Marine Solar Power for Boats is maturing fast. Fresh signals from IEA and IRENA point to cheaper watts, steadier supply chains, and smarter charging that suit Small Craft. This data brief turns those trends into practical moves for skippers who run electronics with solar.

Why IEA/IRENA data matters for Marine PV

Macro energy data can sharpen small onboard decisions. Two items stand out:

- IEA documentation has long used a 12% capacity factor (CF) proxy to estimate distributed PV output in the United States. That gives a sober baseline for real-life yield estimates on moving platforms that face tilt and shading limits. Source: World Energy Balances.

- IRENA tracks costs at scale. Its renewable costs database holds extensive project data for solar PV, enabling clear LCOE trend signals that filter through to retail pricing and small-format modules. Source: Renewable Power Generation Costs in 2024.

Layer in policy evidence from IEA and IRENA, and you get forward signals for supply, pricing, and component choice that directly affect Marine PV on Small Craft. See Medium-Term Renewable Energy Market Report 2016 for early auction and tender trends that helped normalize PV procurement; see U.S. DOE Solar Energy for technology overviews that inform controller and module selection.

Five trends shaping Marine Solar Power Boats

1) Cost and supply stability

Global PV levelized costs trended down over the past decade, with more recent stabilization as supply chains rebalanced. IRENA’s database scale enables this view and reduces noise from outlier projects. Reference: IRENA costs report.

Impact onboard: more wattage per dollar, making it easier to oversize arrays slightly to cover cloudy days. For Small Craft, that means stepping from 100–150 W legacy setups to 200–400 W without a major budget stretch.

2) Realistic capacity factors for boats

IEA’s 12% CF proxy for distributed PV (World Energy Balances) is a useful anchor. Boats often sit below rooftop ideals due to heel, azimuth drift, wake-induced vibrations, boom shading, and rail mounts. Typical marine CF spans about 6–14% depending on latitude and mounting.

The table below turns CF into easy daily energy ranges per 100 Wp, assuming a quality MPPT and clean panels.

| Latitude band | Summer daily energy per 100 Wp | Winter daily energy per 100 Wp | Notes |

|---|---|---|---|

| 20–30° | 450–600 Wh | 200–350 Wh | High sun angle; watch heat on biminis |

| 30–40° | 400–550 Wh | 180–300 Wh | Common cruising belt; moderate CF |

| 40–50° | 320–480 Wh | 120–240 Wh | Lower winter sun; plan for storage |

| 50–60° | 260–420 Wh | 90–180 Wh | Short days; rely on alternator/wind |

Use these as planning ranges. Actuals vary with anchorage orientation, shadow management, and cleanliness. A shroud or radar shadow can cut output by more than 30% for hours at a time.

