Seasonal energy storage represents one of the most challenging aspects of off-grid system design. While daily storage solutions have matured significantly, bridging multi-month energy gaps requires sophisticated strategies that balance technical feasibility with economic viability. International energy authorities have identified seasonal storage as a critical enabler for achieving 100% renewable generation in isolated systems.

Understanding Seasonal Energy Gaps in Off-Grid Systems

Off-grid systems face unique seasonal challenges that grid-tied installations rarely encounter. The fundamental issue stems from the mismatch between energy production and consumption across different seasons.

Production Variability Patterns

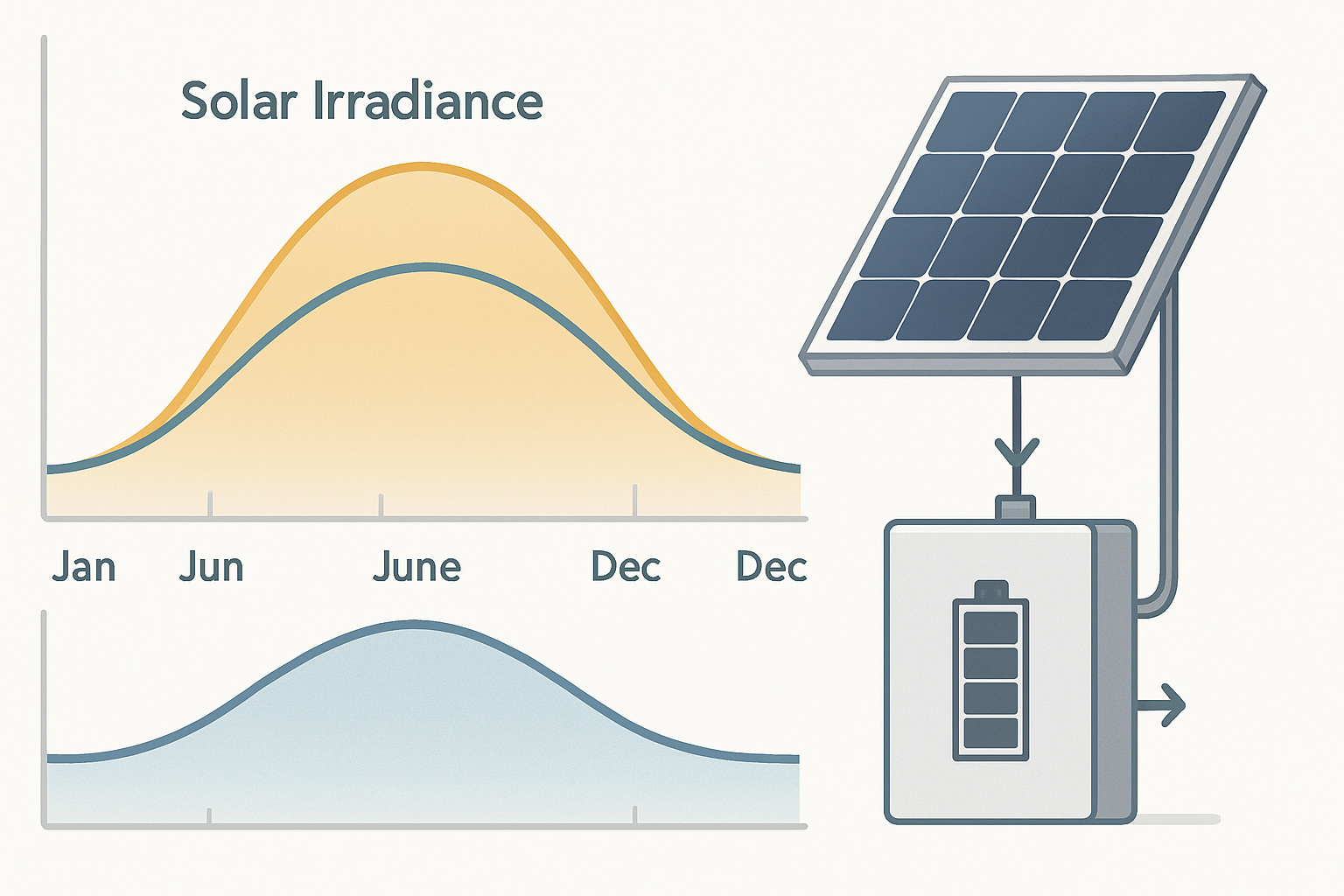

Solar photovoltaic systems experience dramatic seasonal variations, particularly at higher latitudes. Winter production can drop to 20-30% of summer output due to shorter daylight hours and lower sun angles. According to Getting Wind and Solar onto the Grid, latitude plays a crucial role in determining seasonal storage requirements.

Wind resources often complement solar patterns but introduce their own variability. Some regions experience seasonal wind patterns that can partially offset solar deficits, while others face concurrent low-wind, low-sun periods lasting weeks or months.

