Choosing between flexible marine solar panels and rigid marine solar panels is about matching hardware to your deck, sailing pattern, and loads. This piece gives you practical differences that matter at sea: real output impacts from heat and tilt, mounting realities, service life, and total cost. You will see where each panel type fits inside boat solar power systems, with clear use-case guidance.

What actually matters offshore

- Available area and shape: flat arch or davits favor rigid frames; curved biminis and dodgers favor flexible sheets.

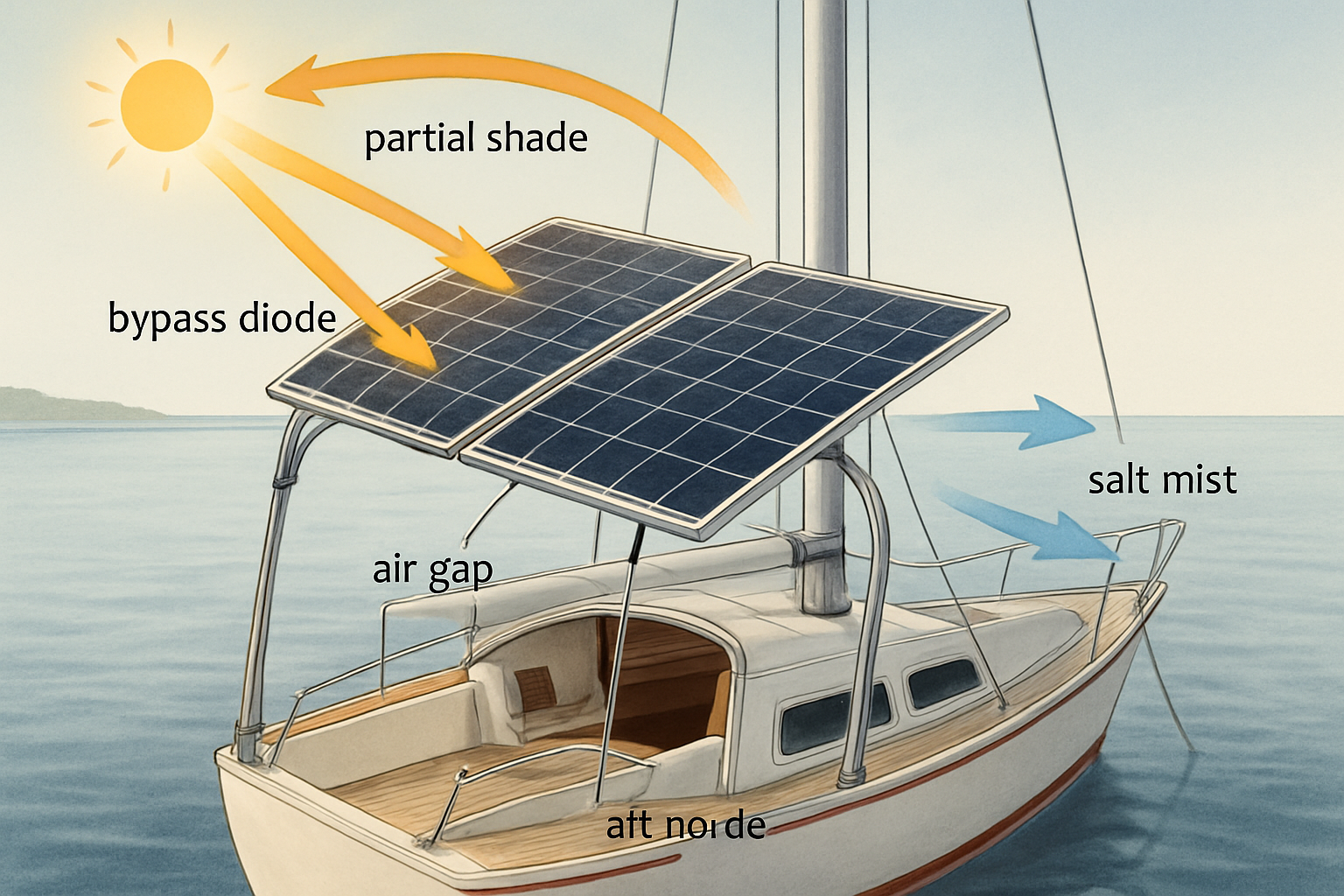

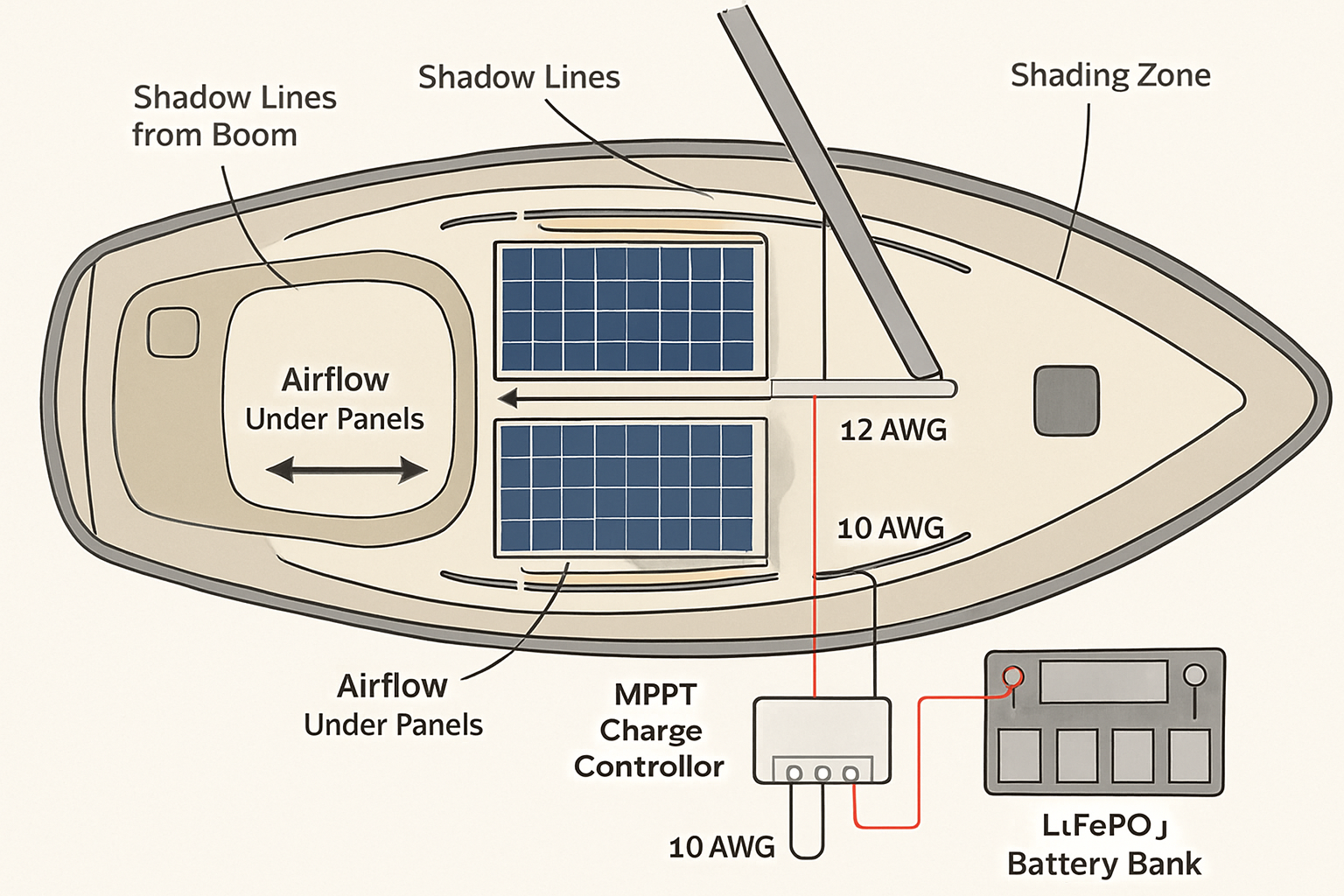

- Heat and airflow: panels run hot on dark decks, which reduces power. Air gaps help.

