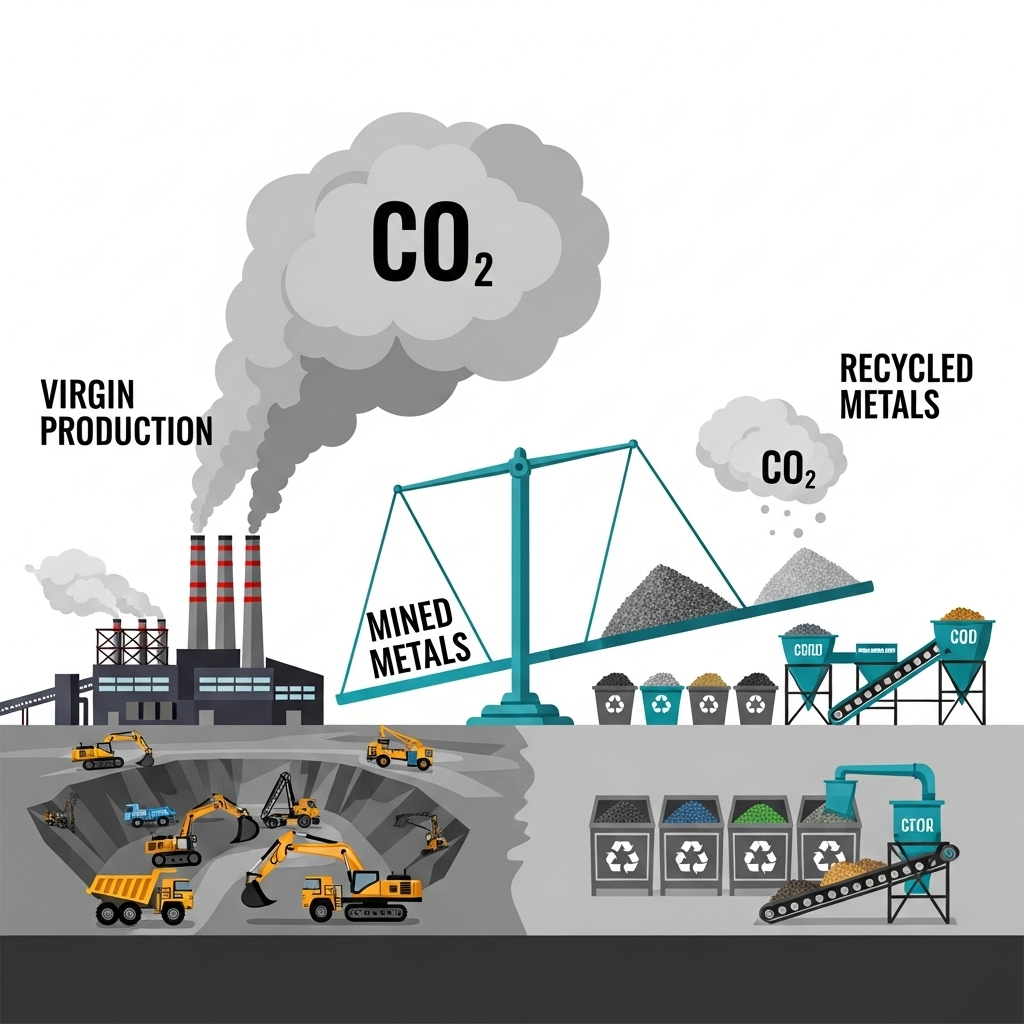

The global shift to clean energy is built on a foundation of metal. Lithium, cobalt, copper, and nickel are the building blocks of solar panels, wind turbines, and the energy storage systems that make them reliable. But this progress comes with a hidden environmental cost: the intensive process of mining and refining virgin materials. Fortunately, a powerful solution exists. Recycling these essential metals not only conserves resources but also dramatically reduces greenhouse gas (GHG) emissions, paving the way for a truly sustainable energy future.

The Carbon Footprint of Mining and Refining

Extracting metals from the earth is an inherently disruptive and energy-intensive process. Before we can appreciate the benefits of recycling, we must first understand the environmental weight of primary production.

Energy-Intensive Extraction

Many critical minerals exist in low concentrations within ore deposits. This means vast amounts of rock and soil must be moved, crushed, and processed to yield a small amount of usable metal. According to analysis from Argonne National Laboratory, this initial extraction is the most energy-intensive stage. As highlighted in the IEA's report, The Role of Critical Minerals in Clean Energy Transitions, the energy required to produce metals from raw ore contributes significantly to the overall carbon footprint of clean energy technologies.

