Lithium iron phosphate (LiFePO4) batteries are increasingly popular for their long lifespan, efficiency, and inherent safety. However, their reliability hinges on one critical factor: proper installation. While LiFePO4 chemistry is remarkably stable, incorrect installation procedures introduce unnecessary risks. This guide provides a systematic approach to installing your 12V LiFePO4 battery safely, ensuring your energy system is both dependable and secure from the start.

Pre-Installation Checklist: Setting the Stage for Safety

Before you touch a terminal, thorough preparation is essential. A clean, organized approach minimizes errors and creates a secure working environment. This initial phase is just as important as the connections themselves.

Gathering the Right Tools and Protective Gear

Using the correct equipment is non-negotiable for safety and effectiveness. You will need insulated tools, especially wrenches, to prevent accidental short circuits. A quality voltmeter is crucial for verifying voltage before making connections. Additionally, have wire strippers, crimpers, and a torque wrench on hand. Personal Protective Equipment (PPE) is mandatory; always wear safety goggles and insulated gloves to protect yourself from electrical hazards.

Preparing the Installation Environment

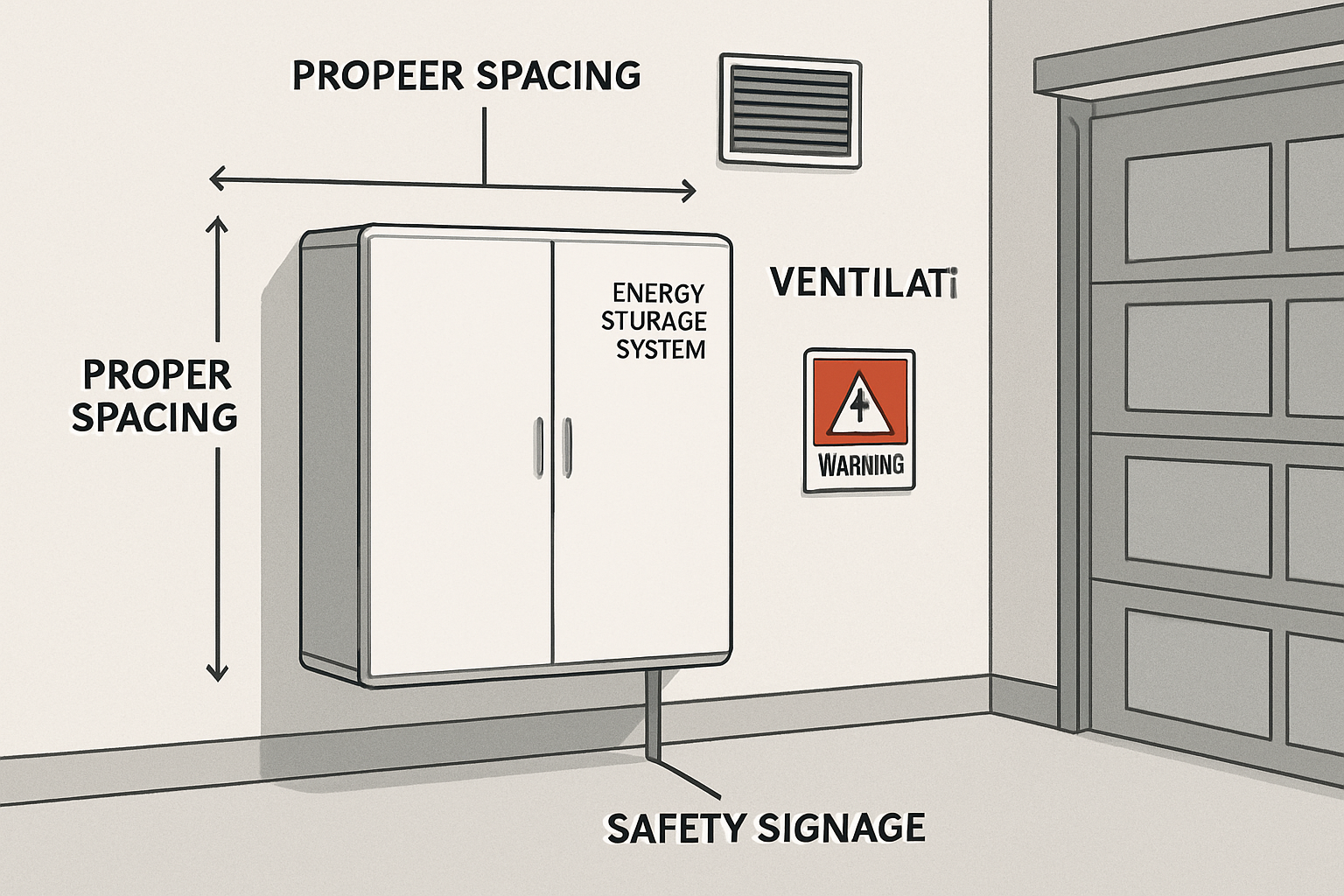

The location of your battery significantly impacts its performance and safety. Choose a cool, dry, and well-ventilated space. Proper airflow helps dissipate heat generated during charging and discharging, even though LiFePO4 batteries produce minimal to no gas. Keep the area clear of flammable materials and avoid direct sunlight, which can cause temperatures to exceed safe operating limits.

