Achieving energy independence with an off-grid solar system is a powerful goal. The foundation of a successful system is an accurate forecast of its energy production over many years. However, initial estimates can often be overly optimistic. Small, persistent predictive modeling errors can compound over time, leading to a significant gap between expected and actual off-grid yield. This can compromise your energy security and the financial return on your investment. Understanding these common pitfalls is the first step toward building a truly resilient and reliable power solution.

Misinterpreting Weather and Environmental Data

The most obvious input for a solar forecast is sunlight, but the data used is often too generic. Real-world conditions at your specific location introduce variables that standard weather data might miss, impacting long-term yield forecasting.

Overlooking Microclimate Variations

Regional weather forecasts provide a good baseline, but they cannot capture your property's unique microclimate. A forecast might predict a full day of sun for your area, while your specific location experiences morning fog that burns off late or afternoon cloud cover that forms over a nearby ridge. As the International Energy Agency (IEA) notes in its Getting Wind and Solar onto the Grid report, local factors can create significant deviations from regional predictions. These daily, small-scale weather patterns, if not accounted for, create a cumulative deficit in your energy production over months and years.

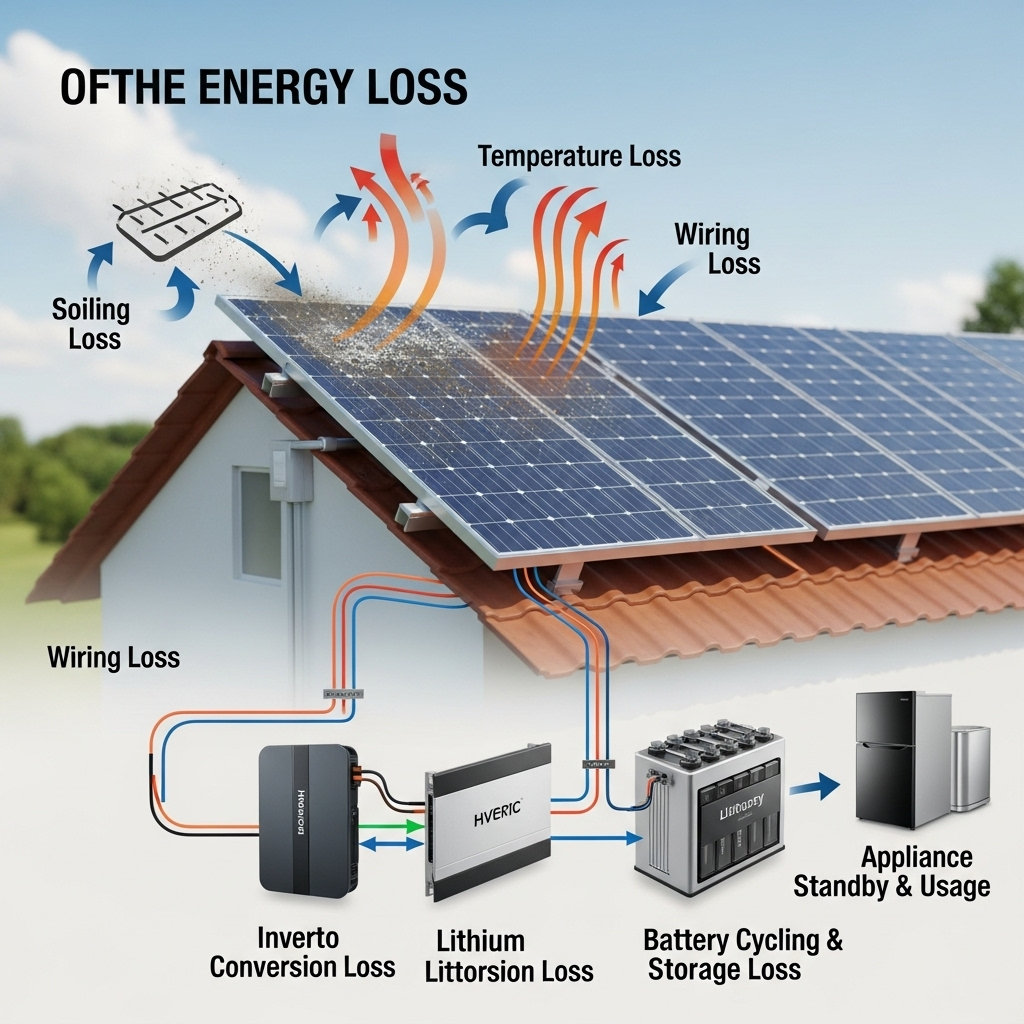

Underestimating Soiling and Snow Losses

Solar panels are rarely perfectly clean. Dust, pollen, bird droppings, and industrial pollutants accumulate on the surface, a process known as soiling. This film blocks sunlight and can reduce a panel's output by 5% to 15% or more in some environments. Similarly, a few inches of snow can halt production entirely. A reliable forecast must include a realistic 'soiling loss factor' based on your local environment and a practical cleaning schedule. Ignoring this is a direct overestimation of your available power.

