After designing dozens of off-grid systems across different climates—from snow-covered cabins in Minnesota to monsoon-prone farms in Southeast Asia—I've learned that seasonal variability isn't just a challenge to overcome. It's the defining factor that separates reliable off-grid systems from those that leave you in the dark when you need power most.

Most off-grid system failures happen during seasonal extremes. Winter brings reduced solar production and increased heating loads. Monsoon seasons deliver weeks of cloudy skies. Summer heat waves spike cooling demands while reducing battery efficiency. The key to off-grid success lies in designing systems that anticipate and adapt to these predictable yet challenging seasonal patterns.

Understanding Seasonal Energy Patterns

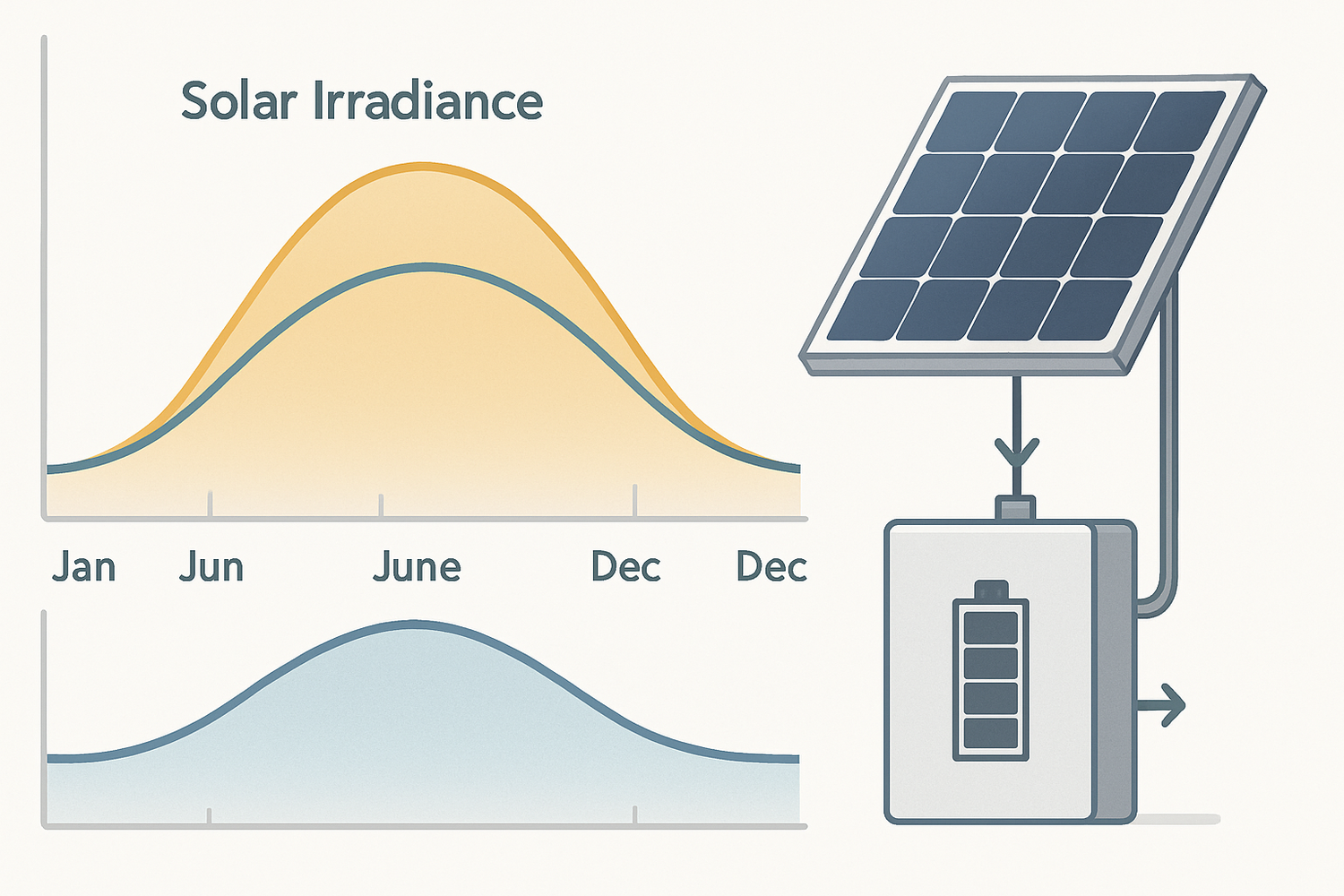

Seasonal variability affects every component of your off-grid system. Solar irradiance can drop by 60-70% during winter months in northern latitudes, while load patterns shift dramatically based on heating, cooling, and lighting needs.

