Heat is a persistent challenge in power electronics, and for an Energy Storage System (ESS), the inverter is the operational core. Its ability to manage temperature directly dictates the system's efficiency, reliability, and longevity. Effective ESS inverter thermal design is not a luxury; it is a fundamental requirement for unlocking peak performance and protecting your energy investment. A failure to manage heat leads to reduced power output and premature component failure.

Why Thermal Management is Crucial for ESS Inverters

The process of converting DC power from batteries to AC power for use in homes or businesses generates a significant amount of heat. How this heat is managed is a critical engineering challenge that impacts every aspect of the inverter's operation.

The Link Between Heat and Performance Degradation

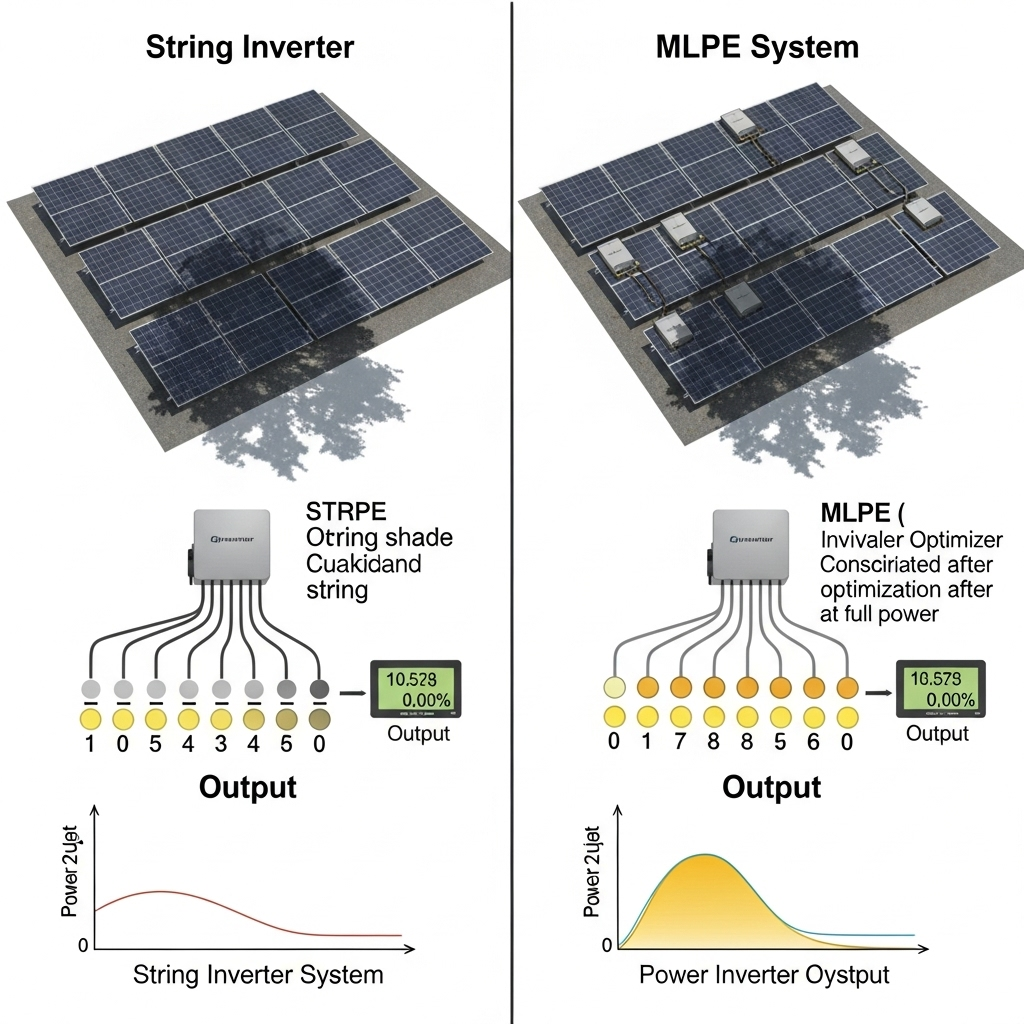

High temperatures are the primary enemy of electronic components. For an inverter, excess heat reduces the efficiency of its semiconductors, meaning more energy is lost as heat in a self-perpetuating cycle. To protect itself, an inverter will initiate a process called thermal derating. This is an automatic, self-preservation mechanism where the inverter intentionally reduces its power output to lower internal temperatures and prevent catastrophic failure. Consistent overheating, even if it doesn't cause immediate failure, significantly shortens the lifespan of crucial components like capacitors and control boards.

