Installing an energy storage system (ESS) involves more than connecting wires. It requires navigating a complex web of safety standards to ensure every project is secure, compliant, and approved without delay. For installers, the three most important acronyms are UL 9540, NFPA 855, and AHJ. Mastering their interplay is the key to a successful installation.

This checklist provides a systematic approach for installers. It helps you align the UL 9540 system certification with NFPA 855 installation code, all while satisfying the specific demands of the local Authority Having Jurisdiction (AHJ). Following these steps can streamline your workflow and build a reputation for safety and professionalism.

Understanding the Regulatory Triangle: UL 9540, NFPA 855, and the AHJ

Think of these three elements as a team. UL 9540 certifies the equipment's safety as a complete unit. NFPA 855 provides the rules for installing that equipment. The local AHJ then enforces those rules, often with their own specific interpretations. A compliant installation successfully addresses all three.

UL 9540: The System Safety Standard

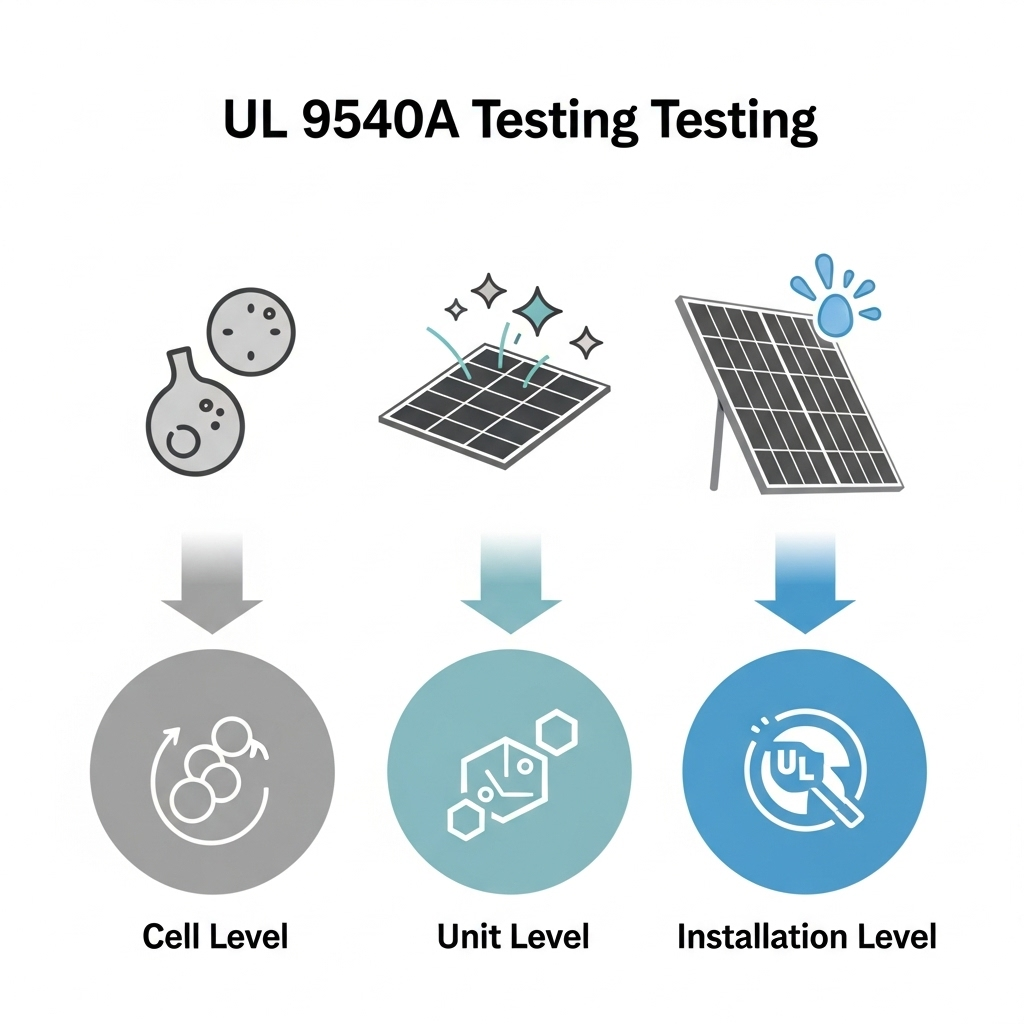

UL 9540 is a product safety standard, not an installation code. It certifies that the battery, inverter, management software, and containment structure have all been tested together as an integrated system. This is a critical distinction. Using a UL-listed battery with a UL-listed inverter does not create a UL 9540 certified system. The entire ESS must be listed as a single unit. This certification often relies on data from UL 9540A, a test method that evaluates fire propagation risk, which informs safe installation practices.

NFPA 855: The Installation Blueprint

NFPA 855, the Standard for the Installation of Stationary Energy Storage Systems, is your primary installation guide. It outlines the 'how' and 'where' of setting up an ESS. Key provisions cover:

- Siting: Rules for installing in garages, outdoors, or dedicated rooms.

- Spacing: Minimum distances required between ESS units and from other objects like walls, windows, and egress paths.

- Capacity Limits: Maximum energy capacity (in kWh) allowed in a given space or fire area.

- Fire Protection: Requirements for smoke detectors, heat detectors, or even fire suppression systems, depending on the system's size and location.

The AHJ: The Final Authority

The Authority Having Jurisdiction (AHJ) is the local official responsible for approving your installation. This is typically the local fire marshal or building inspector. The AHJ interprets and enforces the national codes like NFPA 855 and the National Electrical Code (NEC). Crucially, they can also impose stricter local requirements. Early and clear communication with the AHJ is a cornerstone of a smooth project.

