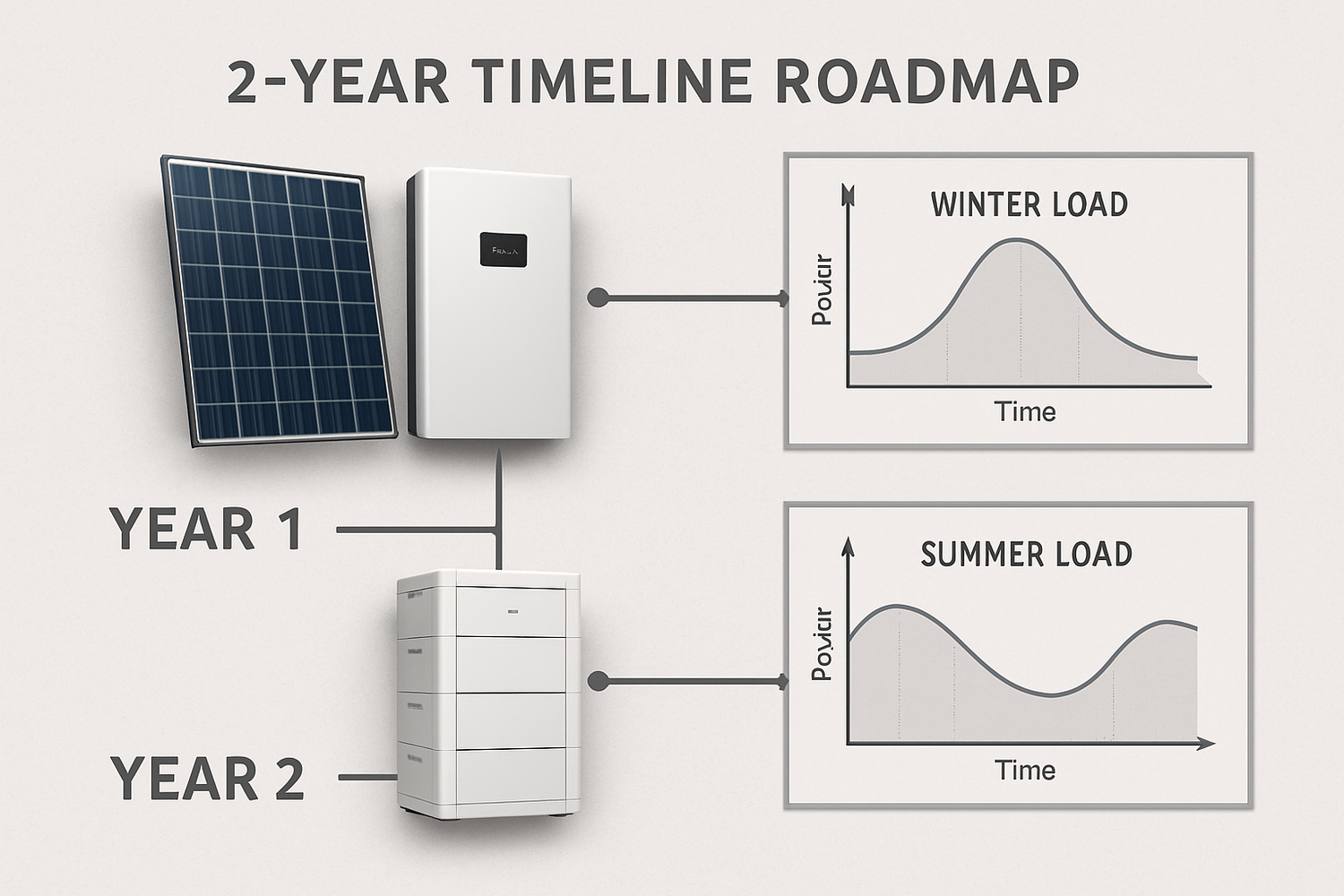

Off-grid homeowners face their greatest challenge when seasonal energy demands clash with reduced solar production. Winter heating loads can spike 300-400% while solar generation drops by 60-80% in northern regions. This comprehensive 2-year roadmap provides a strategic approach to achieving year-round energy balance through systematic upgrades, smart load management, and data-driven optimization.

Understanding Seasonal Load Variability Challenges

Seasonal load balancing requires understanding the complex relationship between energy production and consumption patterns. According to IEA's System Integration of Renewables research, variable renewable energy systems face increasing integration challenges as penetration levels rise, particularly during seasonal transitions.

Critical Load Analysis Framework

Start by categorizing your loads into three priority levels:

- Essential loads: Lighting, refrigeration, communication systems (typically 20-30% of total consumption)

- Comfort loads: Heating, cooling, hot water (often 50-70% during peak seasons)

- Discretionary loads: Entertainment, workshops, electric vehicle charging (remaining 10-20%)

Data from off-grid installations shows heating loads can consume 8-12 kWh daily during winter months, compared to 2-3 kWh in summer. This 400% seasonal variation demands strategic planning rather than simple oversizing.

Production vs. Demand Mismatch

Solar production follows predictable seasonal patterns, but the mismatch with consumption creates critical gaps. December solar production averages 1.2-1.8 kWh per kW of installed capacity in northern climates, while July can deliver 5-7 kWh per kW. Meanwhile, heating demands peak exactly when production reaches its minimum.

Year One: Foundation Building and System Assessment

Months 1-3: Comprehensive Energy Audit

Begin with detailed monitoring using smart meters and data loggers. Track consumption patterns across all loads, noting seasonal variations and identifying inefficiencies. Install temperature sensors to correlate heating/cooling demands with outdoor conditions.

