Winter transforms off-grid systems from reliable power sources into potential failure points. The harsh reality is that most system failures occur during cold months, not because of equipment defects, but due to fundamental sizing mistakes made during the design phase.

According to Getting Wind and Solar onto the Grid, system integration challenges emerge gradually as variable renewable energy grows on power systems. This principle becomes critical in winter when solar production drops by 60-80% while heating loads can triple overnight.

Mistake #1: Ignoring Temperature-Dependent Load Variations

The most devastating mistake involves using summer load profiles for winter sizing calculations. Heating systems don't just add load—they create entirely different consumption patterns that peak during the lowest solar production hours.

Real-world data shows that heating loads can surge from 2 kWh daily in summer to 15-20 kWh in winter. Electric heat pumps, while efficient, demand 3-5 kW continuously during cold snaps. Resistance heating can pull 8-12 kW, creating massive power deficits during already challenging solar conditions.

Smart load analysis requires hourly consumption modeling across different temperature ranges. Systems sized for 8 kWh daily consumption fail catastrophically when winter loads reach 25 kWh while solar production drops to 1-2 kWh daily.

The Thermal Load Cascade Effect

Winter loads create cascade effects that multiply sizing errors. As indoor temperatures drop, heating systems run longer cycles. Reduced battery capacity in cold conditions means more frequent generator starts. Each generator cycle consumes fuel and creates maintenance demands that weren't factored into the original sizing.

Mistake #2: Underestimating Solar Production Losses

Standard sizing calculations often use annual average solar data, completely missing winter's brutal reality. December solar production can drop to 15-25% of July levels, but most designers apply simple 30% derating factors across all seasons.

Snow coverage compounds these losses dramatically. Even light snow reduces panel output by 80-90%. Heavy snow can eliminate production for days or weeks. The assumption that snow "slides off" panels works only for steep installations with minimal shading—conditions that don't exist in many off-grid locations.

Geographic factors amplify these challenges. Northern latitudes experience not just reduced irradiance but also shortened daylight hours. A system receiving 8 peak sun hours in summer might get only 2-3 hours in winter, creating a 60-75% reduction in daily energy harvest.

The Albedo Advantage Myth

Many designers count on snow albedo to boost panel performance, but this benefit rarely materializes in practice. Albedo gains require specific conditions: fresh snow, optimal panel angles, and clear skies. These conditions occur infrequently and provide minimal compensation for massive direct irradiance losses.

Mistake #3: Battery Capacity Miscalculations in Cold Weather

LiFePO4 batteries lose 20-40% capacity as temperatures drop below freezing. At -20°C, available capacity can fall to 50% of rated specifications. Yet most sizing calculations ignore these temperature effects entirely.

The problem extends beyond capacity reduction. Cold batteries accept charge slowly, creating bottlenecks during limited solar windows. A battery bank that charges efficiently in 4 hours during summer might need 8-10 hours in winter—time that simply isn't available from reduced solar production.

| Temperature (°C) | Available Capacity | Charge Rate | Effective Storage |

|---|---|---|---|

| 25°C | 100% | 100% | 100% |

| 0°C | 85% | 70% | 60% |

| -10°C | 70% | 50% | 35% |

| -20°C | 50% | 30% | 15% |

Effective storage—the combination of capacity and charge acceptance—drops to 15% of summer performance at -20°C. Systems that provide 3 days of backup in summer might deliver less than 12 hours in extreme cold.

Mistake #4: Inadequate Backup Generation Planning

Generator sizing represents another critical failure point. Most off-grid systems include generators sized for summer loads, typically 5-8 kW units that handle basic household needs plus some charging capacity.

Winter demands change everything. Heating loads alone can consume 8-12 kW continuously. Add battery charging requirements, and total demand reaches 15-20 kW. A properly sized winter generator should handle peak loads plus provide 3-5 kW charging capacity for rapid battery recovery.

Runtime calculations suffer from similar oversights. Summer might require 2-3 hours of daily generator operation. Winter can demand 8-12 hours daily during extended cloudy periods. Fuel consumption multiplies accordingly, creating logistics challenges that weren't anticipated during system design.

Cold Weather Generator Performance

Generators lose efficiency in cold weather, consuming 10-20% more fuel while producing slightly less power. Cold starting becomes problematic, requiring block heaters or heated enclosures. These auxiliary systems add parasitic loads that further complicate sizing calculations.

Mistake #5: Ignoring System Parasitic Loads

Winter parasitic loads multiply dramatically but remain invisible in most sizing calculations. Battery thermal management systems can consume 500-1000W continuously. Heated equipment enclosures add another 200-500W. Pipe heating, water system freeze protection, and ventilation fans create additional constant loads.

According to Next Generation Wind and Solar Power, system integration challenges require careful attention to all system components, including those that seem minor during initial planning.

These parasitic loads operate 24/7, consuming 12-24 kWh daily—often exceeding total solar production during winter months. Systems that ignore these loads experience mysterious battery depletion and frequent low-voltage shutdowns.

Mistake #6: Poor Weather Data and Seasonal Modeling

Most sizing tools use average weather data that masks critical seasonal variations. A location might average 4.5 peak sun hours annually, but winter months might deliver only 1.5 hours while summer provides 7+ hours.

Worst-case scenario planning requires analyzing historical weather patterns for extended cloudy periods. Some regions experience 10-14 consecutive days with minimal solar production. Systems sized for 3-5 day autonomy fail catastrophically during these extended periods.

Temperature cycling adds another layer of complexity. Daily temperature swings of 20-30°C create thermal stress on all system components while causing significant battery performance variations throughout each day.