- Shading and rigging: lines, radar, and booms cast moving shadows that can drop output sharply. Layout and wiring mitigate loss.

- Loads and battery: fridge, instruments, and autopilot set your daily energy target. LiFePO4 banks and MPPT controllers raise usable yield under partial sun.

Orientation and tilt shape production over the day and across the seasons. According to the IEA Next Generation Wind and Solar Power, a tilt change shifts the annual profile and tracking can add 12–25% yield in sunny regions. Boats cannot track the sun, so surface choice and mounting angle do the heavy lifting. The full report reiterates these tilt-yield trade-offs (IEA full report).

Performance and efficiency on a boat

Efficiency ranges and heat behavior

Rigid marine solar panels typically deliver 18–22% module efficiency. Flexible marine solar panels often sit around 16–20%, though premium cell types can be higher. Heat cuts output: many modules have a temperature coefficient near −0.35% to −0.45% per °C above 25°C. Deck-mounted flexible sheets can run 20°C hotter than ambient, trimming 7–10% power during midday. Rigid frames mounted on rails with a 20–40 mm air gap run cooler and hold closer to nameplate.

Seasonal and daily shape also matter. The IEA notes that a greater equator-facing tilt can improve winter production at the expense of peak-summer output. On a boat, a small wedge under rigid modules can favor shoulder seasons if you often anchor outside peak summer.

Realistic daily yield ranges

- Flat 100 W panel in good summer sun at anchor: roughly 400–600 Wh/day. Cloud and haze drop this to 200–400 Wh/day.

- Shoulder seasons at mid-latitudes: 200–450 Wh/day per 100 W, depending on tilt and shading.

- Heat penalty: expect 5–10% less for adhesive-mounted flexible sheets under similar conditions due to higher cell temps.

Regional irradiance, tilt, and design drive capacity factor. The EIA tracks wide capacity factor ranges on land-based PV, reflecting how sun and configuration shape yield; the same drivers apply at small scale on boats.

Shading and wiring strategy

- Panel layout: keep boom and radar shadows off the same cell strings. If unavoidable, use two smaller panels spaced apart rather than a single larger one.

- Bypass diodes: both flexible and rigid panels include them, but partial shading can still clip a third to two-thirds of a panel’s power.

- MPPT controllers: wire multiple panels in parallel (with fuses) if shading is frequent, so a shaded panel does not throttle a whole series string.

Durability, mounting, and safety

Mechanical life and environment

Rigid glass-aluminum modules resist microcracks and UV better and usually last longer on deck hardware. Flexible laminates save weight and tolerate gentle curvature, but repeated flex and foot traffic can induce cracks and moisture ingress. Expect a shorter service window in harsh UV and salt unless shading, cooling, and strain relief are well managed.

Global PV improvements continue. Summaries from Energy.gov indicate steady gains in module design and system practices, which also filter down to small craft use over time.

Mounting realities

- Flexible: adhesives on smooth gelcoat or fabric lacing on bimini tops. Leave edges vented for airflow and drainage. Use cable strain relief and a soft backing to avoid chafe.

- Rigid: stainless brackets on arches, rails, or davits. Maintain an air gap for cooling. Use isolating pads to reduce vibration.

- Corrosion: choose marine-grade hardware and sealed connectors. Use dielectric grease on MC4s and drip loops to keep water out.

Climate-driven variability is real. IRENA’s Year in Review underscores that resource shifts and extremes affect renewable output planning. On boats, this supports designing with a buffer: modest oversizing and good battery storage practice.

