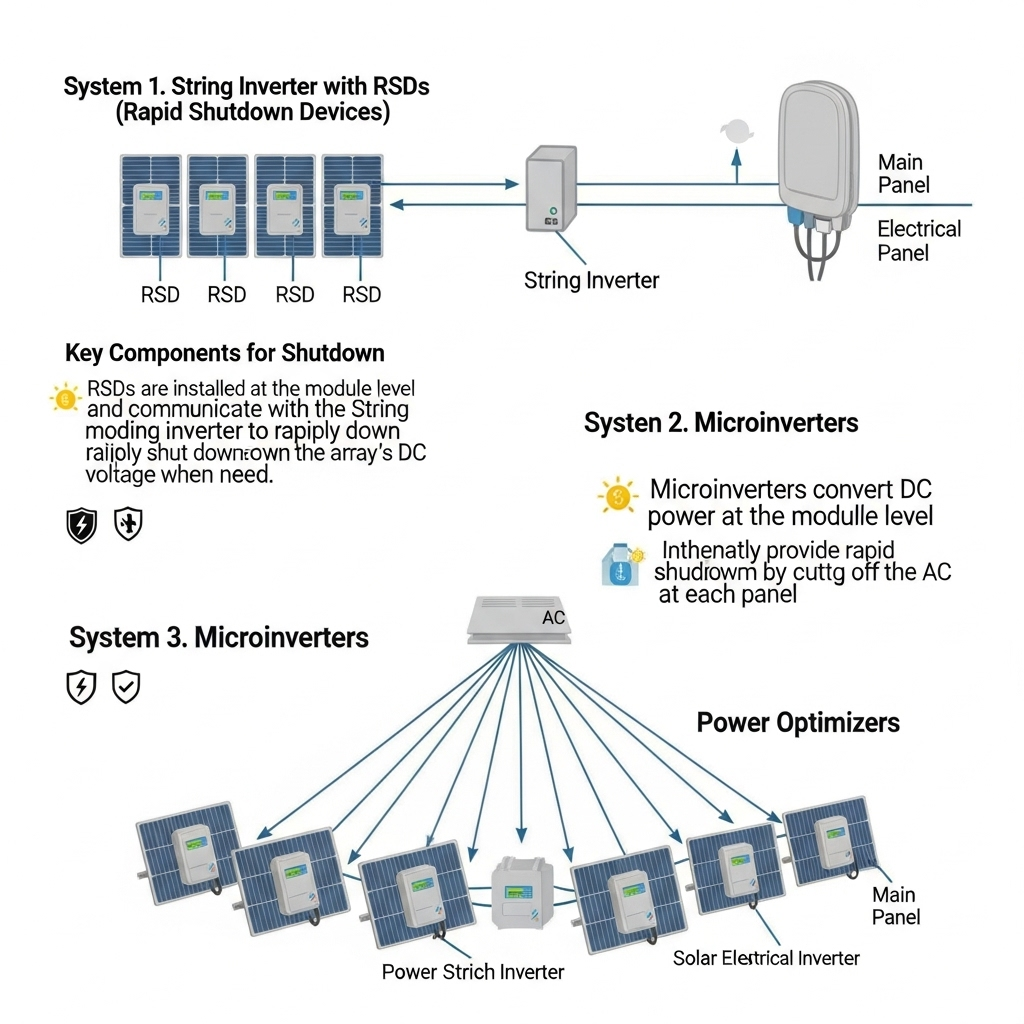

Ensuring the safety of a solar energy system is paramount, especially for first responders. Rapid shutdown requirements were developed to provide a safe way to de-energize the high-voltage DC conductors of a solar array. This allows firefighters to work without the risk of electrical shock. Achieving compliance depends heavily on your choice of inverter technology. This text breaks down how traditional string inverters, microinverters, and power optimizers each address these critical safety standards.

Understanding Rapid Shutdown Requirements

Safety regulations are not just guidelines; they are mandatory codes that dictate how solar systems must operate under specific conditions. For solar arrays, the primary concern is the high DC voltage that is present whenever the sun is shining, even if the system is disconnected from the grid.

The Core Mandate: NEC 690.12

The National Electrical Code (NEC) section 690.12 is the standard that governs rapid shutdown in the United States. The primary goal is to reduce the voltage of the solar array's conductors to a safe level in a short amount of time. When rapid shutdown is initiated, conductors within the array boundary must be reduced to 80 volts or less within 30 seconds. Conductors outside the array boundary must be reduced to 30 volts or less within the same timeframe. This function ensures that firefighters can safely cut into a roof or wall without encountering energized wiring.

