Module choices can raise or lower levelized cost of energy (LCOE) by several percentage points. Small technical gaps add up across 20–30 years. This piece flags seven common module selection mistakes that push LCOE higher, then shows practical fixes grounded in field data and standards.

For context, LCOE is the present value of capital, O&M, and financing costs over the plant life divided by lifetime energy. As summarized by the U.S. Energy Information Administration, it captures long-run cost competitiveness across technologies and designs (EIA).

Modern PV costs reflect many small advances over time. Public agencies highlight steady gains in efficiency, reliability, and manufacturing that continue to push LCOE lower (U.S. DOE/energy.gov; IRENA). The points below align with that direction.

The 7 module selection mistakes that inflate LCOE

Mistake 1: Chasing peak STC efficiency without system context

Nominal efficiency at Standard Test Conditions (STC) tells you area per watt. It does not guarantee higher energy per installed DC watt in the field. STC is defined at 25°C module temperature, 1,000 W/m² irradiance, and AM 1.5 (IEA Technology Roadmap 2010). A 20% vs 19% module may cut area-related balance-of-system (BOS) costs, yet other factors like temperature, low-light behavior, and mismatch can dominate lifetime yield.

Fix:

- Model energy per dollar of total installed cost, not STC watts alone. Include BOS impacts from area and weight.

- Use site-specific hourly simulations. Include soiling, temperature profiles, shading, and spectral effects.

- For constrained rooftops, higher efficiency can reduce racking and labor per kW. For open land, prioritize parameters that lift net yield and availability.

Mistake 2: Ignoring temperature coefficients

Real modules run hot. A 0.35%/°C vs 0.28%/°C Pmax coefficient looks small, but at a 20°C rise above STC, that is ~7.0% vs ~5.6% loss. Over years, that gap compounds.

Fix:

- Select modules with tighter Pmax temperature coefficients for warm sites.

- Improve mounting airflow and tracker back-ventilation.

- Model cell temperature, not only ambient. Use realistic NOCT/POA-based inputs.

Mistake 3: Underestimating degradation and early-life effects

Annual degradation (e.g., 0.55%/yr vs 0.35%/yr) shifts lifetime energy by several percent. Early effects like LID/LeTID and potential-induced degradation can erode the first years if not controlled. Better materials and process controls have reduced these risks across the industry (U.S. DOE).

Fix:

- Compare warranted degradation and third-party field data. Look for 0.3–0.4%/yr class modules for long asset lives.

- Request PID/LeTID test results and factory process controls.

- Price the long tail: a 0.2%/yr improvement can add ~4–6% more lifetime energy over 25 years.

Mistake 4: Treating bifacial as a drop-in swap

Bifacial gains depend on albedo, height, row spacing, tracker design, and layout. Systems not tuned for bifacial often miss 5–10% potential yield. Research shows that spacing, elevation, ground cover, and layout choices are material to bifacial output (Pelaez et al., 2018), and need joint optimization with module selection.

Fix:

- Simulate bifacial with site albedo and tracker geometry. Validate with on-site reflectance checks.

- Consider brighter ground cover, modestly higher tables, and wider spacing where economics support it.

- Use backsheet light management and cable routing that avoids rear shading.