Ignoring Temperature-Related Inefficiencies

Solar panels are tested for efficiency at a standard temperature of 25°C (77°F). However, on a sunny day, the surface of a dark panel can easily reach 65°C (150°F) or higher. For every degree above 25°C, most crystalline silicon panels lose about 0.3% to 0.4% of their power output. A forecast that uses average annual air temperature instead of realistic peak operating temperatures will inflate production figures, especially for systems in hot climates.

Errors in System Design and Component Assumptions

A solar energy system is more than just panels. Each component has its own efficiency curve and lifespan. Flawed assumptions about how these parts work together are a major source of off-grid energy forecasting inaccuracy.

Inaccurate Component Degradation Models

Every component in your system degrades over time. Solar panels typically lose about 0.5% of their efficiency per year. Inverters and charge controllers have a finite lifespan. Batteries, the heart of an off-grid system, degrade with each charge and discharge cycle. High-performance LiFePO4 (Lithium Iron Phosphate) batteries offer a long cycle life, but even they have a predictable degradation curve. A forecast that applies a simplistic, linear degradation rate—or worse, ignores it—will fail to represent the system's declining output in years 10, 15, and 20.

Mismatching Inverter and Battery Sizing

Proper component synergy is crucial. A solar array might be capable of producing 5 kW of power at peak sun, but if the inverter is only rated for 4 kW, that extra 1 kW is 'clipped' and lost forever. Conversely, a grossly oversized inverter can be inefficient when operating at the lower power levels common for most of the day. Likewise, the battery bank must be sized to absorb the array's full output while meeting your load demands. An undersized battery bank can't store all the energy you generate, wasting precious kilowatt-hours.

Neglecting Wiring and Balance of System (BOS) Losses

Energy is lost as it travels through the system. This includes resistance in the wiring (voltage drop), inefficiencies in fuses and breakers, and other small losses from the Balance of System (BOS) components. While each individual loss is small, they add up. It is standard practice to factor in a 2-3% loss for these elements, but amateur forecasts often overlook them completely. The table below shows how these seemingly minor errors can accumulate.

| Error Source | Optimistic Estimate (Loss Ignored) | Realistic Estimate (Loss Included) |

|---|---|---|

| Soiling Loss | 0% | 5% |

| Temperature Derating | 0% | 8% |

| Wiring (BOS) Loss | 0% | 2% |

| Inverter Inefficiency | 2% | 5% |

| Total Cumulative Yield Reduction | ~2% | ~18-20% |

Flawed Consumption and Load Profiling

Accurate forecasting is a two-way street. It requires not only predicting generation but also precisely understanding consumption. Errors in estimating your energy needs are just as damaging as errors in estimating your production.

Relying on Average Instead of Peak Load

Calculating your total daily energy use and dividing by 24 hours gives you an average load. This number is almost useless for designing a reliable off-grid system. Your system must be able to handle peak loads—those moments when you run multiple high-draw appliances at once, such as a well pump, microwave, and air conditioner. A forecast based on average demand will lead to a system that is undersized and prone to shutting down when you need it most.

Failing to Account for 'Phantom Loads'

Many modern electronics draw a small amount of power even when they are 'off'. This standby power, often called a phantom load, can come from televisions, chargers, and any device with a remote control or digital clock. A single device might only draw a watt or two, but with dozens of such devices in a home, these phantom loads can add up to a significant and constant drain on your battery, depleting your stored energy faster than expected.

Assuming Static Future Energy Needs

A 25-year forecast must anticipate how your life might change. Will you add an extension to your home? Purchase an electric vehicle? Install a new workshop with power tools? Your energy needs are unlikely to remain static. A good forecast includes a buffer or a plan for modular expansion, allowing your system to grow with you. A static forecast locks you into a system that may be inadequate in just a few years.