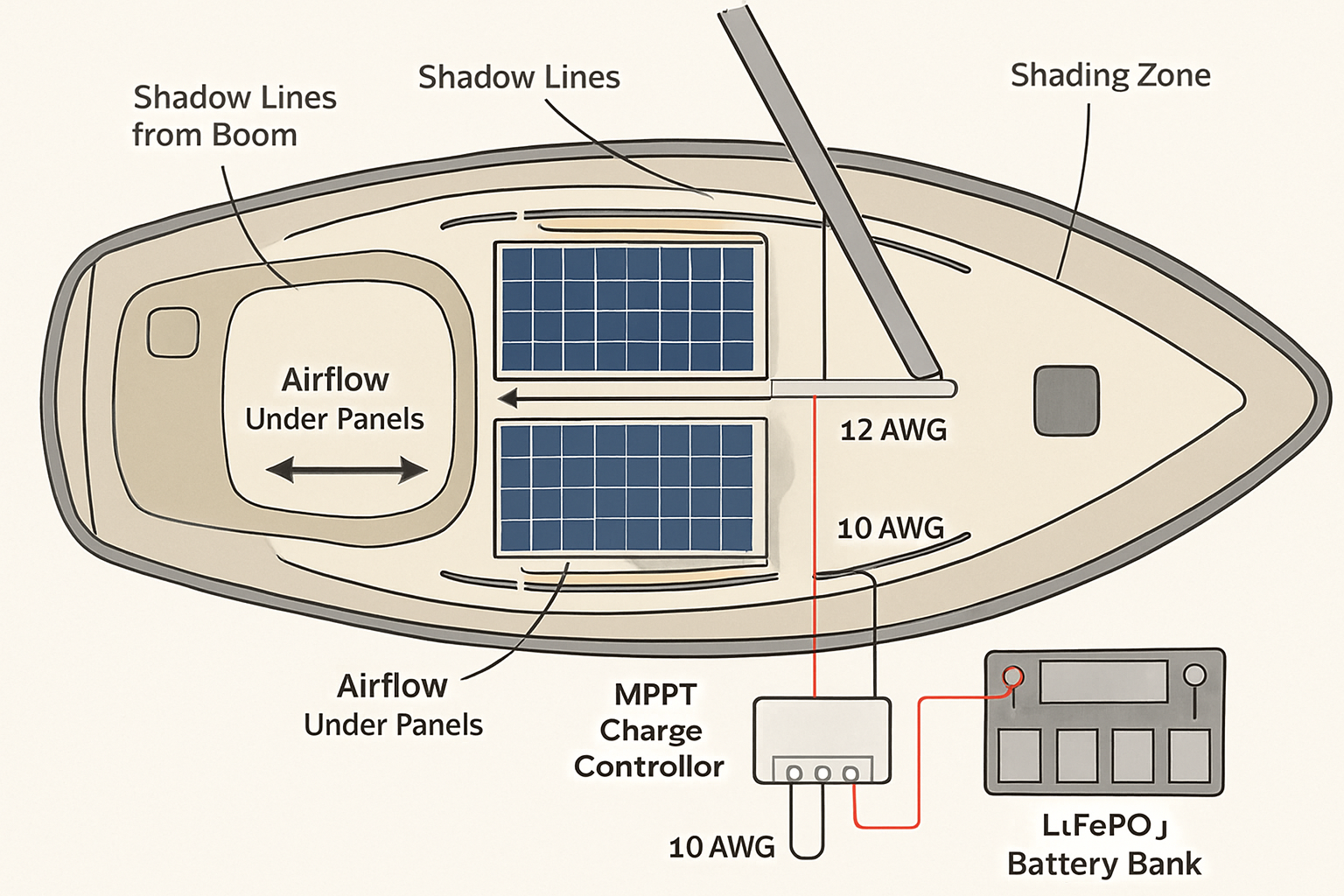

3) Battery and charge control convergence

LiFePO4 has become the reference chemistry for small vessels seeking deep-cycle life, strong charge acceptance, and thermal stability. Pair it with MPPT controllers that support lithium profiles and temperature-aware limits. Basic PV and charging concepts are summarized on DOE’s solar energy page.

What changes with this trend: higher usable daily throughput, faster recovery during short sun windows, and stable voltage for sensitive electronics. For boats that run autopilots, plotters, or a DC fridge, this directly translates into longer quiet hours without starting the engine.

4) Policy-driven scale and parts availability

IEA tracked the shift from feed-in tariffs to auctions and tenders, which expanded PV deployment and standardized procurement (IEA Medium-Term report). This scale-up improved availability of small-format modules, MC4 connectors, and compact MPPTs in marine catalogs. More supply often means fresher stock, better binning, and faster replacement cycles for damaged panels offshore.