Pre-Installation Compliance Checklist

Success begins long before you arrive on site. Thorough preparation prevents costly mistakes and delays. According to a report by the IEA, a shortage of skilled personnel able to properly conceive and install systems is a known barrier to adoption. A detailed checklist helps bridge this gap.

Site Assessment and System Siting

- Verify Location Compliance: Does the proposed location (e.g., attached garage, outdoor wall) meet NFPA 855 criteria? Note restrictions related to living spaces.

- Measure Spacing Clearances: Use a tape measure to confirm that the planned spot meets all spacing requirements—typically 3 feet between units and from critical surfaces.

- Plan Egress Paths: Ensure the ESS does not obstruct any required exit paths from the building.

- Assess Ventilation: Determine if the location has adequate ventilation to prevent heat buildup, as specified by the manufacturer.

Documentation and Design Review

- Confirm UL 9540 Listing: Obtain the certificate for the specific ESS model to prove it is listed to UL 9540.

- Secure the UL 9540A Report: If you plan to install units closer together than the 3-foot default, you will likely need the system's UL 9540A test report to justify the reduced spacing to the AHJ.

- Prepare Detailed Plans: Create a clear site plan showing the ESS location, clearances, and electrical single-line diagram. These documents are essential for your permit application.

Engage the AHJ Early

- Schedule a Pre-Application Meeting: Contact the local building or fire department to discuss the project. This shows professionalism and helps uncover local amendments or preferences.

- Present Your System Data: Bring the UL 9540 certificate and UL 9540A test summary to the meeting. Explain how your design meets or exceeds code requirements.

- Ask for a Local Checklist: Some AHJs provide their own checklists. Asking for one demonstrates your commitment to compliance.

On-Site Installation and Verification Checklist

With a solid plan, the on-site work becomes a process of methodical execution and verification. As noted in an IRENA report on electrification projects, the use of checklists and standard operating procedures is a best practice for ensuring quality installations.

Mechanical and Electrical Installation

- Follow the Manual: Adhere strictly to the manufacturer's installation manual. Deviating from it can void the UL 9540 listing and the warranty.

- Ensure Physical Protection: In locations like garages, install vehicle impact protection (e.g., steel bollards) if required by NFPA 855.

