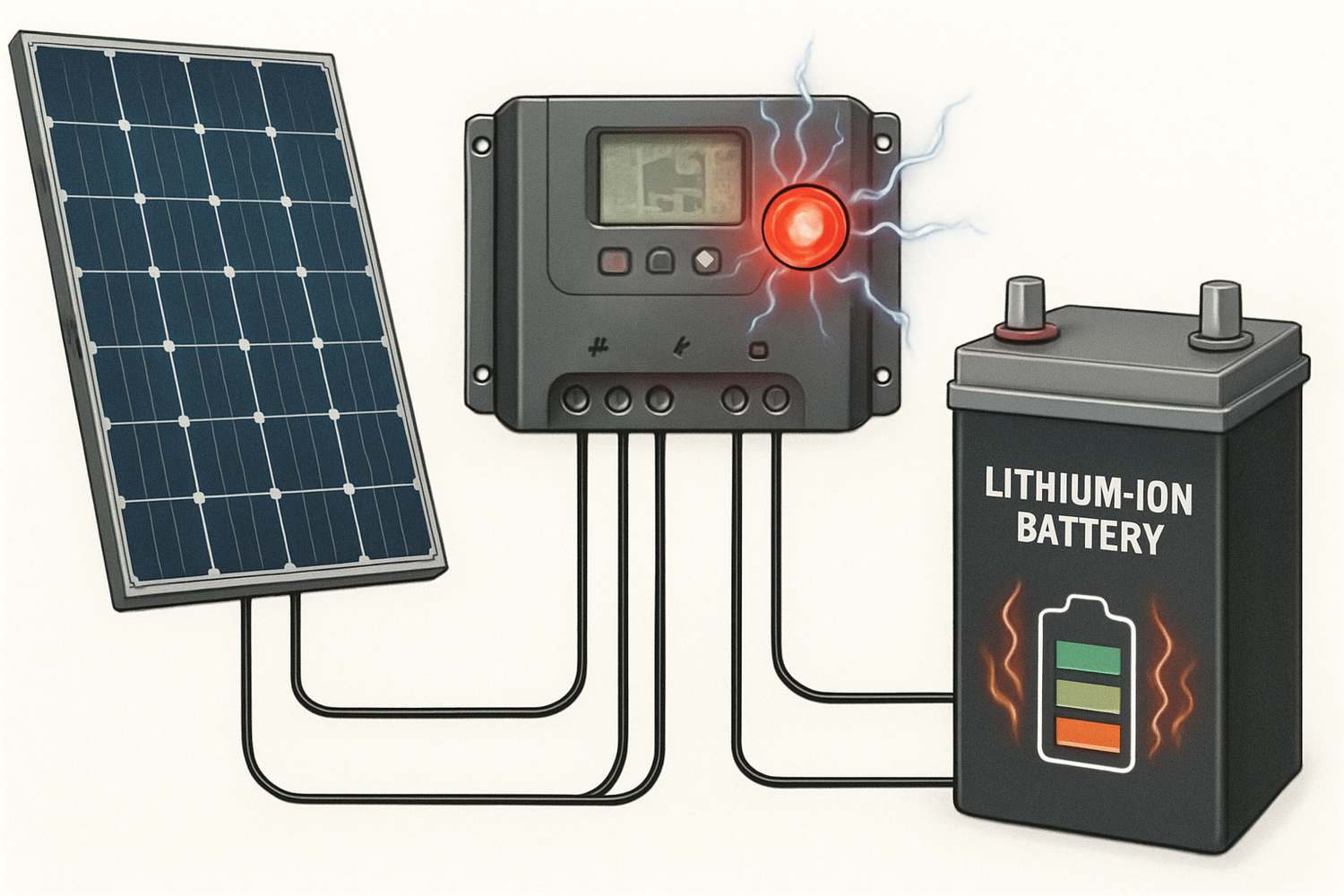

In any solar energy system, the charge controller acts as the gatekeeper between your solar panels and your valuable lithium-ion battery bank. Its job is to manage the flow of energy, ensuring the battery charges safely and efficiently. However, when a controller malfunctions or is improperly configured, it can silently cause irreversible damage to your batteries, shortening their lifespan and compromising your energy independence. Recognizing the warning signs is crucial to protecting your investment.