Emissions Beyond Energy Use

The environmental impact is not limited to energy consumption. The mining process itself releases potent greenhouse gases. This includes emissions from heavy machinery, transportation, and chemical reactions used in refining. For example, the development of cobalt and nickel resources can lead to substantial sulfur dioxide emissions. These factors combine to create a significant environmental burden long before the metal ever reaches a manufacturing facility.

Supply Chain and Price Instability

A heavy reliance on primary mining also exposes the global market to supply chain disruptions and price volatility. Geopolitical instability in resource-rich regions can impact the availability and cost of critical minerals. Developing a robust secondary supply through recycling helps insulate against these risks, creating a more resilient and predictable market for manufacturers and consumers alike.

The Data-Backed Benefits of Metal Recycling

The case for recycling becomes undeniable when you look at the numbers. Shifting from a linear 'take-make-dispose' model to a circular one offers profound environmental advantages, chief among them being a massive reduction in GHG emissions.

The 80% Reduction Figure Explained

Research provides a clear and compelling statistic. A 2025 IEA report, The State of Energy Innovation, states that using recycled battery metals like nickel, cobalt, and lithium can reduce greenhouse gas emissions by up to 80% compared to producing them from mines. This staggering reduction is possible because recycling bypasses the most carbon-heavy stages of production: ore extraction, transportation, and initial smelting. Instead, the process starts with a concentrated source of high-quality material, requiring far less energy to return it to a usable state.

A Closer Look at Key Metals

The benefits vary by metal, but the trend is consistent across the board. By recovering materials from end-of-life products, we can significantly lower the carbon intensity of our supply chains. The following table illustrates the potential GHG savings for several key metals used in energy systems.

| Metal | Production Method | Relative GHG Emissions Intensity |

|---|---|---|

| Copper | Conventional Mining Route | ~4x Higher |

| Copper | Recycled from Scrap | ~1x (Base) |

| Aluminum | Primary Production | ~20x Higher |

| Aluminum | Recycled Production | ~1x (Base) |

| Nickel | Primary Smelting | ~5x Higher |

| Nickel | Recycled (Secondary) | ~1x (Base) |

As the table shows, the savings are substantial. For instance, producing copper from scrap can lower the GHG emissions intensity to about a quarter of that from conventional mining routes. This data underscores the power of the circular economy as a climate-action tool.

Building a Sustainable Metal Supply Chain

Transitioning to a circular model is not just an environmental imperative; it is also an economic opportunity. As the volume of end-of-life solar panels and batteries grows, so does the potential to create a robust domestic source of critical materials.

The Growing Market for Recycled Materials

The economic viability of metal recycling is already proven. The market value for recycled battery metals saw an almost eleven-fold increase between 2015 and 2023. This growth signals a strong financial incentive to recover and reuse these valuable resources, turning potential waste streams into profitable revenue streams. This shift helps create a more resilient supply chain, less dependent on the fluctuating prices of primary materials.

