Setting up a solar energy storage system is a significant step towards energy independence. However, the safety and efficiency of your entire investment hinge on one critical detail: the wiring. Misinformation about solar battery wiring is widespread and can lead to underperformance, equipment damage, or severe safety hazards. This text separates fact from fiction, providing clear, reliable guidance for protecting your solar setup.

Myth 1: Any Copper Wire Will Do the Job

The Fiction

A common belief is that as long as a wire is made of copper, its size doesn't matter much for connecting batteries. This myth suggests that using a thinner, less expensive wire is an acceptable way to cut costs.

The Fact

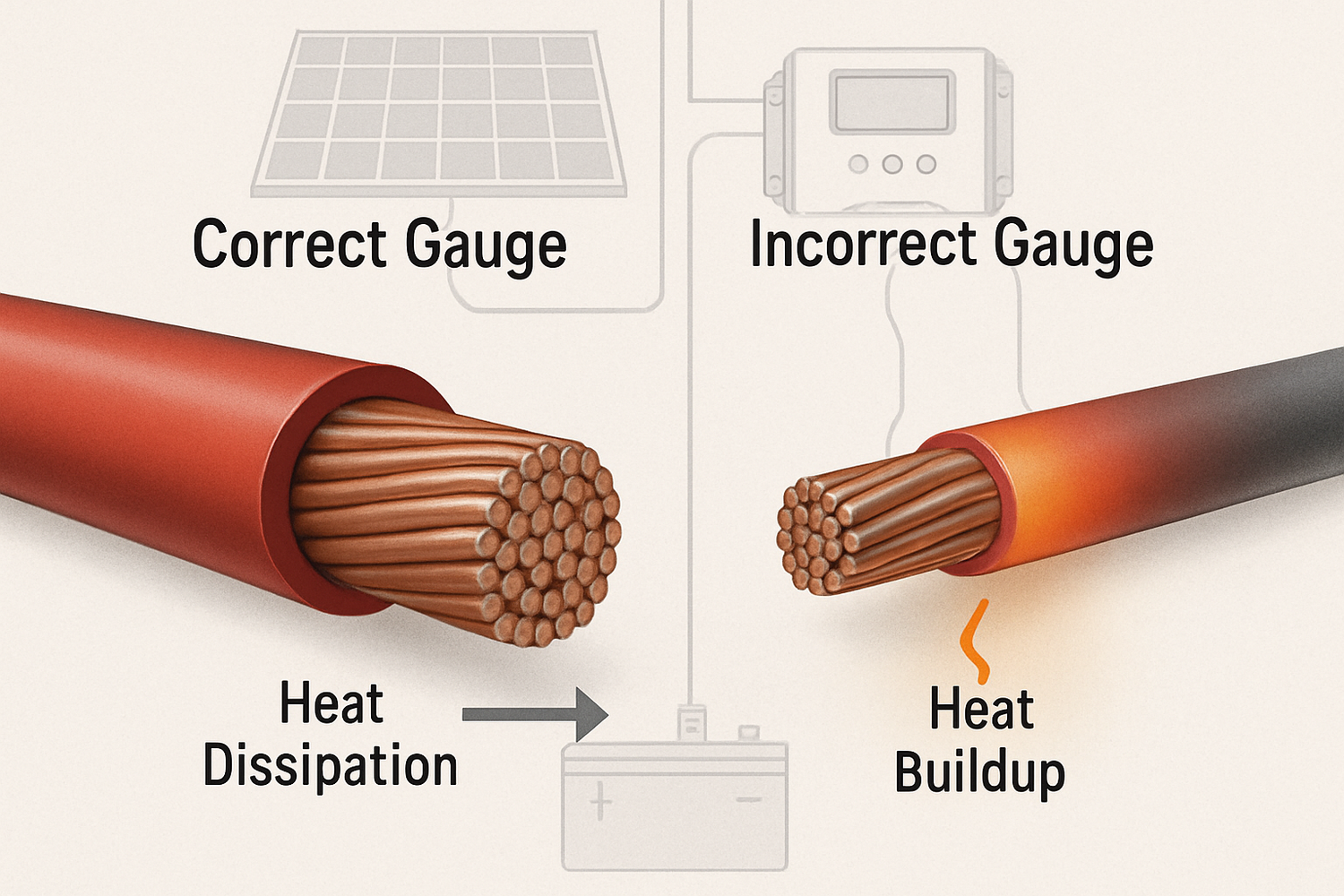

Wire size, or gauge, is one of the most critical factors in solar battery wiring. Using an undersized wire is a frequent and dangerous error. Wires that are too thin for the current they must carry create high resistance. This resistance leads to two major problems: significant voltage drop and dangerous overheating. A voltage drop means less power reaches your batteries and inverter, crippling your system's efficiency. More critically, overheating can melt the wire's insulation and connections, creating a serious fire hazard. According to the National Electrical Code (NEC), a voltage drop of more than 3% is not recommended for these circuits. Always use PV-rated wire with the correct American Wire Gauge (AWG) for your system's amperage and the distance of the wire run. A lower AWG number indicates a thicker wire capable of handling more current safely.

