Winter power outages can turn your off-grid paradise into a frozen nightmare. Smart storage design makes the difference between comfortable energy independence and emergency generator dependency during the coldest months.

Understanding Winter Energy Challenges

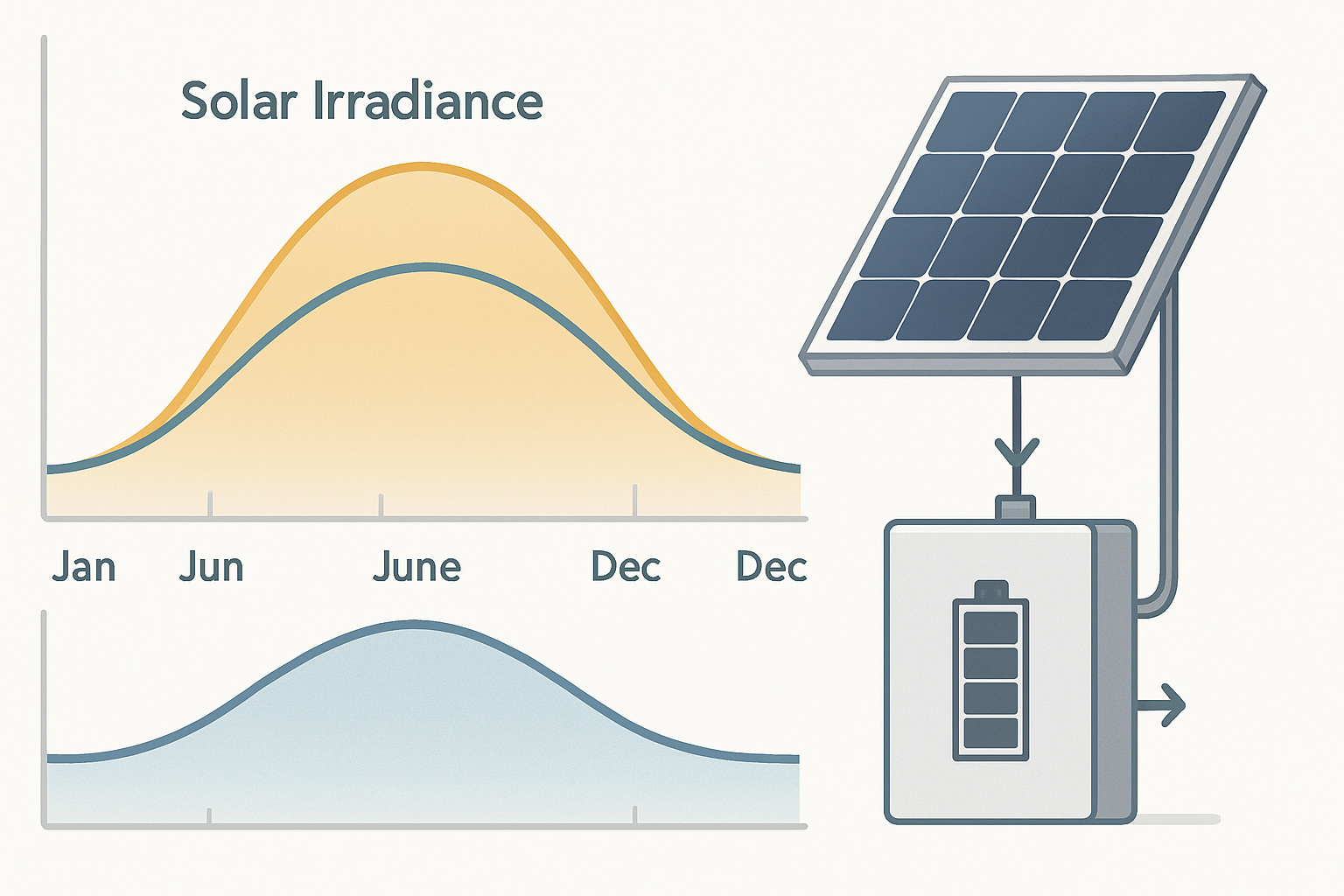

Winter transforms your off-grid energy equation. Solar production drops by 60-80% during the shortest days, while heating loads can triple your baseline consumption. Traditional grid-tied homes rely on utility backup, but off-grid systems must be self-sufficient.

Temperature affects every component in your system. Battery capacity decreases significantly below freezing, inverter efficiency drops, and equipment failures spike during extreme cold. According to IRENA's thermal energy storage outlook, seasonal storage becomes critical when renewable generation varies dramatically throughout the year.

The Real Cost of Winter Blackouts

A single winter blackout costs more than preventive storage upgrades. Frozen pipes, spoiled food, and emergency heating expenses add up quickly. Generator fuel costs during extended outages can exceed $200 per day, while backup hotel stays drain budgets further.

Smart storage prevents these cascading failures. Properly sized LiFePO4 systems maintain power during multi-day storms, eliminating emergency expenses and safety risks.

Strategic Storage Architecture for Winter Resilience

Winter-proof storage requires three-tier redundancy: primary batteries, backup generation, and emergency load shedding. Each tier activates based on state-of-charge thresholds and weather forecasts.