- Verify Wiring and Connections: Double-check that all DC and AC wiring gauges, conduit, and overcurrent protection devices match the plans and NEC requirements. The integrity of these connections is vital for achieving the expected solar storage performance and safety.

Fire Safety and Hazard Mitigation

The table below summarizes common fire safety requirements based on NFPA 855 for residential installations. Always confirm these with your local AHJ.

| Location | Minimum Spacing Between Units | Fire Detection Requirement | Typical Signage |

|---|---|---|---|

| Attached Garage | 3 ft (0.9 m) | Interconnected smoke alarm | Emergency Shutdown, Battery Type |

| Detached Accessory Structure | 3 ft (0.9 m) | Local smoke alarm | Emergency Shutdown, Battery Type |

| Outdoors (on exterior wall) | 3 ft (0.9 m) | Not typically required | Emergency Shutdown |

| Indoors (utility room) | 3 ft (0.9 m) | Interconnected heat/smoke detector | Emergency Shutdown, Battery Type, No Storage |

- Install Required Signage: Mount all necessary placards, including emergency shutdown instructions and markings that identify the type of battery technology.

- Test Detection Systems: If smoke or heat detectors are required, ensure they are installed correctly, interconnected to the home's system if needed, and tested.

The Final Inspection and Handover

The final steps are about demonstrating compliance and empowering the customer. Proper project closeout solidifies your reputation and ensures the client's long-term safety.

Preparing for the AHJ Inspection

- Organize Your Documentation: Have a binder or digital folder ready with the UL 9540 certificate, UL 9540A report summary, installation manual, approved plans, and your completed checklist.

- Conduct a Final Walkthrough: Before the inspector arrives, walk the site one last time with your checklist to catch any final details.

- Be Present and Prepared: Attend the inspection to answer any questions. Your presence shows you stand behind your work. Soft costs like permitting and inspections are a necessary part of the project, and being prepared makes them go smoothly, as outlined in IRENA's analysis of renewable power generation costs.

Customer Handover

- Provide a Document Package: Give the homeowner copies of all key documents, including the warranty, manuals, and a diagram of the system.

- Explain System Operation: Walk the customer through how the system works, what the indicators mean, and how to perform an emergency shutdown.

- Discuss Maintenance: Outline the simple maintenance tasks the homeowner should be aware of, such as keeping the area around the unit clear.

A Foundation for Safe Energy Storage

Navigating the requirements of UL 9540, NFPA 855, and the local AHJ does not have to be intimidating. By adopting a systematic, checklist-driven approach, installers can transform a complex process into a manageable workflow. This method not only ensures compliance and safety but also builds trust with clients and authorities, establishing your business as a leader in quality energy storage installations.

Disclaimer: This checklist is for informational purposes only and does not constitute legal or professional installation advice. Always consult the latest versions of UL 9540, NFPA 855, local building codes, and the manufacturer's installation manual before starting any project.

Frequently Asked Questions

What is the main difference between UL 9540 and NFPA 855?

UL 9540 is a product safety standard that certifies the energy storage system (ESS) as a single, integrated unit. NFPA 855 is an installation standard that provides rules on how and where to safely install that certified system.

Can I install an ESS that is not listed to UL 9540?

While possible in some areas, it is highly discouraged and often not permitted. An AHJ would likely require a much more rigorous and costly field evaluation for a non-listed system. Using a UL 9540 listed system simplifies the approval process immensely.

What if my local AHJ has requirements not listed in NFPA 855?

The local AHJ has the final say. Local amendments and requirements supersede the national code. This is why engaging the AHJ early in the planning process is so important to identify and incorporate any unique local rules.

Do I always need a UL 9540A test report for an installation?

Not always. A UL 9540A report is primarily used to justify installations that deviate from the default prescriptive requirements of NFPA 855, such as installing multiple ESS units with less than 3 feet of separation. If you follow all standard spacing and siting rules, the AHJ may not require it, but it is always good to have available.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.