Winter transforms off-grid energy systems from reliable power sources into challenging puzzles. Reduced solar production, increased heating loads, and battery performance degradation create the perfect storm for system failures. Yet thousands of off-grid homes maintain consistent power through even the harshest winters.

The difference lies in strategic system sizing and intelligent storage design. This comprehensive guide reveals the engineering principles, calculation methods, and proven strategies that separate resilient winter systems from those that fail when temperatures drop.

Understanding Winter Energy Dynamics

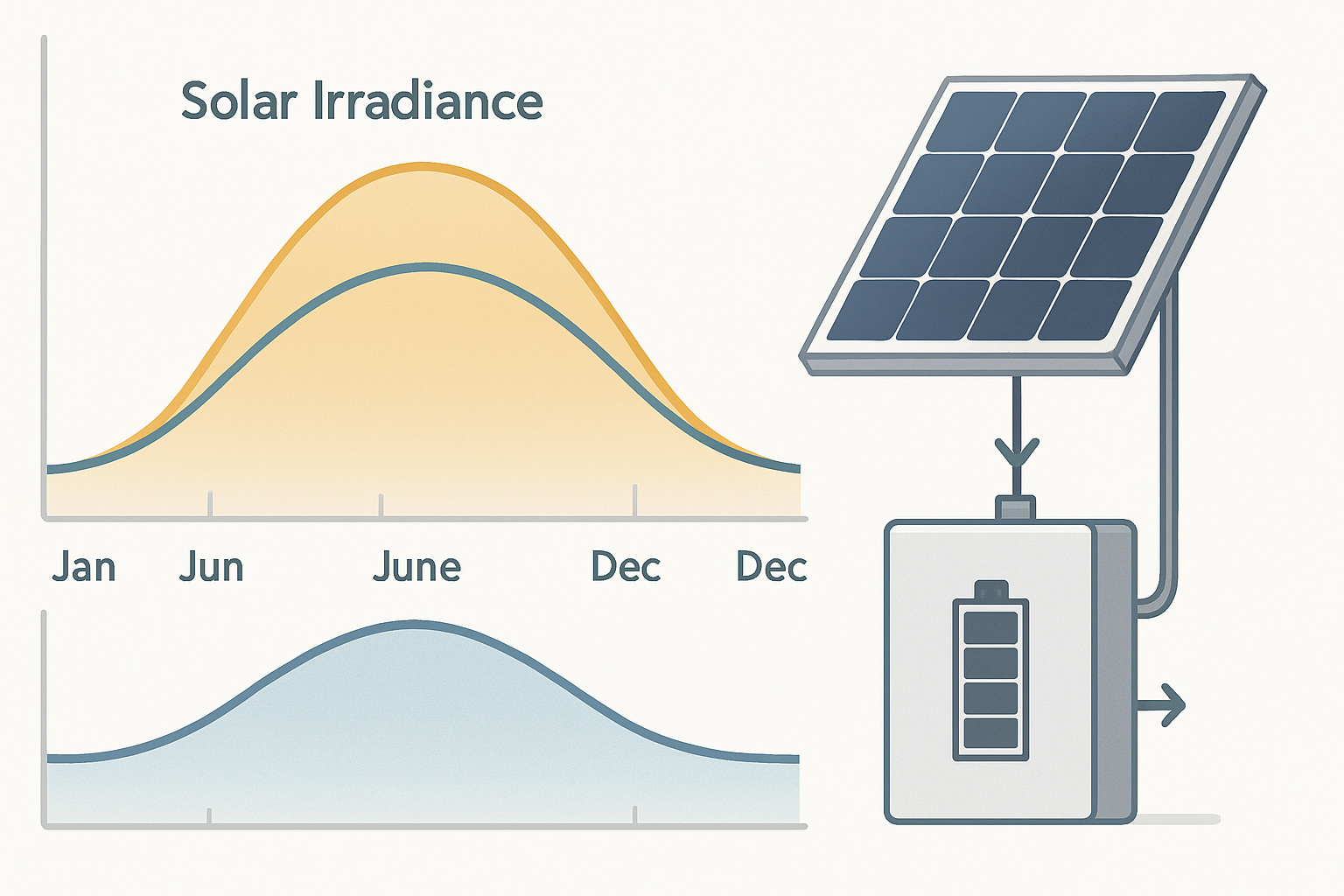

Winter fundamentally alters the energy equation for off-grid systems. Solar irradiance drops 40-60% in northern latitudes, while heating loads can triple electricity consumption. Battery capacity decreases by 20-30% in sub-freezing temperatures, creating a triple challenge that requires sophisticated planning.

Quantifying Solar Production Losses

Solar production varies dramatically by geographic location and season. At 45°N latitude, December solar irradiance averages just 1.2 kWh/m²/day compared to 6.8 kWh/m²/day in June. This 82% reduction demands careful array sizing calculations.

