Inverter derating is a persistent challenge in the solar and energy storage industry. To prevent heat damage, inverters automatically reduce their power output when temperatures climb. This protective measure, while necessary, directly impacts energy production and financial returns. Now, a fundamental shift in semiconductor technology, driven by Silicon Carbide (SiC) and Gallium Nitride (GaN), is rewriting the rules of thermal management and tackling derating at its source.

The Root of the Problem: Why Traditional Inverters Generate So Much Heat

Understanding why derating happens requires a look inside a traditional inverter. The power semiconductors, typically made of silicon (Si), are the heart of the power conversion process, but they are also the primary source of waste heat.

Switching Losses in Silicon-Based Inverters

Power inverters convert DC electricity from solar panels or batteries into AC electricity for use in homes and businesses. This process involves switching electrical currents on and off thousands of times per second. Traditional silicon-based transistors, like MOSFETs and IGBTs, are not perfectly efficient. During each switching cycle, a small amount of energy is lost as heat. Compounded over millions of cycles, this results in significant thermal buildup. Conduction losses, or the heat generated as current flows through the components, further add to the thermal load.

The Vicious Cycle of Heat and Inefficiency

Heat and inefficiency create a negative feedback loop in silicon components. As the internal temperature of the inverter rises, the electrical resistance of the silicon transistors increases. Higher resistance leads to greater energy loss in the form of heat, which in turn raises the temperature further. This cycle accelerates as ambient temperatures increase, forcing the inverter to derate its power output to avoid catastrophic failure. This reality underscores why innovations in power electronics are central to improving system performance, a goal highlighted in reports on clean energy innovation. According to the IEA's Clean Energy Innovation report, enhancing the efficiency of electronic devices is a critical area of development.

The Semiconductor Revolution: Introducing SiC and GaN

SiC and GaN are known as wide-bandgap (WBG) semiconductors. The 'bandgap' is the energy required to excite an electron to a state where it can conduct electricity. Materials with wider bandgaps can operate at much higher voltages, temperatures, and frequencies than silicon. This capability unlocks a new level of performance in power electronics.

What Makes Wide-Bandgap Semiconductors Different?

The primary advantages of SiC and GaN stem directly from their superior physical properties. They exhibit lower resistance, switch faster, and manage heat more effectively. These attributes allow for the design of power conversion systems that are more efficient and compact.

| Property | Silicon (Si) | Silicon Carbide (SiC) | Gallium Nitride (GaN) |

|---|---|---|---|

| Bandgap (eV) | 1.1 | 3.3 | 3.4 |

| Thermal Conductivity (W/mK) | 150 | 490 | 130-230 |

| Max Operating Temperature | ~150°C | >200°C | >200°C |

| Critical Electric Field (MV/cm) | 0.3 | 3.0 | 3.3 |

SiC: The Powerhouse for High-Voltage Applications

Silicon Carbide is exceptionally robust, making it ideal for high-power applications like large-scale solar inverters and energy storage systems. Its thermal conductivity is more than three times that of silicon, allowing heat to be drawn away from critical components far more effectively. This thermal resilience, combined with its ability to handle high voltages, enables SiC-based inverters to operate with greater efficiency and reliability under heavy loads.

GaN: The Speed Demon for Compact Designs

Gallium Nitride excels in high-frequency switching. GaN transistors can switch on and off much faster than silicon or even SiC devices, which dramatically reduces switching losses. This high-speed capability allows engineers to use smaller inductors and capacitors in the inverter design, leading to systems that are significantly smaller, lighter, and more power-dense. This is particularly advantageous for residential energy storage systems where space is a premium.

How SiC and GaN Directly Combat Inverter Derating

The theoretical benefits of SiC and GaN translate into direct, practical solutions for thermal derating. By tackling the root cause—excessive heat generation—these materials create a more resilient and efficient inverter.

Slashing Switching Losses, Slashing Heat

Because SiC and GaN devices switch more efficiently, they generate fundamentally less waste heat. Every percentage point of efficiency gained is a reduction in the thermal load the cooling system must handle. An inverter that runs cooler from the start is far less likely to reach its thermal derating threshold, even under demanding conditions.

Higher Operating Temperatures, Wider Performance Window

The ability of SiC and GaN to function reliably at temperatures exceeding 200°C gives designers a much larger thermal margin. While a silicon inverter might start derating at an internal temperature of 80°C, a SiC or GaN inverter can continue operating at full power well beyond that point. This higher thermal tolerance expands the inverter's optimal operating range, a critical factor in achieving the high efficiency detailed in the ultimate reference for solar storage performance. This resilience ensures consistent power output in real-world conditions, not just in ideal laboratory settings.