Solar Resource Variations

Solar irradiance follows predictable seasonal patterns, but the magnitude varies significantly by location. In Minneapolis, December solar production averages just 1.2 kWh/m²/day compared to 6.8 kWh/m²/day in July. This five-fold difference demands careful system sizing to maintain reliability year-round.

Temperature also affects photovoltaic performance. While cold weather actually improves solar panel efficiency, shorter daylight hours and frequent snow coverage more than offset this benefit. Conversely, extreme summer heat can reduce panel output by 10-15% compared to standard test conditions.

Load Profile Seasonality

Your energy consumption patterns change dramatically with seasons. Heating loads can triple winter electricity demand in cold climates, while air conditioning creates summer peaks in hot regions. Lighting needs increase during short winter days, and water pumping demands often peak during dry seasons.

Understanding these patterns requires detailed load analysis. I recommend tracking actual consumption for at least one full year before finalizing system design. This data reveals consumption peaks that theoretical calculations often underestimate.

Battery Performance Considerations

Temperature significantly impacts battery performance and lifespan. LiFePO4 batteries maintain excellent performance across wide temperature ranges, typically operating efficiently from -20°C to 60°C. However, charging rates must be reduced in freezing conditions to prevent damage.

Modern lithium battery management systems automatically adjust charging parameters based on temperature, ensuring optimal performance while protecting cell integrity. This temperature compensation becomes critical during winter months when batteries may experience sub-zero conditions.