Challenges and Innovations

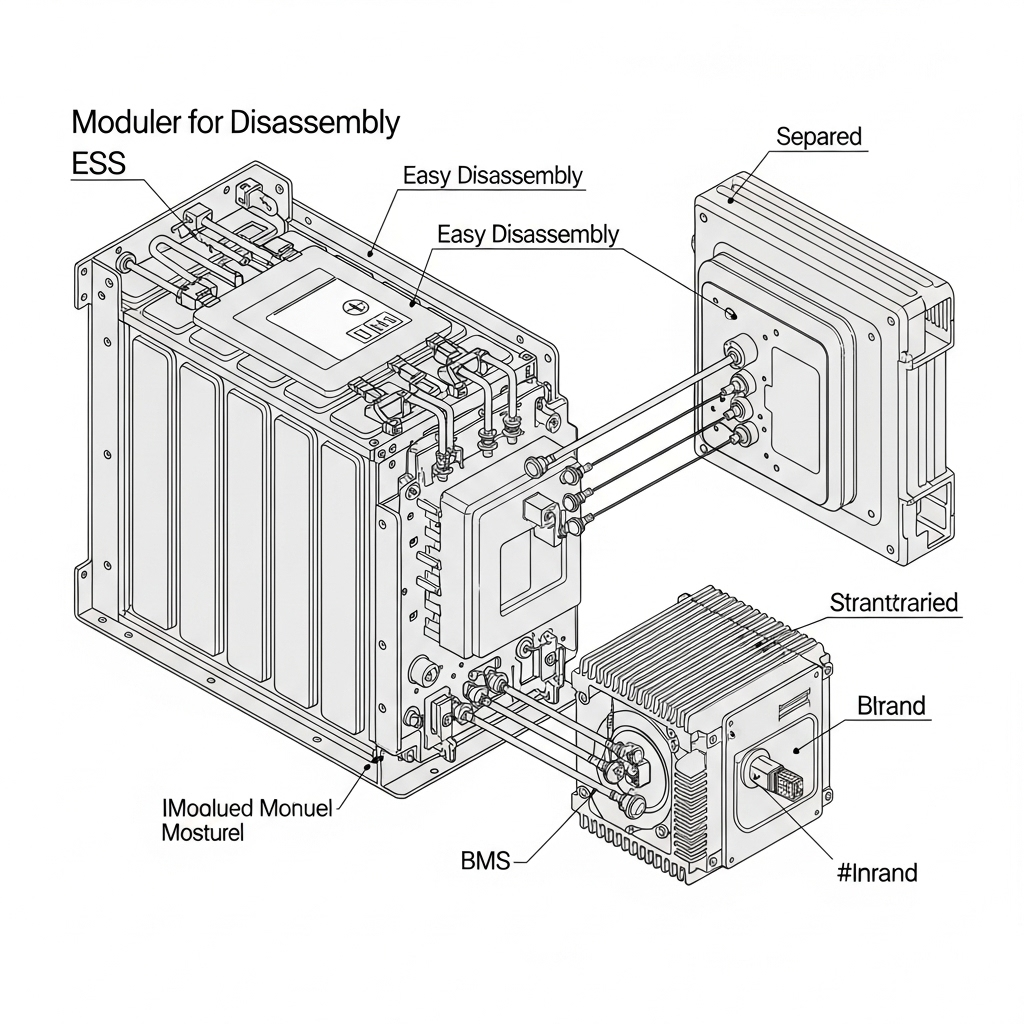

Despite the clear benefits, challenges remain. The complexity and diversity of battery designs can make disassembly and material separation difficult. Highly reactive elements like lithium require specialized handling processes. Furthermore, regulatory hurdles related to the transportation of end-of-life batteries can slow down the development of a seamless recycling infrastructure. However, innovation is rising to meet these challenges. New sensor technologies, data analytics, and automated sorting systems are improving the efficiency and safety of recycling processes, making it easier to recover high-purity materials.

System Performance and Lifecycle Extension

A crucial part of the circular economy begins long before recycling: extending the operational life of a product. A well-designed and properly maintained energy storage system will serve you for many years, delaying its entry into the end-of-life stream. Understanding how to care for your system is the first step in a circular approach. Monitoring key metrics, for example, can maximize the longevity of your batteries. You can find detailed guidance in the Ultimate Reference for Solar Storage Performance, which helps you get the most out of your investment before recycling becomes necessary.

A Greener Future Forged from Recycled Metals

The evidence is clear: recycling metals is not merely a waste management strategy but a core pillar of decarbonization. By embracing a circular economy for critical minerals, we can build the clean energy future on a foundation that is both environmentally sound and economically resilient. The remarkable up-to-80% reduction in GHG emissions offered by recycled metals provides a powerful incentive to invest in collection infrastructure, advance recycling technologies, and design products for easier disassembly. This path allows us to meet our growing energy needs without compromising the health of our planet, ensuring that the transition to renewable energy is truly sustainable from start to finish.

Frequently Asked Questions

Why is mining for metals so bad for the environment?

Mining is environmentally intensive due to several factors. It requires enormous amounts of energy to extract and process ore, which often releases significant greenhouse gases. It also involves land disruption, potential water contamination, and the release of pollutants like sulfur dioxide during the refining of metals such as cobalt and nickel.

Is recycling 100% efficient? What happens to the waste?

No recycling process is 100% efficient, but modern methods achieve very high recovery rates for valuable metals. The processes do create some by-products, such as sodium sulphate from battery recycling, which must be managed responsibly. However, as noted in IEA analysis, the overall environmental benefit of recycling far outweighs the impact of managing these by-products.

Are recycled metals as good as newly mined ones?

Yes. Once a metal is refined, its atomic structure is identical regardless of its source. Recycled copper, lithium, or aluminum is indistinguishable from its mined counterpart in terms of quality and performance. It can be used in the same high-performance applications, including new batteries and electronic components, without any compromise.

What metals in solar and battery systems are most valuable for recycling?

In lithium-ion batteries, the most valuable metals for recovery are typically cobalt, nickel, lithium, and copper. For solar panels, valuable materials include silver, copper, and aluminum. While bulk materials like glass and aluminum frames are also highly recyclable, the recovery of these scarcer critical minerals provides the greatest economic and environmental benefits.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.