Defining the 'PV Array Boundary'

The NEC defines the 'PV array boundary' as the area extending one foot in all directions from the edge of the array. This distinction is important because the voltage requirements are different inside and outside this zone. Equipment located inside the boundary, like the solar panels and their wiring, has a higher voltage allowance than the cables running from the roof to the inverter located on the ground. How an inverter system manages voltage in these two zones is key to its compliance strategy.

Compliance Pathways for Each Inverter Type

String inverters, microinverters, and power optimizers can all be part of a compliant system, but they achieve this goal through fundamentally different methods. The choice impacts system design, complexity, and cost.

String Inverters: The Traditional Approach

A standard string inverter works by connecting multiple solar panels in a series 'string'. This configuration creates a high DC voltage that is sent to a single, centralized inverter for conversion to AC power. By itself, a string inverter cannot shut down the voltage at the module level. The panels continue to produce high-voltage DC power as long as there is sunlight. To comply with rapid shutdown, these systems require additional hardware, known as Module-Level Power Electronics (MLPE). These are typically small devices installed on the back of each panel that can interrupt the flow of power when triggered, effectively de-energizing the DC wiring.

Microinverters: Inherent Compliance

Microinverters offer a more integrated solution. In this setup, a small inverter is installed on every single solar panel, converting DC power to AC power right at the source. Because the conversion happens at the panel, there is no high-voltage DC wiring running from the roof to a central inverter. When the main AC circuit is shut down (for example, by a firefighter at the main service panel), the microinverters automatically stop producing AC power. This design inherently meets rapid shutdown requirements without any additional components, as the hazardous high-voltage DC is eliminated from the system's wiring.

Power Optimizers: A Hybrid Solution

Power optimizers combine features of both string and microinverter systems. Like microinverters, a power optimizer is a small electronic device installed at each solar panel. However, instead of converting DC to AC, it conditions the DC power and sends it to a central string inverter. According to the U.S. Department of Energy, this DC-to-DC conversion can increase power generation and efficiency. As explained in an EERE success story, innovative DC-DC optimizers can increase power generation by managing the output of each panel individually. For rapid shutdown, the central inverter signals the optimizers to reduce their voltage output to a safe level, typically one volt per module. This action de-energizes the DC conductors, meeting NEC requirements.

A Comparative Analysis for System Design

Choosing the right technology involves balancing safety compliance with factors like cost, complexity, and long-term performance. The best option depends on the specific needs of the project.

| Feature | String Inverter with RSDs | Microinverters | Power Optimizers |

|---|---|---|---|

| Compliance Method | Requires add-on devices | Inherent to the design | Inherent to the system |

| System Complexity | Higher (more components and wiring) | Lower (simplified wiring) | Moderate (module-level devices plus central inverter) |

| Potential Points of Failure | Inverter, plus each RSD device | Each microinverter is a potential point of failure | Central inverter, plus each optimizer |

| Cost Implications | Lower inverter cost, but add-on costs for RSDs | Higher upfront equipment cost | Moderate upfront cost |

| Monitoring Capabilities | System-level (module-level requires extra hardware) | Built-in module-level monitoring | Built-in module-level monitoring |

Cost vs. Complexity Trade-offs

While a string inverter may appear to be the most affordable option initially, the total cost increases when you add the necessary rapid shutdown devices. This also adds complexity to the installation and creates more potential points of failure on the roof. Microinverters and power optimizers integrate this functionality, which can lead to a simpler and faster installation. Evaluating the total installed cost, not just the price of the inverter, is crucial for an accurate comparison.

