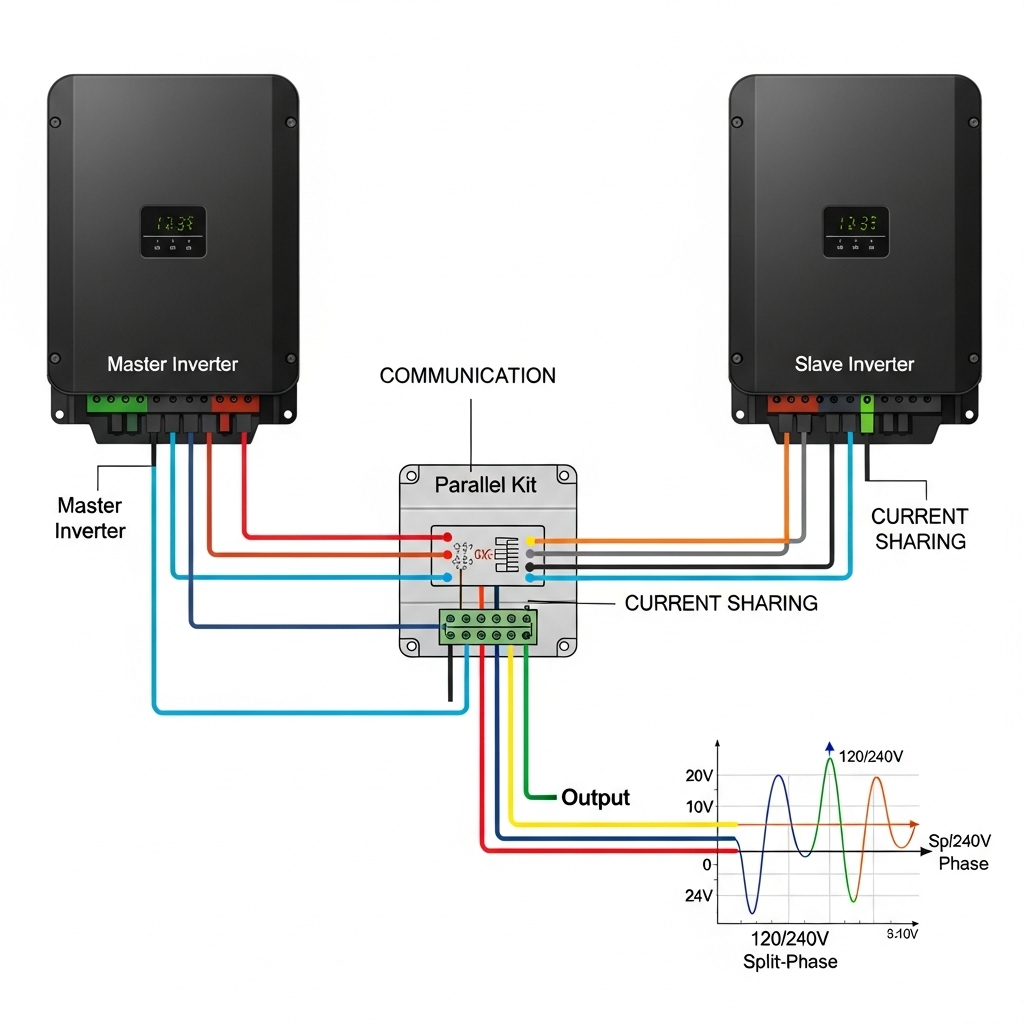

Powering large appliances like air conditioners, well pumps, or electric vehicle chargers requires 240-volt split-phase electricity. Standard single inverters typically supply 120V. To bridge this gap, you can use a parallel kit to link two hybrid inverters. This setup synchronizes their outputs to generate a stable 120/240V split-phase supply. This review examines the components, critical features, and technical considerations of using parallel kits to achieve higher power output and capability.

Understanding the Core Components: What's in a Parallel Kit?

A parallel kit is more than just a few wires; it's a dedicated system designed to make two inverters operate as a single, cohesive unit. The primary goal is perfect synchronization to create a safe and stable power source. These kits typically include a few key components that handle communication and power management.

The Parallel Communication Cable

The communication cable is the central nervous system of the parallel setup. It establishes a master-slave relationship between the two inverters. The master inverter dictates the operational parameters, such as voltage and frequency, while the slave inverter follows its lead precisely. This constant communication ensures both units are perfectly synchronized, producing a clean sine wave with a 180-degree phase difference, which is the foundation of split-phase power.

