A solar charge controller is a vital component in any off-grid solar power system. It acts as a gatekeeper, regulating the flow of energy from your solar panels to your battery bank. Its primary job is to prevent overcharging, which can damage batteries and shorten their lifespan. The two most common types of controllers are Pulse Width Modulation (PWM) and Maximum Power Point Tracking (MPPT). Choosing the right type and, more importantly, the correct size is fundamental for the efficiency, safety, and longevity of your entire energy system.

Core Differences in PWM and MPPT Technology

Understanding the operational principles of each controller type is the first step in making an informed sizing decision. They manage power in fundamentally different ways, which directly impacts system design and performance.

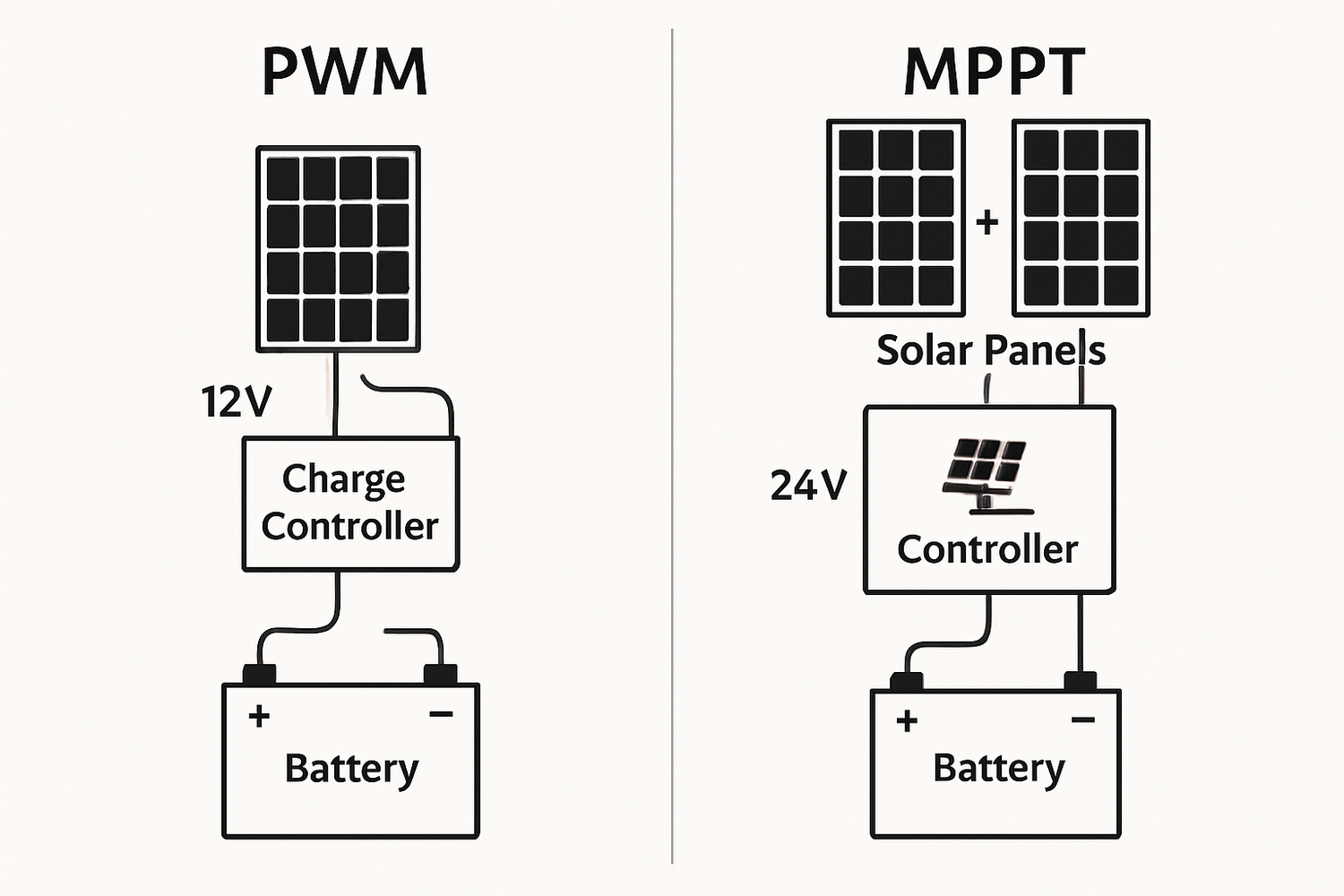

How PWM Controllers Work

A PWM controller functions like a simple, intelligent switch. It connects the solar array directly to the battery bank. As the battery charges, the controller rapidly opens and closes the switch to modulate the current and maintain a safe voltage. This 'pulse' of energy is what gives the technology its name. For this direct connection to work, the nominal voltage of the solar panel array must match the nominal voltage of the battery bank. For example, you would use a 12V panel to charge a 12V battery.

How MPPT Controllers Work

An MPPT controller is a more sophisticated device. It is essentially a DC-to-DC converter that optimizes the match between the solar array and the battery. It constantly tracks the array's maximum power point, which is the voltage and current combination that yields the most power. The controller then converts the higher voltage from the panels down to the appropriate voltage for the battery, boosting the current in the process. This allows you to use higher voltage solar arrays (with panels wired in series) to charge lower voltage battery banks, such as using a 48V array to charge a 24V battery bank. This capability significantly increases system design flexibility and energy harvest.

Efficiency and Performance Comparison

The technological differences lead to significant variations in performance. MPPT controllers consistently outperform PWM controllers, especially in specific conditions. According to the International Energy Agency, maximizing the integration of renewable energy sources is crucial for maintaining the quality and security of the electricity supply. Efficient components are central to this effort. An MPPT controller can provide a power boost of up to 30% compared to a PWM controller, particularly in colder weather when panel voltage is higher.