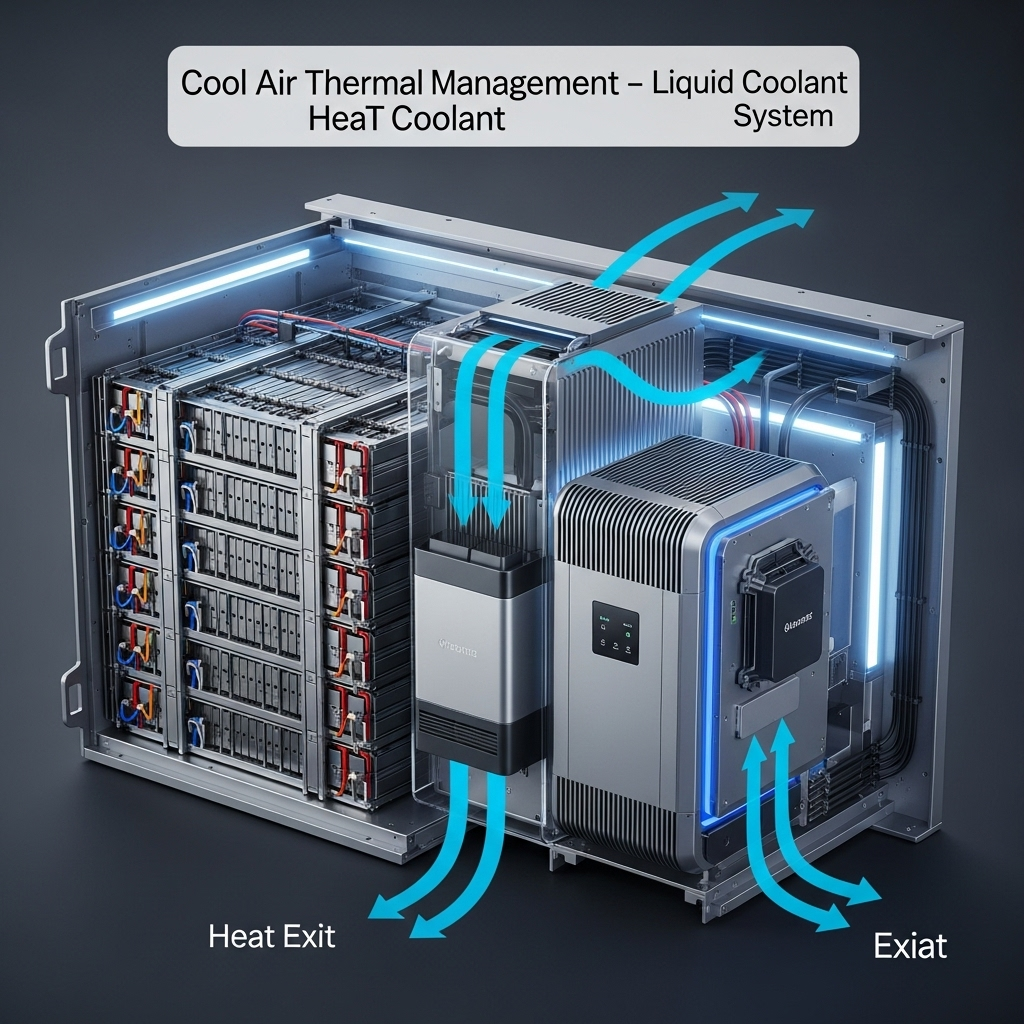

Enabling Smaller, More Efficient Cooling Systems

Since SiC and GaN inverters generate less heat, they don't require the same bulky and complex cooling systems as their silicon counterparts. Research from the National Renewable Energy Laboratory (NREL) has shown that advanced thermal management in SiC inverters can lead to a significantly reduced system footprint. This allows for smaller heat sinks, less powerful fans, and more compact enclosure designs, reducing system cost, weight, and complexity.

The Real-World Impact on Solar and Storage Systems

The shift to SiC and GaN is more than an engineering exercise; it delivers tangible benefits for system owners and operators. These advantages enhance both the performance and the long-term value of a renewable energy investment.

Increased Annual Energy Production (AEP)

For a solar or storage system, every hour spent in a derated state is an hour of lost production. By minimizing derating, SiC and GaN inverters maximize the energy harvested and delivered over the system's lifetime. In hot climates, this can translate to a significant increase in annual energy production and, consequently, a faster return on investment. The reliability of such components is a cornerstone of project viability, as noted in the Electricity Storage Valuation Framework from IRENA.

Enhanced System Reliability and Lifespan

Heat is the enemy of all electronic components. By operating at lower internal temperatures, SiC and GaN inverters reduce thermal stress across the entire system, including capacitors, circuit boards, and connectors. This leads to fewer component failures and a longer operational lifespan for the inverter. As innovations in thermal energy storage and management evolve, integrating more efficient power electronics will be key. The Innovation outlook: Thermal energy storage report highlights how improved management technologies can reduce costs and expand deployment.

A New Era for Inverter Design

Silicon Carbide and Gallium Nitride represent a pivotal evolution in power electronics. They address the fundamental thermal limitations of silicon, paving the way for inverters that are not only more efficient but also more resilient to the primary cause of power loss: heat. By drastically reducing derating, these advanced materials ensure that solar and energy storage systems can deliver their full potential, providing more clean energy and greater value for years to come.

FAQ

Are SiC and GaN inverters more expensive?

Initially, the component cost for SiC and GaN devices can be higher than for silicon. However, the system-level savings from smaller cooling components, reduced energy loss, and increased power density often make the total cost of ownership competitive or even lower. The overall value comes from improved efficiency and longevity.

Can I replace a silicon inverter with a SiC/GaN model?

Yes, many SiC and GaN inverters are designed as direct replacements for older silicon-based models. They offer superior performance, often in a smaller and lighter package. Always consult the product specifications to ensure compatibility with your solar array or battery system.

How much does derating really affect my energy production?

The impact varies significantly based on your climate and installation environment. In hot regions like the American Southwest or Australia, derating can reduce annual energy production by several percent. Inverters built with SiC or GaN technology minimize these losses, protecting your investment and maximizing your energy independence.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.