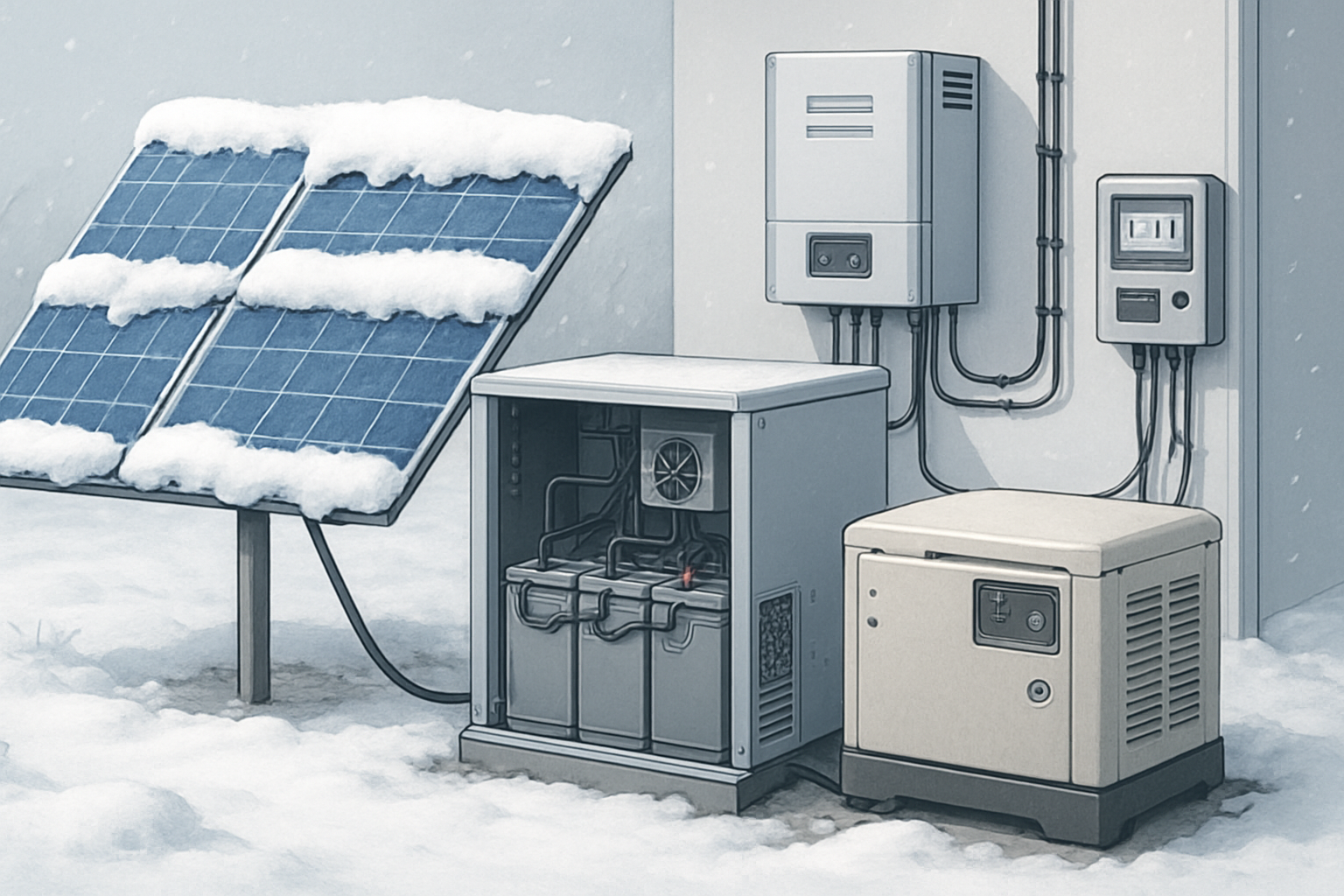

Winter System Design Strategies

Winter represents the most challenging season for off-grid systems in temperate climates. Reduced solar production coincides with peak energy demand, creating the perfect storm for system failures.

Solar Array Sizing for Winter Production

Designing for winter requires oversizing your solar array relative to summer needs. The exact sizing depends on your latitude and local climate patterns. For reliable winter operation, I typically size arrays to meet 100% of winter loads during the shortest days of the year.

This approach often results in arrays 2-3 times larger than needed for summer production. While this increases upfront costs, it eliminates the need for backup generators during most winter periods. Our Ultimate Guide to Off-Grid Winter Sizing and Storage provides detailed calculations for different climate zones.

| Latitude Range | Winter/Summer Irradiance Ratio | Recommended Array Oversizing |

|---|---|---|

| 30-40°N | 0.4-0.5 | 2.0-2.5x |

| 40-50°N | 0.3-0.4 | 2.5-3.0x |

| 50-60°N | 0.2-0.3 | 3.0-4.0x |

Storage Capacity Planning

Winter storage requirements extend beyond daily cycling to accommodate multi-day weather events. Extended periods of snow cover or persistent cloud cover can eliminate solar production for 5-7 days in some regions.

I recommend sizing battery banks to provide 3-5 days of autonomy during winter months, based on reduced loads and available backup generation. LiFePO4 batteries excel in these applications due to their excellent low-temperature performance and deep discharge capabilities.

The key insight from our 9 Data-Driven Tips to Survive Low-Sun Winters Off-Grid analysis shows that systems with adequate winter storage rarely require backup generation, while undersized systems depend heavily on generators during extended weather events.

Load Management During Low-Production Periods

Smart load management becomes crucial during winter months. Priority load circuits ensure essential systems maintain power while deferrable loads wait for better production conditions.

Implementing load shedding strategies can extend battery autonomy significantly. Non-essential loads like water heating, clothes washing, and workshop equipment can be automatically disconnected when battery state-of-charge drops below predetermined thresholds.

Managing Monsoon and Extended Cloudy Periods

Monsoon seasons and extended cloudy periods present unique challenges distinct from winter conditions. While temperatures remain moderate, solar production can drop to 10-20% of clear-sky values for weeks at a time.

Humidity and Corrosion Protection

High humidity during monsoon periods accelerates corrosion of electrical connections and components. Proper enclosure design with adequate ventilation prevents condensation buildup while maintaining weather protection.

Battery systems require particular attention during humid periods. Proper ventilation prevents moisture accumulation while maintaining optimal operating temperatures. Our integrated ESS solutions include climate-controlled enclosures designed for high-humidity environments.

Extended Autonomy Requirements

Monsoon systems often require longer autonomy periods than winter systems. While winter storms typically clear within 3-5 days, monsoon conditions can persist for 2-3 weeks with minimal solar production.