| Feature | PWM Controller | MPPT Controller |

|---|---|---|

| Efficiency | 75-80% | 95-99% |

| Cost | Lower | Higher |

| System Voltage | Panel and battery voltage must match | Can use higher voltage panels than battery |

| Best Use Case | Small, simple systems with 1-2 panels | Medium to large systems, all professional applications |

| Performance in Cold | Standard | Excellent; gains efficiency as temperature drops |

Sizing a PWM Solar Charge Controller

Sizing a PWM controller is a straightforward process focused on current and voltage matching. The controller must be able to handle the total current from the solar array and must have the same nominal voltage as your battery bank.

Calculating the Required Amperage

The primary value you need from your solar panel's specification sheet is the Short Circuit Current (Isc). This is the maximum current the panel can produce. To size the controller, you sum the Isc of all panels connected in parallel and add a safety margin. The National Electrical Code (NEC) recommends a factor of 1.25.

Formula: Controller Amperage = Total Panel Isc x 1.25

For example, if you have two 100-watt panels, each with an Isc of 5.5A, connected in parallel, the calculation is (5.5A + 5.5A) x 1.25 = 13.75A. In this case, a 15A or 20A PWM controller would be a safe choice.

Voltage Considerations

With a PWM controller, the rule is simple: the nominal voltage of the solar panel must match the nominal voltage of the battery. If you have a 12V battery system, you must use 12V nominal panels. Using a 24V panel with a 12V battery and a PWM controller will result in a significant loss of power, as the controller cannot convert the excess voltage.

Sizing an MPPT Solar Charge Controller

Sizing an MPPT controller involves more steps because of its advanced capabilities. You must consider the controller's maximum input voltage, its maximum output current, and the potential for oversizing the solar array.

Determining Maximum Input Voltage (Voc)

This is the most critical safety calculation. The controller's maximum DC voltage input must never be exceeded. You will need the Open Circuit Voltage (Voc) from your panel's datasheet. You must also account for temperature, as panel voltage increases in the cold. The datasheet provides a temperature coefficient for Voc, usually as a percentage per degree Celsius.