Demand Pattern Shifts

Energy consumption patterns shift dramatically with seasons. Heating loads in winter can increase total energy demand by 300-500% compared to summer months. The IEA analysis highlights that electrification of heating creates winter peak demands several times larger than summer peaks, significantly increasing inter-seasonal storage needs.

| Season | Solar Production (% of peak) | Typical Load Increase | Storage Duration Need |

|---|---|---|---|

| Summer | 100% | Baseline | 1-3 days |

| Winter | 20-30% | 200-400% | 30-90 days |

| Shoulder Seasons | 60-80% | 50-150% | 7-14 days |

IEA Framework for Seasonal Storage Implementation

The International Energy Agency has developed a comprehensive framework for integrating seasonal storage into renewable energy systems. This approach recognizes that different storage technologies serve distinct temporal needs.

Multi-Tier Storage Strategy

The China Power System Transformation study outlines a phased approach to storage deployment:

- Short-term storage (hours to days): Battery systems handle daily cycling and short-duration weather events

- Medium-term storage (days to weeks): Extended battery capacity or compressed air systems bridge weather patterns

- Long-term storage (weeks to months): Chemical storage solutions like hydrogen or synthetic fuels provide seasonal bridging

System Integration Phases

IEA research identifies five distinct phases of renewable integration, each requiring different storage approaches. For off-grid systems, phases 3-5 become critical as renewable penetration approaches 100%.

Phase 3 focuses on existing storage utilization, including pumped hydro where available. Phase 4 introduces battery storage for medium-term applications. Phase 5 implements long-term storage solutions essential for seasonal variability management.

IRENA's Hydrogen Storage Solutions for Seasonal Gaps

The International Renewable Energy Agency has positioned hydrogen as a cornerstone technology for seasonal energy storage, despite significant efficiency losses.

Hydrogen Production and Storage Economics

According to Green Hydrogen Cost Reduction analysis, electrolyzer learning rates mirror solar PV development patterns, reaching 16-21% cost reduction curves. This positions hydrogen as increasingly viable for long-duration storage applications.

The round-trip efficiency of hydrogen systems typically ranges from 35-45%, compared to 85-95% for lithium-ion batteries. However, the cost per MWh of stored energy becomes favorable for storage durations exceeding 100 hours.

Off-Grid Hydrogen Implementation Strategies

IRENA identifies three primary hydrogen deployment scenarios for off-grid applications:

- Large off-grid facilities: Access to low-cost renewables but high delivery costs favor on-site production

- Decentralized production: Small modules provide flexibility, offsetting higher per-unit costs with reduced logistics expenses

- Industrial integration: Stable supply requirements justify investment in larger, more efficient systems

