The rapid growth of solar and energy storage systems is fundamentally changing how our electrical grids operate. These inverter-based resources (IBRs) are clean and efficient, but they behave differently from the traditional synchronous generators they are replacing. One of the most critical, yet often overlooked, differences lies in how they respond to electrical faults. When combined with excessive voltage drop from improperly sized conductors, this difference can render standard protection systems useless, creating significant safety risks.

The Shifting Landscape of Grid Protection

Understanding why protection fails requires looking at how it was designed to work in the first place. The old system and the new system operate on fundamentally different principles.

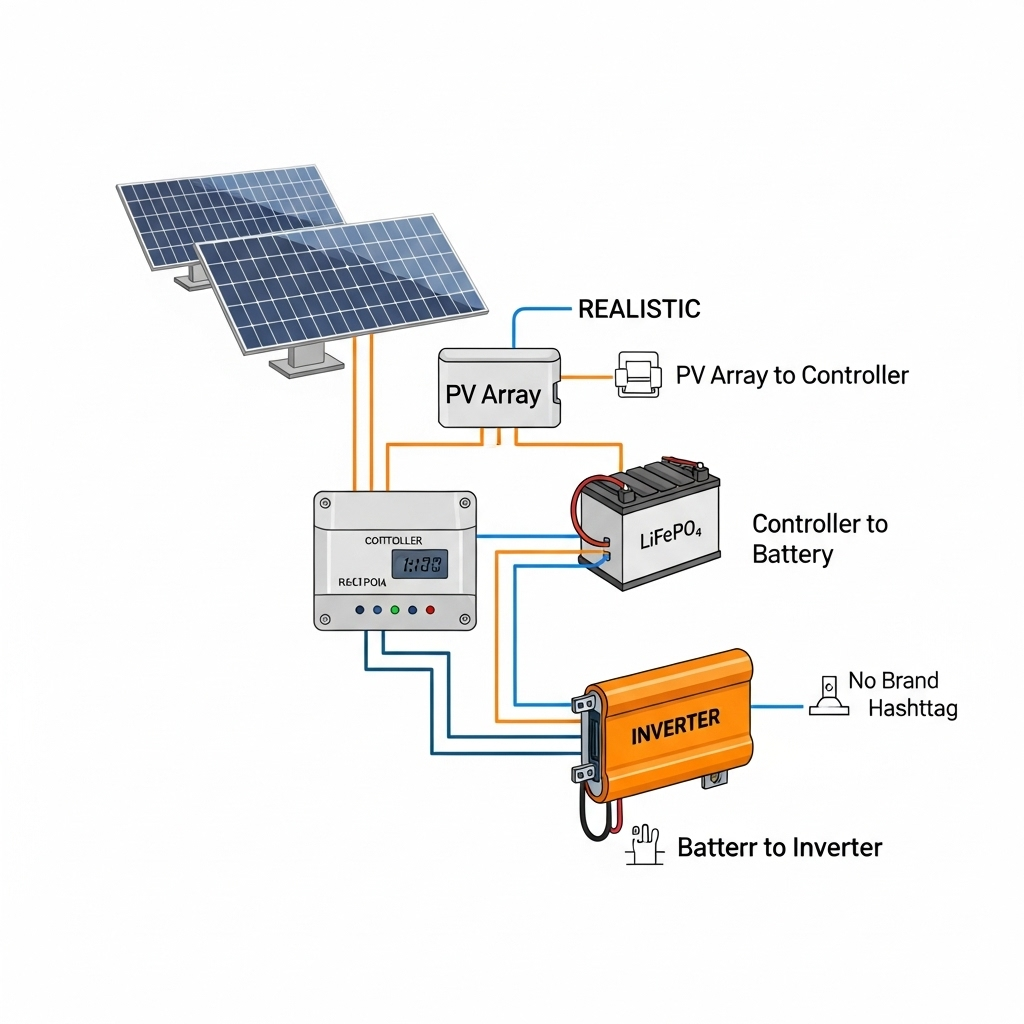

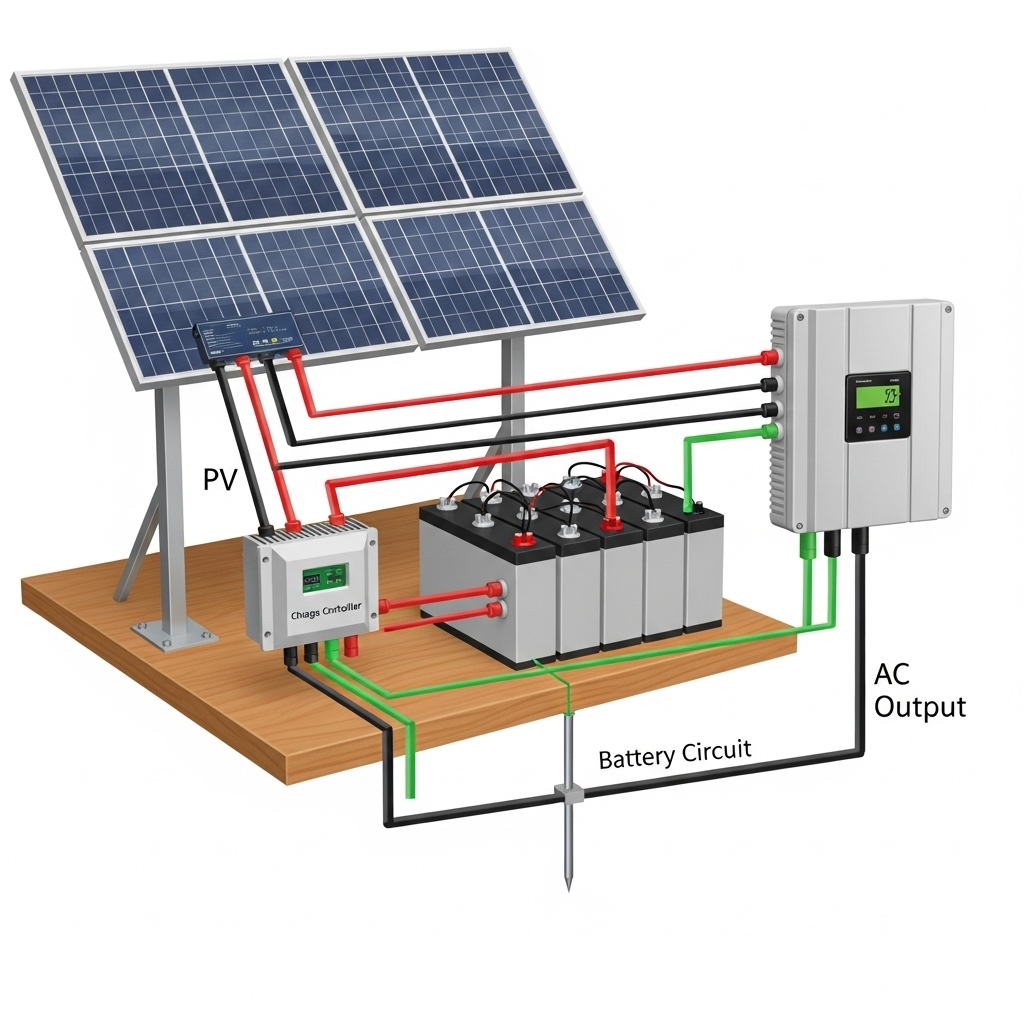

From Synchronous Generators to Inverter-Based Resources

Traditional power grids relied on large, spinning synchronous generators. During a short circuit, these machines could instantaneously inject massive amounts of current—often 5 to 10 times their normal operating level. This huge surge of current, known as fault current, provided a clear and unambiguous signal for fuses and circuit breakers to detect and trip, safely isolating the problem. In contrast, inverters are built with sensitive semiconductor components. They are designed to limit their output current to just slightly above their normal rating, typically around 1.1 to 1.5 times. This self-preservation feature means they cannot produce the high fault currents that legacy protection schemes depend on.

What is Fault Current and Why Does It Matter?