First, calculate the total Voc of your panels wired in series. For example, three panels with a Voc of 22V each, wired in series, have a total Voc of 66V. Then, adjust for the coldest expected temperature. If the coldest temperature is -10°C (and the spec is based on 25°C), the voltage will increase. A robust system design is essential for reliable energy, a principle highlighted in IEA reports like The Power of Transformation. A controller rated for 100V would be a safe choice for this 66V array, providing ample room for cold-weather voltage spikes.

Calculating Maximum Output Current

The controller's amperage rating refers to its maximum output current to the battery. You can calculate this based on the total wattage of your solar array and your battery voltage.

Formula: Output Current = Total Solar Wattage / Battery Voltage

For instance, an 800-watt solar array charging a 24V battery bank would produce approximately 800W / 24V = 33.3A. You would select a controller with a rating higher than this, such as a 40A model.

The Advantage of Oversizing Panels

With MPPT controllers, it is common practice to 'oversize' the solar array, meaning the array's potential power output is higher than the controller's rating. For example, you could connect 1000W of solar panels to an 800W-rated controller (e.g., 40A at 24V). The controller will protect itself by limiting the output to 800W. This strategy significantly improves energy harvest on cloudy days and during the morning and evening hours, leading to a greater total daily energy yield.

Practical Application and System Integration

Correct sizing ensures your controller works harmoniously with the rest of your system, particularly your batteries. This synergy is key to building a resilient and efficient energy solution.