Primary Storage Sizing

Calculate winter storage needs using worst-case scenarios. Size batteries for 5-7 days of autonomy during December/January conditions. This covers typical storm durations plus recovery time for solar charging.

| Load Type | Summer (kWh/day) | Winter (kWh/day) | Multiplier |

|---|---|---|---|

| Base loads | 8 | 12 | 1.5x |

| Heating | 2 | 18 | 9x |

| Hot water | 4 | 6 | 1.5x |

| Total daily | 14 | 36 | 2.6x |

For a 36 kWh daily winter load, install minimum 180 kWh usable capacity (5 days × 36 kWh). Add 20% safety margin for battery aging and temperature derating.

Thermal Management Systems

LiFePO4 batteries lose 20-30% capacity at 0°F (-18°C). Install battery heating systems that activate below 40°F (4°C) to maintain optimal performance. Insulated battery enclosures reduce heating energy by 60% compared to unprotected installations.

Smart thermal controllers monitor individual cell temperatures and adjust heating accordingly. This prevents hot spots while minimizing parasitic loads during critical periods.

Intelligent Load Management During Winter Peaks

Smart load controllers automatically prioritize essential systems during low-battery conditions. Critical loads like refrigeration and communication maintain power while non-essential loads shed automatically.

Dynamic Load Prioritization

Program load controllers with battery state-of-charge thresholds:

- 100-80% SOC: All loads active

- 80-60% SOC: Shed electric vehicle charging, workshop tools

- 60-40% SOC: Reduce heating setpoints by 3°F, disable hot tub

- 40-20% SOC: Emergency mode - critical loads only

- Below 20% SOC: Activate backup generator

This tiered approach extends battery runtime during extended cloudy periods while maintaining comfort and safety.

Weather-Predictive Controls

Modern systems integrate weather forecasting to optimize energy usage. When storms approach, controllers pre-charge batteries to 100% and reduce discretionary loads proactively.

Machine learning algorithms analyze historical weather patterns and consumption data to predict optimal charging strategies. These systems achieve 15-20% better performance compared to reactive controls.

Backup Generation Integration

Generators serve as the final safety net in comprehensive winter storage systems. Size backup generators for essential loads only - batteries handle peak demands while generators maintain baseline charging.

Hybrid Generator Strategies

Install generators sized for 40-60% of peak load rather than 100%. Batteries supply surge power while generators run at optimal efficiency for extended periods. This approach reduces fuel consumption by 40% compared to oversized generators.

Automatic transfer switches activate generators based on battery SOC and weather conditions. Smart controllers prevent unnecessary cycling while ensuring batteries never reach critical depletion.

Alternative Backup Technologies

Micro-hydro systems provide excellent winter backup where water flow remains consistent. Small wind turbines complement solar during winter storms when wind speeds increase.

According to IEA's system integration analysis, diverse renewable sources improve overall system reliability by reducing correlation between generation sources.

Advanced Monitoring and Maintenance

Winter conditions stress off-grid systems beyond normal operating parameters. Comprehensive monitoring prevents small issues from becoming major failures during critical periods.

Predictive Maintenance Protocols

Monitor battery internal resistance, voltage imbalances, and temperature variations. Trending data reveals degradation patterns before failures occur. Replace batteries showing 20% capacity loss before winter season begins.

Track inverter efficiency and harmonic distortion. Winter heating loads create challenging power factor conditions that stress power electronics. Schedule maintenance during fall months when weather permits safe access.

Remote Monitoring Capabilities

Cellular or satellite monitoring systems provide real-time status updates during storms. Remote diagnostics identify issues before they cause outages, enabling proactive maintenance scheduling.

Cloud-based analytics compare your system performance against similar installations in your region. This benchmarking reveals optimization opportunities and validates design decisions.

Economic Optimization Strategies

Winter storage investments pay dividends through avoided outage costs and reduced generator fuel consumption. Calculate return on investment using total cost of ownership rather than upfront equipment costs.

Phased Implementation Approach

Build winter resilience incrementally over 2-3 seasons. Start with core battery capacity and thermal management, then add backup generation and advanced controls. This spreads costs while providing immediate benefits.

Prioritize upgrades based on failure modes analysis. Address single points of failure first, then optimize for efficiency and convenience features.

| Phase | Investment | Reliability Gain | Payback Period |

|---|---|---|---|

| Core storage | $25,000 | 80% | 3.2 years |

| Thermal management | $3,000 | 15% | 2.1 years |

| Smart controls | $5,000 | 5% | 4.8 years |

Future-Proofing Your Winter Storage

Design systems with expansion capability as energy needs grow. Modular battery architectures allow capacity additions without replacing existing equipment. Plan electrical infrastructure for 150% of initial capacity.

Emerging technologies like green hydrogen storage show promise for seasonal energy storage applications. While current costs remain high, learning rates similar to solar PV suggest future viability for long-term storage needs.

Smart off-grid storage transforms winter from a survival challenge into comfortable energy independence. Proper sizing, thermal management, and intelligent controls eliminate blackout risks while optimizing operating costs. Start planning your winter-proof system today - your future self will thank you when the next blizzard hits.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.