Fault current is the electrical surge that occurs during a fault condition like a short circuit. Protective devices are calibrated to specific fault current thresholds. When they detect a current above this level, they open the circuit. According to a report from the IEA, the displacement of synchronous generators leads to a reduction in the current supplied during short circuits. As the IEA's Integrating Solar and Wind study points out, this reduction in available fault current poses significant challenges for legacy protection systems, which use the magnitude of the current to detect and locate faults.

How Voltage Drop Compromises Inverter Protection

Voltage drop is the reduction in electrical potential along the path of a current-carrying wire. While some voltage drop is unavoidable, excessive levels in inverter-rich sites can effectively blind the very devices designed to protect the system.

The Direct Link Between Voltage and Current

During a fault, the impedance of the circuit plummets, which should cause the current to surge. However, if the conductors connecting the inverter to the protection device are too long or too thin, they introduce significant resistance. This resistance causes a voltage drop that works against the inverter's ability to supply current. The inverter sees a lower voltage at its terminals and its current output is consequently limited even before its electronic protection kicks in. The result is a fault current that is much lower than expected.

Blinding the Protective Devices

This creates a dangerous scenario. A fault occurs, but the combination of the inverter's inherent current limit and the high voltage drop in the wiring means the current reaching the circuit breaker never gets high enough to trip it. The breaker remains closed, unaware of the hazardous condition downstream. The fault continues to draw current, potentially leading to overheating, fire, and catastrophic equipment failure. The protective device has been effectively blinded by the voltage drop.