Key Components Under Thermal Stress

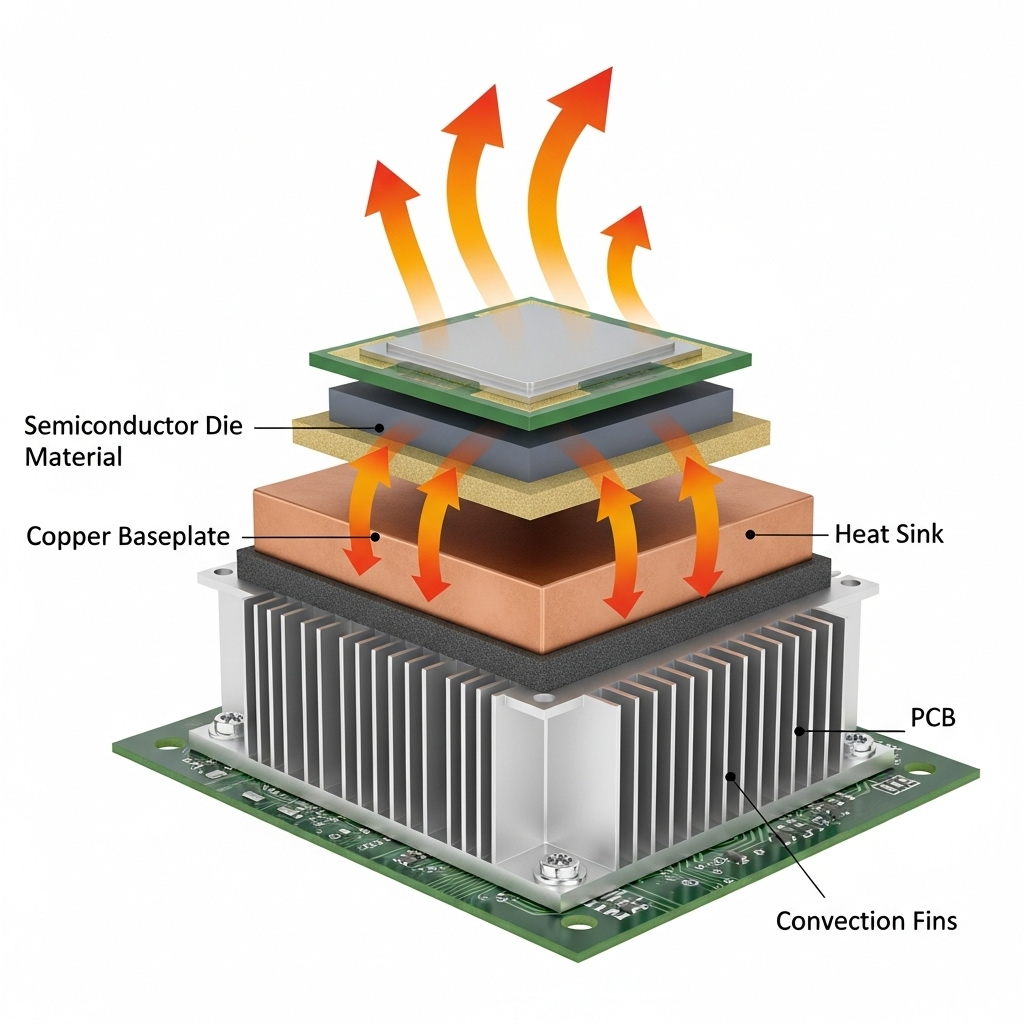

Several components within an ESS inverter are particularly vulnerable to thermal stress:

- Capacitors: These are essential for smoothing and filtering electrical currents. Heat accelerates the evaporation of their internal electrolyte, which degrades their performance and eventually leads to failure.

- Semiconductors (IGBTs & MOSFETs): These power transistors are the heart of the inversion process. They generate substantial heat during switching operations. If this heat isn't dissipated effectively, it can lead to reduced efficiency and thermal runaway, a condition that can destroy the component.

- Magnetic Components: Inductors and transformers experience heat generation from core losses and winding resistance. Overheating reduces their efficiency and can damage their insulation.

Financial and Operational Impacts of Poor Thermal Design

The consequences of inadequate thermal management extend beyond technical issues. Reduced energy yield from derating translates directly to a lower return on investment. System downtime and increased maintenance calls add to the operational costs. For advanced systems using grid-forming inverters to provide grid stability, thermal stress can compromise their ability to support the grid, undermining a key function of modern energy storage.