The Current Sharing Cable

While the communication cable handles synchronization, the current sharing cable manages the workload. It provides real-time feedback between the inverters, allowing them to balance the electrical load evenly. Without effective current sharing, one inverter could become overloaded while the other remains underutilized. This imbalance reduces system efficiency and can lead to premature failure of the overworked unit.

The Main Circuit Board or Module

Some parallel kits include a dedicated circuit board or module that acts as the central controller. This board processes the signals from both inverters and makes micro-adjustments to maintain stability. It governs the phase angle, voltage output, and load distribution. In systems without an external board, this logic is built directly into the inverters' firmware and activated once the parallel cables are connected.

Key Features to Evaluate in a Split-Phase Parallel System

Not all parallel systems are created equal. When selecting a split-phase hybrid inverter and its corresponding parallel kit, several performance features determine the reliability and safety of your power system. A robust system ensures both your appliances and your investment are protected.

Synchronization Accuracy and Stability

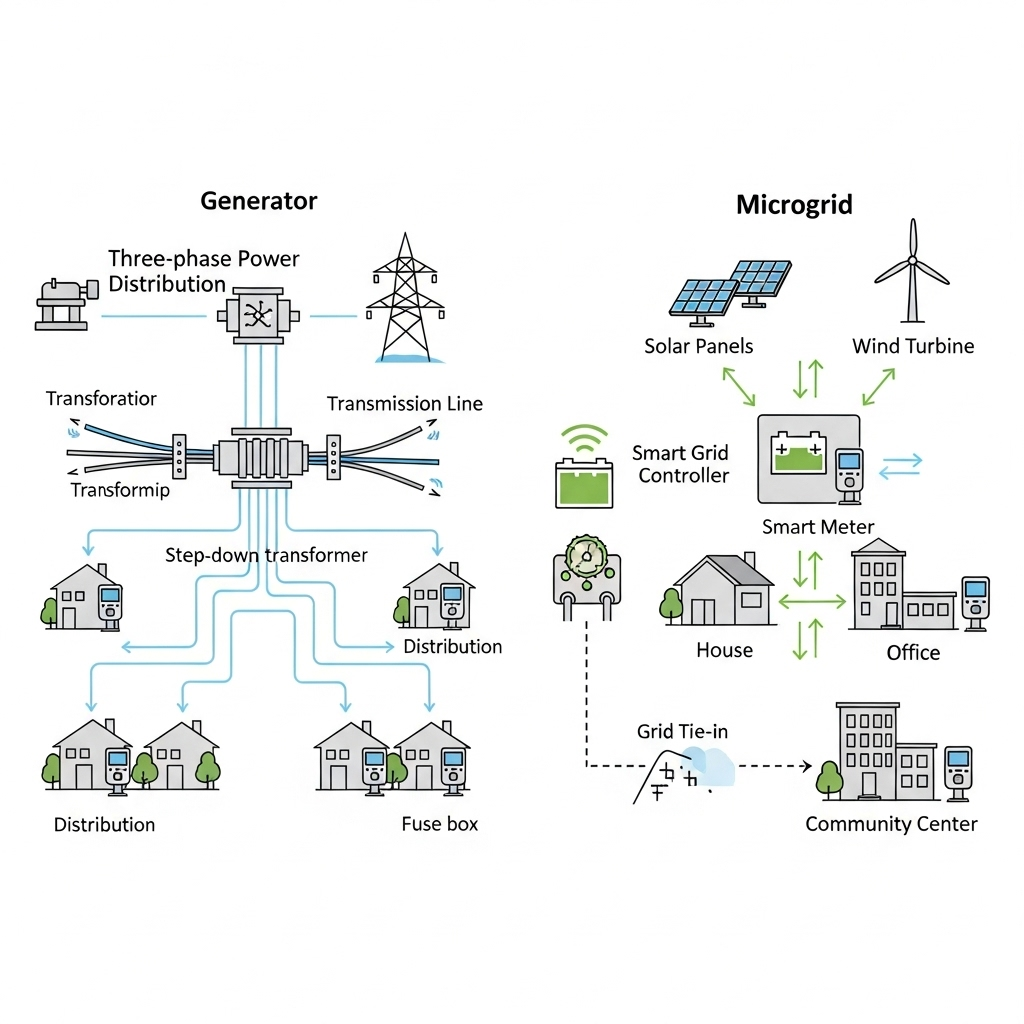

The most critical function of a parallel system is maintaining a perfect 180-degree phase shift between the two 120V outputs. Any deviation can result in voltage fluctuations and an unstable power supply, potentially damaging sensitive electronics. According to a report on Grid Codes for Renewable Powered Systems, the controllability of inverter-based generators is fundamental to system stability. This principle is especially true in a microgrid or off-grid setting where the inverters are responsible for creating the grid signal.