Inspecting Your Battery and Components

Upon receiving your battery, perform a careful inspection. Look for any physical damage, such as cracks, dents, or leaks in the casing. Use your voltmeter to check its state of charge; it should arrive partially charged. Examine all cables, lugs, and connectors to ensure they are in perfect condition before you begin.

The Connection Process: A Step-by-Step Approach

With preparation complete, you can move on to the connection phase. A methodical and precise process is key to building a robust and safe battery bank. Pay close attention to every detail, from configuration to final torque.

Understanding Series vs. Parallel Connections

How you connect multiple batteries determines your system's voltage and capacity. It's vital to use identical batteries in terms of model, capacity, and age to prevent imbalances.

| Connection Type | Effect on Voltage | Effect on Capacity (Ah) | Primary Use Case |

|---|---|---|---|

| Series | Increases (Adds up) | Stays the same | Applications requiring higher voltage (e.g., 24V or 48V systems). |

| Parallel | Stays the same | Increases (Adds up) | Applications requiring longer runtime and more energy storage. |

Secure and Correct Wiring

Proper wiring is fundamental to safety. Always use correctly sized cables for the expected current to prevent overheating. When making connections, follow the correct sequence: connect the positive (+) terminal first, followed by the negative (-). When disconnecting, reverse the order: negative (-) first, then positive (+). Use a torque wrench to tighten terminal bolts to the manufacturer's specifications, which typically ranges from 5 to 15 Nm for common terminal sizes. A secure connection prevents electrical arcing and ensures minimal resistance.

The Role of the Battery Management System (BMS)

A high-quality LiFePO4 battery includes an integrated Battery Management System (BMS). The BMS is the brain of the battery, providing critical protection against overcharging, over-discharging, short circuits, and extreme temperatures. It actively monitors the cells to ensure they operate within safe limits, which is a cornerstone of the technology's reliability. According to a report from the IEA on Clean Energy Innovation, the deployment of advanced battery chemistries relies heavily on these sophisticated management systems to ensure stability and performance.

System Integration and Final Checks

Once the battery bank is assembled, the next step is to integrate it with your broader energy system. This involves connecting it to charge controllers and inverters and implementing final safety measures.

Connecting to Your Inverter and Charge Controller

When connecting the battery to your charge controller and inverter, ensure these components are configured with the correct charging parameters for LiFePO4 chemistry. Using settings designed for lead-acid batteries can damage your LiFePO4 battery and create safety risks. Double-check that all connections are secure and that polarity is correct throughout the system.

The Importance of Fusing and Disconnects

Fuses and circuit breakers are critical safety devices that protect your system from overcurrent events. A main fuse, such as a Class T fuse, should be installed on the positive line, close to the battery terminal. This protects the wiring and components in the event of a short circuit. It is also wise to install a master disconnect switch to safely de-energize the entire system for maintenance.

Final System Verification

Before powering up, conduct a final verification. Methodically check every connection for tightness and correct polarity. Use your voltmeter to confirm the voltage at the battery terminals and at the inputs of your charge controller and inverter. Once you are confident everything is correct, power on your system components sequentially, starting with the battery, then the charge controller, and finally the inverter.

Long-Term Safety and Maintenance

A safe installation is the first step. Ongoing vigilance and simple maintenance will ensure your system remains reliable for years to come. Your battery system is a long-term investment that benefits from periodic attention.

Routine Inspections

Periodically inspect your battery system. Check that all terminal connections remain tight and look for any signs of corrosion or damage to the cables. Keeping the battery and its surroundings clean and free of dust or debris also helps with heat dissipation.

Environmental Monitoring

Continue to monitor the battery's environment. Ensure it remains within the recommended temperature range to maximize its lifespan and performance. Extreme heat or cold can negatively impact the battery's health. As detailed in an analysis of solar storage performance metrics, maintaining optimal operating conditions is crucial for achieving the expected longevity and efficiency from your energy storage system.

Understanding Warning Signs

Be aware of any warning signs that might indicate a problem. This could include unusual smells, any visible swelling of the battery case, or fault codes from your BMS or inverter. If you notice any of these signs, immediately and safely power down the system, disconnect the battery, and consult a professional for assistance.

Final Thoughts on a Secure Installation

A properly installed 12V LiFePO4 battery is a cornerstone of a safe, efficient, and reliable energy solution. By focusing on careful preparation, following correct procedures, and conducting routine checks, you can ensure your system delivers dependable power for its entire service life. This diligence protects your investment and provides peace of mind as you move toward greater energy independence.

Disclaimer: This guide provides general information and is not a substitute for professional advice. Electrical work can be dangerous. Always comply with local codes and regulations, and consider consulting a qualified electrician.

Frequently Asked Questions

Can I mix old and new LiFePO4 batteries?

It is strongly discouraged. Mixing batteries of different ages, capacities, or from different manufacturers can lead to imbalances. This imbalance reduces the overall performance and lifespan of your battery bank and can create potential safety issues.

What size cables should I use for my 12V battery?

Cable size, or gauge, depends on the current (amps) it needs to carry and its length. Using undersized cables is a significant fire risk because they can overheat. Always consult a wire gauge chart and your system's specifications to select the appropriate size for your application.

Do I need to ventilate my LiFePO4 battery compartment?

Yes. While LiFePO4 batteries do not produce gas during normal operation like lead-acid batteries, ventilation is still important for heat dissipation. Adequate airflow prevents the battery from overheating, which protects its long-term health and ensures safe operation.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.