| System Current (Amps) | Max Distance at 12V (Feet) | Recommended AWG | Max Distance at 24V (Feet) | Recommended AWG |

|---|---|---|---|---|

| 20 | 10 | 10 AWG | 20 | 10 AWG |

| 50 | 8 | 4 AWG | 16 | 4 AWG |

| 100 | 8 | 1/0 AWG | 16 | 1/0 AWG |

| 200 | 6 | 4/0 AWG | 12 | 4/0 AWG |

Disclaimer: This table is for general guidance only. Always consult a professional and use a specific voltage drop calculator for your system's parameters.

Myth 2: Fuses and Breakers Are Optional Add-ons

The Fiction

Some believe that if a system is designed correctly, with matched components and loads, overcurrent protection devices (OCPDs) like fuses and circuit breakers are unnecessary. They are seen as an extra expense rather than a core component.

The Fact

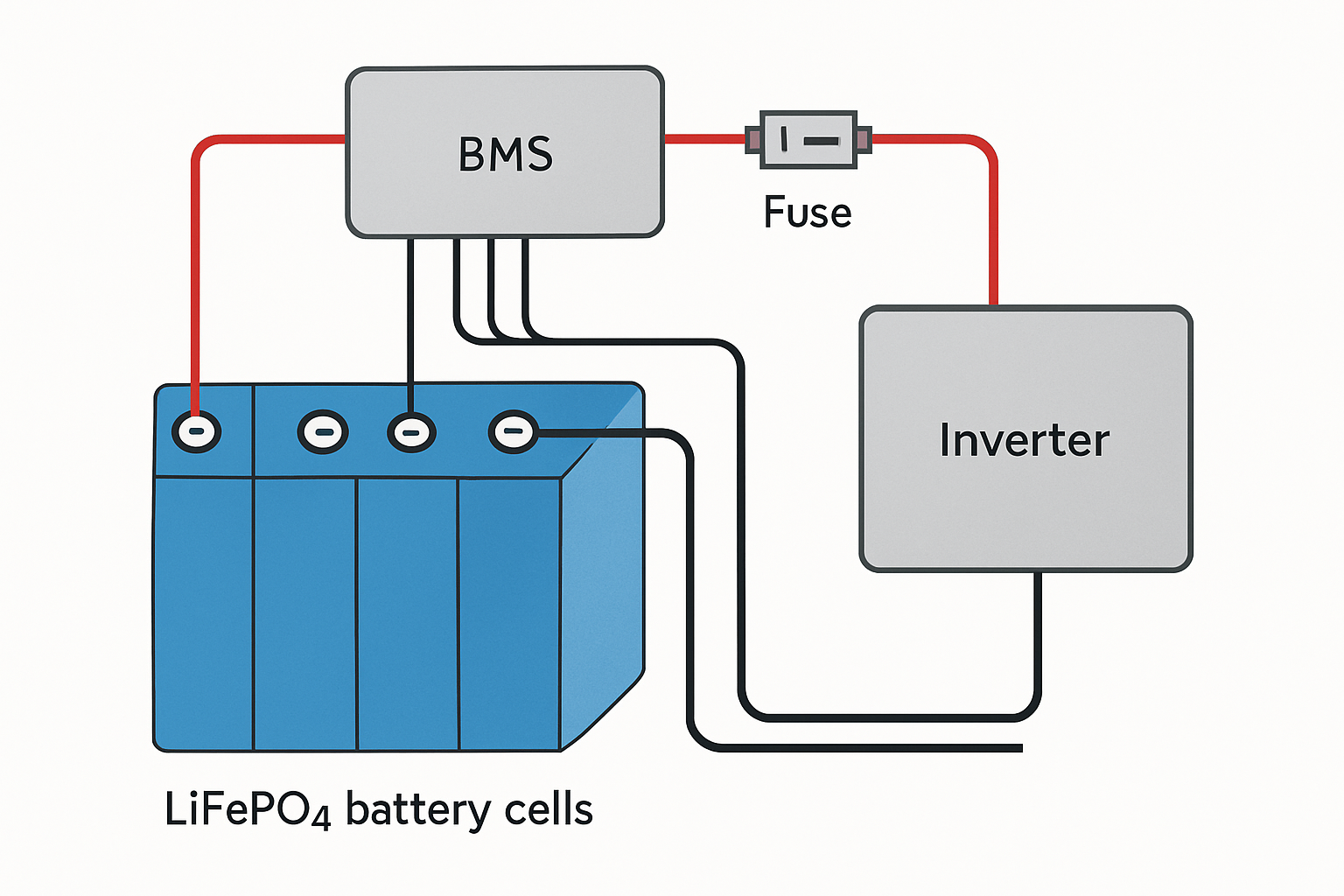

Overcurrent protection is non-negotiable for safety. Fuses and breakers are your system's primary defense against short circuits and overloads, which can cause fires or destroy expensive equipment. A battery bank, especially a LiFePO4 battery system, can deliver extremely high currents during a fault. An OCPD is designed to safely interrupt this flow of current before it can damage your wiring or components. According to an analysis by the International Energy Agency (IEA), robust investment in low-emission power technologies requires adherence to strict safety standards to ensure long-term viability. Place a correctly rated DC fuse or breaker as close to the battery's positive terminal as possible. This protects the entire circuit. Each parallel string of batteries should also have its own fuse for added protection.

Myth 3: Series and Parallel Connections Are Interchangeable

The Fiction

This myth suggests that how you connect multiple batteries—in series or parallel—doesn't significantly matter as long as they are all connected. The choice is often made without fully grasping the impact on voltage and capacity.

The Fact

Series and parallel connections have fundamentally different outcomes and are not interchangeable.

- Series Connection: Connecting the positive terminal of one battery to the negative terminal of the next. This adds the voltages together while the capacity (Amp-hours) remains the same. For example, two 12V 100Ah batteries in series create a 24V 100Ah bank. This is often used to meet the higher voltage requirements of inverters.

- Parallel Connection: Connecting positive terminals to positive terminals and negative to negative. This keeps the voltage the same but adds the capacities. Two 12V 100Ah batteries in parallel create a 12V 200Ah bank, effectively doubling the runtime.

Myth 4: Grounding Is Only for Grid-Tied Systems

The Fiction

There's a common misconception that off-grid solar systems, being isolated from the utility grid, do not require grounding. The thinking is that since there's no connection to the grid's ground, there's no need to create one.