Load Sharing Performance

Effective load sharing ensures system longevity and optimal performance. An ideal system distributes the load between inverters with minimal deviation, even when powering reactive loads like motors. Poor load sharing can be caused by mismatched cable lengths, poor connections, or inferior control logic. This imbalance forces one inverter to work harder, generating more heat and stress. Monitoring key metrics is vital. A comprehensive look at solar storage performance shows how factors like Depth of Discharge (DoD) and Round-Trip Efficiency (RTE) are impacted by overall system configuration and health.

| Feature | Ideal Load Sharing | Poor Load Sharing |

|---|---|---|

| Current Distribution | Balanced within 2-5% between inverters | Deviation greater than 10% |

| Temperature | Both inverters operate at similar temperatures | One inverter runs significantly hotter |

| Appliance Behavior | Motors start smoothly, lights don't flicker | Motors struggle to start, noticeable voltage sag |

| System Lifespan | Maximized due to even wear | Reduced due to stress on one unit |

Scalability and Future-Proofing

Your energy needs may grow over time. Some parallel systems are designed for more than just split-phase operation; they allow you to add more inverters to increase overall power capacity. For example, you could start with a 2-inverter split-phase system and later add a third or fourth inverter in parallel to double your output. Choosing a system with this flexibility provides a clear upgrade path without needing to replace your initial equipment.

The Installation and Configuration Process: A Technical Overview

Setting up a parallel inverter system requires careful attention to detail. While not overly complex, the process must be followed precisely to ensure safety and proper operation. Always consult the manufacturer's documentation before beginning.

Physical Installation and Wiring

The first step is to physically connect the parallel kit's cables between the inverters. It is crucial that the inverters are identical models with matching firmware versions. Using dissimilar models can lead to communication failures. The DC input wiring from the battery bank and the AC output wiring to the main electrical panel must also be identical in length and gauge for both inverters to help ensure balanced performance.

Software Configuration and Settings

Once the hardware is connected, you must configure the inverters' software settings. This typically involves accessing the control panel on one of the inverters and designating it as the 'master'. You will then select the 'parallel' or 'split-phase' operational mode. This action tells the inverters to synchronize their outputs. During this process, you will also confirm settings for grid interaction, such as Low Voltage Ride Through (LVRT) and anti-islanding protocols. As noted by IRENA, grid codes often specify these requirements to ensure that distributed generators do not create safety hazards during a grid outage.

Final Considerations for Your System

Implementing a split-phase system with parallel hybrid inverters is an effective way to power an entire home, including high-demand 240V appliances. The key to success lies in selecting a high-quality, matched set of inverters and a dedicated parallel kit designed for them. Proper installation and configuration are paramount for creating a system that is not only powerful but also safe and reliable for years to come. By focusing on synchronization accuracy, load sharing, and proper setup, you can build a robust energy solution tailored to your needs.

Disclaimer: This article is for informational purposes only. It is not a substitute for professional electrical advice. Always consult with a qualified electrician and adhere to all local electrical codes and regulations during installation.

Frequently Asked Questions

Can I use a parallel kit with inverters from different brands?

No. Parallel kits and inverters are designed as a proprietary system. Mixing brands can lead to communication errors, poor performance, and potential equipment damage due to incompatible control algorithms and communication protocols.

Do I need two separate battery banks for two parallel inverters?

No, a single, properly sized battery bank is used to power both inverters. The inverters draw from this common DC source and work together to create the AC output. Ensure the battery bank's C-rating and capacity can handle the combined load.

How does split-phase parallel operation affect inverter efficiency?

There can be a minor efficiency loss due to the constant communication and synchronization required. However, a well-designed system minimizes this. The primary benefit of powering high-load appliances on a 240V circuit often outweighs the slight dip in overall efficiency.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.