Snow accumulation compounds these losses. Even light snow coverage can reduce panel output by 90%, while heavy accumulation eliminates production entirely until clearing occurs. According to U.S. Department of Energy research, proper tilt angle optimization can minimize snow retention and maximize winter collection.

Temperature-Dependent Load Variations

Heating represents the largest variable load in winter off-grid systems. Electric resistance heating consumes 3.41 kWh per hour per kW of capacity, while heat pumps maintain 2-4 COP even in moderate cold. Space heating loads can reach 15-25 kWh daily in well-insulated homes during peak winter conditions.

Parasitic loads also increase significantly. Refrigeration systems work harder, water pumps run longer to prevent freezing, and lighting operates extended hours. These "invisible" loads often add 20-30% to winter consumption calculations.

Advanced Storage Sizing Methodologies

Traditional battery sizing formulas fail in winter conditions. Effective winter storage design requires multi-factor analysis incorporating temperature effects, extended autonomy periods, and load prioritization strategies.

Temperature Compensation Calculations

LiFePO4 batteries lose approximately 1% capacity per degree Celsius below 15°C. At -10°C, available capacity drops to 75% of rated values. Proper sizing must account for this derating through temperature compensation factors.

| Temperature Range | Capacity Multiplier | Recommended Oversizing |

|---|---|---|

| 0°C to -10°C | 0.85x | 1.18x |

| -10°C to -20°C | 0.75x | 1.33x |

| -20°C to -30°C | 0.65x | 1.54x |

Thermal management systems can maintain battery temperatures above critical thresholds. Insulated battery enclosures with heating elements consume 50-200W continuously but preserve full capacity and extend battery life significantly.

Autonomy Period Design

Winter weather patterns create extended low-production periods. Analysis of historical weather data reveals 7-14 day periods with minimal solar generation occur annually in most northern climates. Conservative sizing targets 10-day autonomy at 50% average load.

The calculation formula becomes: Required Storage (kWh) = Daily Load × Autonomy Days × Temperature Derating Factor × Safety Margin (1.2)

For a 15 kWh daily winter load with 10-day autonomy at -10°C: 15 × 10 × 1.33 × 1.2 = 239 kWh usable storage capacity.