Cost, weight, and lifecycle at a glance

| Attribute | Flexible marine solar panels | Rigid marine solar panels |

|---|---|---|

| Weight (approx., 100 W) | 2–3 kg | 6–8 kg |

| Thickness | 2–3 mm | 30–35 mm |

| Typical module efficiency | 16–20% | 18–22% |

| Temperature behavior | Hotter on deck; −0.35% to −0.45%/°C reduces output | Cooler due to airflow; better sustained power |

| Curvature tolerance | Mild curve only (check maker limits) | Flat only |

| Walkability | Generally not advised; risk of microcracks | Not designed for foot traffic |

| Mounting | Adhesive, fabric lacing | Arch/davit brackets, rails |

| Retail cost per watt | About $2.0–$3.0/W | About $0.8–$1.5/W |

| Service life on boats | Often 2–5 years in harsh UV | Often 10–20+ years with care |

| Best fit | Curved biminis/dodgers, weight-sensitive craft | Arches, hard tops, and space for rails |

Large-scale PV modules often carry 20–25 year performance warranties on land. While boats are harsher, the land benchmark shows why rigid modules tend to outlast laminates. The trend toward improved module designs noted by Energy.gov supports better longevity across the board.

Which suits your boat? Use-case matrix

| Boat profile | Typical mounting surface | Recommended panel type | Notes |

|---|---|---|---|

| Daysailer or weekender | Bimini or small cabin top | Flexible if space is tight; rigid if a small rail mount is possible | 100–200 W keeps lights and instruments topped up |

| Coastal cruiser (30–40 ft) | Stern arch, davits | Rigid | 300–600 W for fridge and electronics at anchor |

| Performance or racing | Curved deck, low weight target | Flexible | Weight and aerodynamics beat peak efficiency |

| Liveaboard with hard top | Hard top or arch | Rigid | Space and airflow favor higher output and longer life |

System integration tips that prevent disappointments

Controller and wiring

- MPPT controller sized at 1.2–1.5× array STC power helps in cool, clear conditions.

- Match panel Voc and Vmp to controller limits. Parallel strings help under shading; add fuses per string.

- Keep voltage drop under 3% on long runs. Use tinned marine cable and sealed breakers.

Battery and charging profiles

LiFePO4 banks accept charge efficiently and reduce gen-set hours. Set absorption and float to the battery spec. Good solar inverter or hybrid controller settings avoid chronic undercharge. Energy.gov materials highlight rising roles for storage alongside PV, supporting reliable onboard power (Energy.gov).

Thermal and mechanical care

- Provide airflow. Even flexible sheets benefit from a thin spacer grid to cut heat soak.

- Strain relief on all leads. Boats move. Cables should not carry panel weight.

- Rinse salt, then clean with mild soap. No aggressive solvents on laminates.

Make the call: a simple selector

- If your only usable area is a curved bimini or dodger, choose flexible marine solar panels sized for your daily Wh target.

- If you have an arch, davits, or hard top, choose rigid marine solar panels for better cooling, durability, and cost per watt.

- If weight and stealth matter more than lifetime, flexible wins. If lifecycle cost and long-term output matter more, rigid wins.

IEA analysis shows tilt can shift seasonal energy toward winter (IEA report). If you winter cruise at higher latitudes, a slight tilt on rigid mounts pays back with more usable cold-season energy. For tropical summers, flat mounts are fine and easier to live with.

Safety note (non-legal advice): follow marine electrical standards and manufacturer documentation. Use proper overcurrent protection and isolation. This content is informational only.

FAQs

Are flexible panels really walkable?

Some claim light foot traffic is possible, but repeated loads can cause microcracks. Treat both panel types as non-walkable to preserve output.

How much curve can flexible panels tolerate?

Only mild curvature. Many allow a gentle bend, such as a few centimeters over a meter. Exceeding maker limits can damage cells and laminates.

Can I mix flexible and rigid panels on the same controller?

Use separate MPPT inputs for unlike panels. Different IV curves and shading responses make shared strings inefficient.

What daily energy should I budget per 100 W?

Plan 300–500 Wh/day per 100 W for a flat deck in fair weather. Expect less in shoulder seasons and during heat or haze.

Do I need an MPPT controller?

Yes for most setups. MPPT improves yield, especially in cool mornings and under partial shade. It also manages voltage safely.

How does tilt influence my decision?

Small tilts can shift energy toward winter. IEA analysis supports the benefit of adjusted tilt in temperate seasons. Rigid mounts make small tilt wedges simple.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.