The Fact

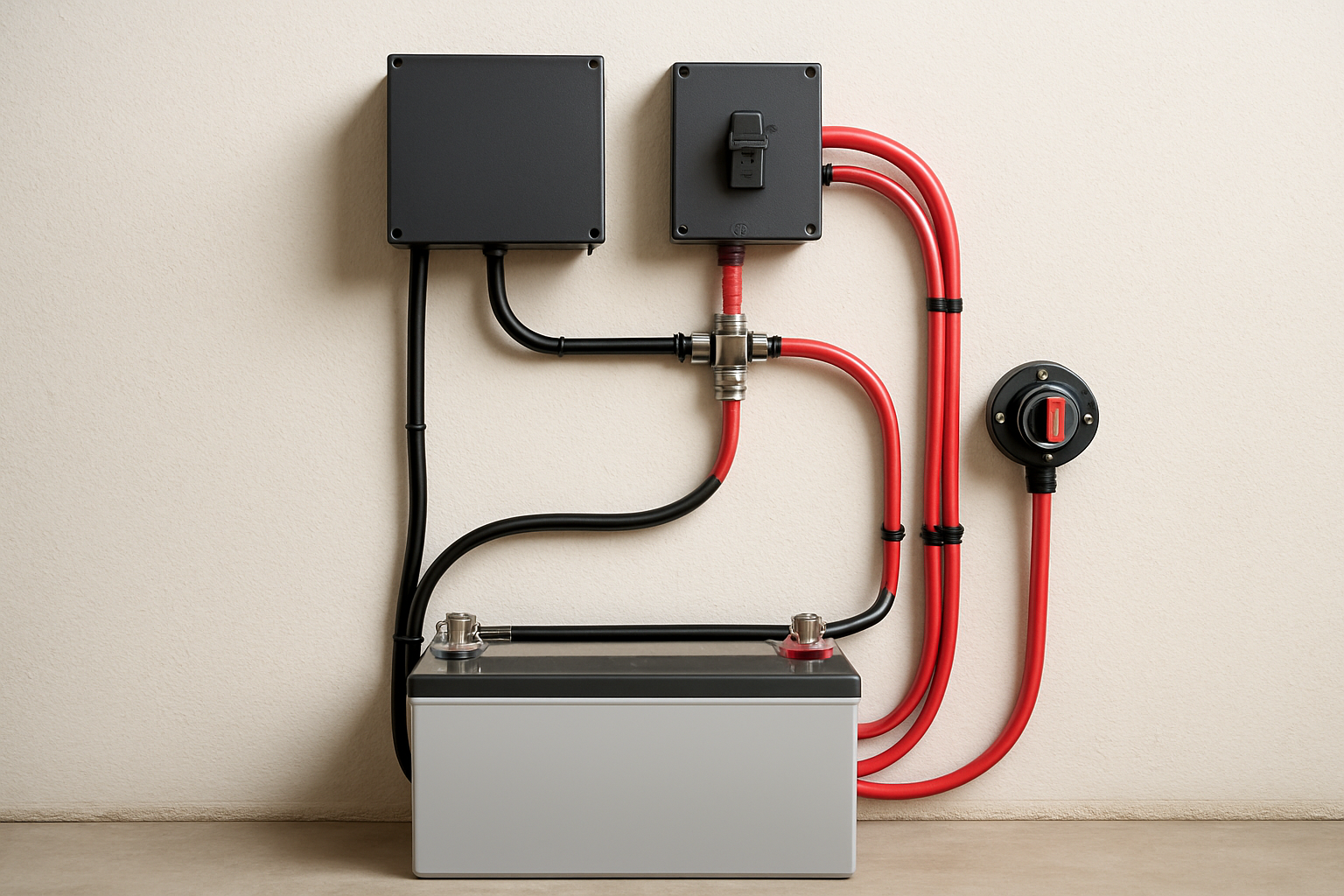

Grounding is a critical safety measure for all electrical systems, including off-grid solar setups. Proper grounding provides a safe path for fault currents to dissipate into the earth, protecting both people from electric shock and equipment from damage caused by lightning strikes or internal faults. An ungrounded system can lead to static electricity buildup or allow metal casings of components like inverters and battery enclosures to become energized during a fault, creating a severe shock hazard. A proper grounding system involves driving one or more ground rods deep into the earth and connecting them with a copper wire to the frames of your solar panels, mounting racks, and the chassis of your inverter and other equipment. The goal is to achieve a resistance to earth of less than 5 ohms.

Putting It All Together for a Safe System

Correct solar battery wiring is not about following arbitrary rules; it's about applying electrical principles to ensure safety, longevity, and performance. By debunking these common myths, you can make informed decisions for your solar setup. Always prioritize proper wire sizing, install overcurrent protection, use the correct series or parallel configuration, and implement a robust grounding system. As highlighted in research on energy storage, understanding the nuances of system performance is key to maximizing your investment. For a deeper look into performance metrics, the ultimate reference on solar storage performance offers valuable insights. According to a report from the International Renewable Energy Agency (IRENA), reliable energy storage is determined by factors including battery efficiency and depth of discharge, which are directly impacted by wiring quality. By adhering to best practices, you ensure your renewable energy solution operates as a reliable and powerful asset for years to come.

Frequently Asked Questions

What happens if I use a wire that is too long?

Longer wires increase total resistance, which causes a greater voltage drop. This means the voltage at the end of the wire (at your inverter or charge controller) will be lower than the voltage at the battery. This reduces system efficiency, wastes power, and can cause devices to operate improperly. To compensate for long wire runs, you must use a thicker wire (a lower gauge).

Can I mix different types or sizes of batteries?

No, it is strongly recommended to use batteries of the identical brand, model, voltage, capacity, and age in the same battery bank. Mixing batteries leads to imbalances during charging and discharging. The stronger batteries will overcompensate for the weaker ones, leading to overcharging or deep discharging of individual units, which significantly shortens the lifespan of the entire bank.

How tight should my terminal connections be?

Connections should be snug and secure, but not over-tightened. Loose connections create high resistance, leading to heat buildup and potential fire hazards. Over-tightening can damage the battery terminals or the bolts. It is best to use a torque wrench and follow the manufacturer's specifications for torque values to ensure a solid, safe connection.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.