Core Principles of Effective ESS Inverter Thermal Design

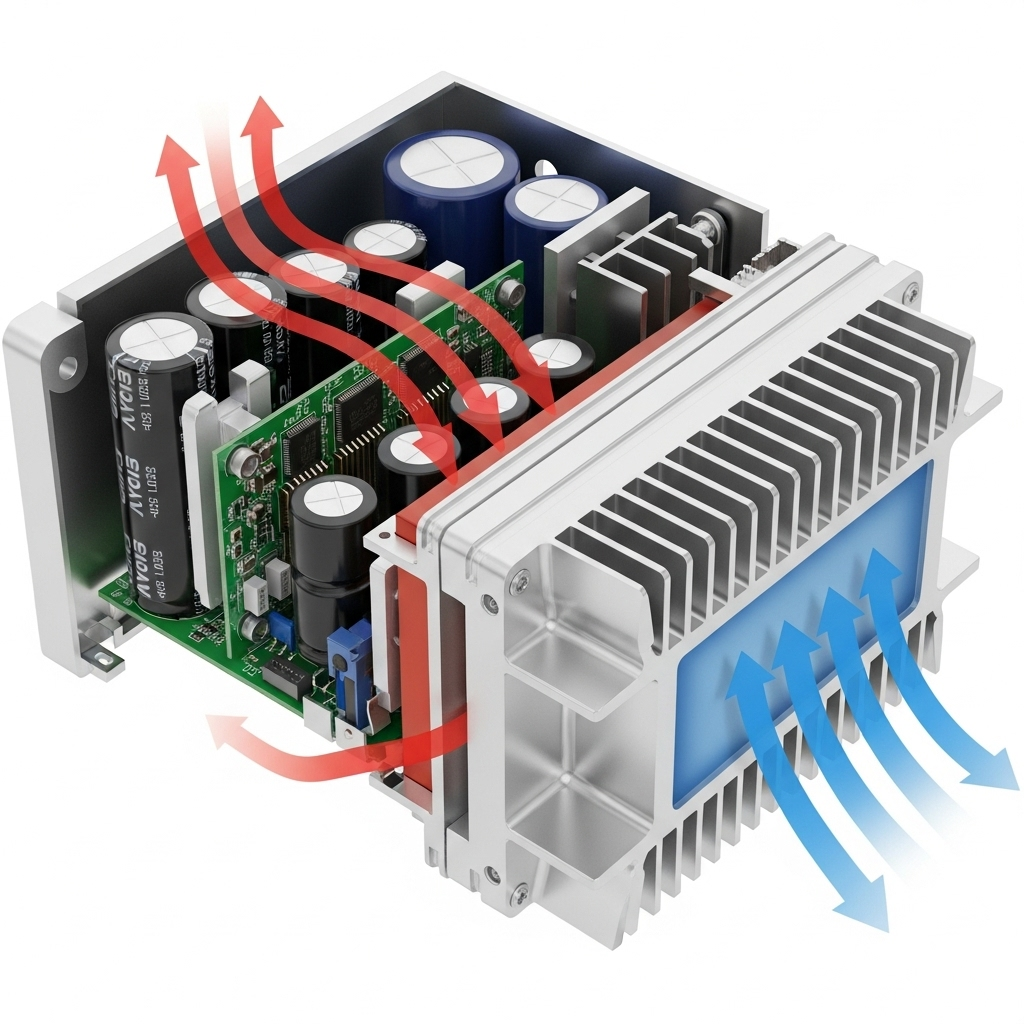

A robust thermal management strategy combines passive and active cooling methods to efficiently transfer heat away from critical components and dissipate it into the surrounding environment.

Passive Cooling Solutions

Passive cooling relies on natural physical processes to manage heat without consuming additional power. These methods are silent, reliable, and require no maintenance.

- Heat Sinks: A heat sink is a fundamental component designed to absorb heat from electronic devices and dissipate it into the air. Its performance depends on the material (typically aluminum or copper), surface area, and fin design, which maximizes contact with the surrounding air.

- Natural Convection: This involves designing the inverter's enclosure and component layout to promote a natural airflow. Hot air rises, drawing cooler air in from below. Proper ventilation and spacing are critical for this to work effectively.

Active Cooling Solutions

Active cooling uses energy to accelerate heat removal, making it suitable for higher-power inverters or those installed in challenging environments.

| Cooling Method | Description | Advantages | Disadvantages |

|---|---|---|---|

| Forced Air (Fans) | Uses fans to move a high volume of air across heat sinks. | Highly effective, cost-efficient, widely used. | Consumes power, generates noise, requires maintenance (cleaning/replacement). |

| Liquid Cooling | Circulates a liquid coolant through a closed loop to absorb heat and release it via a radiator. | Extremely efficient for high heat loads, allows for compact designs. | More complex, higher cost, potential for leaks. |

| Advanced Technologies | Includes heat pipes and vapor chambers that use phase-change principles to transfer heat with very high thermal conductivity. | Superior heat transfer over long distances, silent operation. | Higher cost, typically used in high-density applications. |

Understanding and Mitigating Inverter Derating

Derating is a common feature in all power electronics, but its frequency and severity can be managed with proper planning and system design.

