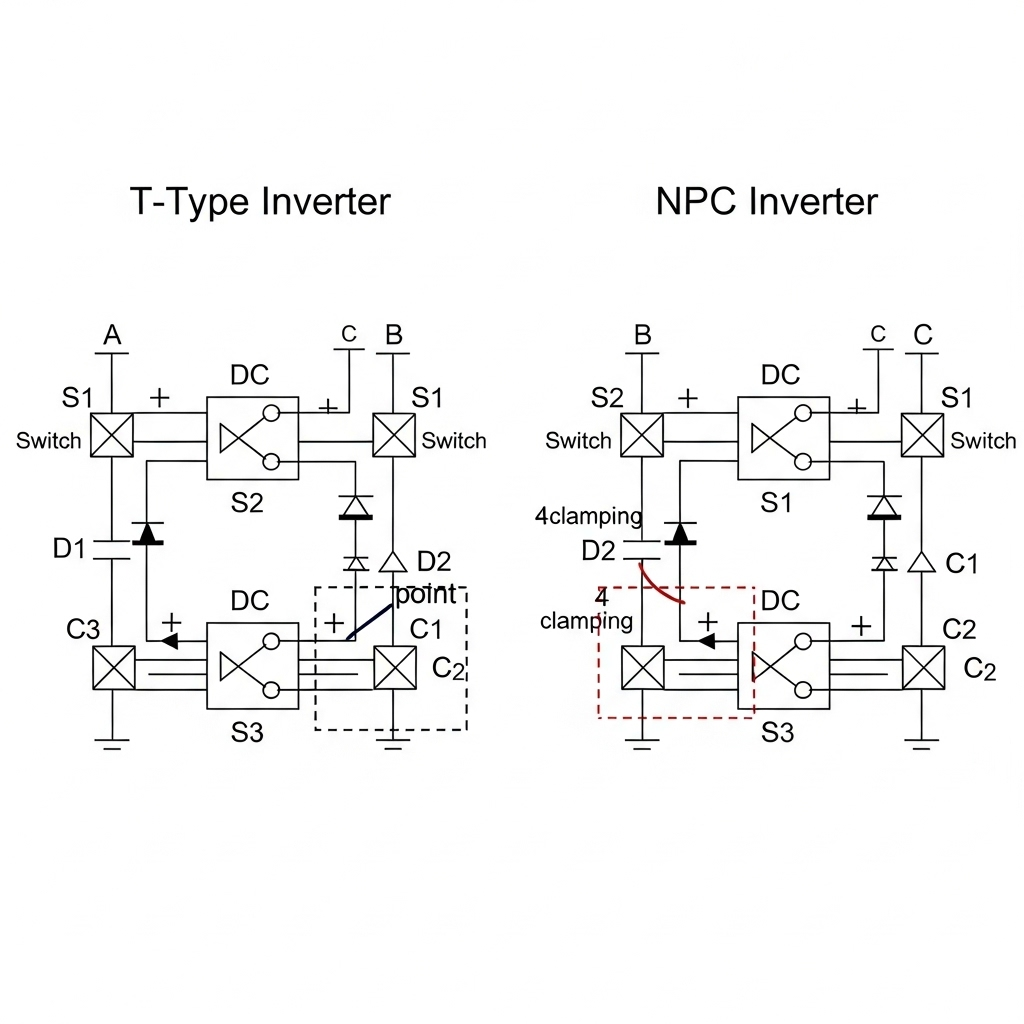

Discontinuous PWM strategies take loss reduction a step further. The core principle is to 'clamp' one of the inverter's three output phases to the positive or negative DC rail for a portion of each cycle. During this clamped period, the switches for that phase do not operate at all, effectively eliminating switching losses for one-third of the time. This can dramatically reduce overall heat generation, though it may require more sophisticated filtering to manage harmonic distortion.

| Modulation Technique | Primary Advantage | Key Disadvantage | Typical Application |

|---|---|---|---|

| SPWM (Sinusoidal PWM) | Simplicity, low harmonics | Higher switching losses | Low-cost or older inverter designs |

| SVPWM (Space Vector PWM) | Lower switching losses, better DC voltage use | More complex to implement | High-performance commercial and utility inverters |

| DPWM (Discontinuous PWM) | Lowest switching losses | Can increase harmonic distortion | Efficiency-critical applications where thermal constraints are tight |

Advanced Strategies for Loss Reduction

Beyond the core PWM algorithm, several other factors can be optimized to reduce heat and improve performance. A holistic approach to inverter design considers the interplay between modulation, hardware, and operational parameters.

The Role of Switching Frequency

The choice of switching frequency presents a classic engineering trade-off. A higher frequency allows for smaller and lighter magnetic components (inductors and transformers), but it also increases switching losses proportionally. Modern inverters using Silicon Carbide (SiC) or Gallium Nitride (GaN) switches can operate efficiently at much higher frequencies than older IGBT-based designs, but the fundamental trade-off remains. The modulation strategy must be aligned with the chosen frequency and device capabilities.

Optimizing Dead Time

To prevent a catastrophic short circuit (shoot-through), a small delay known as 'dead time' is inserted whenever one switch in a phase leg turns off and the opposite one turns on. While necessary for safety, excessive dead time distorts the output waveform and increases losses. Advanced inverters employ adaptive dead-time control, which constantly adjusts this delay to the minimum safe value, optimizing both safety and efficiency.

Integrating Modulation with System Design

The most effective designs align the modulation strategy with the overall system goals. For instance, improving component reliability is crucial to prevent faults and reduce downtime. As noted in research from the International Energy Agency, reducing the incidence of faults directly increases system availability. A modulation technique that lowers thermal stress contributes directly to this goal. Furthermore, effective thermal management is a cornerstone of reliability. As detailed in the Ultimate Reference for Solar Storage Performance, maintaining optimal operating temperatures can significantly extend the lifespan of both inverters and batteries.

Putting It All Together

Choosing the right modulation technique is a critical decision in inverter design that goes far beyond academic theory. It has a direct and measurable impact on thermal performance, energy yield, and long-term reliability. While traditional SPWM is proven, advanced methods like SVPWM and DPWM offer a clear path to lower switching losses and cooler operation.

As renewable energy systems become more integrated into our power infrastructure, the demands on inverter performance will only increase. The evolution of grid codes, as explored by IRENA in its report Grid Codes for Renewable Powered Systems, requires inverters to provide more sophisticated grid support functions. Fulfilling these roles efficiently requires minimizing internal losses. By leveraging advanced modulation, engineers can build systems that are not only compliant but also highly efficient and resilient, paving the way for a more stable and sustainable energy future.

Frequently Asked Questions

What is the main difference between SPWM and SVPWM?

SPWM generates switching signals by comparing a reference sine wave to a carrier wave for each phase independently. SVPWM treats the three phases as a single unified space vector, which allows it to use optimized switching patterns. This reduces the total number of switching events and makes better use of the DC input voltage, leading to lower losses and higher efficiency.

Can changing the modulation technique solve all overheating issues?

While optimizing the modulation strategy is a powerful way to reduce internal heat generation from switching losses, it is not a complete solution on its own. Proper heatsinking, active cooling like fans, good ventilation around the unit, and managing high ambient temperatures are all essential components of a comprehensive thermal management system.

Is a higher switching frequency always better?

Not necessarily. A higher switching frequency allows for smaller, lighter, and often less expensive magnetic components. However, it also directly increases switching losses, which generates more heat. The ideal frequency is a careful balance between the physical size of the inverter, its cost, and its operational efficiency, tailored to the specific application and the type of semiconductor devices used.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.