Impact on Fault Ride-Through Capabilities

Fault Ride-Through (FRT) is a critical inverter function that allows it to remain online during brief grid voltage sags, ensuring grid stability. However, pre-existing voltage drop from conductors can compound the problem. A minor grid voltage sag, when combined with the voltage drop in the site's wiring, can push the voltage at the inverter's terminals below its FRT threshold. This can cause the inverter to disconnect unnecessarily, contributing to grid instability. As the IEA highlights in its research, FRT is a key capability for power plants to maintain generation during fault conditions.

Conductor Sizing: The First Line of Defense

Preventing protection breakdown starts with a fundamental design principle: proper conductor sizing. It is not just about efficiency; it is a critical safety requirement.

Beyond Simple Ampacity Calculations

Many designers size conductors based only on ampacity—the maximum current a wire can safely carry without overheating. While essential, this is not sufficient for inverter-based systems. In long wire runs, voltage drop often becomes the primary limiting factor long before ampacity is a concern. A wire might be thick enough to handle the current without melting, but it can still have enough resistance to cause unacceptable voltage drop and compromise protection.

A Practical Approach to Sizing for Protection

A widely accepted best practice is to design for a voltage drop of 2-3% or less on DC circuits and 3-5% on AC circuits. This requires careful calculation based on the conductor's length, material, and cross-sectional area. For a deeper dive into performance metrics and ensuring your system operates at its peak, understanding the relationship between components is key. A comprehensive overview of solar storage performance can provide valuable context for these calculations.

| Conductor Size (AWG) | Current (Amps) | Length (feet) | Voltage (V) | Approximate Voltage Drop (%) |

|---|---|---|---|---|

| 10 | 30 | 100 | 48 | ~4.1% |

| 8 | 30 | 100 | 48 | ~2.6% |

| 6 | 30 | 100 | 48 | ~1.6% |

Disclaimer: This table provides illustrative values. Always perform precise calculations for your specific application and consult local electrical codes.

The Role of System Voltage

One of the most effective strategies to combat voltage drop is to increase the system's DC voltage. Since power is the product of voltage and current (P = V x I), a higher system voltage delivers the same amount of power with less current. For example, a 10kW system at 48V requires over 200A, while at 400V it requires only 25A. Lower current dramatically reduces voltage drop, allowing for longer wire runs or smaller, more cost-effective conductors without compromising safety.

Advanced Solutions and Future-Proofing

As grids continue to evolve, so will the technologies designed to protect them. New inverter designs and smarter protection schemes are on the horizon.

Grid-Forming Inverters

A new class of inverters, known as grid-forming inverters, offers a promising solution. Unlike conventional grid-following inverters, they can create their own stable voltage and frequency reference. More importantly, some are being designed to safely provide higher fault currents, better mimicking the behavior of synchronous generators and making them more compatible with existing protection schemes.

Adaptive Protection Schemes

The industry is also developing adaptive protection systems. These advanced relays do not rely solely on current magnitude. As noted in the IEA's System Integration of Renewables report, these future schemes may use communication between devices or analyze time-domain signatures of voltage and current waveforms to detect and locate faults with much greater speed and accuracy, even in low-fault-current conditions.

Key Takeaways for System Designers and Installers

In the modern era of inverter-based energy systems, voltage drop is more than an efficiency loss—it is a critical safety parameter. The failure to account for its impact on fault currents can lead to a complete breakdown of system protection. Always calculate voltage drop for every circuit and prioritize proper conductor sizing from the initial design phase. This proactive approach is the most reliable way to ensure a safe, efficient, and resilient solar and energy storage installation.

Frequently Asked Questions

What is a safe level of voltage drop for inverter circuits?

While standards vary, a common best practice for DC circuits in solar and storage systems is to target a voltage drop of 2-3% or less. For AC circuits, 3-5% is often acceptable. However, for ensuring protection coordination, minimizing it as much as practically possible is the safest approach.

Can I just use a larger circuit breaker to solve the problem?

No, this is extremely dangerous. Using a larger breaker would make the problem worse. The issue is that the fault current is *too low* to trip the correctly sized breaker. A larger breaker would require an even higher current to trip, meaning it would almost certainly never trip during a fault in this scenario, creating a serious fire and safety hazard.

Does this issue affect both AC and DC wiring?

Yes. Voltage drop affects both the DC side (from panels or batteries to the inverter) and the AC side (from the inverter to the point of connection). Both must be calculated and managed carefully. Poor DC-side sizing can lead to inverter underperformance and nuisance trips, while poor AC-side sizing can directly impact protection coordination with the building's main electrical panel.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.