Strategic System Architecture

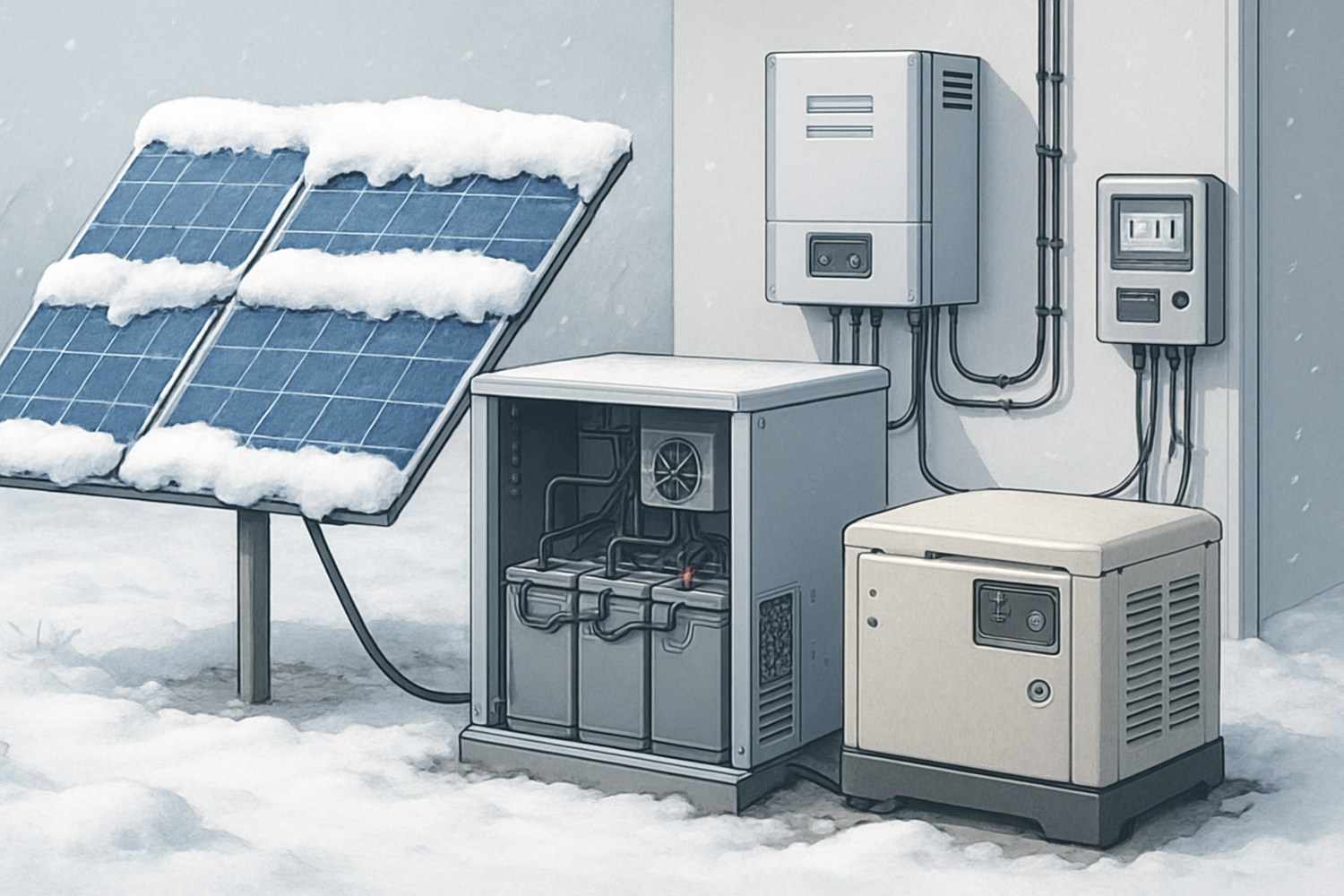

Resilient winter systems employ hybrid generation approaches and intelligent load management. Single-source renewable systems prove inadequate during extended weather events, necessitating backup generation integration.

Hybrid Generation Integration

Wind resources often complement solar production during winter months. Small wind turbines generate 20-40% of annual production during winter months when solar output peaks in summer. This natural complementarity reduces storage requirements by 15-25%.

Backup generators provide essential reliability during extreme weather events. Modern automatic start systems monitor battery state-of-charge and weather forecasts, activating generation before critical battery depletion occurs. Proper generator sizing targets 125% of maximum continuous load to allow battery charging while supporting critical loads.

Load Prioritization Systems

Intelligent load controllers automatically shed non-essential loads as battery capacity decreases. Three-tier load classification ensures critical systems maintain power while reducing consumption during shortage periods.

Critical loads (Tier 1) include refrigeration, communications, and essential lighting. Comfort loads (Tier 2) encompass space heating, entertainment systems, and convenience appliances. Luxury loads (Tier 3) include hot tubs, electric vehicle charging, and high-power tools.

Smart controllers disconnect Tier 3 loads at 60% battery capacity, Tier 2 loads at 40%, maintaining only Tier 1 systems until generation resumes or backup power activates.

Economic Optimization Strategies

Winter system sizing involves significant capital investment. Cost-effective design balances reliability requirements against economic constraints through strategic component selection and phased implementation approaches.

Storage vs Generation Trade-offs

Adding battery capacity costs $400-600 per kWh for quality LiFePO4 systems, while solar array expansion costs $1.50-2.50 per watt installed. Economic analysis often favors moderate storage oversizing combined with generator backup over massive battery installations.

The optimal balance depends on fuel costs, maintenance requirements, and reliability preferences. Remote locations with expensive fuel delivery favor larger battery systems, while accessible sites benefit from generator-assisted approaches.

Seasonal Load Management

Demand-side management reduces winter sizing requirements through strategic load shifting and efficiency improvements. Thermal mass heating systems store energy during peak solar production for evening use, reducing battery cycling and storage requirements.

According to IRENA's thermal energy storage research, thermal storage systems can reduce electrical heating loads by 30-50% through intelligent scheduling and thermal mass utilization.

Implementation and Monitoring

Successful winter systems require ongoing monitoring and adaptive management. Real-time performance tracking enables proactive adjustments before system failures occur.

Performance Monitoring Systems

Comprehensive monitoring tracks solar production, battery performance, load consumption, and weather conditions. Advanced systems correlate performance data with weather forecasts, providing 3-7 day advance warning of potential shortages.

Key monitoring parameters include battery temperature, state-of-charge trends, daily energy balance, and generator runtime hours. Automated alerts notify users when performance deviates from expected ranges, enabling corrective action before critical failures.

Seasonal Maintenance Protocols

Pre-winter system preparation significantly improves reliability. Battery equalization, connection tightening, and backup generator testing should occur before cold weather arrives. Snow removal equipment and procedures ensure solar array accessibility during winter storms.

Regular winter inspections identify developing issues before they cause failures. Monthly battery voltage checks, generator exercise runs, and load analysis maintain system health throughout the challenging winter months.

Building Resilient Winter Power

Mastering off-grid winter sizing requires understanding the complex interactions between reduced generation, increased loads, and temperature-dependent storage performance. Success comes from methodical analysis, conservative sizing, and intelligent system integration.

The strategies outlined here—temperature compensation, extended autonomy planning, hybrid generation, and smart load management—form the foundation of resilient winter energy systems. Combined with proper monitoring and maintenance, these approaches ensure reliable power regardless of weather conditions.

Winter energy independence remains achievable with proper planning and execution. The investment in robust sizing and storage pays dividends through decades of reliable operation, even during the most challenging weather events.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.