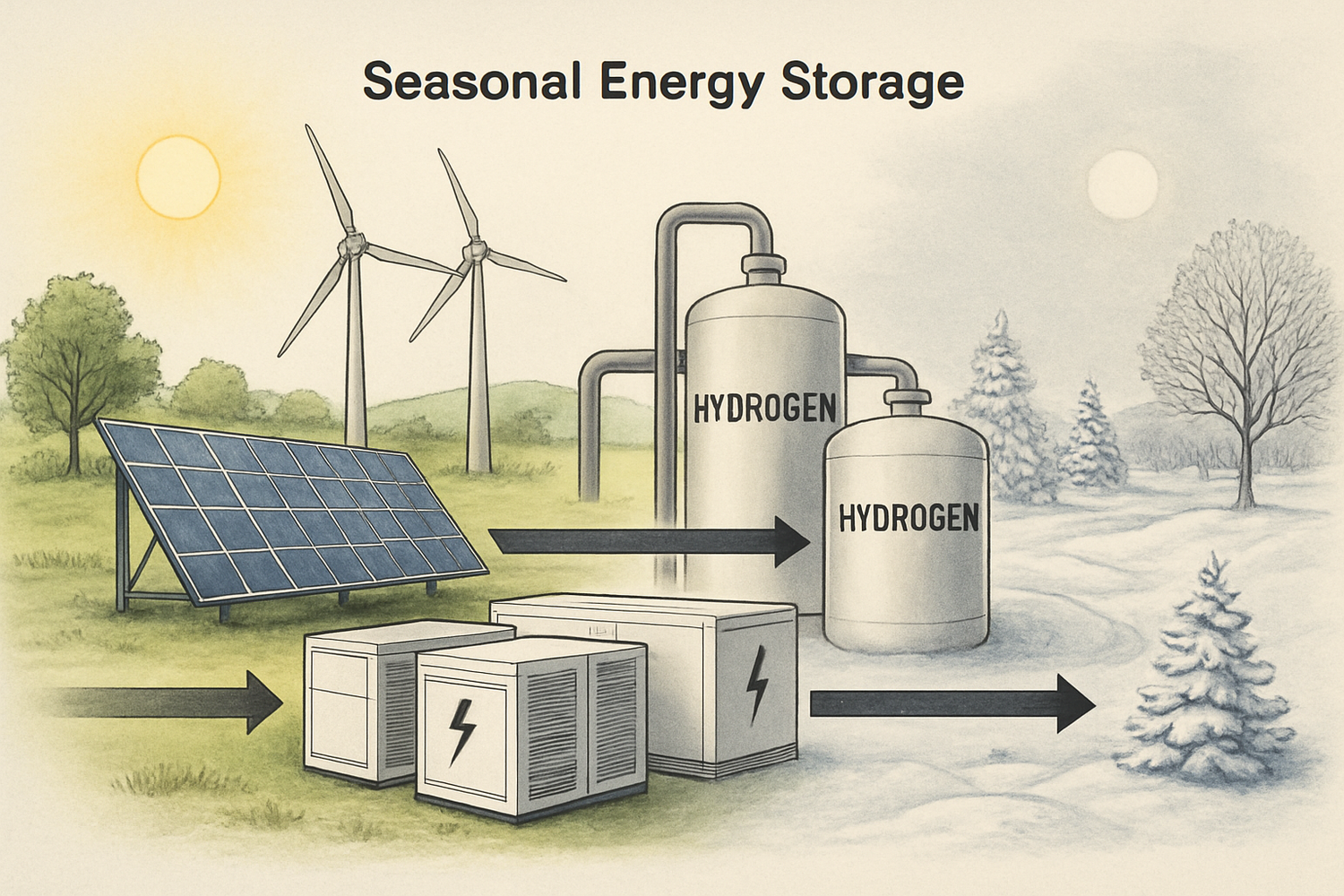

Hybrid Storage Architecture for Seasonal Reliability

Optimal seasonal storage strategies combine multiple technologies to maximize efficiency while minimizing costs. This hybrid approach leverages each technology's strengths across different time domains.

Battery-Hydrogen Integration

LiFePO4 batteries excel at daily cycling and short-term storage, while hydrogen systems handle extended periods. A typical hybrid configuration allocates 80-90% of daily energy cycling to batteries, reserving hydrogen for seasonal gaps exceeding 7-14 days.

Smart energy management systems optimize the transition between storage modes, maximizing battery utilization during favorable conditions while preserving hydrogen reserves for extended low-production periods.

Predictive Storage Management

Advanced systems incorporate weather forecasting and seasonal modeling to optimize storage deployment. Machine learning algorithms analyze historical patterns and real-time conditions to determine optimal charging and discharging strategies across different storage technologies.

| Storage Technology | Optimal Duration | Round-trip Efficiency | Capital Cost ($/kWh) |

|---|---|---|---|

| LiFePO4 Batteries | 4-100 hours | 90-95% | 300-500 |

| Hydrogen Systems | 100+ hours | 35-45% | 50-150 |

| Compressed Air | 8-40 hours | 70-80% | 100-300 |

Implementation Guidelines and Best Practices

Successful seasonal storage implementation requires careful system sizing, component selection, and operational strategies based on site-specific conditions.

Sizing Methodologies

Seasonal storage sizing begins with comprehensive load and resource analysis spanning multiple years. The Integrating Solar and Wind report emphasizes that flexibility needs vary significantly across regions based on natural resources and historical development patterns.

Critical sizing parameters include:

- Worst-case seasonal production deficits over 10-20 year periods

- Temperature-dependent load variations and heating requirements

- System degradation and aging effects on storage capacity

- Backup generation integration for extreme weather events

Economic Optimization Strategies

Cost-effective seasonal storage requires balancing capital investment against reliability requirements. Systems designed for 99.5% availability may require 40-60% more storage capacity than those targeting 95% reliability.

Phased implementation allows systems to grow with demand and technology improvements. Initial deployments focus on battery storage for daily needs, with hydrogen systems added as seasonal gaps become apparent through operational experience.

Future Outlook and Technology Development

Seasonal storage technologies continue evolving rapidly, with significant improvements expected in efficiency, cost, and integration capabilities over the next decade.

Emerging technologies like iron-air batteries and advanced compressed air systems promise to fill the gap between short-term batteries and long-term hydrogen storage. These solutions target the 24-168 hour duration range with improved efficiency and lower costs.

Grid-forming inverters and advanced microgrid controllers enable more sophisticated storage management, allowing seamless transitions between different storage technologies while maintaining power quality and system stability.

The convergence of artificial intelligence and energy storage creates opportunities for predictive optimization that can significantly improve seasonal storage efficiency and reduce overall system costs.

As renewable energy costs continue declining and storage technologies mature, off-grid systems with comprehensive seasonal storage capabilities become increasingly competitive with traditional grid connections, especially in remote locations where grid extension costs are prohibitive.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.