Sign 1: Persistent Overcharging and High Voltage Alarms

One of the most direct ways a controller can harm a lithium-ion battery is by consistently pushing its voltage beyond safe limits. This is a clear indicator of a problem that needs immediate attention.

Understanding Voltage Limits for LiFePO4 Batteries

Lithium Iron Phosphate (LiFePO4) batteries, a popular choice for energy storage, have strict voltage windows for optimal health. Typically, the absorption charge voltage is set between 14.4V and 14.6V, while the float voltage is around 13.6V. Exceeding these thresholds, even for short periods, can lead to serious issues. When overcharged, excess energy causes side reactions within the battery, generating heat and gas. This can result in a swollen casing, electrolyte leakage, and permanent capacity loss.

How a Faulty Controller Causes Overcharging

Overcharging often stems from incorrect settings within the controller, a failed voltage sensor, or low-quality internal components that cannot regulate power accurately. If the controller fails to stop or reduce the charging current once the battery reaches its target voltage, it continuously forces energy into an already full battery. This not only degrades the battery's internal structure but also poses a significant safety risk.

Sign 2: Frequent Undercharging and Low Voltage Disconnects

Just as damaging as overcharging is the failure to charge the battery completely. A controller that consistently undercharges your battery prevents it from reaching its full potential and can shorten its life.

The Dangers of Incomplete Charging Cycles

When a lithium-ion battery is not fully charged regularly, its Battery Management System (BMS) may struggle to perform cell balancing. This leads to an imbalance where some cells have a higher state of charge than others. Over time, this imbalance reduces the battery's usable capacity and can lead to premature failure of the weaker cells. Undercharging can also prevent the battery from delivering its rated power, leading to unexpected system shutdowns when you need power most.

Controller Settings That Lead to Undercharging

This issue can be caused by controller settings that are too conservative, such as a low absorption voltage or an insufficient absorption time. A controller that is too small for the solar array can also be a culprit, as it may not be able to process all the available solar energy. According to research from the International Renewable Energy Agency (IRENA), battery performance is directly tied to its efficiency and depth of discharge, both of which are managed by the controller. An improper setup, as detailed in their report Electrification with renewables: Enhancing healthcare delivery in Mozambique, compromises the entire system's reliability.

Sign 3: Inaccurate State of Charge (SoC) Readings

Your controller's State of Charge (SoC) display is the fuel gauge for your battery. If this reading is unreliable, you are essentially flying blind, making decisions based on faulty information that can lead to battery damage.

Why Accurate SoC is Critical

An accurate SoC reading helps you manage your energy usage effectively, preventing deep discharges that can harm the battery. It also informs the controller's charging algorithm. If the controller thinks the battery is fuller than it is, it may end the charging cycle prematurely. Conversely, if it thinks the battery is less full, it might attempt to overcharge it.

How Controllers Miscalculate SoC

Basic controllers often estimate SoC based solely on voltage, which is an unreliable method for LiFePO4 batteries due to their flat voltage curve. More advanced controllers use sophisticated algorithms and current measurements (coulomb counting) for better accuracy. However, even these can drift over time if they fail to periodically re-synchronize with the battery at a full charge. The best systems feature direct communication between the controller and the battery's BMS for the most precise data.

Sign 4: Excessive Heat Generation

While it's normal for electronic components to generate some heat, a charge controller or battery that is consistently hot to the touch is a major red flag. Heat is a primary enemy of battery longevity.

The Link Between Heat and Battery Degradation

High temperatures accelerate the chemical reactions inside a lithium-ion battery, leading to faster degradation of the electrolyte and other components. This results in a permanent reduction in capacity and a shorter service life. A hot controller can also raise the ambient temperature around the battery, compounding the problem. Overheating can be a symptom of overcharging, as excess energy is dissipated as heat.