What is Derating and How Does it Work?

Derating is a built-in safety protocol. The inverter's internal sensors monitor component temperatures. When a preset threshold is reached, the control system limits the power output. This relationship is defined by a 'derating curve' found in the product's technical datasheet, which shows how much power the inverter can sustain at different ambient temperatures. It's important to note that other factors, such as high altitude (where thinner air is less effective at cooling) and high IP-rated enclosures (which trap heat), also contribute to derating.

Practical Steps to Prevent Overheating and Derating

You can take several practical steps to ensure your inverter operates in an optimal thermal environment:

- Strategic Installation: Install the inverter in a cool, shaded, and well-ventilated area. Avoid locations like uninsulated attics or direct sunlight. Always respect the manufacturer's clearance requirements to ensure sufficient space for airflow around the unit.

- Proper Sizing: Design the system so the inverter is not constantly operating at its peak power limit. A properly sized inverter handles typical loads without pushing its thermal limits.

- Regular Maintenance: Periodically inspect and clean heat sink fins and fan air inlets. Dust and debris act as insulators, trapping heat and reducing cooling efficiency.

Analyzing Performance Data for Thermal Insights

Modern ESS inverters offer sophisticated monitoring capabilities. By analyzing historical performance data, you can identify patterns of thermal derating. Does it happen at the same time every sunny day? This could indicate a ventilation or placement issue. A data-driven approach is essential for optimizing system output. For a comprehensive overview of key metrics, the ultimate reference on solar storage performance offers valuable insights into what to look for.

The Future of Inverter Thermal Management

Innovation in materials science and smart technology continues to push the boundaries of what is possible in thermal design, promising more efficient and resilient inverters.

Innovations in Materials and Components

The adoption of wide-bandgap semiconductors, such as Silicon Carbide (SiC) and Gallium Nitride (GaN), is a significant development. These materials can operate at higher temperatures with greater efficiency, which reduces the amount of waste heat generated and lessens the burden on the cooling system.

Smart Cooling and Predictive Maintenance

The next generation of inverters will feature intelligent cooling systems. Using AI and machine learning, these systems can predict thermal loads and proactively adjust fan speeds or other cooling mechanisms. This not only improves efficiency but also enables predictive maintenance, alerting users to potential issues before they cause downtime. The IEA emphasizes that deploying smart controls is a key strategy to facilitate the grid integration of renewables.

System-Level Integration

Future designs will focus on integrating the inverter's thermal management with the broader energy system. As noted in another IEA report, integrated designs that combine PV, heat pumps, and energy storage are a critical area for future innovation. For example, waste heat from an inverter could potentially be repurposed for water heating, turning a liability into an asset and improving overall system efficiency.

A Proactive Approach to Thermal Health

Ultimately, the thermal design of an ESS inverter is a cornerstone of its performance and reliability. It is not an isolated feature but an integrated system of choices, from component selection and layout to enclosure design and installation guidelines. By understanding the principles of heat management and taking proactive steps to ensure a cool operating environment, you safeguard the longevity of your inverter and maximize the energy yield of your entire storage system.

Frequently Asked Questions

How can I tell if my ESS inverter is overheating?

Look for warning lights or error codes on the inverter's display. You might also hear the cooling fans running at maximum speed for extended periods. The most definitive sign is checking your system's monitoring software, which will show high internal temperature readings and a corresponding reduction in power output (derating).

Does the location of my inverter really matter that much?

Absolutely. An inverter installed in a hot, enclosed space with poor ventilation, such as a garage attic in summer or in direct sunlight, is far more likely to overheat. This forces it to derate its power output frequently to protect itself and will significantly shorten its operational lifespan compared to one installed in a cool, well-ventilated location.

What is the ideal operating temperature for an ESS inverter?

While most inverters are designed to operate in a wide ambient temperature range (e.g., -25°C to 60°C or -13°F to 140°F), their peak efficiency and longevity are achieved in a more controlled environment, typically around 25°C (77°F). Always consult the manufacturer's technical datasheet for specific operating temperature ranges and the derating curve.

Can I add an external fan to help cool my inverter?

While directing an external fan at an inverter might provide some marginal benefit by improving local airflow, it is not a solution for a fundamental installation or design issue. It may not effectively cool the internal components where heat is most critical. Furthermore, modifying the inverter or its enclosure could void the manufacturer's warranty. It is always better to address the root cause, such as improving ventilation or relocating the unit.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.