This extended duration requires either oversized battery banks or alternative generation sources. The How to Design Off-Grid Systems for Monsoon Reliability guide explores various strategies for maintaining power during extended low-production periods.

Water Management and Drainage

Proper drainage around solar installations prevents water damage and maintains safe access for maintenance. Elevated mounting systems allow water runoff while preventing panel shading from accumulated debris.

Ground-mounted systems require careful site preparation to prevent flooding and erosion. Proper grading directs water away from electrical equipment while maintaining panel accessibility during wet conditions.

Summer Peak Load Management

Summer presents different challenges, with peak cooling loads often coinciding with maximum solar production. However, heat-related efficiency losses and equipment failures can still compromise system reliability.

Cooling Load Integration

Air conditioning represents the largest single load in many off-grid homes during summer months. Efficient system design matches cooling loads with peak solar production, minimizing battery cycling and extending system life.

Variable-speed heat pumps offer excellent efficiency and can modulate output to match available solar production. Smart controllers can increase cooling during peak production periods, pre-cooling spaces before evening hours when solar production declines.

Heat Management for Electronics

High temperatures reduce the efficiency and lifespan of electronic components. Inverters, charge controllers, and battery management systems all require adequate cooling to maintain peak performance.

Proper ventilation design ensures adequate airflow while preventing dust ingress. Shade structures protect equipment from direct sunlight while allowing natural convection cooling. Some installations benefit from active cooling systems during extreme temperature events.

Battery Temperature Control

While LiFePO4 batteries tolerate high temperatures better than other chemistries, extreme heat still reduces capacity and accelerates aging. Battery enclosures should include temperature monitoring and active or passive cooling systems.

Underground installation or earth-bermed enclosures provide natural temperature moderation, keeping batteries cooler in summer and warmer in winter. This thermal mass effect reduces temperature swings and improves overall system performance.

Advanced Forecasting and Predictive Management

Modern off-grid systems benefit from weather forecasting and predictive load management. These technologies enable proactive system adjustments before challenging weather arrives.

Weather-Based System Optimization

Integration with weather forecasting services allows systems to prepare for challenging conditions. Battery charging can be prioritized when clear weather precedes predicted storms, while non-essential loads can be deferred when extended cloudy periods are forecast.

The Solar Forecast Arbiter platform, developed with DOE funding, provides standardized solar forecasting that grid-tied systems use for planning. Similar forecasting principles apply to off-grid systems, helping optimize energy management decisions.

Load Scheduling and Demand Response

Smart scheduling systems shift flexible loads to optimize renewable energy utilization. Water heating, battery charging for electric vehicles, and other deferrable loads can be automatically scheduled during peak production periods.

This demand response capability becomes particularly valuable during seasonal transitions when production and load patterns change rapidly. Automated systems adapt faster than manual management, maintaining optimal system performance throughout the year.

Predictive Maintenance Scheduling

Seasonal maintenance requirements vary significantly throughout the year. Solar panel cleaning becomes critical after dusty summer months, while battery equalization may be needed after heavy winter cycling.

Predictive maintenance systems monitor component performance and schedule maintenance activities based on actual usage patterns rather than arbitrary time intervals. This approach reduces maintenance costs while improving system reliability.

Component Selection for Year-Round Reliability

Selecting components that perform reliably across seasonal extremes requires understanding how temperature, humidity, and cycling patterns affect different technologies.

Battery Technology Considerations

LiFePO4 batteries excel in seasonal applications due to their wide operating temperature range, excellent cycle life, and minimal maintenance requirements. Unlike lead-acid batteries, LiFePO4 cells maintain consistent capacity across temperature ranges and don't require regular maintenance.

The integrated battery management systems in modern LiFePO4 installations automatically adjust charging parameters based on temperature and state-of-charge, ensuring optimal performance throughout seasonal variations. Our Case Study: Winter-Proofing a Cabin with LiFePO4 ESS demonstrates real-world performance across extreme seasonal conditions.

Inverter Sizing and Selection

Inverter selection must account for peak seasonal loads while maintaining efficiency during light-load conditions. Modern inverters with wide efficiency curves perform well across varying load conditions, crucial for systems with significant seasonal load variations.