Controller Malfunctions Causing Overheating

Overheating in a controller can be caused by several factors: an overloaded system where the controller is too small for the solar array, poor ventilation, or internal component failure. Less efficient Pulse Width Modulation (PWM) controllers tend to generate more heat than their more advanced Maximum Power Point Tracking (MPPT) counterparts, as they regulate voltage by dissipating excess energy.

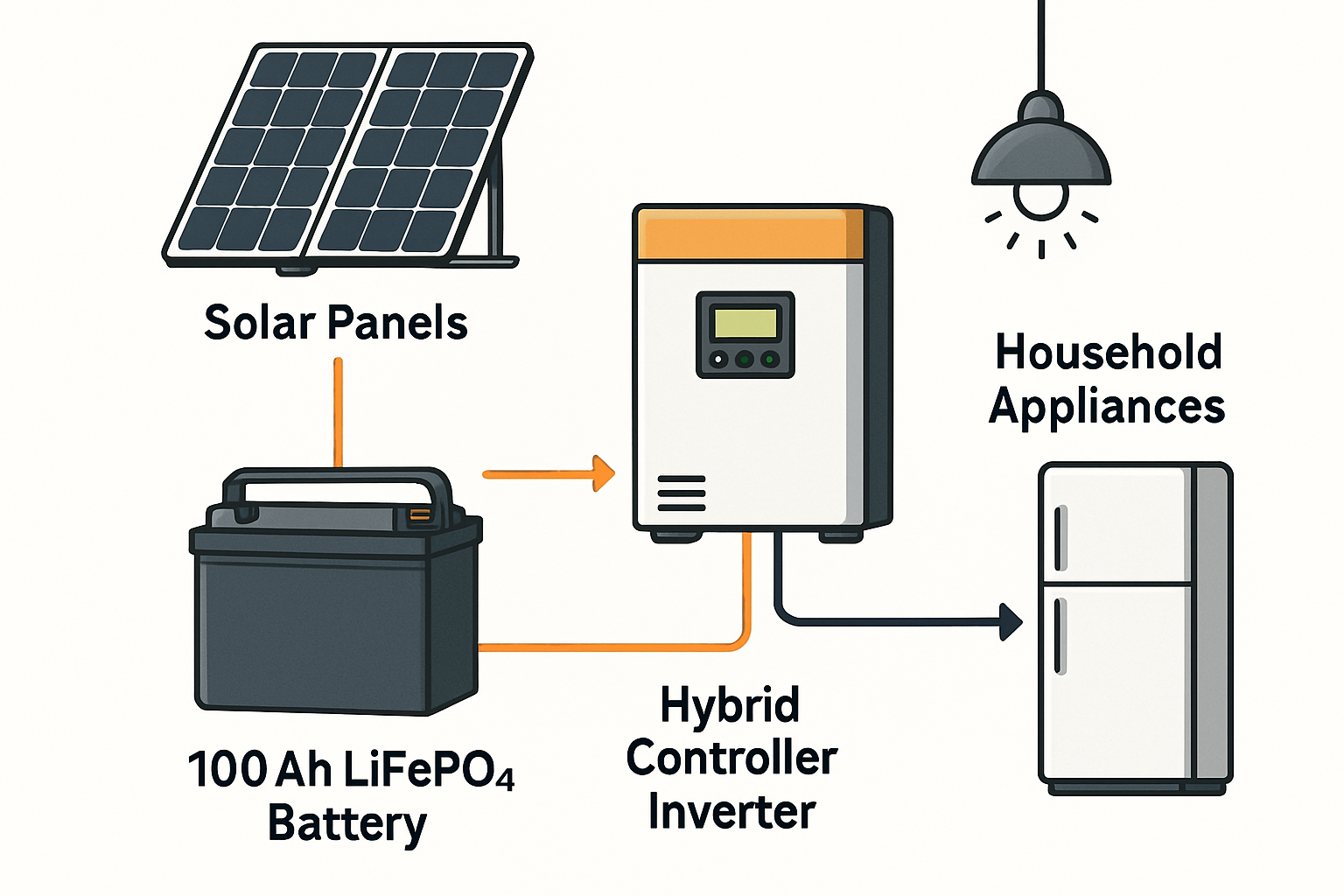

Sign 5: Lack of Communication with the Battery's BMS

Modern energy storage relies on seamless integration. A controller that operates in isolation, ignoring the battery's own management system, is a recipe for inefficiency and potential damage.

The Role of the Battery Management System (BMS)

The Battery Management System (BMS) is the brain of your lithium-ion battery. It monitors critical parameters like cell voltage and temperature and is designed to protect the battery from unsafe conditions. It is the ultimate safety net, capable of disconnecting the battery to prevent damage from over-voltage, under-voltage, or extreme temperatures.

When Controller and BMS Don't Communicate

When a charge controller and BMS can communicate (a feature known as 'closed-loop communication'), they work as a team. The BMS can tell the controller to reduce or stop charging if a cell is nearing its voltage limit or if the temperature is too high. Without this communication, the controller follows its own pre-programmed settings, which might not be ideal for the battery's real-time condition. This can lead to the BMS frequently intervening by disconnecting the battery, causing system instability and inefficient charging. A hybrid controller inverter combination is often designed to ensure this vital communication link is robust.

Choosing the Right Controller for Optimal Battery Health

Protecting your lithium battery starts with selecting a high-quality controller that is fully compatible with its chemistry. An advanced MPPT controller is generally the superior choice over a PWM controller for lithium systems due to its higher efficiency and more precise control.

| Feature | Generic / PWM Controller | Advanced / MPPT Controller |

|---|---|---|

| Efficiency | 70-85% | 95-98% |

| Battery Type Support | Often limited, may lack specific LiFePO4 profiles | Programmable for specific lithium chemistries |

| BMS Communication | Typically none (Open-Loop) | Often includes CAN/RS485 ports (Closed-Loop) |