Key metrics to establish:

- Hourly consumption profiles for each season

- Peak demand periods and duration

- Current system efficiency ratings

- Battery state-of-charge patterns during challenging periods

Months 4-6: Efficiency Upgrades

Focus on reducing loads before expanding generation. Implement LED lighting conversions, upgrade insulation, and replace inefficient appliances. These improvements typically reduce overall consumption by 15-25% while improving comfort.

Priority efficiency measures:

- Heat pump installation for heating/cooling (COP 3-4 vs. resistance heating)

- Smart thermostats with scheduling capabilities

- High-efficiency appliances with ENERGY STAR ratings

- Building envelope improvements (insulation, air sealing)

Months 7-9: Smart Load Management Implementation

Deploy intelligent load controllers and programmable systems. Water heating, for example, can shift to midday solar production hours, reducing evening battery drain by 20-30%. Install smart switches for non-essential loads that automatically disconnect during low battery conditions.

Months 10-12: Initial Storage Expansion

Based on first-year data, calculate optimal battery expansion. LiFePO4 systems offer excellent performance in temperature extremes and can handle the deep cycling required for seasonal applications. Size storage to handle 3-5 days of essential loads during worst-case scenarios.

| System Size | Recommended Battery Capacity | Typical Cost Range | Autonomy Days |

|---|---|---|---|

| 5 kW Solar | 20-30 kWh LiFePO4 | $8,000-12,000 | 3-4 days |

| 10 kW Solar | 40-60 kWh LiFePO4 | $16,000-24,000 | 4-5 days |

| 15 kW Solar | 60-90 kWh LiFePO4 | $24,000-36,000 | 4-6 days |

Year Two: Advanced Integration and Optimization

Months 13-15: Solar Array Optimization

Analyze year-one production data to identify optimal expansion strategies. Consider dual-tilt arrays or tracking systems to maximize winter production. Adding 20-30% additional capacity specifically oriented for winter sun angles can improve December-February generation by 15-25%.

Strategic solar placement considerations:

- Steeper tilt angles (latitude + 15°) for winter optimization

- South-facing orientation with minimal shading

- Ground-mount systems for snow management

- Bifacial panels to capture reflected snow radiation

Months 16-18: Hybrid System Integration

Integrate backup generation for extended low-production periods. Modern inverter-generators can automatically start during predetermined battery levels, providing seamless backup power while maintaining battery health through controlled charging.

According to China Power System Transformation findings, hybrid systems with multiple generation sources achieve 99%+ reliability through complementary resource planning and flexible operation strategies.

Months 19-21: Advanced Energy Management

Deploy sophisticated energy management systems that forecast weather patterns and pre-condition loads accordingly. These systems can pre-heat water during sunny periods, adjust heating schedules based on weather forecasts, and automatically prioritize critical loads during shortage periods.

Months 22-24: Performance Validation and Fine-Tuning

Complete the second winter with full system monitoring and validation. Document system performance against design targets and identify any remaining optimization opportunities.

Strategic Load Balancing Techniques

Thermal Mass Integration

Leverage thermal mass to shift heating loads to peak solar production hours. Water thermal storage systems can store 8-12 hours of heating energy, effectively time-shifting loads from evening peaks to midday solar abundance.

Demand Response Strategies

Implement automated demand response that adjusts loads based on available energy. Smart water heaters, HVAC systems, and even refrigeration can modulate their consumption to match production patterns while maintaining comfort and functionality.

Seasonal Load Shifting

Plan energy-intensive activities during favorable seasons. Schedule major maintenance, workshops, and discretionary loads during spring and fall when the production-demand balance is most favorable.

Economic Optimization and ROI Analysis

This 2-year approach spreads investments over time while maximizing each upgrade's effectiveness. Year-one efficiency improvements typically reduce system sizing requirements by 20-30%, lowering overall investment costs.

| Investment Phase | Typical Cost | Annual Savings | Payback Period |

|---|---|---|---|

| Efficiency Upgrades | $5,000-8,000 | $800-1,200 | 5-7 years |

| Smart Controls | $2,000-3,500 | $400-600 | 4-6 years |

| Storage Expansion | $15,000-25,000 | $1,500-2,500 | 8-12 years |

| Solar Addition | $8,000-15,000 | $1,000-1,800 | 6-10 years |

Financing Strategies

Spread investments across the 24-month timeline to manage cash flow while capturing immediate benefits from each upgrade phase. Many efficiency improvements generate savings that help fund subsequent upgrades.

Monitoring and Continuous Improvement

Successful seasonal load balancing requires ongoing monitoring and optimization. Install comprehensive monitoring systems that track:

- Real-time production and consumption

- Battery state-of-charge and cycling patterns

- Load prioritization effectiveness

- Weather correlation analysis

Use this data to refine control algorithms, adjust load schedules, and identify additional optimization opportunities. Systems that incorporate machine learning can automatically adapt to changing patterns and improve performance over time.

Long-term Maintenance Planning

Develop preventive maintenance schedules that account for seasonal demands. Battery maintenance, generator testing, and system cleaning should align with seasonal transitions to ensure peak performance when needed most.

Future-Proofing Your System

Design flexibility into your roadmap to accommodate changing needs and emerging technologies. Modular ESS systems allow capacity expansion, while standardized communication protocols ensure compatibility with future smart home technologies.

Consider emerging solutions like vehicle-to-home integration, which can provide additional storage capacity and backup power. Electric vehicles with bidirectional charging capability can serve as mobile energy storage, particularly valuable during seasonal transitions.

This systematic 2-year approach transforms challenging seasonal load balancing from a constant struggle into a manageable, optimized system. Through careful planning, strategic investments, and continuous monitoring, off-grid homes can achieve reliable year-round energy independence while minimizing costs and maximizing comfort.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.