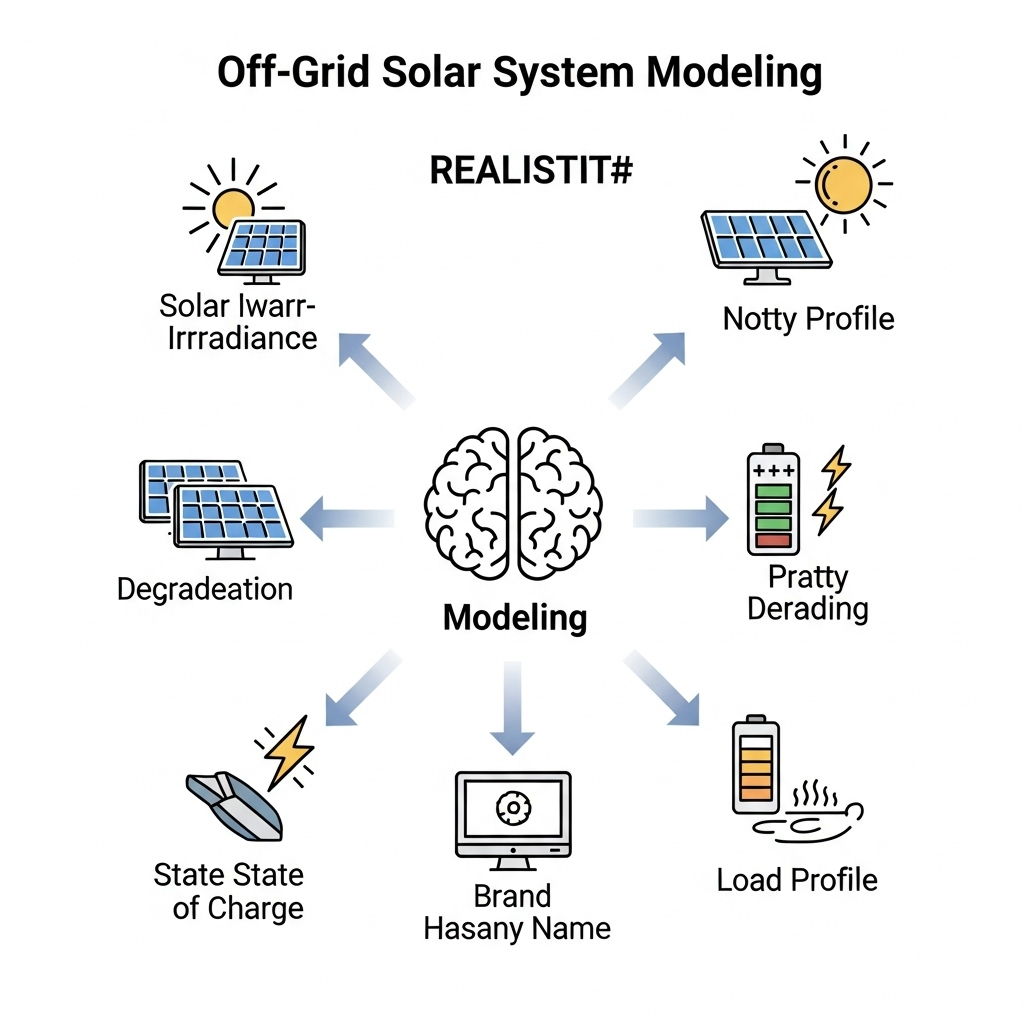

From Prediction to Performance

Closing the gap between a forecast and reality requires a shift in perspective. An initial forecast is a starting point, not a guarantee. The key to long-term success is to use high-quality components that provide transparent data, allowing you to monitor and adapt. A robust energy storage system (ESS) with an integrated battery management system, for example, gives you real-time information on state of charge, consumption, and generation. This data empowers you to make informed decisions, adjust your usage patterns, and refine your understanding of your system's capabilities. Understanding the core metrics of your components is vital. A deep dive into the specifics of battery health, such as that found in the ultimate reference for solar storage performance, can help you set realistic expectations for your system's lifespan and output. By moving from a static prediction to dynamic, data-driven management, you can ensure your off-grid system delivers on its promise of energy independence for decades.

Frequently Asked Questions

What is the most accurate an off-grid solar forecast can be?

Professional forecasting software can achieve high accuracy, often within 5-10% of actual production for the first year. However, long-term yield forecasting accuracy over 20+ years is more challenging due to unpredictable variables like component degradation and changes in energy use. The goal is to create a conservative, realistic model rather than an overly optimistic one.

What is the biggest forecasting mistake people make?

The most common and impactful error is underestimating or completely ignoring the combined effect of multiple small losses. People often focus only on the peak wattage of their panels and overlook the cumulative impact of soiling, heat, wiring losses, and component degradation, which can easily reduce actual yield by 20% or more compared to the 'sticker' rating.

How can I improve the forecast for my own system?

Start by conducting a thorough load analysis, measuring your actual peak and average energy consumption. Use local, specific weather data if possible, and apply conservative loss factors for soiling, temperature, and system inefficiencies. Most importantly, invest in a monitoring system that provides real-time data on both production and consumption. This allows you to compare actual performance against your forecast and make adjustments.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.