| Lifespan Impact | Can shorten battery life due to imprecise charging | Maximizes battery life through precise control |

To ensure all components in your system work together harmoniously, it's helpful to understand their individual impact on efficiency. A detailed analysis of solar storage performance provides valuable data on how different parts of a system contribute to overall output and longevity.

A Final Check on Your System's Health

Your lithium-ion battery is a significant investment and the heart of your energy storage system. The controller, while a smaller component, has an outsized impact on its health and longevity. By regularly monitoring for signs of overcharging, undercharging, inaccurate readings, excess heat, and ensuring proper communication with the BMS, you can prevent costly damage. Upgrading to a high-quality, compatible controller is a small price to pay to safeguard your energy independence for years to come.

Frequently Asked Questions

Can the wrong controller settings void my lithium battery warranty?

Yes, in many cases. Battery manufacturers provide specific charging parameters, including voltage and current limits. Using an improperly configured or incompatible controller that fails to adhere to these specifications can be considered misuse, which may void the warranty. Always consult your battery's technical documentation.

What is the difference between a PWM and an MPPT controller for lithium batteries?

A PWM (Pulse Width Modulation) controller is a simpler, less expensive device that essentially acts as a switch, connecting the solar panels to the battery. An MPPT (Maximum Power Point Tracking) controller is more sophisticated, converting excess solar panel voltage into a higher charging current, which can increase energy harvest by up to 30%. For lithium batteries, MPPT controllers are highly recommended because they offer greater efficiency and the precise, multi-stage charging control needed for optimal battery health.

How often should I check my controller's settings?

It is good practice to verify your controller's settings after the initial installation to ensure they match the battery manufacturer's recommendations. Afterward, a check once per year or whenever you notice unusual system behavior—such as the warning signs mentioned in this article—is advisable to ensure everything remains optimized for your battery's health.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.