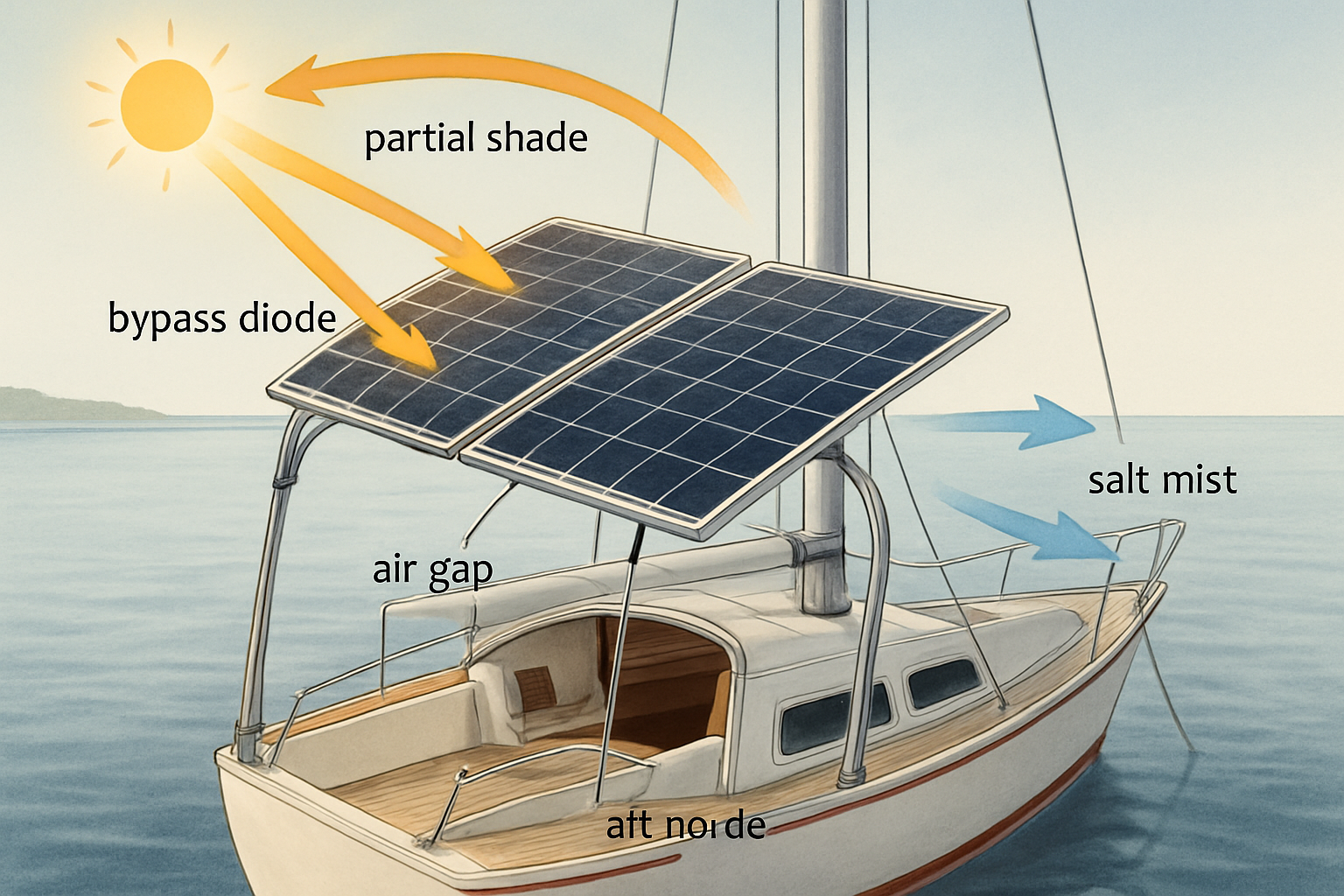

5) Marine-proofing lessons from offshore energy

Offshore energy projects push corrosion, sealing, and monitoring practices that filter down to small craft. The IRENA Floating Offshore Wind Outlook highlights the need for coexistence at sea and robust assets. For Marine PV, that means favoring ETFE-laminated modules, tinned copper cabling, IP67 junctions, and brackets that tolerate vibration. These are not new ideas, but uptake is rising as component prices ease.

From trend to cockpit: what to change this season

| Trend | Data signal | Onboard adjustment |

|---|---|---|

| Cheaper watts | IRENA cost database shows durable PV cost competitiveness | Target 200–400 W on Small Craft; accept a 10–20% oversize buffer |

| Lower CF afloat | IEA 12% rooftop proxy is generous for boats | Plan with 6–14% CF; add storage for low-sun days |

| LiFePO4 uptake | DOE notes strong PV+storage pairing potential | Use LiFePO4 with BMS; MPPT must support lithium charge limits |

| Standardized parts | IEA policy reports show scaled procurement | Buy MC4/rail gear from reputable lines; keep spares onboard |

| Marine hardening | Offshore lessons emphasize durability | Pick ETFE, IP67, tinned copper, anti-vibration mounts |

Sizing with data: a quick, repeatable workflow

Goal: match your daily energy budget with a PV array and battery that track IEA/IRENA signals.

- Step 1 — Daily load: Sum your 24-hour DC load. Example: 420–600 Wh/day for typical cruising electronics.

- Step 2 — CF choice: Pick a conservative CF from the table for your latitude and shadow behavior. Example: 10% in summer, 7% shoulder seasons.

- Step 3 — Array size: Daily energy per 100 Wp at 10% CF is roughly 240 Wh. If you need 480 Wh/day, plan for 200 Wp in summer. Add 25–50% margin for shade and dirt if you cannot tilt or clean daily.