Mistake 5: Overlooking mismatch and IV curve binning

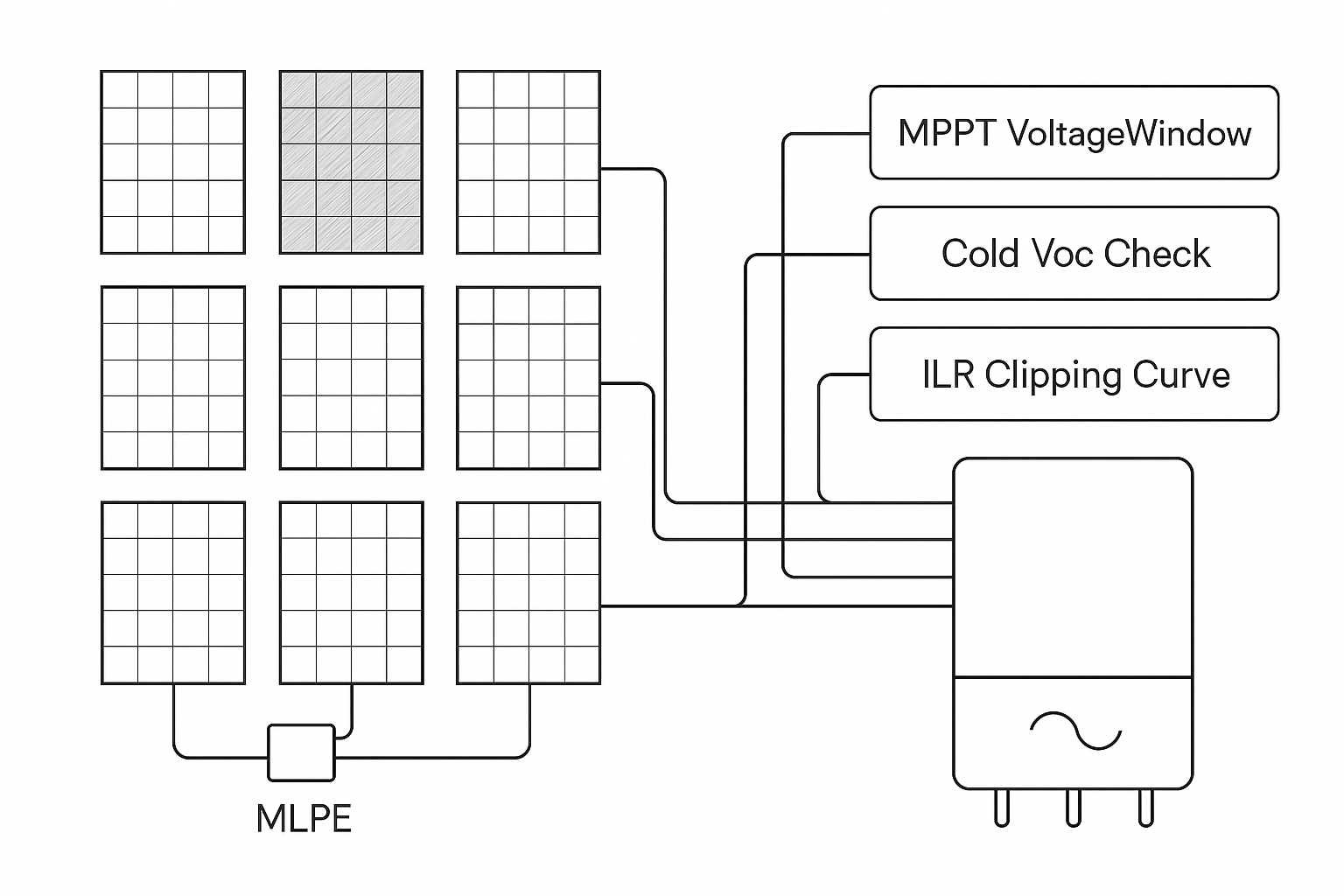

Module mismatch from initial tolerance, uneven soiling, and age-driven divergence costs energy. In residential, module-level power electronics (MLPE) keep each module at its maximum power point, cutting mismatch loss. Larger systems can benefit from better binning, tighter tolerances, or selective MLPE. Prior work finds measurable reductions in mismatch with MLPE or improved binning practices (MacAlpine, Erickson, Brandemuehl, 2012).

Fix:

- Specify narrow power tolerances and consistent IV characteristics.

- Use sub-string fusing and string-level monitoring to flag outliers.

- Apply MLPE on complex roofs or partial shading. For utility sites, evaluate selective DC optimizers on edge rows or known shade paths.

Mistake 6: Neglecting bill of materials (BOM) trade-offs that inflate BOS and logistics

Glass and polymer selections drive weight, durability, and transport cost. Thinner glass or alternative front materials can cut freight and handling, if reliability is maintained. Simpler, proven polymers can reduce material cost without hurting performance, per public analyses of non-cell cost levers (IEA Technology Roadmap 2010).

Fix:

- Request crate density and weight per pallet. Freight per watt matters, especially for remote sites.

- Choose BOM combinations validated by accelerated and field testing.

- Quantify BOS impacts from module weight and size for labor, lifting, and racking.

Mistake 7: Poor module–inverter–system integration

String length mistakes cause clipping at peak or poor MPPT windows at low irradiance. Inverters can trip on ground or arc-fault events; reducing false trips improves availability. Availability losses directly raise LCOE; boosting component reliability reduces outages and maintenance needs. Improving design to prevent nuisance trips helps protect yield (IEA Next-Generation Wind and Solar).

Fix:

- Map IV curves across temperature to MPPT envelopes. Size strings for both cold and hot extremes.

- Specify inverters with robust AFCI/ground-fault detection and proven firmware.

- Use energy storage or east–west arrays to flatten peaks, reduce clipping, and increase value capture, as system design choices can shift quantity and timing of energy (IEA: From cost to value).