Mistake #7: Inadequate System Monitoring and Load Management

Winter demands active system management, not passive operation. Systems without comprehensive monitoring cannot identify developing problems before they become critical failures. Battery state-of-charge, temperature monitoring, and load tracking become essential for winter survival.

Load prioritization systems allow automatic shedding of non-critical loads when battery levels drop. Without these systems, heating loads can drain batteries to damaging levels, creating expensive repair costs and potential safety hazards.

Smart charging controllers that adjust charging parameters based on battery temperature prevent damage from cold-weather charging attempts. Standard charge controllers often damage batteries by attempting full-rate charging when batteries cannot accept the energy.

Building Resilient Winter Systems

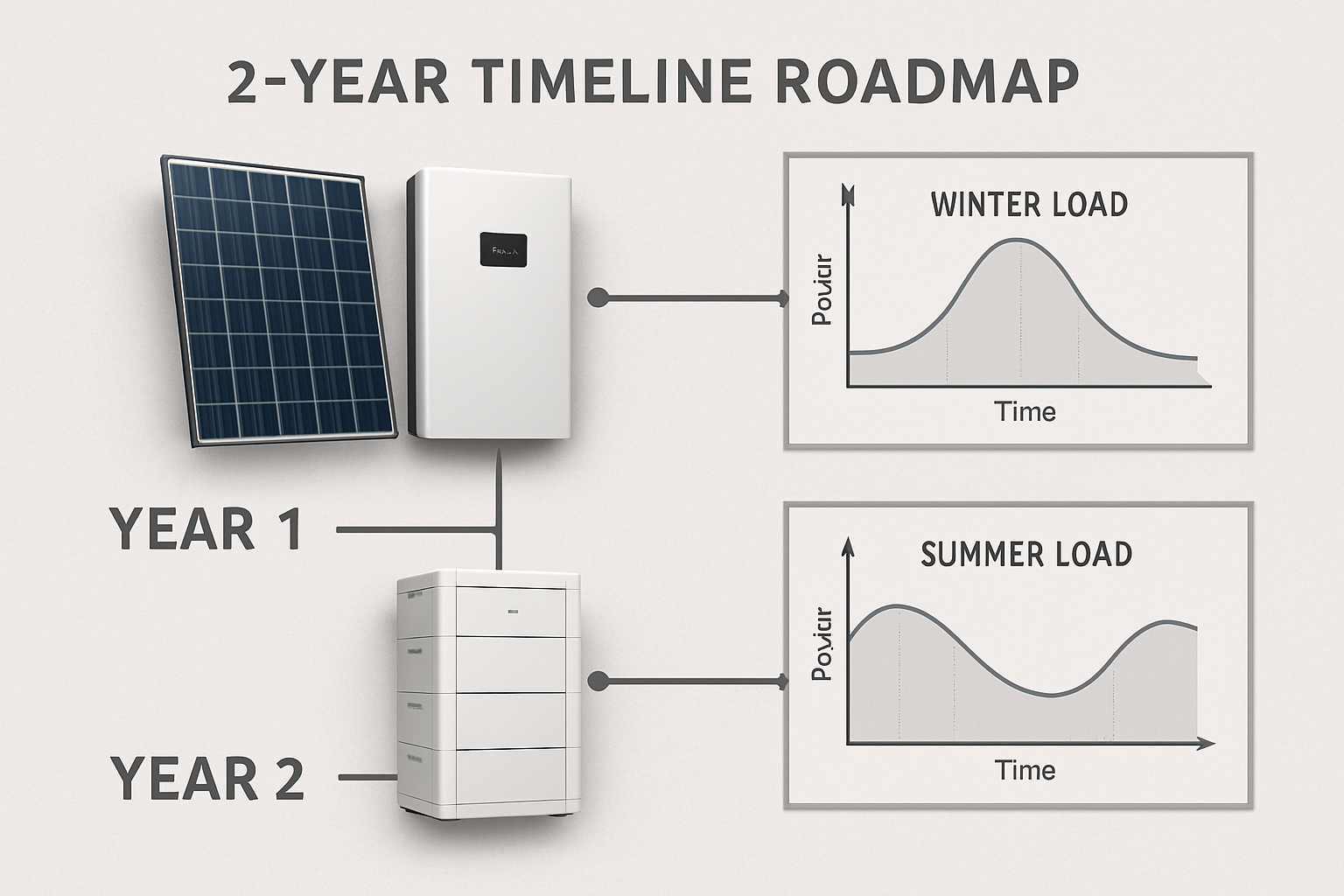

Successful winter off-grid systems require oversizing all major components by 150-300% compared to summer requirements. Solar arrays need 2-3x capacity to compensate for reduced production. Battery banks require 2.5-4x capacity to handle both increased loads and reduced performance.

Thermal management becomes as important as electrical design. Battery heating systems, insulated enclosures, and temperature monitoring prevent cold-weather failures. Generator block heaters and automatic starting systems ensure backup power availability during critical periods.

The EERE Success Story on New York's resilient solar systems demonstrates how proper integration of storage and backup systems creates truly resilient power solutions capable of handling extreme weather events.

The Cost of Getting It Wrong

Undersized winter systems don't just inconvenience—they create dangerous situations. Heating system failures in extreme cold pose life safety risks. Battery damage from improper cold-weather operation creates expensive replacement costs. Generator overloading leads to premature failure and costly repairs.

The financial impact extends beyond equipment replacement. Emergency service calls during winter storms cost 2-3x normal rates. Temporary heating solutions consume expensive propane or kerosene. Lost productivity from power outages multiplies the true cost of sizing mistakes.

Proper winter sizing requires upfront investment but prevents catastrophic failures that cost far more than initial oversizing. A system designed for winter resilience provides reliable power year-round, not just during favorable seasons.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.