- Step 4 — Battery: Size storage for at least 1.5–2 days of autonomy. For 500 Wh/day, that is about 1–1.3 kWh usable. A 12.8 V, 100 Ah LiFePO4 offers ~1.28 kWh nominal; usable depends on BMS settings.

- Step 5 — Charge control: Choose an MPPT that can handle Voc at cold dawn and Isc under reflection spikes. Program lithium absorption and float per battery maker guidance.

Reality check with IEA’s 12% baseline (IEA overview): if your plan needs 15% CF to work, it is likely too optimistic for a rail-mounted array. Add watts or add storage.

Case snapshot: small cruiser at 35°N

Profile: 9 m sailboat, flat rail mounts, two 120 W panels (240 Wp), LiFePO4 12.8 V 100 Ah, MPPT with lithium profile.

- Planned loads: 520 Wh/day.

- Summer yield assumption: 10% CF ⇒ roughly 240 Wh per 100 Wp ⇒ 576 Wh/day from 240 Wp under clean, low-shade days.

- Shoulder season yield: 7% CF ⇒ ~168 Wh per 100 Wp ⇒ 403 Wh/day; deficit covered by battery and short engine charge every few days.

Takeaway: the system clears peak-sun periods, but needs either an extra 100 W panel or better shade management to get through spring and autumn without the alternator.

Component choices aligned with the data

Modules

Favor monocrystalline modules with ETFE surface and robust junction boxes. Back-contact or high-efficiency cell formats help when deck space is limited. Demand IEC salt-mist and UV claims, and ask for measured Isc and Voc at STC on the label. Lower LCOE upstream (IRENA) means you can step up in build quality without a steep price penalty.

Charge controllers

Pick MPPT with lithium profiles, temperature input, and low-noise operation. PV volatility at sea—including reflections—makes fast MPP tracking valuable. Cross-check your Voc at the coldest expected morning; leave 10–20% controller headroom.

Batteries

LiFePO4 with a marine-ready BMS offers stable voltage, long cycle life, and high acceptance. Secure the pack against vibration and salt. If you need large draws (windlass, thruster), consider a separate starter/AGM bank or a dedicated high-rate LFP with proper protection.

Policy, planning, and the near-term outlook

IEA’s policy tracking shows tenders and auctions scaling PV markets (IEA Medium-Term). That scale supports healthier inventories for small-format gear. IRENA’s offshore work highlights robust marine practices (Floating offshore wind outlook) that continue to inform corrosion-resistant parts. For price and deployment context across markets, see energy statistics from EIA.

Near-term view: panel availability looks solid, MPPT features continue to improve, and LiFePO4 prices remain competitive. Expect incremental gains in cell efficiency and better high-temperature behavior, which helps output on hot decks.

What this means onboard

- Design with CF realism. If your plan only works above 12% CF, add watts or storage.

- Shift budget from fancy mounts to more wattage and a capable MPPT. Cost trends support this trade.

- Prioritize durability: ETFE skins, IP67 junctions, tinned copper, and anti-vibration brackets extend service life in salt.

- Keep data simple: log daily Wh in/out for two weeks, adjust targets, then lock the configuration.

Reference the sources below for the data pillars that underpin these choices: IRENA costs, IEA balances, IEA policy trends, and DOE solar basics.

Disclaimer: This material is for information only and does not constitute legal, safety, engineering, or investment advice.

FAQ

How does the IEA 12% capacity factor help me size Marine PV?

It gives a sober upper bound for small distributed PV in fixed settings. Boats often see 6–14% CF. If your plan needs more than 12%, expect shortfalls and add wattage or storage.

Does IRENA’s cost trend mean panels will get cheaper again?

IRENA data points to long-run cost competitiveness. Short-term prices can swing with supply chains. Treat any dip as a chance to add watts or upgrade to more durable modules.

Can thin, flexible panels match framed modules at sea?

They save weight and shape to curves, but heat and foot traffic reduce lifespan and yield. Framed, ventilated modules with ETFE skins typically hold output better over time.

What controller features matter most for LiFePO4?

Accurate lithium charge profiles, temp compensation, programmable absorption/float, and fast MPP tracking. Ensure Voc/Isc headroom and clean cable runs to limit voltage drop.

Will marine energy standards affect small-boat solar?

Offshore energy work promotes corrosion resistance and better sealing. Expect more small-format gear rated for salt mist, UV, and vibration as practices filter down. See IRENA offshore outlook.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.