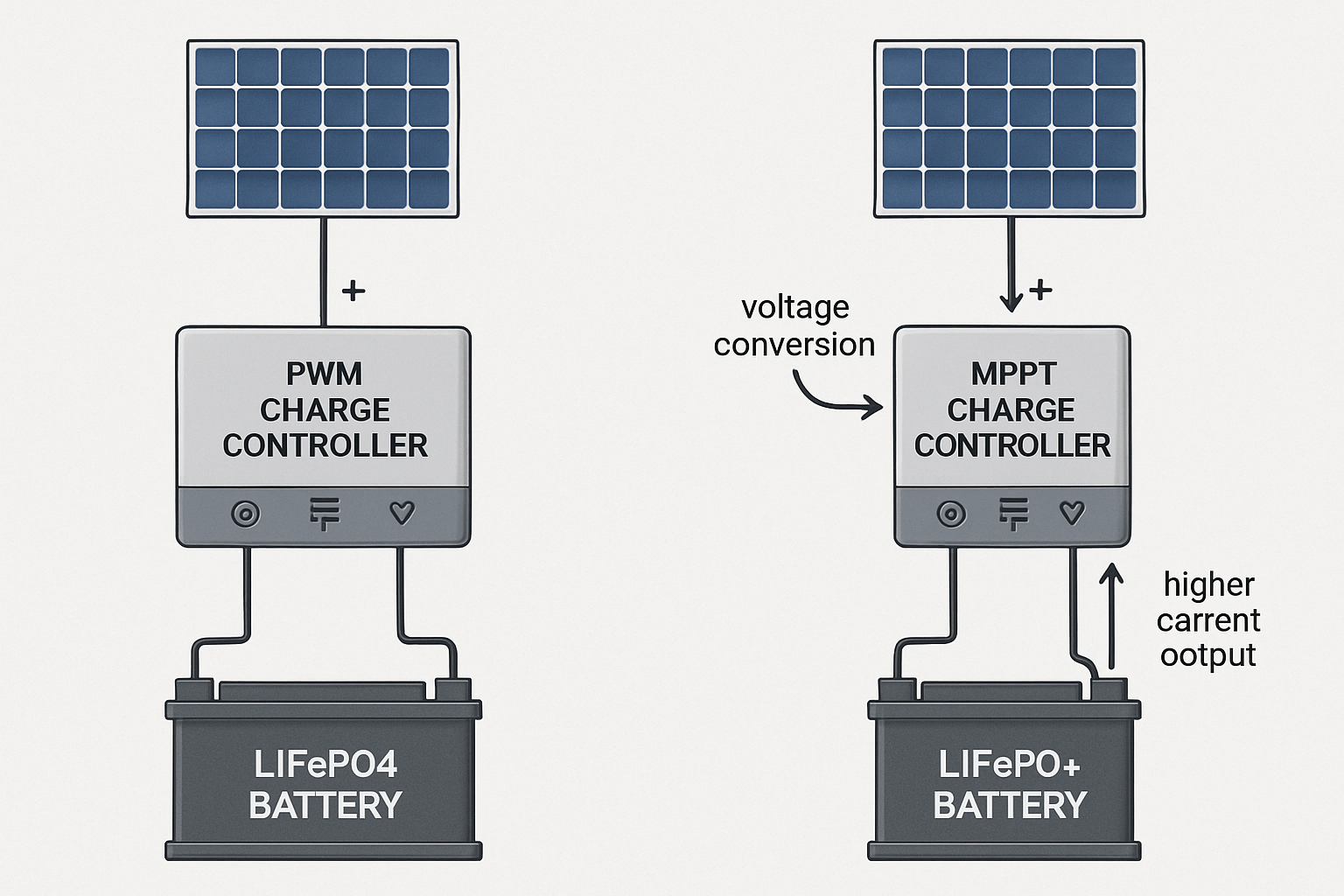

Matching the Controller to Your Battery System

Modern charge controllers are compatible with various battery chemistries, but they are especially beneficial for lithium-based batteries like Lithium Iron Phosphate (LiFePO4). These batteries have specific charging voltage requirements to ensure safety and a long cycle life. A programmable MPPT controller allows you to set precise charging parameters, which is critical for getting the most out of a high-performance 12v 100ah LiFePO4 lithium battery. Proper charging protects your investment and ensures reliable power for years.

When to Choose PWM vs. MPPT

The choice ultimately depends on your system's size, complexity, and goals.

- Choose PWM for very small, cost-sensitive applications. Examples include a single panel on an RV for battery maintenance or a small solar-powered gate opener. In these cases, the simplicity and low cost of PWM are advantageous.

- Choose MPPT for nearly all other systems. If you have multiple panels, if your panels have a higher voltage than your battery bank, or if you want to maximize your energy harvest, MPPT is the superior choice. As research from the U.S. Department of Energy shows, power optimization technology can increase production anywhere from 5% to 15%, making the initial investment in MPPT worthwhile.

Making the Right Choice for Your System

Properly sizing your solar charge controller is not merely a technical step; it's a strategic decision that impacts your entire system's performance. A PWM controller offers a simple solution for small-scale needs where budget is the primary driver. An MPPT controller, however, provides the efficiency, flexibility, and power optimization required for a modern, high-performing solar energy system. By carefully calculating your voltage and amperage needs, you ensure your controller not only protects your valuable battery bank but also maximizes every watt of power your panels produce, bringing you closer to true energy independence.

Frequently Asked Questions

Can I use a 24V solar panel with a 12V battery?

Yes, but only with an MPPT charge controller. An MPPT controller can efficiently convert the higher voltage from the 24V panel down to the 12V needed for the battery. A PWM controller cannot do this; it requires the panel and battery voltages to match.

What happens if my charge controller is undersized?

An undersized charge controller can be damaged by excessive current or voltage from the solar panels. It may overheat, shut down frequently, or fail completely. This not only risks the controller but also fails to deliver the full potential power to your batteries, reducing your overall energy harvest.

Is it okay to oversize my solar array for my MPPT controller?

Yes, moderately oversizing the solar array (e.g., by 20-30%) is a common and effective strategy. The MPPT controller will limit, or 'clip,' the power output to its maximum rating, protecting itself. This approach significantly boosts power generation during non-ideal conditions like cloudy weather or low sun angles, increasing your total daily energy yield.

How does temperature affect charge controller sizing?

Temperature is critical, especially for MPPT controller sizing. Solar panel voltage increases as the temperature drops. You must calculate the maximum possible voltage your array can produce in the coldest expected temperature for your location and ensure it is below the controller's maximum voltage input rating to prevent damage.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.