Multiple inverter configurations can optimize efficiency across seasonal load patterns. Smaller inverters handle base loads efficiently, while larger units activate during peak demand periods. This staged approach maintains high efficiency year-round.

Charge Controller Optimization

MPPT charge controllers with wide input voltage ranges accommodate varying solar production conditions throughout the year. Advanced controllers include temperature compensation and programmable charging profiles optimized for different battery chemistries and seasonal conditions.

The ability to adjust charging parameters remotely becomes valuable during seasonal transitions when optimal settings may change rapidly. Modern controllers support remote monitoring and adjustment, enabling fine-tuning without site visits.

Economic Optimization Across Seasons

Designing for seasonal variability involves balancing upfront costs against long-term reliability and fuel savings. The optimal design varies based on local energy costs, fuel availability, and reliability requirements.

Cost-Benefit Analysis of Oversizing

The decision between oversizing renewable generation versus adding backup generation depends on local fuel costs and system utilization patterns. Our analysis in Oversizing PV vs Adding Batteries: What Works in Winter? provides detailed economic comparisons for different scenarios.

In most cases, oversizing solar arrays proves more cost-effective than relying on backup generation for seasonal gaps. Solar panels have no fuel costs and minimal maintenance requirements, while generators require regular maintenance and fuel deliveries.

Phased Implementation Strategies

Large off-grid systems can be implemented in phases, starting with core reliability requirements and expanding capacity over time. This approach spreads costs while ensuring immediate system functionality.

The 2-Year Roadmap to Balance Seasonal Loads in Off-Grid Homes outlines practical implementation phases that prioritize essential loads while building toward full seasonal autonomy.

Return on Investment Calculations

Seasonal reliability improvements provide quantifiable benefits through reduced generator runtime, eliminated fuel costs, and improved system lifespan. These benefits often justify the additional investment in oversized renewable generation and storage.

Proper economic analysis must include all costs of backup generation, including fuel, maintenance, replacement parts, and the hidden costs of system downtime during fuel shortages or mechanical failures.

Future-Proofing Your Seasonal Design

Climate change and evolving energy needs require forward-thinking design approaches that accommodate changing conditions and expanding loads over time.

Climate Change Adaptation

Historical weather data may not accurately predict future conditions as climate patterns shift. Design margins should account for increasing weather extremes and changing seasonal patterns.

More frequent extreme weather events require robust system designs with adequate reserve capacity. The Stop Winter Blackouts: Build Smarter Off-Grid Storage guide addresses strategies for maintaining power during increasingly severe weather events.

Expandability and Modularity

Modular system designs accommodate future expansion without major infrastructure changes. Properly planned electrical panels, conduit systems, and equipment mounting allow seamless capacity additions as needs evolve.

Battery systems benefit particularly from modular design, allowing capacity increases without replacing existing equipment. Modern BMS systems support parallel battery bank expansion, enabling gradual capacity growth over time.

Technology Integration Pathways

Emerging technologies like seasonal hydrogen storage and advanced weather forecasting will enhance off-grid system capabilities. Design flexibility ensures systems can integrate new technologies as they become cost-effective.

The question addressed in Do You Need Hydrogen for Seasonal Gaps in Off-Grid? explores how emerging storage technologies might complement traditional battery systems for extreme seasonal applications.

Putting It All Together: Your Seasonal Design Action Plan

Successfully designing for seasonal variability requires systematic analysis of your specific conditions, careful component selection, and ongoing optimization. The investment in proper seasonal design pays dividends through years of reliable operation and energy independence.

Start by thoroughly analyzing your local climate patterns and load requirements across all seasons. Use this data to size renewable generation and storage capacity with adequate margins for extreme conditions. Select components proven to perform reliably across your expected temperature and humidity ranges.

Remember that seasonal design isn't just about surviving the worst conditions—it's about optimizing your entire system for year-round efficiency and reliability. The strategies outlined here, combined with quality components and professional installation, create off-grid systems that deliver dependable power regardless of seasonal challenges.

Your path to seasonal energy independence starts with understanding your unique requirements and implementing proven design strategies. The resources referenced throughout this guide provide detailed implementation guidance for each aspect of seasonal system design.

Disclaimer: This article provides general guidance for educational purposes. Consult qualified professionals for system design and installation specific to your location and requirements.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.