Reliability and Maintenance Considerations

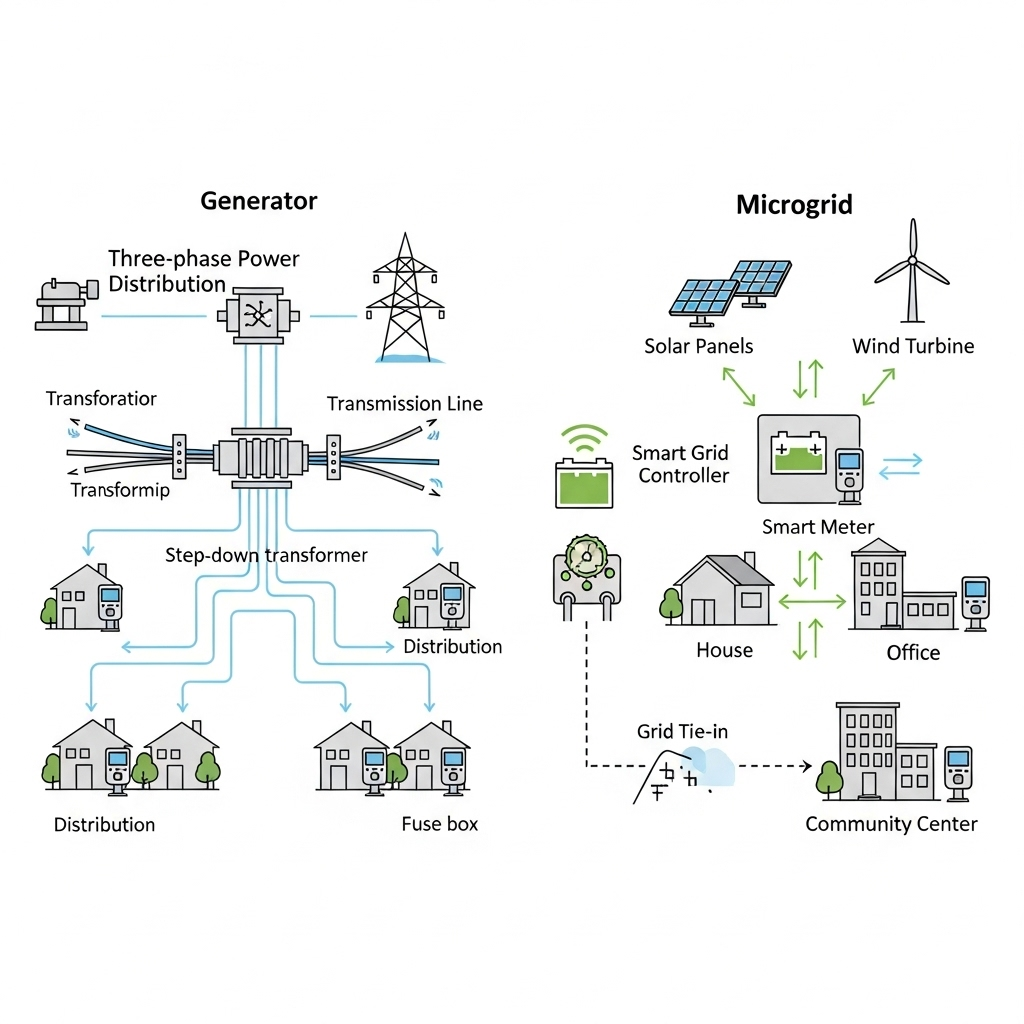

System reliability is directly linked to its complexity. With string inverters, a failure in the central unit or any of the rapid shutdown devices can impact performance. Microinverters decentralize the conversion process, so the failure of one unit only affects a single panel. Power optimizers present a hybrid scenario. The International Energy Agency (IEA) notes that appropriate technical grid connection rules are critical for ensuring PV plants operate reliably, a factor influenced by inverter technology. For a deeper analysis of system performance, considering factors beyond initial setup is key, as detailed in the ultimate reference on solar and storage performance.

Final Thoughts on Compliance

All three inverter technologies provide a clear path to achieving rapid shutdown compliance. The decision is not about which is 'better' overall, but which is the best fit for your specific application. Microinverters and power optimizers offer a streamlined, integrated approach to safety, while string inverters provide a compliant solution through the use of additional components. By understanding the technical differences in how each system meets these critical safety standards, you can design a solar energy system that is not only efficient and powerful but also fundamentally safe.

Frequently Asked Questions

Is rapid shutdown required for all solar installations?

Rapid shutdown requirements are part of the NEC and have been adopted by most jurisdictions in the United States for rooftop solar installations on buildings. Ground-mounted systems may have different requirements. It is essential to check with your local authority having jurisdiction (AHJ) to confirm the specific codes that apply to your project.

Can I add rapid shutdown capability to an older string inverter system?

Yes, it is possible to retrofit an older solar system with rapid shutdown functionality. This typically involves installing module-level rapid shutdown devices that are compatible with your existing string inverter and modules. This upgrade is often performed when other system maintenance or expansion is taking place.

Do microinverters or power optimizers have any disadvantages regarding rapid shutdown?

The primary consideration is that both technologies place complex electronic components on the roof, where they are exposed to heat and weather. While these devices are built to be durable, a failure requires working on the roof to replace the individual unit. However, their inherent ability to meet rapid shutdown requirements without extra parts is a significant advantage in terms of system simplicity and installation speed.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.