Data snapshot: typical LCOE impacts

Ranges vary by site, climate, and pricing. Use as screening values, then refine in detailed models.

| Mistake | Typical loss or extra cost | Primary fix | Notes / sources |

|---|---|---|---|

| Ignoring temperature coefficient | ~1–2% annual yield in hot sites | Pick lower |γ| Pmax; improve airflow | STC vs field temperature gap: IEA 2010 |

| Underestimating degradation | ~4–6% lifetime energy vs 0.55%→0.35%/yr | Better processes, warranties | DOE reliability focus |

| Untuned bifacial design | Missed 5–10% rear-side gain | Optimize height/spacing/albedo | Pelaez et al.; IEA 2016 |

| Mismatch losses | ~1–3% energy | MLPE, tighter binning | Industry research; MLPE in residential |

| Heavy/inefficient BOM | ~0.5–1.5% capex per W | Thinner glass, proven polymers | IEA 2010 |

| Stringing/MPPT mistakes | ~1–4% clipping/MPPT loss | Thermal string design; inverter choice | IEA 2016 |

| Availability lapses | ~0.5–2% downtime | Reduce false trips; robust O&M | IEA 2016 |

Project example: heat and degradation decisions

Assume a 10 MWdc site with average cell temperature 45°C. Compare two modules identical in capex:

- Module A: −0.35%/°C, 0.55%/yr degradation

- Module B: −0.28%/°C, 0.35%/yr degradation

Temperature loss at 45°C: A ≈ 7.0%, B ≈ 5.6%. Yield improves ~1.4% for B. Over 25 years, B’s lower degradation adds roughly another 4–6% energy. Combined, Module B can deliver ~5–7% more lifetime energy. If capex is similar, LCOE drops by a comparable margin.

This simplified example shows why focusing on temperature and degradation can beat a small STC efficiency difference. It aligns with public guidance that many incremental improvements combine to push LCOE down (U.S. DOE).

Orientation, timing, and value

Fixed-tilt arrays often face the equator for maximum annual yield. In some sites, an east–west orientation can pack more modules on a roof or single-inverter block, flatten peaks, reduce clipping, and shift energy toward morning and late afternoon. Analyses show that design choices can modify the quantity and timing of energy and raise system value (IEA: From cost to value). The same report notes that some east–west setups can accommodate substantially more modules on limited area, which improves BOS per watt and can lower LCOE.

Modules, inverters, and storage: design as a team sport

Module selection does not live alone. Inverter MPPT ranges, string sizing, and protection schemes influence availability. Storage can catch clipped peaks and time-shift mid-day excess to late hours, improving revenue value. Doubling storage capacity in a constrained system can meaningfully raise the value of variable renewables in certain contexts (IEA 2016). Coordinating module choice with hybrid inverters and energy storage systems helps unlock those gains.

- For homes and small businesses, lithium-based ESS integrated with hybrid inverters can firm PV output and reduce grid imports at peak prices.

- For off-grid or weak-grid sites, right-sizing storage with temperature-robust modules stabilizes voltage and reduces generator runtime.

Global trend reports from IRENA and IEA highlight that technology integration and reliability improvements lower whole-system costs, not just module dollars per watt.

Practical takeaways you can apply this week

- Score modules with a weighted LCOE model: include temperature, degradation, mismatch, BOS, logistics, and availability.

- Use bifacial only with a layout tuned for it. If you cannot modify height, spacing, and ground cover, reassess the business case.

- On hot sites, prioritize low |γ| and light, durable BOMs that cut handling costs.

- On shaded or complex roofs, add MLPE to cap mismatch and boost uptime.

- Pair module selection with inverter MPPT checks and evaluate storage for clipping recapture and price arbitrage.

Public agencies continue to track these levers and their impact on cost and value (U.S. DOE; IEA 2010; IEA 2016; IRENA).

Disclaimer: Site results vary. This is technical information, not legal or investment advice.

FAQ

How can I reduce LCOE from module selection without raising capex?

Target parameters that boost energy: lower temperature coefficient, lower annual degradation, and lower mismatch. Light, proven BOMs can reduce logistics and labor. Combine with better string design to cut clipping. These steps improve MWh without a big price premium, tightening LCOE.

Do higher-efficiency modules always cut LCOE?

Not always. Efficiency reduces area-driven BOS. But if temperature, degradation, or mismatch are worse, lifetime energy can suffer. Model total cost per lifetime MWh, not STC watts alone.

What is a realistic bifacial gain?

On tuned systems with 0.2–0.3 albedo, 5–10% is common. Poor layouts can deliver near-zero gain. Height, spacing, and ground cover reflectivity are key knobs. Validate with site-specific simulations.

Where can I find neutral definitions and methods for LCOE?

See public materials from EIA for LCOE concepts and sector snapshots, plus broader PV technology context from IEA and U.S. DOE.

How does storage influence module selection?

Storage allows denser DC sizing and east–west layouts by catching peaks and shifting energy. That can reduce clipping and raise value capture. Pick modules with reliable thermal behavior and predictable degradation to align with the storage charge window and inverter limits.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.